Professional Documents

Culture Documents

Sec-I 130

Uploaded by

Panchal ShaileshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec-I 130

Uploaded by

Panchal ShaileshCopyright:

Available Formats

2007 SECTION I

07

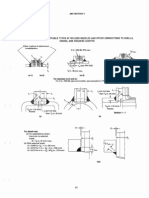

TABLE PW-39 MANDATORY REQUIREMENTS FOR POSTWELD HEAT TREATMENT OF PRESSURE PARTS AND ATTACHMENTS

Minimum Holding Temperature, of Material P-No. 1 Group No. 1,2,3

(Oe)

Minimum Holding Time at Normal Temperature for Weld Thickness (Nominal) Up to 2 in. (50 mm) 1 hr/in. (2 min/mm), IS min minimum Over 2 in. (50 mm) to 5 in. (125 mm) 2 hr plus IS min for each additional inch over 2 in. (SO mm) Over 5 in. (125 mm) 2 hr plus IS min for each additional inch (2S mm) over 2 in. (SO mm)

GENERAL NOTES:

(a) Postweld heat treatment is not mandatory for P-No. 1 materials under the following conditions: (1) for circumferential butt welds in pressure parts with a nominal wall thickness of \ in. (19 mm) or less at the joint (2) for fillet welds used on slip-on and socket welding flanges and fittings conforming to the rules of PW-41, when the following conditions are met: (a) a fillet weld throat thickness of ~ in. (13 mm) or less, regardless of base metal thickness (b) a minimum preheat of 200F (9S0C) when the thickness of a pressure part at the weld exceeds \ in. (19 mml (3) for fillet welds attaching nonpressure parts to pressure parts that have a throat thickness of ~ in. (13 mm) or less, provided preheat to a minimum temperature of 200F (9S0C) is applied when the thickness of the pressure part exceeds \ in. (19 mm) (4) for welds used to attach extended heat absorbing surface to tubes and insulation attachment pins to pressure parts (S) for tubes or pressure retaining handhole and inspection plugs or fittings that are secured by physical means (rolling, shoulder construction, machine threads, etc.> and seal welded, provided the seal weld has a throat thickness of ~ in. (10 mm) or less, and preheat to a minimum temperature of 200F (9S0C) is applied when the thickness of either part exceeds \ in. (19 mm) (6) for studs welded to pressure parts for purposes not included in (d) above, provided preheat to a minimum temperature of 200F (9S0Cl is applied when the thickness of the pressure part exceeds \ in. (19 mm) (7) for tube-to-tubesheet welded attachment of P-No. I, Group Nos. 1 and 2 material in firetube boilers in accordance with Fig. PFT-12.1 sketches (f) and (g), if the depth of the weld groove or preparation does not exceed ~ in. (10 mml, provided a minimum preheat of 200F (9S0C) is applied when the tubesheet thickness exceeds \ in. (19 mm) (8) for fillet welds attaching connections to a vessel, provided that all of the following conditions are met: (a) the diameter of the finished opening (diameter din Figs. PG-33.1, PG-33.2, and PW-lS) does not exceed that allowed in PG-32.1.2 or 2 in. (SO mm), whichever is less (b) the throat thickness does not exceed ~ in. (10 mm) (cl preheat to a minimum temperature of 200F (9S0Cl is applied when the thickness of either part exceeds \ in. (19 mm) (d) the connections are not placed in the vessel such as to form ligaments, the efficiency of which would affect the vessel thickness (9) for combination groove and fillet welds attaching nonpressure parts to pressure parts, with a weld thickness of ~ in. (13 mm) or less, provided preheat to a minimum of 200F (9S0C) is applied when the thickness of the pressure part exceeds \ in. (19 mm) (10) for corrosion-resistant weld metal overlay cladding of pipe or tube materials, provided that all of the following conditions are met: (a) the thickness of the overlay cladding is ~ in. (6 mm) or less (b) preheat to a minimum temperature of 200F (9S0C) is applied when the thickness of the pressure part exceeds \ in. (19 mm) (c) the pipe or tube material (1) does not exceed NPS S (ON 12S) outside diameter (2) is not used as a drum or shell (11) for combination groove and fillet welds attaching connections to a vessel as depicted in Fig. PW-16.l(z), provided all of the following conditions are met: (a) both the tube and vessel are P-No. I, Group No.1 or 2 material (b) the diameter of the finished opening does not exceed that allowed in PG-32.1.2 or 2 in. (SO mm), whichever is less (c) the nominal thickness of the weld does not exceed ~ in. (10 mm) (d) the connections are not placed in the vessel such as to form ligaments, the efficiency of which would affect the vessel thickness (e) a minimum preheat of 200F (9S0C) is applied when the thickness of either part exceeds \ in. (19 mm) (f) for welds attaching nonload-carrying studs not exceeding ~ in. (13 mm) in diameter when using an automatic arc stud welding or automatic resistance stud welding process (12) for butt welds and corner joints in fireboxes and waterlegs meeting the requirements of PFT-21, with or without the addition of fillet welds, when the nominal thickness does not exceed \ in. (19 mm) (b) When it is impractical to postweld heat treat at the temperature specified in this Table, it is permissible to carry out the postweld heat treatment at lower temperatures for longer periods of time in accordance with Table PW-39.1. (c) For all P-No. 1 Group No.1 materials, and for P-No. 1 Group No.2 materials having a maximum actual carbon content of 0.30%, the postweld heat treatment requirement of PWT 11.2 for tubes welded to tubular manifolds or headers is not mandatory when all of the following conditions are met: (1) the tubes do not exceed 2 in. (SO mm) 0.0. (2) the header does not exceed NPS 8 (ON 200) (3) the header thickness does not exceed ~ in. (13 mm) (4) a minimum preheat of 200F (9S0C) is applied

92

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Astm A847Document5 pagesAstm A847Mohamed FaroukNo ratings yet

- List Applicable WPS StructureDocument7 pagesList Applicable WPS StructureFerdie OSNo ratings yet

- Signed Off - SMAW11 - q1 - m5 - Welding Fillet Weld On Carbon Steel PLate - v3Document101 pagesSigned Off - SMAW11 - q1 - m5 - Welding Fillet Weld On Carbon Steel PLate - v3Christian Jake Respicio100% (1)

- 34-Samss-010 2018Document9 pages34-Samss-010 2018asimazami69No ratings yet

- How to Determine the Right Preheating and Interpass TemperaturesDocument4 pagesHow to Determine the Right Preheating and Interpass TemperaturesMohammad RizwanNo ratings yet

- Report - Form - MT - PT - RT - Ut - Cal - 2015Document9 pagesReport - Form - MT - PT - RT - Ut - Cal - 2015YuwantoniAlNo ratings yet

- Komatsu Pc75uu 3 Shop ManualDocument20 pagesKomatsu Pc75uu 3 Shop ManualRaymond100% (58)

- Rebar Processing SolutionsDocument27 pagesRebar Processing SolutionsParam SaxenaNo ratings yet

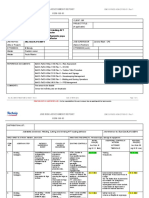

- R057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpoolDocument16 pagesR057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpooldharwinNo ratings yet

- Site QAQC PlanDocument9 pagesSite QAQC PlanP SHANKAR BABU100% (1)

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshNo ratings yet

- Sec-I 139Document1 pageSec-I 139Panchal ShaileshNo ratings yet

- Sec-I 138Document1 pageSec-I 138Panchal ShaileshNo ratings yet

- Sec-I 140Document1 pageSec-I 140Panchal ShaileshNo ratings yet

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocument1 pageTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshNo ratings yet

- Sec-I 132Document1 pageSec-I 132Panchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNo ratings yet

- Sec-I 136Document1 pageSec-I 136Panchal ShaileshNo ratings yet

- Sec-I 133Document1 pageSec-I 133Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshNo ratings yet

- Sec-I 131Document1 pageSec-I 131Panchal ShaileshNo ratings yet

- Sec-I 129Document1 pageSec-I 129Panchal ShaileshNo ratings yet

- Sec-I 128Document1 pageSec-I 128Panchal ShaileshNo ratings yet

- Sec-I 127Document1 pageSec-I 127Panchal ShaileshNo ratings yet

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocument1 pageFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshNo ratings yet

- Sec-I 126Document1 pageSec-I 126Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Boiler welding design rules for joints of unequal thicknessDocument1 pageBoiler welding design rules for joints of unequal thicknessPanchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Sec-I 119Document1 pageSec-I 119Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocument1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshNo ratings yet

- Sec-I 121Document1 pageSec-I 121Panchal ShaileshNo ratings yet

- Sec-I 116Document1 pageSec-I 116Panchal ShaileshNo ratings yet

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocument1 pageFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshNo ratings yet

- Sec-I 114Document1 pageSec-I 114Panchal ShaileshNo ratings yet

- Sec-I 117Document1 pageSec-I 117Panchal ShaileshNo ratings yet

- Sec-I 113Document1 pageSec-I 113Panchal ShaileshNo ratings yet

- Sec-I 112Document1 pageSec-I 112Panchal ShaileshNo ratings yet

- Horizontal-return tubular boiler locationsDocument1 pageHorizontal-return tubular boiler locationsPanchal ShaileshNo ratings yet

- Standard Specification: For Open Web Steel Joists, K-SeriesDocument54 pagesStandard Specification: For Open Web Steel Joists, K-SeriesPaolo PaoitNo ratings yet

- Eaton Eaton Basket Screen DataDocument2 pagesEaton Eaton Basket Screen Dataadalcayde2514No ratings yet

- Vocational Diploma Practical Time TbaleDocument5 pagesVocational Diploma Practical Time TbaleSundaramoorthy KaliappanNo ratings yet

- Rodney Hunt AuctionDocument3 pagesRodney Hunt AuctionJim KinneyNo ratings yet

- ASME Section VIII Division 1, 2017 Edition Metric N3 Nozzle CalculationsDocument4 pagesASME Section VIII Division 1, 2017 Edition Metric N3 Nozzle CalculationsTEAM xILUMINATYxNo ratings yet

- Ultrasonic Testing of Welds in Accordance With AWS D1Document5 pagesUltrasonic Testing of Welds in Accordance With AWS D1Woodrow FoxNo ratings yet

- Work Area For QCDocument4 pagesWork Area For QCPankaj ShrivastvaNo ratings yet

- Knowledge in Autocad Plant3DDocument5 pagesKnowledge in Autocad Plant3DrajNo ratings yet

- JRA-CDA-PL-071-REV-0 - Welding, Cutting and Grinding AFT Loading DeflectorDocument4 pagesJRA-CDA-PL-071-REV-0 - Welding, Cutting and Grinding AFT Loading DeflectorMiller DutraNo ratings yet

- BSI Standards Publication: BS EN IEC 60974-1:2018+A1:2019Document20 pagesBSI Standards Publication: BS EN IEC 60974-1:2018+A1:2019Global QualityNo ratings yet

- MIGDocument7 pagesMIGMuhammad RedzuanNo ratings yet

- Ccsviiid1 2156Document2 pagesCcsviiid1 2156DieguitoOmarMoralesNo ratings yet

- 00 DM-350 Manual P10322-1Document72 pages00 DM-350 Manual P10322-1André Moura100% (1)

- Gemet 504Document1 pageGemet 504A K NairNo ratings yet

- Oerlikon - Pipe - Mills - Market - Segment - enDocument26 pagesOerlikon - Pipe - Mills - Market - Segment - entanveer ahmedNo ratings yet

- Rj2 User GuideDocument1,143 pagesRj2 User Guidegmlud100% (1)

- TransPocket 1500Document6 pagesTransPocket 1500vcotofanaNo ratings yet

- Thungsten ClassificationDocument3 pagesThungsten ClassificationBoyan RadomirovNo ratings yet

- Fiat Kobelco w230 Evolution Wheel Loader Service ManualDocument20 pagesFiat Kobelco w230 Evolution Wheel Loader Service Manualroberta100% (41)

- BgasDocument8 pagesBgassudhakar rajendranNo ratings yet