Professional Documents

Culture Documents

PWHT of P91

Uploaded by

Howo4DieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWHT of P91

Uploaded by

Howo4DieCopyright:

Available Formats

5.

POST WELD HEAT TREATMENT : Arrangements: - A minimum of four thermocouples shall be placed such that at least two are on the weld and the other two on the base material on either side of the weld within the heating band at 180 degrees apart about 50mm from the weld joint. Two standby thermocouple shall also be provided on the weld in case of any failure of the thermocouple. The width of the heated circumferential band on either side of the weld must be at least 5 times the thickness of the weld. In case of fillet joints the heating band shall be six times the thickness of the base material. (Ref Fig - 2). An insulation of about 10mm thickness shall be provided between the cable and weld joint.

5.1

Obtain the clearance for post weld heat treatment cycle from QAE / Welding Engineer. The PWHT temp for P91 with P91 material shall be 760 + 10C and the soaking time shall be 2.5 minutes per mm of weld thickness, subject to a MINIMUM OF TWO HOURS. clearance.

Heating shall be done by Induction heating only.

All records shall be reviewed by

Welding

Engineer prior to PWHT

The rate of heating / cooling: - Thickness (Above 350C) Thickness Thickness = Actual thickness as measured. 5.2

upto 60mm - 110C/ hr.(max) > 60mm - 55C/ hr.(max)

INSULATION: The width of the insulation band beyond the heating band shall be at least two times the heating band width on either side of the weldment. The recording of time & temp shall be continuously monitored with a calibrated recorder right from preheating. This will be ensured at every one hour by site authorized personnel.

5.3

PREVENTIVE MEASURES DURING POWER FAILURE AND NONFUNCTIONING OF EQUIPMENT' S.

No interruption is allowed during welding and PWHT. Hence all the equipment for the purpose of power supply, welding , heating etc., shall have alternative arrangements. (diesel generator for providing power to the welding and heating equipments, standby welding and heating equipments, reserve thermocouple connections, gas burner arrangement for maintaining temp etc.) Following preventive measures shall be adopted until normal power supply or backup power supply through diesel generator is

(a) During start of preheating:

In case of any power failure/interruption during preheating, the weld fit-up shall be insulated and brought to room temperature. After the electric supply resumes the joint shall be preheated as per Clause No: 4.1. ( Ref : Fig 3)

(b) During GTAW / SMAW: Use gas burner arrangement to maintain the temperature at 80 to 100C upto a length of 50mm on either side from weld centre line along the complete circumference of the pipe. Root welding shall be continued after power is restored and preheating temperature is raised to 220C. During the above period temperature shall be recorded through contact type Thermometer. ( Ref : Fig4) (c) During cooling cycle after SMAW welding to holding temperature at 80 to 100C for one hour. ( Ref : Fig 5) Care shall be taken to avoid faster cooling rate by adequate insulation. The required temp 80 to 100C shall be maintained by gas burner arrangements till power resumes / start of PWHT. (d) During post weld heat treatment; The following shall be followed: *1) *2) During heating cycle The whole operation to be repeated from the beginning. ( Ref : Fig 6) During soaking Heat treat (soak) subsequently for the entire duration. (complete period). ( Ref : Fig 7) The heating rate shall be as per the chart. 3) During cooling (above 350C ). Reheat to soaking temperature and cool at the required rate. ( Ref : Fig 8) * Temp should not be allowed to fall below 80 to 100C. Gas burner arrangement shall be used to maintain the temperature. 5.4 In all the above cases (a to d) the temp. measurement on the weld joint by means of contact type calibrated temp. Gauges shall be employed to record the temper-ature at regular Intervals of 15 minutes in the logbook by Quality Assurance Engineer / Welding Engineer.

5.5

TEMPERATURE MONITORING: The welding and heat treatment chart given in Figure 9 shall be followed for the following details. The actual PWHT chart shall be monitored for the following: a) Preheat b) Inter pass Temperature (GTAW + SMAW) c) Controlled cooling and Holding at 80 to 100C for minimum one hour under insulation. Start PWHT after minimum one hour of soaking. d) Heating to PWHT e) Soaking at PWHT f) Cooling to 350C g) Cooling to Room Temperature (under insulation)

5.6

CAUTION

THE PWHT TEMP. SHALL NOT DEVIATE FROM THE VALUES SPECIFIED IN THE CHART RANGE SINCE ANY DEVIATIONS TO THE SPECIFIED HOLDING TEMPERATURE WELDMENT. RANGE, WILL ADVERSLY AFFECT THE MECHANICAL UNDER NO PROPERTIES OF THE WELDMENT AND MAY LEAD TO REJECTION OF THE THE WELD JOINTS SHOULD BE KEPT DRY. CIRCUMSTANCES ANY WATER / LIQUID IS ALLOWED TO COME IN CONTACT ITH WELD AS WELL AS PREHEATED PORTION OF PIPE.

ARRANGEMNT FOR POST WELD HEAT TREATMENT Insulate 2 Times Heating Band Width Heating Band W= 8 X T min or as recommended by the equipment supplier fibre glass cloth or Ceramic wool

TC1 Induction Cable

50mm

50mm TC 4 at 180 apart

TC2

TC 3

TC5, TC6 ( Spare TC) shall be fixed at 90, 270 to TC3 Fig - 2

Power Failure during Preheating

Temp in deg c Theoretical curve Actual curve

350 220 100 80 RT

POWER CUT

After power resumes

Time

Immediately cover the joint by insulation, if welding has not been started. Start preheat as per Cl.4.1 after power resumes Fig-3

Power Failure during GTAW/SMAW

Temp in deg c Theoretical curve Actual curve

350 220 100 80 RT Time During power cut Maintain 80 - 100 c by immediate insulation and heating by burners

After power resumes

Fig - 4

Power Failure during PWHT heating cycle

Temp in deg c 760 10 Theoretical curve Actual curve

350 220 100 80 RT Power cut Time

Rate of heating shall be adhered

Fig - 6

Power Failure during PWHT soaking cycle

Temp in deg c 760 10 T T1 Actual curve

350 220 100 80 RT

Power cut

Theoretical curve T1 =T

Time

Fig - 7

Temp in deg c 760 10

Preheating and PWHT by induction heating

Power Failure during PWHT cooling cycle

Temp in deg c 760 10

350

Actual curve Theoretical curve

220 100 80 RT 1 2 3 4 5 Time 6

350 220

Fig - 9 Operation

Preheat Welding by GTAW +SMAW Cooling

Sl. 100 No

80 RT

1 2 3 4

Temp c

220 C 220 C-350 C 80 - 100 C

Rate of cooling shall be adhered

100 C/hr

Free fall heat insulated) Rate (While of cooling/Heating

Time

100 C/hr

Holding at 80-100 C for min 1 hr.Holding shall continue till the start of PWHT Fig - 8 Heating to PWHT Reach 760 10 C for P91 + P91 Soaking at PWHT 760 10 at 2.5minutes /mm ( minimum 2 hrs) As per clause 5.1 As per clause 5.1

7 8

Cooling Cooling

Cooling to 350C Cooling to Room temperature under insulation

NOTE 1.Purging shall be ensured for minimum root and two further passes of SMAW. 2.Ensure removal of all purging dam arrangements after welding.. 3.For electrodes details strictly follow W PS/EWS.

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- PT BM 183 DC 00007 PWHT ProcedureDocument7 pagesPT BM 183 DC 00007 PWHT Procedureeldobie3100% (1)

- Erection & Welding of P91 Pipe MaterialDocument10 pagesErection & Welding of P91 Pipe MateriallightsonsNo ratings yet

- Welding of P91Document37 pagesWelding of P91nishant361100% (4)

- p91 Pwht. AwsDocument4 pagesp91 Pwht. AwssantyagoNo ratings yet

- Optimal Hardness of P91 WeldmentsDocument50 pagesOptimal Hardness of P91 Weldmentsspamfilter02100% (2)

- WPSASMEDocument76 pagesWPSASMERama TamaNo ratings yet

- P91 Repair With NiCrDocument76 pagesP91 Repair With NiCrElias KapaNo ratings yet

- Preheat and Interpass TempDocument2 pagesPreheat and Interpass TempUche UrchNo ratings yet

- Mild Steel to Stainless Steel Welding Materials CatalogDocument334 pagesMild Steel to Stainless Steel Welding Materials CatalogTran Chi Binh DDC100% (1)

- Definition of Buttering From ASME Section IXDocument2 pagesDefinition of Buttering From ASME Section IXsanket100% (3)

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Post WeldDocument4 pagesPost WelddanemsalNo ratings yet

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- P 36 Material 15NiCuMoNb5-6-4Document13 pagesP 36 Material 15NiCuMoNb5-6-4Mudassar Iqbal100% (1)

- PWHT Procedure for Boiler OverhaulDocument10 pagesPWHT Procedure for Boiler OverhaulDedy Trianda100% (1)

- 09-00 - Shell and Tube Heat Exchangers For Routine ServiceDocument17 pages09-00 - Shell and Tube Heat Exchangers For Routine ServiceFolayemiNo ratings yet

- P91 Welding ProcedureDocument1 pageP91 Welding ProcedureJaymin100% (2)

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocument3 pagesEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Metrode Welding Duplex & Superduplex Stainless SteelsDocument18 pagesMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- IIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesDocument81 pagesIIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesAsad Bin Ala QatariNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- Ingenieria de La Soldadura PDFDocument11 pagesIngenieria de La Soldadura PDFedscesc10100% (1)

- Limits and State of The Art of The New Creep Resistant SteelsDocument64 pagesLimits and State of The Art of The New Creep Resistant SteelsRené Galbraith BerraNo ratings yet

- T 91 WeldingDocument12 pagesT 91 WeldingMohammad KhaliquzzamaNo ratings yet

- Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocument12 pagesWelding of CrMo Steels For Power Generation and Petrochemical ApplicationsDries Vandezande100% (1)

- Dissimilar Welds in Refinery Services - B JackDocument18 pagesDissimilar Welds in Refinery Services - B JackSayiram GovindasamyNo ratings yet

- P91 Welding and PWHT ProcedureDocument4 pagesP91 Welding and PWHT ProcedureHatem Ragab100% (2)

- 6GR RequirementsDocument1 page6GR Requirementswalitedison100% (1)

- Metrode Dissimilar Consumable SelectorDocument7 pagesMetrode Dissimilar Consumable SelectorClaudia MmsNo ratings yet

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (1)

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Method Statement For Titanium PipeworkDocument3 pagesMethod Statement For Titanium Pipeworkprem nautiyalNo ratings yet

- CHAPTER XIII IBR Welder QualificationDocument11 pagesCHAPTER XIII IBR Welder QualificationAnubhav Lakhmani100% (1)

- PWHTDocument103 pagesPWHTChetan B KapadiaNo ratings yet

- Electrode Selection ChartDocument4 pagesElectrode Selection Chartsunitbhaumik100% (2)

- MIZAT PWHT Procedure Ensures Welded Joints Meet StandardsDocument9 pagesMIZAT PWHT Procedure Ensures Welded Joints Meet StandardsM. R. Shahnawaz KhanNo ratings yet

- Percentage Wall Reduction Is The Most FrequentlyDocument4 pagesPercentage Wall Reduction Is The Most Frequentlysanketpavi21No ratings yet

- P 91 Piping WeldingDocument81 pagesP 91 Piping Weldingneelapu mahesh reddy100% (1)

- Welding Superduplex Stainless Steels SuccessfullyDocument11 pagesWelding Superduplex Stainless Steels Successfullymuarabadak100% (1)

- Post Weld Heat TreatmentDocument10 pagesPost Weld Heat Treatmentcristian291011No ratings yet

- Tube To Tube-Sheet Welding For Special Process Heat ExchangersDocument16 pagesTube To Tube-Sheet Welding For Special Process Heat Exchangers4nagNo ratings yet

- Metrode P92TP Welding ConsumablesDocument23 pagesMetrode P92TP Welding Consumablespipedown456No ratings yet

- TDC-10B Heat Treatment For C12A Steel CastingsDocument2 pagesTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- PWHTDocument13 pagesPWHTcv100% (2)

- PWHT ProcedureDocument10 pagesPWHT ProcedureMohammed Kamal100% (11)

- Sample Heat Treatment ProcedureDocument13 pagesSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- Heat Treatment Fls ShaftDocument15 pagesHeat Treatment Fls ShaftOKky Sasongko100% (1)

- Heat Treatment of Thin Wall Tanks by Internal Oil Firing MethodDocument7 pagesHeat Treatment of Thin Wall Tanks by Internal Oil Firing MethodKrishna VachaNo ratings yet

- Heat Treatment Procedure GuideDocument15 pagesHeat Treatment Procedure GuideVijay ShamNo ratings yet

- (En) R-6L Kiln Instruction ManualDocument5 pages(En) R-6L Kiln Instruction ManualNepomuseno RaveloNo ratings yet

- Pro PWHT 006 Rev 1 - Procedure For PWHTDocument6 pagesPro PWHT 006 Rev 1 - Procedure For PWHTsugumar100% (1)

- Post-Weld Heat Treatment Procedure for Storage TanksDocument6 pagesPost-Weld Heat Treatment Procedure for Storage TanksKaramSobhy100% (1)

- LANL Engineering Standards Manual PWHT ProcedureDocument6 pagesLANL Engineering Standards Manual PWHT ProcedurevictorbirlanNo ratings yet

- 1.heat Treatment - Avsp 01Document10 pages1.heat Treatment - Avsp 01Siva100% (1)

- Jpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Document9 pagesJpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Anoop N Kutty100% (1)

- Giude Lines For Heat TreatmentDocument91 pagesGiude Lines For Heat TreatmentMassimo FumarolaNo ratings yet

- Amigos Technical PWHT ProcedureDocument12 pagesAmigos Technical PWHT Procedurevsnaiduqc50% (2)

- 246334715Document1 page246334715Howo4DieNo ratings yet

- Technical Advisory For Scaffolds PDFDocument6 pagesTechnical Advisory For Scaffolds PDFPcEngNo ratings yet

- Moshell CommandsDocument76 pagesMoshell CommandsIsac Lima75% (12)

- HOw To Login To RNCDocument10 pagesHOw To Login To RNCRashid MagorwaNo ratings yet

- Scaffolding TrainingDocument4 pagesScaffolding TrainingHowo4DieNo ratings yet

- Engineering Drawings ManualDocument48 pagesEngineering Drawings ManualHowo4DieNo ratings yet

- Elbow LR 1Document1 pageElbow LR 1Howo4DieNo ratings yet

- 2G Answer MCQ Interview Very Important Problem + OptimizationDocument12 pages2G Answer MCQ Interview Very Important Problem + OptimizationyusufshabanNo ratings yet

- PDFDocument6 pagesPDFEng Ahmed Al ShaerNo ratings yet

- Structural Steel: Group IncDocument34 pagesStructural Steel: Group IncHowo4DieNo ratings yet

- FDocument7 pagesFHowo4DieNo ratings yet

- Charts Aid in Design of Horizontal Form WorkDocument4 pagesCharts Aid in Design of Horizontal Form WorkHowo4DieNo ratings yet

- Writing Work Method Statement Plain English Guidelines 0231Document24 pagesWriting Work Method Statement Plain English Guidelines 0231Vincent TengNo ratings yet

- Elbow LR 1Document1 pageElbow LR 1Howo4DieNo ratings yet

- Bue (Ics)Document14 pagesBue (Ics)Howo4DieNo ratings yet

- Missing Back Plates Inside Box Columns at 4 CornersDocument3 pagesMissing Back Plates Inside Box Columns at 4 CornersHowo4DieNo ratings yet

- PIP STF05511 Fixed Industrial StairsDocument13 pagesPIP STF05511 Fixed Industrial StairsGiammarco Negrini100% (2)

- Scaffolds in ArabicDocument31 pagesScaffolds in ArabicHowo4DieNo ratings yet

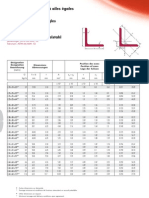

- American EqualChanelDocument9 pagesAmerican EqualChanelTuan Nguyen MinhNo ratings yet

- Fers U Britanniques À Ailes ParallèlesDocument2 pagesFers U Britanniques À Ailes ParallèlesHowo4DieNo ratings yet

- How To Write An EmailDocument4 pagesHow To Write An EmailHowo4DieNo ratings yet

- The Designers' Guide To The Use of Expamet Hy-RibDocument34 pagesThe Designers' Guide To The Use of Expamet Hy-Ribprasad perkaNo ratings yet

- Spherical - Tank Erection ProcessDocument30 pagesSpherical - Tank Erection ProcessJavierfox9889% (9)

- Fers U Normaux Américains: Désignation Designation Bezeichnung Dimensions Abmessungen Surface OberflächeDocument4 pagesFers U Normaux Américains: Désignation Designation Bezeichnung Dimensions Abmessungen Surface OberflächeHowo4DieNo ratings yet

- ErectionDocument55 pagesErectionAjay Sastry100% (7)

- Oracle WorkflowDocument122 pagesOracle WorkflowHowo4DieNo ratings yet

- Cambering BeamsDocument7 pagesCambering BeamsskidbarNo ratings yet

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- How To Write An EmailDocument4 pagesHow To Write An EmailHowo4DieNo ratings yet

- Safe Scaffolding GuideDocument46 pagesSafe Scaffolding Guidedox4use100% (1)

- Quinn Polycarbonate Multi-Wall Technical ManualDocument24 pagesQuinn Polycarbonate Multi-Wall Technical ManualCal MoranNo ratings yet

- Mechanical Engineering Design Elective Module on Industrial TribologyDocument8 pagesMechanical Engineering Design Elective Module on Industrial TribologyNarayan ManeNo ratings yet

- Slide Share BDocument42 pagesSlide Share BShakeel WaseemNo ratings yet

- MC 7 007 Fc001 VentiladorDocument3 pagesMC 7 007 Fc001 VentiladorLeandro CiceroNo ratings yet

- Applications and Challenges of Carbon-Fibres Reinforced CompositesDocument13 pagesApplications and Challenges of Carbon-Fibres Reinforced CompositesDinar IstiyantoNo ratings yet

- Class 10 Concise Chemistry Chemical Bonding SolutionsDocument30 pagesClass 10 Concise Chemistry Chemical Bonding SolutionsPIYUSH DikshitNo ratings yet

- DC Motor Characteristics ExperimentDocument7 pagesDC Motor Characteristics Experimentbilalkhan3567No ratings yet

- Chapter 4Document22 pagesChapter 4Nawaf Al-TamimiNo ratings yet

- SZX 10Document40 pagesSZX 10janinaNo ratings yet

- SUDA Fiber Laser Cutting Machine FC1530-1000W 2020.6.2Document15 pagesSUDA Fiber Laser Cutting Machine FC1530-1000W 2020.6.2marceilinus devaluantoNo ratings yet

- Eni BLASIA FSXDocument2 pagesEni BLASIA FSXranjanguptNo ratings yet

- Force, Torque and Power MeasurementDocument10 pagesForce, Torque and Power MeasurementABIISHEK TNo ratings yet

- Catálogo SEDIVERDocument32 pagesCatálogo SEDIVEREnver Rojas DiazNo ratings yet

- Acfrogdqwiqzrbpa - Dx5iq8b7boh87u6kfmmlgnazpqsruasluj3lrkl8cz1klidl6zhvbkhemqm3ohteid1cehhsqyfkvzds1mczx1hqj7y Amtzrb0yip1nr3yabt B0hkqfygawg8bkmeaDocument326 pagesAcfrogdqwiqzrbpa - Dx5iq8b7boh87u6kfmmlgnazpqsruasluj3lrkl8cz1klidl6zhvbkhemqm3ohteid1cehhsqyfkvzds1mczx1hqj7y Amtzrb0yip1nr3yabt B0hkqfygawg8bkmeaRafaela Saar100% (1)

- RM62N0DI24B3SMA0A: Product DatasheetDocument2 pagesRM62N0DI24B3SMA0A: Product DatasheetRaNo ratings yet

- Properties of SteelDocument61 pagesProperties of SteelCharizza Montarin CENo ratings yet

- Final .Mat Energy Collector Using Piezoelectric Sensor For Public ChargingDocument68 pagesFinal .Mat Energy Collector Using Piezoelectric Sensor For Public ChargingArneitou Queroyla CagungunNo ratings yet

- Design of Chemical Reactors: Required Reading: Chapter 22 (Reactors) of Turton Et Al. (2018)Document61 pagesDesign of Chemical Reactors: Required Reading: Chapter 22 (Reactors) of Turton Et Al. (2018)toofan shamssNo ratings yet

- Analysis of High Rise Building Including Earthquake and Wind LoadsDocument52 pagesAnalysis of High Rise Building Including Earthquake and Wind Loadsclarkgagui100% (1)

- Topic: Visual::Worksheet Number:154Document7 pagesTopic: Visual::Worksheet Number:154kunjal_radiaNo ratings yet

- Fluid DynamicsDocument3 pagesFluid DynamicsKaanNo ratings yet

- Calculation of Natural Gas Isentropic ExponentDocument8 pagesCalculation of Natural Gas Isentropic ExponentsekharsamyNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- CBSE Class 7 Science Light WorksheetDocument3 pagesCBSE Class 7 Science Light WorksheetRajesh Swami100% (2)

- Modelingperforatesinmufflersusingtwo PortsDocument12 pagesModelingperforatesinmufflersusingtwo PortsTowerNo ratings yet

- Lighitng LebanonDocument138 pagesLighitng Lebanonmohammad kassarNo ratings yet

- SEMASPEC Facility Fluids Metrics and Test MethodsDocument87 pagesSEMASPEC Facility Fluids Metrics and Test Methods2684079623No ratings yet

- New Process Performance IE4 Motors: Product NotesDocument2 pagesNew Process Performance IE4 Motors: Product NotesCali MelendezNo ratings yet

- Yasir Mudakir Khan: Familiarization With The Oscilloscope and Proteus SoftwareDocument4 pagesYasir Mudakir Khan: Familiarization With The Oscilloscope and Proteus SoftwareSaad AliKhanNo ratings yet

- SabsDocument348 pagesSabsRobert Nicodemus Pelupessy67% (9)