Professional Documents

Culture Documents

Making A PCB Is Very Simple

Uploaded by

Prateek MangalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Making A PCB Is Very Simple

Uploaded by

Prateek MangalCopyright:

Available Formats

Making a PCB is very simple; it does not consume a lot of time and the results look professional.

After reading this How-To and watching the step by step video, you will be able to make your own PCB in your workshop using just a few inexpensive materials. Many people use protoboard and point-to-point wire everything, but needing multiple copies of the same circuit is the reason that forces many away from using protoboard. After making your first circuit board, you might not point-to-point wire anything again!

For your first circuit board, one goal is to keep the circuit single sided so you can etch using single sided copper clad. This will allow you to gain some experience before moving on to double-sided. If you need topside traces, simply run a few jumper wires on the top. There are many complete circuit layouts you could try like the Hack a Day design challenge winner. Here is a list of materials you will need to produce a single-sided board. With the exception of the copper clad and PCB drills, everything on this list is easily obtained at your local store. Materials: Muratic acid, common household hydrogen peroxide, safety goggles, good quality magazine pages (cut to 811), laser printer, single sided 1 ounce copper clad, a plastic container the board will fit in, soft plastic brush, clothes iron, lacquer thinner, rubber gloves, paper towel, tin snips, drill or rotary tool, PCB drill bits, Scotch Brite scrubbing pad, good ventilation, 5gallon plastic pail full of water. Now, here is how you do it:

Print the bottom side layer on a piece of paper from a high quality magazine. Use one actual page from the magazine, the thicker and shinier the magazine paper the better, but do not use the cover. You must use a laser printer, not an inkjet. If your printer uses ink cartridges and not toner cartridges, it will not work. If you do not have a laser printer, you can work around this by printing to white paper and using a photocopier set to the darkest setting to copy the layout to the magazine paper. If the paper jams in the printer, you are not using a thick-enough magazine page. Again, do not use the magazine covers, as they do not work. Magazine pages are used because they work well, and they are cheap! The reason they work is because the paper is very glossy and the toner does not adhere well to the glossy pages. The printing used on the magazine page is ink and it does not come off, but toner does. Toner is actually a plastic polymer, and different toners may yield varied results. In our experience, a genuine HP toner cartridge was used with great success; an Office Max brand yielded poor results. The sole purpose of the toner is the protect the copper below it from etching away, you only want the uncovered areas to etch. Next, wash your hands to remove any oils. Keep handling to a minimum once the pages are printed and do not touch the laser printing with your fingers; this could get oils on the printing. Keep pages as flat as possible.

Very carefully, remove the copper clad from the packaging. Do not touch the copper surface for the same reason as above. You can cut the copper clad to size using a tin snip if needed. Use the

Scotch Brite scrubbing pad to gently buff the surface (Scotch Brite is a popular brand of of plastic scrubbing pad meant to emulate steel wool). Do not use steel wool because it will embed steel into the copper. Clean off the residual dust with a slightly damp paper towel.

Find a hard, very flat, sturdy, heat resistant surface. Empty the water out of the clothes iron and set the iron on the hottest setting. Allow the iron to get hot.

This is both side of a piece of copper clad. Place the blank side facing down and copper side facing up. Align printing/paper onto copper clad board with the printing facing the copper. Do not allow it to move.

Firmly press the iron onto the back of the magazine paper, sandwiching it between the copper clad and the iron. Pressing hard without moving the iron, hold the iron perfectly still for one full minute. Do not move the iron at all during this minute, and push hard, really hard! Then, for four more minutes, slowly move the iron around making sure to put a lot of pressure on the paper, but not allowing the paper to slide on the copper. When done, let the board fully cool before you move it at all. This will allow the toner to adhere to the copper and prevent you from being burned. Put the board in cold water and let soak for five minutes. After five minutes, try to peel the wet paper from the board leaving only the toner/print from your laser printer. Only the toner should be left adhering to the copper. If the paper does not come off easily, let it soak in the water for a while longer. If necessary, rub with your finger to remove any paper, leaving only the toner. Its ok if there are a few excess paper fibers stuck to the toner.

If you find not every trace adhered to the copper clad or it is misaligned, use lacquer thinner and paper towel to clean the toner from the copper board and start over. If the traces look good then move on. Inspect the traces carefully, however, because what you see now will be your finished product.

In a well-ventilated area with a fan, add 2-cups hydrogen peroxide to a plastic container. Gently pour in 1-cup Muriatic acid, to create the etching solution. Always wear goggles, gloves, and do not inhale the fumes. Do not use any metal containers, measuring cups, stainless steel sinks, or tools with this mixture as this mixture will aggressively etch metal. Acid safety, think triple A, for Always Add the Acid, its whatever is in the container that will end up splashing. This etching solution, while made with common chemicals, should command respect. It is dangerous to yourself and surroundings, treat it with respect. Ferric Chloride is another common etching solution, it is not a safer solution to use, both are equally dangerous.

Put the board copper side up in the plastic container filled with etching solution. Use a soft plastic brush to gently wipe the board. You will notice the copper begin to dissolve. It takes about 3-4 minutes to get all the exposed copper dissolved. You just have to watch to make sure it is gone in all areas between the traces. Do not leave the board in the etching mix for too long as the traces will dissolve under the toner that is protecting them.

Use lacquer thinner (paint thinner and acetone do not work well) and a paper towel to remove any toner left on top of the copper traces.

Tinning prevents the copper from oxidizing, which can make it hard to solder to in the future. If you choose, you can tin all the traces with solder and a soldering iron now. This actually makes drilling much easier because it helps to center the drill bit. Make sure to clean off excess flux if you do this. You could use Tinit to chemically plate the copper. Here is a different tutorial describing its use. Drill all the holes for the through-hole parts using the correct size PCB drill bit and rotary tool. Drill large mounting holes with a normal drill. PCB drill bits are carbide and made to drill through fiber glass that would quickly dull standard bits. There are a few very common sizes of bits and these are often sold in packs. We use .0260 for IC holes and .0310 for resistors and caps.

Print out the top side silkscreen layer on magazine paper and iron this onto the top side, using the same processes as above. Again, run under water and peel off the paper. Now you have the component IDs on the top side. Here is a different video using essentially the same method:

You can make really nice PCBs of your own circuit design using this simple method, and we look forward to seeing your future projects using this method coming in on the tip line. Look for more How-Tos like this one in the How-To category.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Apm p5 Course NotesDocument267 pagesApm p5 Course NotesMusumbulwe Sue MambweNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elastic Modulus SFRCDocument9 pagesElastic Modulus SFRCRatul ChopraNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Manual 40ku6092Document228 pagesManual 40ku6092Marius Stefan BerindeNo ratings yet

- 2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODADocument13 pages2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODAehsan ershadNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- WEEK6 BAU COOP DM NextGen CRMDocument29 pagesWEEK6 BAU COOP DM NextGen CRMOnur MutluayNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Interruptions - 02.03.2023Document2 pagesInterruptions - 02.03.2023Jeff JeffNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Fedex Service Guide: Everything You Need To Know Is OnlineDocument152 pagesFedex Service Guide: Everything You Need To Know Is OnlineAlex RuizNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDocument27 pagesSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Continue: Rudolf Bultmann Theology of The New Testament PDFDocument3 pagesContinue: Rudolf Bultmann Theology of The New Testament PDFpishoi gerges0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- STM - Welding BookDocument5 pagesSTM - Welding BookAlvin MoollenNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- CH 1 India Economy On The Eve of Independence QueDocument4 pagesCH 1 India Economy On The Eve of Independence QueDhruv SinghalNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- SEERS Medical ST3566 ManualDocument24 pagesSEERS Medical ST3566 ManualAlexandra JanicNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementDocument33 pagesADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

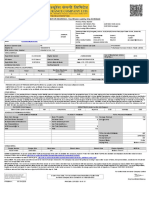

- Employees' Pension Scheme, 1995: Form No. 10 C (E.P.S)Document4 pagesEmployees' Pension Scheme, 1995: Form No. 10 C (E.P.S)nasir ahmedNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEDocument1 pageMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VNo ratings yet

- Strobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maDocument2 pagesStrobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maShane FairchildNo ratings yet

- Building and Other Construction Workers Act 1996Document151 pagesBuilding and Other Construction Workers Act 1996Rajesh KodavatiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Functions of Commercial Banks: Primary and Secondary FunctionsDocument3 pagesFunctions of Commercial Banks: Primary and Secondary FunctionsPavan Kumar SuralaNo ratings yet

- Test & Drain Valve Model 1000Document2 pagesTest & Drain Valve Model 1000saifahmed7No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- TSB 120Document7 pagesTSB 120patelpiyushbNo ratings yet

- TEVTA Fin Pay 1 107Document3 pagesTEVTA Fin Pay 1 107Abdul BasitNo ratings yet

- Sample Opposition To Motion To Strike Portions of Complaint in United States District CourtDocument2 pagesSample Opposition To Motion To Strike Portions of Complaint in United States District CourtStan Burman100% (1)

- Marine Lifting and Lashing HandbookDocument96 pagesMarine Lifting and Lashing HandbookAmrit Raja100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Efs151 Parts ManualDocument78 pagesEfs151 Parts ManualRafael VanegasNo ratings yet

- Hotel ManagementDocument34 pagesHotel ManagementGurlagan Sher GillNo ratings yet

- Squirrel Cage Induction Motor Preventive MaintenaceDocument6 pagesSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekNo ratings yet

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDocument1 page18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Health Insurance in Switzerland ETHDocument57 pagesHealth Insurance in Switzerland ETHguzman87No ratings yet

- What Is Retrofit in Solution Manager 7.2Document17 pagesWhat Is Retrofit in Solution Manager 7.2PILLINAGARAJUNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)