Professional Documents

Culture Documents

Crushed Concrete SwedishTechnicalDecsription

Uploaded by

qluseqOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crushed Concrete SwedishTechnicalDecsription

Uploaded by

qluseqCopyright:

Available Formats

Sustainable Pavements for European New Member States

General Technical Description

Crushed Concrete in Road Constructions

Translated and summarised from Swedish Road Administrations Allmn teknisk beskrivning Krossad betong i vgkonstruktioner Publ 2004:11.

Hkan Arvidsson, VTI

2(12)

Crushed Concrete in Road Constructions Swedish Road Administration

Foreword

This is a summarised translation of the Swedish technical description for crushed concrete in road constructions. In Swedish it is named: Allmn teknisk beskrivning Krossad betong i vgkonstruktioner Publ 2004:11. In its original language it can be found in the following internet address: http://www.vv.se/filer/publikationer/ATB_Krossad_betong_2004-11.pdf The chapters in this document follow the numbers of the chapters in the Swedish original document. 19 february 2008 Hkan Arvidsson, VTI

Crushed Concrete in Road Constructions Swedish Road Administration

3(12)

Contents

General ............................................................................................................................... 5 1.1 Description of the material......................................................................................... 5 2 Projecting requirements...................................................................................................... 5 2.1 Environmental impact ................................................................................................ 5 2.2 Quality class ............................................................................................................... 5 2.3 Classification.............................................................................................................. 6 2.4 Road base material for pedestrian and bicycle lanes.................................................. 6 2.5 Sub base material ....................................................................................................... 7 2.6 Capping layer material ............................................................................................... 7 2.7 Material for substructure and other fillings................................................................ 7 2.8 Pavement design conditions ....................................................................................... 8 2.9 Constructive design .................................................................................................... 8 3 Performance ....................................................................................................................... 9 3.1 Base layer ................................................................................................................... 9 3.2 Sub base layer and capping layer ............................................................................... 9 3.3 Substructure.............................................................................................................. 10 4 Statements in construction plans ...................................................................................... 10 5 Quality requirements and control ..................................................................................... 10 5.1 General ..................................................................................................................... 10 5.2 Declared properties .................................................................................................. 10 5.3 Reception control ..................................................................................................... 10 5.4 Verification of the performance ............................................................................... 10 6 References ........................................................................................................................ 10 Annex 1 Environmental hazard .......................................................................................... 11 Annex 2 Purity .................................................................................................................... 12 1

4(12)

Crushed Concrete in Road Constructions Swedish Road Administration

Crushed Concrete in Road Constructions Swedish Road Administration

5(12)

General

1.1

Description of the material

The raw material considered is derived from two main sources; recycled from concrete production plants, i.e. residue concrete or crushed concrete from building demolition, i.e. demolition concrete.

Projecting requirements

2.1

2.1.1

Environmental impact

Residue Concrete

Crushed concrete recycled from concrete production plants should be considered to be free of substances that have negative environmental impact.

2.1.2

Demolition Concrete

Demolition concrete should not be to any environmental hazard. It should not contain substances like PAH, PCB, CFC, asbestos, mercury or any other of the buyer specified substances.

2.2

Quality class

A classification of the crushed concrete according to material properties should be performed according to chapter 2.3.

2.2.1

Concrete quality

The quality of the concrete should be determined either by compressive strength or by microDeval. Methods to be used: EN 12390-3: Testing hardened concrete - Part 3: Compressive strength of test specimens EN 1097-1: Tests for mechanical and physical properties of aggregates - Part 1: Determination of the resistance to wear (micro-Deval)

6(12)

Crushed Concrete in Road Constructions Swedish Road Administration

2.2.2

Purity

Purity means absence of other materials than paste of cement and aggregates of crushed rock or natural gravel.

2.3

Classification

A concrete material with either high compressive strength or low micro-Deval value gives a crushed concrete of Quality class 1.

Table 2.3-1 Quality class Crushed concrete Classification of crushed concrete Concrete quality

One of these requirements should be fulfilled Documented records Strength class

C-value K-value

Purity MicroDeval

Amount of concrete Brick,

density >1.6 maximum

Compressive strength, drill cores

Light weight concrete,

density <1.6 maximum

Others

maximum

minimum

No 1 2 3 4

MPa

C30/37 C20/25 C12/15 -

MPa K40 K25 K12

-

MPa 30 20 10

25 35 50 -

Weight % 100 95 80 50

Weight % 0 5 20 50

Weight % 0 1 5 50

Weight % 0 0.5 2 10

C-value: according to EN 206-1 Brick = mineral material with particle density > 1.6 Mg/m Light weight concrete = mineral material with particle density < 1.6 Mg/m Others = e.g. wood, plastic, paper, bitumen etc.

2.4

Road base material for pedestrian and bicycle lanes

Material for base layer for pedestrian and bicycle lanes should fulfil requirements for quality class 1 or 2. The micro-Deval value should not exceed 25. If the traffic passes of heavy vehicles, during construction, are few the maximum of micro-Deval value of 35 can be accepted. Particle size distribution should be determined according to EN 933-1 (sieving). The requirements are described in table 2.4-1

Table 2.4-1 Requirements for particle size distribution for base layer of crushed concrete

Sieve, mm

Upper maximum Normal maximum Normal minimum Lower mimimum

0.063

7 6 3 2

0.25

14 12 6 4

1

28 25 13 10

4

50 45 25 20

16 31.5

90 79 56 46 98 75 64

45

63

90 80 98

Crushed Concrete in Road Constructions Swedish Road Administration

7(12)

2.5

Sub base material

Material for sub base layer should fulfil requirements for quality class 1 or 2. The micro-Deval value should not exceed 25. If the traffic passes of heavy vehicles, during construction, are few the maximum of micro-Deval value of 35 can be accepted. Particle size distribution should be determined according to EN 933-1 (sieving). The requirements are described in table 2.4-1

Table 2.5-1 Requirements for particle size distribution for sub base layer of crushed concrete

Sieve, mm

Upper maximum Normal maximum Normal minimum Lower mimimum

0.063

7 6 -

0.25

14 12 -

1

28 25 -

4

50 45 10 2

16

90 79 26 14

31.5

98 42 28

45

63

90

125

50 35 43 90 98

2.6

Capping layer material

Material for the capping layer should fulfil requirements for quality class 3. Particle size distribution should be determined according EN 933-1 (sieving). The requirements for the amount of fines (0.063/tot) should not exceed 11 % (by weight).

2.7

Material for substructure and other fillings

Material for unbound substructures and other fillings should fulfil requirements for quality class 4.

8(12)

Crushed Concrete in Road Constructions Swedish Road Administration

2.8

Pavement design conditions

For pavement design input from chapter 2.8.1 and 2.8.2 should be used. If other properties are used they should be declared and approved by the buyer.

2.8.1

Bearing capacity

The modulus of elasticity from table 2.8-1 should be used for each quality class. The modulus of elasticity is not dependent of the time of the year.

Table 2.8-1 Modulus of elasticity for unbound materials

Quality class 1-2 3 4

Modulus of elasticity MPa 450 250 150

If a higher modulus of elasticity should be used the increase of strength must be shown.

2.8.2

Frost heave

Crushed concrete of quality class 1/3 is normally not susceptible for frost heave and considered to belong in frost susceptibility class 1, quality class 4 is slightly susceptible for frost heave and belongs to frost susceptibility class 2. For recommended parameters for pavement design with respect to frost heave, see table 2.8-2.

Table 2.8-2 Recommended parameters for pavement design with respect to frost heave Quality Water Dry Poro- Water Frost Frost Heat class content density sity saturation susceptibility heave conductivity ratio class velocity not frozen 1-2 3 4 6% 10 % 12 % 1.8 t/m 1.6 t/m 1.5 t/m 0.32 0.40 0.43 0.34 0.40 0.42 1 1 2 0 0 0 1.1 W/mK 1.0 W/mK 0.9 W/mK

Heat conduct. frozen 1.2 1.1 1.0

2.9

Constructive design

- Crushed concrete should be avoided in base layer of mainly two reasons. The concrete can be susceptible for salt intrusion (from de-icing in wintertime) and it can also be affected by high stress which can increase crushing of the layer. Crushed concrete should be surfaced by a tight bound layer to resist intrusion of salt solutions.

Crushed Concrete in Road Constructions Swedish Road Administration

9(12)

- To be able to use the growth of strength of the material the thickness of the layer ought to be greater than 150 mm.

Performance

Handling of crushed concrete does not need to vary from the handling of regular materials such as gravel and crushed rock. Methods for compaction of unbound layers are described in following chapters.

3.1

Base layer

Base layer should be compacted with vibrating or oscillating single drum roller according to table 3.1-1. The speed of the roller should be constant within the interval 2.5/4 km/h. The linear load should not exceed 45 kN/m.

Table 3.1-1 Maximum of layer thickness (m) after compaction of road base material.

Roller linear load > 15 kN/m > 25 kN/m > 35 kN/m

*

Water content >8%* 6 passes 0.08 0.20 0.25

Water content >8%* 8 passes 0.15 0.25 0.30

Water content <8% or not determined 6 passes 0.10 0.12

If optimum water content is known, replace 8 % with optimum water content -2 %.

3.2

Sub base layer and capping layer

Base layer should be compacted with vibrating or oscillating single drum roller according to table 3.2-1. The speed of the roller should be constant within the interval 2.5/4 km/h. The linear load should not exceed 45 kN/m.

Table 3.2-1 Maximum of layer thickness (m) after compaction of sub base material and capping layer.

Roller linear load > 15 kN/m > 25 kN/m > 35 kN/m

*

Water content >7%* 6 passes 0.25 0.40 0.50

Water content >7%* 8 passes 0.30 0.45 0.55

Water content <7% or not determined 6 passes 0.25

If optimum water content is known, replace 7 % with optimum water content -2 %.

10(12)

Crushed Concrete in Road Constructions Swedish Road Administration

3.3

Substructure

Specifications are described in ATB VG (ATB ROAD) chapter E5.4.1

Statements in construction plans

In the construction plans, except for the normal statements, also the following statements should be included: Quality class of the materials Reference to this document: Crushed Concrete in Road Constructions.

Quality requirements and control

In this chapter only the sub headlines will be shown. This chapter is about certified materials, declared properties, environmental impact, non certified materials, reception control and verification of the performance.

5.1

General

5.2

Declared properties

5.3

Reception control

5.4

Verification of the performance

References

See corresponding chapter in the Swedish original document. The references are: Swedish laws, European standards (EN 206-1, EN 933-1 and EN 12390-3), data bases and some significant reports in Swedish (except the only report in English: Arm M. 2003. Mechanical Properties of residues as unbound road materials. Doctoral thesis) etc.

Crushed Concrete in Road Constructions Swedish Road Administration

11(12)

Annex 1

Environmental hazard

-When estimating environmental hazard there are three significant parameters: Total content: The total amount of different substances in the material. Leachable quantity: how much of the total content will leach in reasonable period of time Leaching velocity: how fast the leach will occur at different water current.

The most interesting environmentally hazardous substances are heavy metals, salt and organic substances (e.g. PCB).

Crushed Concrete in Road Constructions Swedish Road Administration

12(12)

Annex 2

Purity

In this annex it is in more detail described how to perform the Purity analysis in Table 2.3-1 Classification of crushed concrete. The analyse fraction is 8/tot.

You might also like

- Energies 15 01152 v2Document29 pagesEnergies 15 01152 v2qluseqNo ratings yet

- 1 s2.0 S0378778822005229 MainDocument15 pages1 s2.0 S0378778822005229 MainqluseqNo ratings yet

- Communique PCRA 19 Gender Identity ENGDocument3 pagesCommunique PCRA 19 Gender Identity ENGqluseqNo ratings yet

- Figure 1. Schema of Resilient Response of Granular Material Under Cyclic LoadingDocument7 pagesFigure 1. Schema of Resilient Response of Granular Material Under Cyclic LoadingqluseqNo ratings yet

- Nano SIO2Document7 pagesNano SIO2qluseqNo ratings yet

- Stability Modelling With SLOPE/WDocument246 pagesStability Modelling With SLOPE/WMaya AwonNo ratings yet

- Geotechnical Properties of Anthropogenic Soils in Road EngineeringDocument25 pagesGeotechnical Properties of Anthropogenic Soils in Road EngineeringqluseqNo ratings yet

- Particle size distribution and resilient modulus of lime stabilized clayDocument1 pageParticle size distribution and resilient modulus of lime stabilized clayqluseqNo ratings yet

- MaterialsDocument17 pagesMaterialsqluseqNo ratings yet

- Art6 PDFDocument11 pagesArt6 PDFqluseqNo ratings yet

- tc16 dmt2001Document42 pagestc16 dmt2001qluseqNo ratings yet

- Destrukt NorwegiaDocument16 pagesDestrukt NorwegiaqluseqNo ratings yet

- 21 Baltic Road - Aurstad - Crushed Concrete - Mechanical PropertiesDocument5 pages21 Baltic Road - Aurstad - Crushed Concrete - Mechanical PropertiesqluseqNo ratings yet

- Self-Cementing Properties of Crushed DemolishedDocument5 pagesSelf-Cementing Properties of Crushed DemolishedqluseqNo ratings yet

- LRSM Abstract BookDocument51 pagesLRSM Abstract BookqluseqNo ratings yet

- Acta PDFDocument11 pagesActa PDFqluseqNo ratings yet

- Application of A High-Cycle Accumulation Model To The Analysis of Soil LiquefactionDocument10 pagesApplication of A High-Cycle Accumulation Model To The Analysis of Soil LiquefactionqluseqNo ratings yet

- Long Term Deformations by Creep and Shrinkage in RecycledDocument14 pagesLong Term Deformations by Creep and Shrinkage in RecycledqluseqNo ratings yet

- Emerging Trends in Geotechnical Engineering ProceedingsDocument135 pagesEmerging Trends in Geotechnical Engineering ProceedingsqluseqNo ratings yet

- Frost Resistance of Recycled ConcreteDocument5 pagesFrost Resistance of Recycled ConcreteqluseqNo ratings yet

- Statistical Evaluation of Resilient Models Characterizing Coarse Granular MaterialsDocument17 pagesStatistical Evaluation of Resilient Models Characterizing Coarse Granular MaterialsqluseqNo ratings yet

- Unbound Crushed Concrete in High Volume RoadsDocument12 pagesUnbound Crushed Concrete in High Volume RoadsqluseqNo ratings yet

- Art6 PDFDocument11 pagesArt6 PDFqluseqNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Instructions For Using WinplotDocument38 pagesInstructions For Using WinplotClaudia MuñozNo ratings yet

- Algologicalmerida Ionescu Et AlDocument17 pagesAlgologicalmerida Ionescu Et AlRaed AwwadNo ratings yet

- Quantitative Corpus BasedDocument6 pagesQuantitative Corpus Basedahmn67No ratings yet

- DC Characteristics of A MOS Transistor (MOSFET) : Created in COMSOL Multiphysics 5.3Document20 pagesDC Characteristics of A MOS Transistor (MOSFET) : Created in COMSOL Multiphysics 5.3Anika TabassumNo ratings yet

- SKF Single Plane Graphical Balancing Tutorial ENDocument13 pagesSKF Single Plane Graphical Balancing Tutorial ENVili KamenovaNo ratings yet

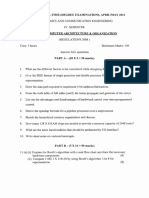

- B - E / B - T E C H (Full-Time) D E G R E E Examinations, April/May 2012Document2 pagesB - E / B - T E C H (Full-Time) D E G R E E Examinations, April/May 2012krithikgokul selvamNo ratings yet

- II Year Civil Engineering Syllabus and Evaluation SchemeDocument12 pagesII Year Civil Engineering Syllabus and Evaluation SchemeSheezan KhanNo ratings yet

- Ice 3Document9 pagesIce 3Gabriel CortesNo ratings yet

- Mathematics-6 q4 w5 Day-34Document20 pagesMathematics-6 q4 w5 Day-34Maribel Felipe ValdezNo ratings yet

- Newtonian Mechanics (Physics Chap 2)Document46 pagesNewtonian Mechanics (Physics Chap 2)anon_815277876No ratings yet

- The 2 - Generation Audi Space Frame of The A2: A Trendsetting All-Aluminium Car Body Concept in A Compact Class CarDocument5 pagesThe 2 - Generation Audi Space Frame of The A2: A Trendsetting All-Aluminium Car Body Concept in A Compact Class CarKld AliNo ratings yet

- PRNCON.EXE Release Notes v11.11.09.1Document4 pagesPRNCON.EXE Release Notes v11.11.09.1Oswaldo GarayNo ratings yet

- IEEE Recommended Guide For Measuring Ground Resistance and Potential Gradients in The EarthDocument20 pagesIEEE Recommended Guide For Measuring Ground Resistance and Potential Gradients in The Earthkimjohn dejesusNo ratings yet

- Lecture2 KlayoutDocument55 pagesLecture2 KlayoutSneha S RevankarNo ratings yet

- ISO 8655-3 2022 Ed.2 - Id.68798 Publication PDF (En)Document14 pagesISO 8655-3 2022 Ed.2 - Id.68798 Publication PDF (En)Qualidade FrilaboNo ratings yet

- Skybox Appliance 8050 Quick Start GuideDocument73 pagesSkybox Appliance 8050 Quick Start GuideNet RunnerNo ratings yet

- David KaplanDocument5 pagesDavid Kaplanmerch100% (1)

- Analyzing Network Traffic with TSharkDocument46 pagesAnalyzing Network Traffic with TSharkJay SingireddyNo ratings yet

- RFPO55 G.8263: SpecificationsDocument5 pagesRFPO55 G.8263: SpecificationsullascsNo ratings yet

- MDVT v140w Drn1 CabinDocument49 pagesMDVT v140w Drn1 CabinambuenaflorNo ratings yet

- Lab 01 ADocument7 pagesLab 01 ApathmakerpkNo ratings yet

- RAB & Spek LiftDocument2 pagesRAB & Spek Liftfatwa1985No ratings yet

- Clutch/Gearshift LinkageDocument19 pagesClutch/Gearshift LinkagegenuineswedeNo ratings yet

- Chapter 5001Document32 pagesChapter 5001jangra014100% (1)

- Kode Program Untuk Led Matrix p10Document5 pagesKode Program Untuk Led Matrix p10IlmisyabanaNo ratings yet

- IUPAC Naming by Aravind AroraDocument30 pagesIUPAC Naming by Aravind Aroratanish gehlotNo ratings yet

- Bending Moment Due To Live Load:: A) IRC Class 70R Load (Tracked Vehicle)Document9 pagesBending Moment Due To Live Load:: A) IRC Class 70R Load (Tracked Vehicle)Tashi TamangNo ratings yet

- Iron Carbon Diagram 6Document15 pagesIron Carbon Diagram 6Harris DarNo ratings yet

- AOAC Official Methods of Analysis for Phosphorus in FertilizersDocument2 pagesAOAC Official Methods of Analysis for Phosphorus in FertilizersDjaloel KhairNo ratings yet

- Computer Architecture Project 2: Understanding Gem5 Branch Predictor StructureDocument5 pagesComputer Architecture Project 2: Understanding Gem5 Branch Predictor StructureAsif MalikNo ratings yet