Professional Documents

Culture Documents

Holophane 02454 Series Brochure 1971

Uploaded by

Alan MastersCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Holophane 02454 Series Brochure 1971

Uploaded by

Alan MastersCopyright:

Available Formats

DUST TIGHT

AND

pl

ENGLOSED

AND

al

ol.! :

GASKETED

FOR

(o

nri

EP

l.-c

INDUSTRY

Underwriters Listed for Use in Dust Tight Class ll, Groups E, F and G and Class III locations.

P!

3+

t///1 il1il

D{T|A! tooT(Altot ts DtuvEttD

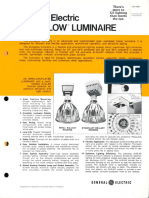

EXCEPTIONAL LIGHTING PENFOFMANCE Prismatically controlled light provides a widespread distribution pattem and high utilization efrciency, permitting spacings of luminaires up to 2 times their mounting height while producing even coverage. 52% ol Iotal light is emitted in the important 0 to 60 degree output zone, making possible the use of fewer luminaires for a given footcandle Ievel or higher levels of illumination for each watt per square foot. Widespread light across the ceiling, up to 21% oI total light output, produces a pleasant environment, and reduces contrast between luminaire and ceiling. Upward light also permits visual inspection of overhead piping and tubiag.

ron taor rYATT/sQuaRt r00T

IARGI I MIDTUM I sin^[ RoolrllR00mlR00r

t3

lt

id 6rihd. .l ld.liJls reli.t d lor '!pid r@ !*urdh illuDimrid rdl.ullrior U lnrds rid otorti. t!n6.

!i y!{ r fia..1,.n. rLr h C6fii.hft ot

LONGI USEFUL LIFE The light controlling prismatic glass assembly is

molded of

ENDURAT-@- a specific thermal shock-resisting glass developed for outdoor operation. These units are sg rugged they can be clealed by hosing even when

EASE OF MAINTENANCE Luminaire is relamped by loosening cam latches on the hood which allows the entire glass assembly to hang safely in the metal bails. Refractor can be removed with one hand for relamping and cleaning.

lighted. For extra mechanical protection, specify versions with cast bottom guards. All exposed metal parts are of cast or anodized aluminum or of stainless steel

to resist deterioration-

WEAIHER AND COPROSION RESISTANCE All-tight enclosure is assured by positive pressure of cam latches which hold prismatic element assembly firnly against gasketed die cast hood. Equally suitable

for indoor or outdoor

use.

POS

ITIVE ACT IO N CAM LATCHES

Coellicienls ol Ulilization-Zonal Cavity Method

2064 500h

300/"

ooh 00k 10./" .62 .45

.38

s0y6 306/.

R.P-r,l.Lahp &

100/. .68

50% 30"h

0"/. .54

.46 .39 .32 .27

acc.-5o

'l 2

It o It

.73 .65 .50

.44 .39

4 5 6 8

.31

rd d HorochM6 No.

02!51

10

24

.71 .60 .52 .45 .39 .33 .29 .25 .22 .1 8

.57

.48

.40 .34 .29 .24

.21

.1

.66 .59 .52 .46 .41 .36 .32 .25 .22

.64

.55 .48

.41

.36

.31

.27 .23

.19

.23

.27 .24 .16

.19

.16

.16 .13

.13

.10

.14

\\\\\ )\

I

200tY.l

LAMP SR''I

ALI.,MINUM

'-.t,'

I#DIAM

Max, Spacing Ratio

2.O

Dimensions in lnches

Diam. Depth

Cat. No.

Lamps 1-200 W. lnc.

Termination

3/a"

Net Wgt. Lbs, Each

o2454

r1%

L|X"

Female

Pipe Tap

llp,lnp",h"pngii"ditrJrT'ff :{-,*'''ffi lrd+5":mJ:'"'"T::"

i'r nr..l nLJSA 7292 J5-273

You might also like

- Njagi Substructures Boq 2020Document76 pagesNjagi Substructures Boq 2020michaelNo ratings yet

- W3 Deep FoundationDocument42 pagesW3 Deep FoundationTeoh Zhi TongNo ratings yet

- Method Statement Slab & Beam ConcretingDocument3 pagesMethod Statement Slab & Beam Concretingudithairesha100% (6)

- Types of FurnitureDocument19 pagesTypes of FurnitureRuthNo ratings yet

- Westinghouse Lighting Condensed Product Catalog 6-81Document40 pagesWestinghouse Lighting Condensed Product Catalog 6-81Alan MastersNo ratings yet

- Reinforcement of A Basement WallDocument8 pagesReinforcement of A Basement WallZein FarahNo ratings yet

- Open Well StaircaseDocument3 pagesOpen Well Staircaseबिजेन्द्र प्रधान100% (2)

- Prepare Masonry MaterialsDocument41 pagesPrepare Masonry Materialsefren gNo ratings yet

- Holophane Prismpack II 1000W Mercury Brochure 4-76Document2 pagesHolophane Prismpack II 1000W Mercury Brochure 4-76Alan MastersNo ratings yet

- Holophane Postop Series Brochure 6-70Document4 pagesHolophane Postop Series Brochure 6-70Alan Masters100% (1)

- Moldcast Pericline Brochure 1987Document20 pagesMoldcast Pericline Brochure 1987Alan MastersNo ratings yet

- Moldcast Pericline Brochure 1997Document20 pagesMoldcast Pericline Brochure 1997Alan MastersNo ratings yet

- GE Lighting Systems Duraglow Series Spec Sheet 4-82Document4 pagesGE Lighting Systems Duraglow Series Spec Sheet 4-82Alan MastersNo ratings yet

- QL Design 126 Post Top Area Lighting Brochure 1985Document12 pagesQL Design 126 Post Top Area Lighting Brochure 1985Alan MastersNo ratings yet

- Wide-Lite Spectra V Commercial Indoor Bulletin 1990Document4 pagesWide-Lite Spectra V Commercial Indoor Bulletin 1990Alan MastersNo ratings yet

- ITT American Electric Scroll & Style Line Post Top Series 45-46-145-146 Spec Sheet 4-80Document8 pagesITT American Electric Scroll & Style Line Post Top Series 45-46-145-146 Spec Sheet 4-80Alan MastersNo ratings yet

- Holophane Expresslite Series Brochure 7-73Document8 pagesHolophane Expresslite Series Brochure 7-73Alan MastersNo ratings yet

- GE Lighting Systems Commercial Lighting Designers Guide 1973Document12 pagesGE Lighting Systems Commercial Lighting Designers Guide 1973Alan MastersNo ratings yet

- Benjamin Lighting Industrial HID Brochure 1974Document60 pagesBenjamin Lighting Industrial HID Brochure 1974Alan MastersNo ratings yet

- Lithonia Outdoor KL Series Low Level Flood Brochure 1-89Document6 pagesLithonia Outdoor KL Series Low Level Flood Brochure 1-89Alan MastersNo ratings yet

- ITT American Electric Quartz Series 170 & 174 Spec Sheet 2-79Document6 pagesITT American Electric Quartz Series 170 & 174 Spec Sheet 2-79Alan MastersNo ratings yet

- Lithonia Outdoor KK Series Area Post Top Brochure 1-89Document10 pagesLithonia Outdoor KK Series Area Post Top Brochure 1-89Alan MastersNo ratings yet

- Holophane Trailblazer Series Brochure 4-78Document4 pagesHolophane Trailblazer Series Brochure 4-78Alan MastersNo ratings yet

- GE Lighting Systems Duraglow Series Spec Sheet 10-77Document4 pagesGE Lighting Systems Duraglow Series Spec Sheet 10-77Alan MastersNo ratings yet

- ITT American Electric Ballast-In-Arm Series 165 & 166 Spec Sheet 2-79Document8 pagesITT American Electric Ballast-In-Arm Series 165 & 166 Spec Sheet 2-79Alan MastersNo ratings yet

- Holophane RSL-350 Series Brochure 3-77Document8 pagesHolophane RSL-350 Series Brochure 3-77Alan MastersNo ratings yet

- McGraw-Edison Power Drawer Concourse Series Brochure 1985Document20 pagesMcGraw-Edison Power Drawer Concourse Series Brochure 1985Alan MastersNo ratings yet

- QL 110 Series Area Lighting Brochure 1984Document12 pagesQL 110 Series Area Lighting Brochure 1984Alan MastersNo ratings yet

- Revere 2700 Mercury Superoval 700w & 1000w Roadway Bulletin 1963Document4 pagesRevere 2700 Mercury Superoval 700w & 1000w Roadway Bulletin 1963Alan MastersNo ratings yet

- Spaulding Lighting Peachtree Spec Sheet 8-84Document2 pagesSpaulding Lighting Peachtree Spec Sheet 8-84Alan MastersNo ratings yet

- Westinghouse Lighting VB-15 Series Roadway Spec Sheet 3-72Document2 pagesWestinghouse Lighting VB-15 Series Roadway Spec Sheet 3-72Alan MastersNo ratings yet

- LSI Dakota Series Spec Sheet 10-90Document2 pagesLSI Dakota Series Spec Sheet 10-90Alan MastersNo ratings yet

- Holophane Cranelite Series Brochure 1971Document2 pagesHolophane Cranelite Series Brochure 1971Alan MastersNo ratings yet

- Spaulding Lighting Baltimore Floodlight Spec Sheet 6-77Document2 pagesSpaulding Lighting Baltimore Floodlight Spec Sheet 6-77Alan MastersNo ratings yet

- Spaulding Lighting Cordova I Spec Sheet 6-77Document2 pagesSpaulding Lighting Cordova I Spec Sheet 6-77Alan MastersNo ratings yet

- Holophane Lobay Prismpack II Series Brochure 8-75Document4 pagesHolophane Lobay Prismpack II Series Brochure 8-75Alan Masters100% (1)

- LSI La Costa Series Brochure 1986Document6 pagesLSI La Costa Series Brochure 1986Alan MastersNo ratings yet

- Holophane Prismawrap Brochure 2-75Document4 pagesHolophane Prismawrap Brochure 2-75Alan MastersNo ratings yet

- Benjamin Lighting Industrial Fluorescent Brochure 1978Document16 pagesBenjamin Lighting Industrial Fluorescent Brochure 1978Alan MastersNo ratings yet

- McGraw-Edison Lawn-Glo Series Brochure 1985Document2 pagesMcGraw-Edison Lawn-Glo Series Brochure 1985Alan MastersNo ratings yet

- McGraw-Edison SPI Lighting Monitor Wall Light Series Brochure 1983Document4 pagesMcGraw-Edison SPI Lighting Monitor Wall Light Series Brochure 1983Alan MastersNo ratings yet

- Holophane Module 600 Series Brochure 12-74Document12 pagesHolophane Module 600 Series Brochure 12-74Alan MastersNo ratings yet

- Sylvania Guide To Energy Saving Lamps Brochure 1990-1991Document16 pagesSylvania Guide To Energy Saving Lamps Brochure 1990-1991Alan MastersNo ratings yet

- Wide-Lite Ballast Tech. Data Bulletin 1987Document4 pagesWide-Lite Ballast Tech. Data Bulletin 1987Alan MastersNo ratings yet

- Sylvania Guide To Energy Saving Lamps Brochure 1986Document12 pagesSylvania Guide To Energy Saving Lamps Brochure 1986Alan MastersNo ratings yet

- Holophane Refractopack Series Brochure 1972Document6 pagesHolophane Refractopack Series Brochure 1972Alan MastersNo ratings yet

- ITT American Electric Package B Dusk-To-Dawn Series 11 Spec Sheet 8-80Document4 pagesITT American Electric Package B Dusk-To-Dawn Series 11 Spec Sheet 8-80Alan MastersNo ratings yet

- Kim Lighting SBC Square Beam Cutoff Brochure 1995Document28 pagesKim Lighting SBC Square Beam Cutoff Brochure 1995Alan MastersNo ratings yet

- QL Design 111 14A & 24A Spec Sheet 1980Document2 pagesQL Design 111 14A & 24A Spec Sheet 1980Alan MastersNo ratings yet

- Spaulding Lighting Anaheim Spec Sheet 4-86Document2 pagesSpaulding Lighting Anaheim Spec Sheet 4-86Alan MastersNo ratings yet

- Holophane RSL-200 Series Brochure 8-78Document8 pagesHolophane RSL-200 Series Brochure 8-78Alan MastersNo ratings yet

- GE Quartzline Lamps Brochure 1960Document8 pagesGE Quartzline Lamps Brochure 1960Alan MastersNo ratings yet

- Revere 6820 Quartzoval Tungsten Halogen Floodlight 500w Bulletin 1966Document2 pagesRevere 6820 Quartzoval Tungsten Halogen Floodlight 500w Bulletin 1966Alan MastersNo ratings yet

- GE Lighting Systems Price Book - Trade Net 1985Document80 pagesGE Lighting Systems Price Book - Trade Net 1985Alan MastersNo ratings yet

- LSI Heritage Series Brochure 1981Document4 pagesLSI Heritage Series Brochure 1981Alan MastersNo ratings yet

- GE Lighting Systems Overview Brochure 1-73Document4 pagesGE Lighting Systems Overview Brochure 1-73Alan Masters100% (1)

- LSI Crescent Series Brochure 1989Document4 pagesLSI Crescent Series Brochure 1989Alan MastersNo ratings yet

- Holophane Spherical Street Light (SSL) Series Brochure 6-78Document4 pagesHolophane Spherical Street Light (SSL) Series Brochure 6-78Alan MastersNo ratings yet

- Spaulding Lighting Ventura Spec Sheet 8-84Document2 pagesSpaulding Lighting Ventura Spec Sheet 8-84Alan MastersNo ratings yet

- Spaulding Lighting Morocco Spec Sheet 4-86Document2 pagesSpaulding Lighting Morocco Spec Sheet 4-86Alan MastersNo ratings yet

- Moldcast Lighting Product Data Sheet MDL Series 4-89Document2 pagesMoldcast Lighting Product Data Sheet MDL Series 4-89Alan MastersNo ratings yet

- Spaulding Lighting Huntington II Spec Sheet 4-86Document2 pagesSpaulding Lighting Huntington II Spec Sheet 4-86Alan MastersNo ratings yet

- Outdoor SubstationDocument2 pagesOutdoor SubstationGabriel EnNo ratings yet

- ITT American Electric American Revolution Post Top Series 47 & 48 Spec Sheet 11-79Document8 pagesITT American Electric American Revolution Post Top Series 47 & 48 Spec Sheet 11-79Alan MastersNo ratings yet

- Wide-Lite Effex Series Floodlight Brochure 1994Document24 pagesWide-Lite Effex Series Floodlight Brochure 1994Alan MastersNo ratings yet

- Spaulding Lighting Sebring Spec Sheet 6-77Document2 pagesSpaulding Lighting Sebring Spec Sheet 6-77Alan MastersNo ratings yet

- Wide-Lite Round Spectra-Lyte Brochure 2003Document6 pagesWide-Lite Round Spectra-Lyte Brochure 2003Alan MastersNo ratings yet

- Holophane Lobay II Series Brochure 11-78Document4 pagesHolophane Lobay II Series Brochure 11-78Alan MastersNo ratings yet

- Philips Retail Merchandising Westinghouse Soft White TRA-PAKS Bulletin 1984Document2 pagesPhilips Retail Merchandising Westinghouse Soft White TRA-PAKS Bulletin 1984Alan MastersNo ratings yet

- Philips Reflector Incandescent Lamps Bulletin 8-91Document4 pagesPhilips Reflector Incandescent Lamps Bulletin 8-91Alan MastersNo ratings yet

- Sylvania Incandescent 100w PAR-38 Colored Lamps 1976Document2 pagesSylvania Incandescent 100w PAR-38 Colored Lamps 1976Alan MastersNo ratings yet

- Philips Silicone Coated Incandescent Lamps Bulletin 7-89Document2 pagesPhilips Silicone Coated Incandescent Lamps Bulletin 7-89Alan MastersNo ratings yet

- Philips Reflector BR Incandescent Lamps Bulletin 10-96Document2 pagesPhilips Reflector BR Incandescent Lamps Bulletin 10-96Alan MastersNo ratings yet

- Philips Retail Merchandising LCH-105 Store Fixture Kit Brochure 1986Document4 pagesPhilips Retail Merchandising LCH-105 Store Fixture Kit Brochure 1986Alan MastersNo ratings yet

- Philips Retail Merchandising Standard Lamps Bulletin 1985Document2 pagesPhilips Retail Merchandising Standard Lamps Bulletin 1985Alan MastersNo ratings yet

- Philips Retail Merchandising Westinghouse 33% Longer Life TRA-PAKS Bulletin 1984Document2 pagesPhilips Retail Merchandising Westinghouse 33% Longer Life TRA-PAKS Bulletin 1984Alan MastersNo ratings yet

- Philips Retail Merchandising Tubular Lamps Bulletin 1986Document1 pagePhilips Retail Merchandising Tubular Lamps Bulletin 1986Alan MastersNo ratings yet

- Philips Retail Merchandising Bug-A-Way Lamps Bulletin 1985Document2 pagesPhilips Retail Merchandising Bug-A-Way Lamps Bulletin 1985Alan MastersNo ratings yet

- Philips Retail Merchandising Soft White Lamps Bulletin 1985Document2 pagesPhilips Retail Merchandising Soft White Lamps Bulletin 1985Alan MastersNo ratings yet

- Philips Quartz Infrared Heat Lamps Bulletin 10-86Document4 pagesPhilips Quartz Infrared Heat Lamps Bulletin 10-86Alan MastersNo ratings yet

- Philips Retail Merchandising Sparkling Clear Lamps Bulletin 1985Document2 pagesPhilips Retail Merchandising Sparkling Clear Lamps Bulletin 1985Alan MastersNo ratings yet

- Philips Retail Merchandising PL Lamp & Adaptor 10-84Document2 pagesPhilips Retail Merchandising PL Lamp & Adaptor 10-84Alan MastersNo ratings yet

- Philips Retail Merchandising 33% Longer Life Soft White Lamps Bulletin 1985Document2 pagesPhilips Retail Merchandising 33% Longer Life Soft White Lamps Bulletin 1985Alan MastersNo ratings yet

- Philips Reflector Metal Halide Lamps Bulletin 12-92Document2 pagesPhilips Reflector Metal Halide Lamps Bulletin 12-92Alan MastersNo ratings yet

- Philips Price Schedule Miniature & Sealed Beam Lamps 12-86Document8 pagesPhilips Price Schedule Miniature & Sealed Beam Lamps 12-86Alan MastersNo ratings yet

- Philips Reflector Incandescent Lamps Bulletin 8-92Document4 pagesPhilips Reflector Incandescent Lamps Bulletin 8-92Alan MastersNo ratings yet

- Philips Price Schedule Large Lamps Net 4-87Document24 pagesPhilips Price Schedule Large Lamps Net 4-87Alan MastersNo ratings yet

- Philips Price Schedule Miniature & Sealed Beam Lamps 3-88Document8 pagesPhilips Price Schedule Miniature & Sealed Beam Lamps 3-88Alan MastersNo ratings yet

- Philips Price Schedule Special Gas Discharge Lamps 8-87Document4 pagesPhilips Price Schedule Special Gas Discharge Lamps 8-87Alan MastersNo ratings yet

- Philips Price Schedule Stage, Studio & Theater Lamps 1-87Document4 pagesPhilips Price Schedule Stage, Studio & Theater Lamps 1-87Alan MastersNo ratings yet

- Philips Price Schedule Photo Lamps 1-87Document8 pagesPhilips Price Schedule Photo Lamps 1-87Alan MastersNo ratings yet

- Philips Price Schedule Large Lamp Excluded Net 4-93Document8 pagesPhilips Price Schedule Large Lamp Excluded Net 4-93Alan MastersNo ratings yet

- Philips PLS 2-Pin Compact Fluorescent Lamps Bulletin 4-93Document2 pagesPhilips PLS 2-Pin Compact Fluorescent Lamps Bulletin 4-93Alan MastersNo ratings yet

- Philips PLS 2-Pin Compact Fluorescent Lamps Bulletin 11-97Document2 pagesPhilips PLS 2-Pin Compact Fluorescent Lamps Bulletin 11-97Alan MastersNo ratings yet

- Philips PLS 2-Pin Compact Fluorescent Lamps Bulletin 1-94Document2 pagesPhilips PLS 2-Pin Compact Fluorescent Lamps Bulletin 1-94Alan Masters100% (1)

- Philips PLL Long Compact Fluorescent Lamps Brochure 2-86Document4 pagesPhilips PLL Long Compact Fluorescent Lamps Brochure 2-86Alan MastersNo ratings yet

- Philips PLL Long Compact Fluorescent Lamps Brochure 4-87Document4 pagesPhilips PLL Long Compact Fluorescent Lamps Brochure 4-87Alan MastersNo ratings yet

- Philips PLL 40w Compact Fluorescent Lamp Bulletin 8-94Document2 pagesPhilips PLL 40w Compact Fluorescent Lamp Bulletin 8-94Alan Masters100% (1)

- SCOPEDocument5 pagesSCOPEMel FNo ratings yet

- 01 UGM Tana River Bridge Book of Drawings 1Document60 pages01 UGM Tana River Bridge Book of Drawings 1aggrey noahNo ratings yet

- Zone 4 Residential Cost EstimateDocument2 pagesZone 4 Residential Cost EstimateSancho AcbangNo ratings yet

- Architecture and Interior Design - 19th Century - Ch03Document11 pagesArchitecture and Interior Design - 19th Century - Ch03Bunduche Inga100% (1)

- 41x50 House PlanDocument1 page41x50 House PlanKhan Noman PathanNo ratings yet

- Product Catalog: & Engineering GuideDocument32 pagesProduct Catalog: & Engineering GuidekamakshiNo ratings yet

- For Cinema, Television and Photography: Light & ShadowDocument7 pagesFor Cinema, Television and Photography: Light & ShadowSergei AbbitjakokovNo ratings yet

- Solution Manual Ruregold 2021webDocument53 pagesSolution Manual Ruregold 2021webdaniel12ddNo ratings yet

- c02112 SQPDocument26 pagesc02112 SQPsgk9494No ratings yet

- Geographic Location & Climate: Italian Romanesque ArchitectureDocument2 pagesGeographic Location & Climate: Italian Romanesque ArchitectureClintAbellaNo ratings yet

- BOQ TempleteDocument172 pagesBOQ TempleteVictorNo ratings yet

- Tools ArchicadDocument9 pagesTools Archicadsarah ambardiniNo ratings yet

- Academic BLK 3 - F2 & f3 PlanDocument1 pageAcademic BLK 3 - F2 & f3 PlanBindu BollempalliNo ratings yet

- ADAM-20160103142314643@en AA Utilisation FactorDocument4 pagesADAM-20160103142314643@en AA Utilisation FactorTien Dang ThanhNo ratings yet

- 1750 - Muslim Religious ArchitectureDocument145 pages1750 - Muslim Religious ArchitectureMaulana Al IndunissyNo ratings yet

- Wooden Work NameDocument55 pagesWooden Work Namenaresh singlaNo ratings yet

- List of Drawings Material Legend General Notes: Drawing LegendDocument1 pageList of Drawings Material Legend General Notes: Drawing LegendHeiren LONo ratings yet

- Transitional Design: Transitional Is The Art of MixingDocument3 pagesTransitional Design: Transitional Is The Art of Mixing灵神No ratings yet

- Best of Irish Kitchens - June-July 2016Document164 pagesBest of Irish Kitchens - June-July 2016Nguyen Binh100% (1)

- Leases Around WoodhavenDocument14 pagesLeases Around WoodhavensamNo ratings yet

- Industrial Building Estimate R0Document10 pagesIndustrial Building Estimate R0swapnilNo ratings yet

- IX. TRUSS and ROOF SYSTEMSDocument38 pagesIX. TRUSS and ROOF SYSTEMSkriengsak ruangdechNo ratings yet