Professional Documents

Culture Documents

LF1 LF2 LF3

Uploaded by

Bilal AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LF1 LF2 LF3

Uploaded by

Bilal AhmadCopyright:

Available Formats

0

MV Distribution Circuit-breakers LF1 - LF2 - LF3 1 to 17.5 kV

We do more with electricity.

Contents

Page Presentation RI stored energy operating mechanism Technical features Dimensions and weights 2 4 6 7

Schneider Electric

Gamme

AMTED397052EN_002_00

Presentation

Application

The Merlin Gerin LF circuit-breakers are three-pole indoor circuit-breakers using SF6 technology. Designed to operate and protect public and industrial distribution networks from 1 to 17.5 kV, they comply with the IEC 56 standard.

The advantages of tried and tested technology

Safety The breaking medium is sulphur hexafluoride (SF6) used at low pressure (0.15 MPa, i.e. 1.5 relative bar). The insulating enclosure containing the 3 poles is equipped with safety membranes. With self-expansion, the breaking technique used in LF circuit-breakers, all current types, capacitive and inductive, can be made or broken without generating overvoltage which could damage your installation. Moreover, the nominal features, nominal current breaking under nominal voltage, are maintained at 0 relative bar of SF6. Reliability The motor charged spring stored energy operating mechanism is a key factor of device reliability: Schneider draws on 25 years of experience on this type of mechanism, 150,000 of which are already in operation. Schneiders mastery of design and checking of sealed systems guarantees sustained device performance well at least 30 years. Increased endurance The mechanical and electrical endurance of LF circuit-breakers are superior to those recommended by the IEC. The LF circuit-breakers have successfully passed mechanical endurance tests for well over 10,000 switching operations, as well as electrical endurance tests several dozen times short-circuit current: these circuit breakers are able to break their nominal current 10,000 times.

Bare fixed LF1.

Less maintenance Throughout device service life, which in normal operating conditions may be at least 30 years, the only maintenance required is on the mechanical operating mechanism once every 10 years or every 10,000 operations. Although no maintenance is performed on poles, a diagnosis is possible: # contact wear can be checked by external pole measurement, # SF6 pressure can be continually monitored by a pressure switch. Environmentally-friendly The LF circuit-breakers are designed to ensure protection of the environment: # the materials used, both insulating and conductive, are identified, and easy to separate and recycle, # the SF6 can be recovered at end of service life and re-used after treatment. Quality Each circuit-breaker undergoes systematic routine tests in order to check quality and conformity: # pole sealing check, # checking proper mechanical operation of the device, plus its associated locking mechanisms, # checking simultaneous closing of contacts, # checking power frequency insulation level, # checking main circuit resistance, # checking auxiliary circuit insulation, # checking switching speeds, # checking switching cycle, # measuring switching times. The results are recorded on the test certificate for each device. The entire circuit-breaker creation and manufacturing process undergoes quality control in accordance with the requirements of the French Quality Assurance Association (AFAQ): ISO 9001 and ISO 9002 certification. The LF circuit-breakers have successfully passed the type tests required by the IEC 56.

The withdrawable version of the LF circuit-breakers is designed to equip the MV functional units of the MCset range.

TED397052EN_002_008.

Gamme

Schneider Electric

Description of the device

The basic fixed version consists of: # 3 poles incorporated in an insulating enclosure of the sealed pressure system type. The sealed assembly is filled with SF6 at low pressure (0.15 MPa, i.e. 1.5 bar). # a RI type operating mechanism, # a front panel housing the manual operating mechanism and the status indicators, # upstream and downstream terminals for power circuit connection, # a terminal block for connection of the external auxiliary circuits.

# a supporting frame equipped with rollers and ground fixing brackets for simplified # circuit-breaker locking in open position by keylock installed on the front plate # wiring of the pressure switch mounted on the cover of the insulating enclosure.

of the operating mechanism, handling and installation,

Optional:

LF3 on supporting frame.

Principle of the self-expansion breaking technique

This technique is the result of many years experience in SF6 technology and of major research work. It combines the effect of thermal expansion to the rotating arc technique in order to create arc blowing and quenching conditions. The result is reduced stored energy and arcing contact erosion, i.e. increased mechanical and electrical endurance. The operating sequence of a self-expansion breaking chamber whose moving part is driven by the mechanical operating mechanism is as follows: Fig.1 Fig.2 Fig.1: the circuit-breaker is closed. Fig.2: on opening of the main contacts (a), the current is shunted into the breaking circuit (b) ; d c e Fig.3: on separation of the arcing contacts, an electric arc appears in the expansion volume (c). This arc rotates under the effect of the magnetic field created by the coil (d) through which flows the current to be broken. The overpressure created by the temperature build-up of the gas in the expansion volume (c) causes a gaseous flow blowing the arc inside the tubular arcing contact (e) and resulting in arc quenching when the current passes through the zero point. Fig.4: the circuit-breaker is open. Fig.3 Fig.4

Electric arc in a self-expansion breaking chamber.

Schneider Electric

Gamme

AMTED397052EN_002_00

RI stored energy operating mechanism

Operation of the mechanical operating mechanism

This mechanism guarantees the device an opening and closing speed unaffected by the operator, for both electric and manual orders. It carries out the O and CO cycles and is automatically recharged by a gear motor within less than 15 s after closing. It consists of: # the stored energy operating mechanism which stores in springs the energy required to open and close the device. # a gear motor electrical charging device with optional manual charging by lever (useful on loss of auxiliary supply). # manual order devices by push buttons on the front panel of the device. # an electrical remote closing device containing a release with an antipumping relay. # an electrical opening device containing one or more releases, for example: 5 shunt trip devices, 5 undervoltage releases with time delay adjustable from 1 to 3 sec, 5 mitop, a low consumption release, used only with the Sepam 100 LA protection relay. # an operation counter. # a position indication device by mechanical indicator (black and white) and a module of 14 auxiliary contacts whose availability varies according to the diagram used. # a device for indicating charged operating mechanism status by mechanical indicator and electrical contact.

RI operating mechanism.

Standard diagram

J KN M M1-M2 M3 QF SD SE Sm1 Sm2 Sm3 Sn SP YF Y01-Y02 YM Mitop Circuit breaker. Anti-pumping relay. Spring charging motor. End-of-charging contacts. Operating mechanism charged indication contact. Circuit breaker auxiliary contacts. Fault (Mitop) trip indication momentary contact. Trip indication maintained contact. Closing pushbutton (outside). Opening pushbutton for shunt release (outside). Opening pushbutton for undervoltage release (outside). Closing disable contact (outside). Pressure-switch contact. Closing release. Shunt opening releases. Undervoltage opening release. Mitop opening release (autonomous).

Sm1 Sm2 Sn Sm3

M J M1 QF M2 SE

KN Y01 YM M3

Y02 SD Mitop SP

YF

TED397052EN_002_008.

Gamme

Schneider Electric

RI operating mechanism low voltage auxiliaries

Electrical spring charging M supply voltages AC (V) 48 - 110 - 220 50 HZ AC (V) 120 - 240 60 HZ DC (V) 24-30-48-60-110-125-220 consumptions AC 380 VA DC 380 W closing release YF 48 - 110 - 220 120 - 240 24-30-48-60-110-125-220 160 VA 50 W opening releases YO1, YO2 48 - 110 - 220 120- 240 24-30-48-60-110-125-220 160 VA 50 W 100 VA 10 W YM MITOP Sepam 100 LA supply Sepam 100 LA supply Sepam 100 LA supply

Opening release combination choices

1st release 2nd release without single shunt release (Y01) double shunt release (Y02) undervoltage release (YM) MITOP single shunt release (Y01) 5O - 4C - 1I double shunt release (Y02) 5O - 3C - 1I undervoltage release (YM) 5O - 5C - 1I 5O - 4C - 1I 5O - 3C - 1I 5O - 4C - 1I 5O - 4C - 1I 5O - 3C - 1I 5O - 3C - 1I MITOP number of contacts available: O: open C: closed I: changeover

5O - 5C - 1I 5O - 4C - 1I 5O - 3C - 1I 5O - 5C - 1I

5O - 5C - 1I

Specific points

Conditions for use This circuit-breaker operates in the following atmospheric and climatic conditions: # climatic condition(1): - 5 C to + 40 C. Standard packaging Basic fixed assembly: packaging on untreated wooden pallet. Fixed assembly with frame: packaging on 2 untreated wooden pallets.

(1) For

other values, please consult us.

Schneider Electric

Gamme

AMTED397052EN_002_00

Technical features

LF1, LF2 circuit-breakers

IEC 56 rated voltage nsulation level rated current kV, 50/60 Hz kV rms 50 Hz - 1 mn kV, impact 1.2/50 s A 630 1250 2000 (1) kA, rms kA, peak kA, rms, 3 s A O-3 mn - CO-3 mn - CO O-0.3 s - CO-15 s - CO O-0.3 s - CO-3 mn - CO ms opening breaking closing LF1 7.2 20 60 12 28 75 LF2 7.2 20 60 12 28 75 17.5 38 95

# #

25 63 25 440

# #

31.5 79 31.5

# #

25 63 25 440

# #

31.5 79 31.5

# # #

50 125 50 440

# # #

40 100 40 440

# # #

31.5 79 31.5 440

breaking capacity Isc making capacity permissible short time withstand current capacitor breaking capacity rated switching sequence

# # #

48 70 65

# # #

48 70 65

# # #

48 70 65

# # #

48 70 65

# # #

48 70 65

operating times

LF3 circuit-breaker

IEC 56 rated voltage insulation level kV, 50/60 Hz kV, rms 50 Hz - 1 mn kV, impact 1.2/50 s rated current (la) A 1250 2500 3150 breaking capacity kA, rms making capacity kA, peak permissible short time withstand current kA, rms, 3 s capacitor breaking A capacity rated switching sequence O-3 mn - CO-3 mn - CO O-0.3 s - CO-15 s - CO O-0.3 s - CO-3 mn - CO operating times ms opening breaking closing ANSI C37.04-C37.06-C37.09 rated maximum voltage kV, 60 Hz rated voltage range K factor rated insulation level kV, rms 60 Hz - 1 mn kV, impact 1.2/50 s rated continuous current A 1200 2000 3000 rated short-circuit current kA, rms (at rated max kV) maximum symmetrical interrupting kA, rms capability and rated short-circuit current closing and latching capability kA, peak (2.7 K times rated short-circuit current) rated interrupting time 60 Hz cycles

(1)

LF3 7.2 20 60

12 28 75

17.5 38 95

# #

25 63 25 440

# #

31.5 79 31.5

# #

40 100 40

# #

50 125 50

# #

25 63 25 440

# #

31.5 79 31.5

# #

40 100 40

# # #

50 125 50

# #

25 63 25 440

# #

31.5 79 31.5

# # #

48 70 65 LF3 4.76 1.24 19 60

# # #

48 70 65 8.25 1.25 36 95

# # #

48 70 65 15 1.3 36 95

# # #

29 36 97 5

# # #

33 41 111 5

# # #

28 36 97 5

Used only in fixed installations: consult us.

TED397052EN_002_008.

Gamme

Schneider Electric

Dimensions and weights

Basic fixed assembly LF1 - LF2 - LF3

50

50 35

connection 25

50

270

on off on off

330

590

A weight (kg)

LF1 493 106

LF2 554 128

LF3 728 149.5

536

34

Fixed assembly with supporting frame LF1 - LF2 - LF3

995

on off on off

330

B C D E weight (kg)

LF1 542 160 145 145 124

LF2 602 180 165 165 148

LF3 776 240 225 225 168

B

555

539

34

Connections

Direct connection on device: # LF1 # LF2 < 2000 A # LF2 < 95 kV impact

3 x 40

Connection on pads: # LF2: 2000 A 1250 A (at 95 kV impact) 630 A (at 95 kV impact)

20 15

# LF3

52 11 11 32

128 8 holes 12.2

3 x 30

40

20

40

15 60

66 40

7.5 63

3 x 2M10 x 26 (used)

22.5

4 x 12

Schneider Electric

Gamme

AMTED397052EN_002_00

Schneider Electric SA

Postal address F-38050 Grenoble cedex 9 tel: +33 (0)4 76 57 60 60 telex : merge 320842 F As standards, specifications and designs change from time to time, please ask for confirmation of the information given in this publication.

This document has been C printed on ecological paper. s

Publishing : Schneider Electric SA Dessign, production : Idra Printing : AMTED397052EN/1 ART.78654 06/1998

You might also like

- Fire Pump Proposal Summary: WeightDocument3 pagesFire Pump Proposal Summary: WeightDerkung Benowat100% (1)

- f0253805 Vacutap VM enDocument10 pagesf0253805 Vacutap VM enhardian syaputraNo ratings yet

- DILO Adapter KitsDocument1 pageDILO Adapter KitsRichard SyNo ratings yet

- GCB-DS New PDFDocument20 pagesGCB-DS New PDFsemajamesNo ratings yet

- A1800 ALPHA Meter BrochureDocument6 pagesA1800 ALPHA Meter Brochurehazime100% (1)

- 11 HSP BushingsDocument21 pages11 HSP BushingsNurulazmi Bin Abd RahmanNo ratings yet

- Main Electrical Equipment List1Document4 pagesMain Electrical Equipment List1Qadir MohtashamNo ratings yet

- EU-TWN High Voltage Electrical Equipment Management Forum: Presentation of IEC 62271-200 Edition 2.0Document27 pagesEU-TWN High Voltage Electrical Equipment Management Forum: Presentation of IEC 62271-200 Edition 2.0Ali AkbarNo ratings yet

- 110/30 kV transformer specsDocument3 pages110/30 kV transformer specsamulya00428No ratings yet

- 2013 MICAFLUID PresentationDocument58 pages2013 MICAFLUID Presentationdenis_alexNo ratings yet

- Gen5 Hydrogen Sensor Prototype Operation GuideDocument16 pagesGen5 Hydrogen Sensor Prototype Operation GuideMarcioNo ratings yet

- Cable Glands REV and REVD SeriesDocument20 pagesCable Glands REV and REVD SeriesTh Nattapong100% (1)

- F400 CatalogueDocument56 pagesF400 CataloguescaliNo ratings yet

- Spectronic SP Catalog PDFDocument8 pagesSpectronic SP Catalog PDFsirpriNo ratings yet

- NATIONAL INSTITUTE FOR RESEARCH, DEVELOPMENT AND TESTING IN ELECTRICAL ENGINEERINGDocument5 pagesNATIONAL INSTITUTE FOR RESEARCH, DEVELOPMENT AND TESTING IN ELECTRICAL ENGINEERINGAnne KelleyNo ratings yet

- DIP5000 Inter Trip Relay ArevaDocument4 pagesDIP5000 Inter Trip Relay ArevaHytham HailNo ratings yet

- MFM 10-1 Mobile Fault LocatorDocument3 pagesMFM 10-1 Mobile Fault Locatormanish100% (1)

- Motor Operating Device UEMC 50: Installation, Operating and Recycling GuideDocument28 pagesMotor Operating Device UEMC 50: Installation, Operating and Recycling Guidemarceloleon4No ratings yet

- Major items of supply for proposed manufacturers and their nationalitiesDocument1 pageMajor items of supply for proposed manufacturers and their nationalitiesAvinash Lal100% (1)

- Unigear Type ZS2 Catalogue - enDocument26 pagesUnigear Type ZS2 Catalogue - ensyedfahadraza627100% (1)

- Reivax RTX Power Rev00 UsaDocument4 pagesReivax RTX Power Rev00 UsaGavinsiauNo ratings yet

- 1 Seccionador ISARC - AREVA VEI - InglesDocument35 pages1 Seccionador ISARC - AREVA VEI - InglesImdigesac EnequeNo ratings yet

- Rxsf1 Rxms1 Rxma1 1mrk 508 015-Ben Auxiliary Signalling and Trippning Relays 1998Document20 pagesRxsf1 Rxms1 Rxma1 1mrk 508 015-Ben Auxiliary Signalling and Trippning Relays 1998hassan karimiNo ratings yet

- GE LV PriceList Wef April-2013Document33 pagesGE LV PriceList Wef April-2013shivaram100% (1)

- The Best T&D InsulatorsDocument26 pagesThe Best T&D InsulatorsBery HamidNo ratings yet

- Bypass SwitchesDocument4 pagesBypass SwitchesCarlos AguiarNo ratings yet

- L170R41 eDocument142 pagesL170R41 eJairo Morales100% (2)

- Product Catalog 0511Document58 pagesProduct Catalog 0511nyxf3jNo ratings yet

- Catalogue Jiangsu Sieyuan HertzDocument24 pagesCatalogue Jiangsu Sieyuan HertzdaminhvienNo ratings yet

- Alstom Technical FlyerDocument2 pagesAlstom Technical Flyerram_kisna007No ratings yet

- Af-650 Quick Guide (En, Es, De, FR, It)Document256 pagesAf-650 Quick Guide (En, Es, De, FR, It)Paulo RodriguesNo ratings yet

- Cable Type and Bushing Type Current TransformersDocument20 pagesCable Type and Bushing Type Current TransformersJohn Raymond LumanlanNo ratings yet

- PGK 110 HB Baur En-GbDocument3 pagesPGK 110 HB Baur En-GbAlan GallagherNo ratings yet

- Siemens: Made in Pakistan Licence Siemens GermanyDocument2 pagesSiemens: Made in Pakistan Licence Siemens GermanyStar UetNo ratings yet

- 11-Zinc Ribbon For HT CrossingsDocument6 pages11-Zinc Ribbon For HT Crossingsmansih457No ratings yet

- Combined Price List Jan 2021Document56 pagesCombined Price List Jan 2021Sudipon DasNo ratings yet

- Low Voltage Current and Voltage Transformers PDFDocument260 pagesLow Voltage Current and Voltage Transformers PDFGustavo GamezNo ratings yet

- High Voltage FusesDocument10 pagesHigh Voltage FusesDuvan Nieto CañonNo ratings yet

- Catalogue Technor GB 0619Document244 pagesCatalogue Technor GB 0619Noviardi BachtarNo ratings yet

- F0126405 PB OLTCsDocument24 pagesF0126405 PB OLTCsshahramkh59100% (1)

- Ss # SDT - 065: Site Acceptance Test Report For 22Kv TransformerDocument6 pagesSs # SDT - 065: Site Acceptance Test Report For 22Kv TransformerSaran Saravanan100% (1)

- ApparatusDocument85 pagesApparatusTap ToanNo ratings yet

- Old LT Panel 400 AmpDocument5 pagesOld LT Panel 400 AmpAbhinav TewariNo ratings yet

- Atv1200 Schneider CatalogoDocument121 pagesAtv1200 Schneider CatalogoEdward PalominoNo ratings yet

- Q881507-9 Installation and Operating Manual PDFDocument1,059 pagesQ881507-9 Installation and Operating Manual PDFngocanhvyNo ratings yet

- OTEF Voltage Transformers 100 KV To 800 KV - Brochure GBDocument4 pagesOTEF Voltage Transformers 100 KV To 800 KV - Brochure GBjoseandres999No ratings yet

- P50 Agile: GE Grid SolutionsDocument288 pagesP50 Agile: GE Grid Solutionsnurahmat57No ratings yet

- Completely Self Protected Distribution (CSP) TransformersDocument11 pagesCompletely Self Protected Distribution (CSP) Transformersjobpei2No ratings yet

- XRIO Converter Manual AREVA P443 P445 ENU TU2.22 V1.000Document13 pagesXRIO Converter Manual AREVA P443 P445 ENU TU2.22 V1.000Sakthi MuruganNo ratings yet

- nkt-06086 Katalog Hochspannungsgarnituren PDFDocument32 pagesnkt-06086 Katalog Hochspannungsgarnituren PDFHoangNo ratings yet

- 06 - CG Instrument TransformersDocument12 pages06 - CG Instrument TransformersMuhammad Fathoni FikriNo ratings yet

- Buchholz RelayDocument12 pagesBuchholz RelaybharathNo ratings yet

- Dry Transformer Training GuideDocument24 pagesDry Transformer Training GuideNguyễn Nhật ÁnhNo ratings yet

- AirRIP® Flex Transformer BushingDocument29 pagesAirRIP® Flex Transformer BushingSandeep BNo ratings yet

- Legrand Electric Limited: Great King Street North B19 2Lf Birmingham - United KingdomDocument2 pagesLegrand Electric Limited: Great King Street North B19 2Lf Birmingham - United Kingdomfebos1No ratings yet

- Buchholz Relay Magnetic SwichDocument4 pagesBuchholz Relay Magnetic SwichSatish RajuNo ratings yet

- ISF2 Catalog PDFDocument8 pagesISF2 Catalog PDFbdikicNo ratings yet

- Telemecanique Power Control & Protection Components TechnicalDocument610 pagesTelemecanique Power Control & Protection Components Technicalslipped_discNo ratings yet

- Icc 1740 V 3Document610 pagesIcc 1740 V 3Richard PuttNo ratings yet

- HG MCCBDocument6 pagesHG MCCBniteshnagpal1990No ratings yet

- Indian Standard: Methods of Test For CablesDocument3 pagesIndian Standard: Methods of Test For CablesBilal AhmadNo ratings yet

- BioDataDocument2 pagesBioDataBilal AhmadNo ratings yet

- Islamic Studies Book 1 PDFDocument251 pagesIslamic Studies Book 1 PDFBilal AhmadNo ratings yet

- The Etiquettes of Marriage and WeddingDocument12 pagesThe Etiquettes of Marriage and WeddingBilal AhmadNo ratings yet

- Form No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBDocument1 pageForm No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBIam KarthikeyanNo ratings yet

- Al - Muhaddithat PDFDocument337 pagesAl - Muhaddithat PDFEl ZéphyrNo ratings yet

- The Ideal Muslim by Muhammad Ali Al-HashimiDocument109 pagesThe Ideal Muslim by Muhammad Ali Al-HashimiAwais ChaudryNo ratings yet

- The Afghanistan Pakistan Theater PDFDocument161 pagesThe Afghanistan Pakistan Theater PDFBilal AhmadNo ratings yet

- Messengers and BooksDocument33 pagesMessengers and Booksumer shafiqueNo ratings yet

- The Signs Before The Day of JudgementDocument43 pagesThe Signs Before The Day of JudgementmoremoneyformeNo ratings yet

- Anatomski Atlas PDFDocument68 pagesAnatomski Atlas PDFIVANANo ratings yet

- The Muslim at Prayer: A Comparative StudyDocument11 pagesThe Muslim at Prayer: A Comparative StudyBilal AhmadNo ratings yet

- List of State Department of Electric Maintains Sub Division HawalDocument3 pagesList of State Department of Electric Maintains Sub Division HawalBilal AhmadNo ratings yet

- Who Moved The StoneDocument6 pagesWho Moved The Stoneazee0% (1)

- D SusaDocument28 pagesD SusaBilal AhmadNo ratings yet

- SERC APDRP 2012 Final Rainawari Form 10Document76 pagesSERC APDRP 2012 Final Rainawari Form 10Bilal AhmadNo ratings yet

- Form No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBDocument1 pageForm No. 10-I: Certificate of Prescribed Authority For The Purposes of Section 80DDBIam KarthikeyanNo ratings yet

- JKPDD: Procedure For Determination of Connected LoadDocument1 pageJKPDD: Procedure For Determination of Connected LoadBilal AhmadNo ratings yet

- SERC APDRP Upto January 2013Document76 pagesSERC APDRP Upto January 2013Bilal AhmadNo ratings yet

- Change Name Consumer FormDocument1 pageChange Name Consumer FormBilal Ahmad100% (1)

- State Departments. S.No Name and Location Id - No: Column1 Column2 Column3Document3 pagesState Departments. S.No Name and Location Id - No: Column1 Column2 Column3Bilal AhmadNo ratings yet

- JKPDD: (Tick Whichever Applicable)Document2 pagesJKPDD: (Tick Whichever Applicable)Bilal AhmadNo ratings yet

- SERC 1-9 FormatDocument18 pagesSERC 1-9 FormatBilal AhmadNo ratings yet

- 25kVA Endingfor The Year 2011-12IDocument94 pages25kVA Endingfor The Year 2011-12IBilal AhmadNo ratings yet

- SERC 1-9 FormatDocument18 pagesSERC 1-9 FormatBilal AhmadNo ratings yet

- VLDSclearifiDocument1 pageVLDSclearifiBilal AhmadNo ratings yet

- SERC RainawariDocument48 pagesSERC RainawariBilal AhmadNo ratings yet

- Public NoticeDocument3 pagesPublic NoticeBilal AhmadNo ratings yet

- Public Notice: WWW - Jkpdd.govDocument3 pagesPublic Notice: WWW - Jkpdd.govBilal AhmadNo ratings yet

- Public Notice: WWW - Jkpdd.govDocument3 pagesPublic Notice: WWW - Jkpdd.govBilal AhmadNo ratings yet

- Dse E800Document2 pagesDse E800mohammad hazbehzadNo ratings yet

- Trouble Shooting GuideDocument18 pagesTrouble Shooting GuideDeyan VelikovNo ratings yet

- MPM80 Series Data Sheet: 2 A Non-Isolated Buck Converter ModuleDocument20 pagesMPM80 Series Data Sheet: 2 A Non-Isolated Buck Converter ModuleytnateNo ratings yet

- Diagrama de Conexión - Catamaran Oukiva PDFDocument1 pageDiagrama de Conexión - Catamaran Oukiva PDFMartín Andrés García100% (1)

- Electrical-Engineering Engineering Analog-Electronics General-Amplifiers Notes PDFDocument32 pagesElectrical-Engineering Engineering Analog-Electronics General-Amplifiers Notes PDFRaja MariyappanNo ratings yet

- Lesson 33 Optical Absorption in Semiconductors PDFDocument44 pagesLesson 33 Optical Absorption in Semiconductors PDFBobbette BobbertNo ratings yet

- Introduction To Semiconductor Lasers For Optical CommunicationsDocument369 pagesIntroduction To Semiconductor Lasers For Optical CommunicationsDetian WangNo ratings yet

- Leoni Whitepaper 11.2016Document4 pagesLeoni Whitepaper 11.2016Rita MizarniNo ratings yet

- PIX-36 Catalogue Schneider 1Document46 pagesPIX-36 Catalogue Schneider 1ARYA JENANo ratings yet

- 80010292Document2 pages80010292Anonymous ZYBA1RNo ratings yet

- PHY 204-Electricity and Magnetism-Ata UlhaqDocument3 pagesPHY 204-Electricity and Magnetism-Ata UlhaqOsamaNo ratings yet

- ABB CQ900 Controller Brochure - V03B. 0612Document10 pagesABB CQ900 Controller Brochure - V03B. 0612Percy GoitsemangNo ratings yet

- NMC-TED300: NIKOMAX Cable Tester With LCD Display, UTP/STP, RJ45, With Length MeasurementDocument2 pagesNMC-TED300: NIKOMAX Cable Tester With LCD Display, UTP/STP, RJ45, With Length MeasurementMaaeglobal ResourcesNo ratings yet

- Catalogue Inverseurs OTMDocument104 pagesCatalogue Inverseurs OTMchahbounnabil100% (1)

- Battery Failure PredictionDocument10 pagesBattery Failure PredictionChris Baddeley100% (1)

- Maninder Seminar Word1 PDFDocument44 pagesManinder Seminar Word1 PDFsankesh burdakNo ratings yet

- Datasheet STD724 TRANSISTORDocument10 pagesDatasheet STD724 TRANSISTORArnoldo DazaNo ratings yet

- PWM - 556Document2 pagesPWM - 556HaSophim100% (1)

- Air-Conditioner: Service ManualDocument54 pagesAir-Conditioner: Service ManualsureshchitraNo ratings yet

- Istruzioni Per La Regolazione Del Freno Serie T - EngDocument2 pagesIstruzioni Per La Regolazione Del Freno Serie T - Engd!egoNo ratings yet

- cfl535f ManualDocument17 pagescfl535f Manualshashi bhushan singhNo ratings yet

- Cgah Chiller IomDocument28 pagesCgah Chiller IomLuong Dao100% (2)

- Ground Fault Sensor: CR7310 SeriesDocument2 pagesGround Fault Sensor: CR7310 SeriesbhaskarinvuNo ratings yet

- Solving Circuit ProblemsDocument33 pagesSolving Circuit Problems19027 PrantoBiswasNo ratings yet

- South Bihar Power Citizen Charter for ConsumersDocument2 pagesSouth Bihar Power Citizen Charter for ConsumersAlok AmanNo ratings yet

- ACS Appl. Energy Mater. 5 (2022) 367-379 PDFDocument13 pagesACS Appl. Energy Mater. 5 (2022) 367-379 PDFEdgar QuintanillaNo ratings yet

- Compact Wideband Circularly Polarized Microstrip Antenna Array For 45Ghz ApplicationDocument5 pagesCompact Wideband Circularly Polarized Microstrip Antenna Array For 45Ghz Applicationnguyễn đắc huyNo ratings yet

- Superposition SourceTransf Mod1Document19 pagesSuperposition SourceTransf Mod1KUSH KHANNA 18BLC1024No ratings yet

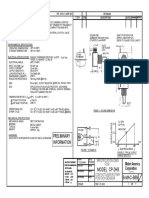

- Preliminary Information: B-MAC-B69 Model Cp-2HbDocument1 pagePreliminary Information: B-MAC-B69 Model Cp-2HbCykhong KhongNo ratings yet

- Be Winter 2018Document2 pagesBe Winter 2018vikram patilNo ratings yet