Professional Documents

Culture Documents

DP1 Jacket Main BE Report

Uploaded by

RAJESH GANESANCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DP1 Jacket Main BE Report

Uploaded by

RAJESH GANESANCopyright:

Available Formats

Doc. No.

: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Technical Document Number: Work Req. Ref.:

CB-93-RE-00-695589

Document Title

DP1 Jacket Main BE Report

Document Abstract:

The document gives a short description of the structure to be removed. Further it gives a detailed description of the work to be performed by the Contractor and the responsibilities the Contractor endorses through the contract. This document is to be read together with the Design Basis for removal.

Keywords:

Contractor Verification/Approval: Doc. established by: Doc. verification/approval: Distribution:

Company Name

Rev. No.

Date revised:

Sign.:

Summary Page Only:

Revision/Status Coding: Issued within Contractor Issued for Company Initial Approval Approved for Call for Tender

XXA XXB XXC

Approved for Onshore Construction Approved for Offshore Construction Approved Technical Document

XXD XXE XXG

Letter A, B etc., indicates document status. The number 00, 01 etc., indicates the number of issues the document has been through (consecutive numbering). Company Verification/Approval: Doc. establ./reviewed by (Company rep.): Document revised: Doc. verification (Company rep.): Doc. approval (Company rep.): Category: Name/Department/Division: Rev. No. Date revised: Sign.:

Marc LeFranc Rolf Erik Sanne Patrick Decosemaeker ge Engen Pedersen

01B 01G

31.10.2003 06.07.2004

Mark off by:

x x x

Operation Study Unclassified

Development Inspection Confidential

Project Test

Research Event

Company approval rep. Other

Type:

Classification:

Requested by:

Company Contributors (Name/Department/Division):

Date

Doc. No.: CB-93-RE-00-695589

General Part

TCP2 Topside

TP1 Topside

DP2 Topside

QP Topside

CDP1 Topside

TCP2 GBS

TP1 GBS

DP2 Jacket

QP Jacket

DP1 Jacket (wreck)

Pipelines

Debris

DP1 Jacket Main report Vol 1

Risk log

DP1 Jacket Drawings Vol 3

Frigg Field Cessation Basic Engineering

Doc. No.: CB-93-RE-00-695589

Table of Contents

1 2 3 4 Introduction ...................................................................................................5 Objectives .....................................................................................................5 Definitions .....................................................................................................6 Jacket Description.........................................................................................6

4.1 4.2 4.3 4.4 Main Data .................................................................................................................. 7 Appurtenances .......................................................................................................... 9 Special Areas .......................................................................................................... 11 Materials.................................................................................................................. 11 Information .............................................................................................................. 13 Introduction ............................................................................................................. 13 Main Hazard Findings ............................................................................................. 13 Objects State .......................................................................................................... 14 Provided Documentations ....................................................................................... 14 Interface .................................................................................................................. 14 General.................................................................................................................... 15 Operative Systems.................................................................................................. 16 Maintenance............................................................................................................ 16 Secure Loose Items ................................................................................................ 16 Transportation ......................................................................................................... 16 Sea Bed Restoration ............................................................................................... 17 Final Survey of Sea Bottom .................................................................................... 17 Disposal................................................................................................................... 17 Waste Treatment..................................................................................................... 17 Engineering ............................................................................................................. 17

5 6 7

Limitations ...................................................................................................12

5.1 6.1 6.2 7.1 7.2 7.3

Cessation Risk Log .....................................................................................13 Assumptions................................................................................................14

Work Description.........................................................................................15

8.1 8.2 8.3 8.4 8.5 8.6 8.7 8.8 8.9 8.10

References..................................................................................................19

Date: 06.07.2004

Revision 01G

Page 3 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Revisions

This document, rev 01G, has been revised since the issuance of the 01B revision. The main change is the new layout (header and footer). Some of the revisions are cosmetic or orthographical alterations with no impact on the technical content. Revisions worth noting are marked and found on the following pages/sections: Page 4 6 8 9 13 14 14 14 15 16 16 16 17 17 17 17 19 Section Revisions 3. Definitions 4.1.2 4.2 Appurtenances 6. Cessation risk log 6. 2 (old) Reporting 7.1 Objects state 7.3 Interface (topside) 8.2 (old) Verification 8.5 (old) Removal aids 8.6 (old) Temporary structures 8.9 (old )Decommissioning of systems 8. 6 Sea bed restoration 8.7 Final survey of sea bottom 8.8 Disposal 8.10 Engineering 9. References Revision Page added Two last lines deleted Reference to figure 2 has been omitted Launch runner frame added to text Entire section, including header, re-edited Subchapter deleted Heading and first sentence altered Last sentence rewritten This subchapter has been deleted This subchapter has been deleted This subchapter has been deleted This subchapter has been deleted Last sentence deleted First and last sentences deleted First two sentences deleted and replaced by new sentence First sentence rewritten Reference 7 updated to include 2004 inspections

Date: 06.07.2004

Revision 01G

Page 4 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Introduction

The Frigg Field is in the termination phase. Production will stop in 2004 and after cleaning the installations will be removed as given in the Frigg Field Cessation plan. A part of this operation is the removal and the disposal of the Jackets DP1, DP2 and QP. The document presents the activities the potential contractors have to perform in the frame of the removal operation of the DP1 structure. Further, more specific requirements and guidelines on analyses procedure and conditions for structures are given in the basis documents for the removal activities. Also the present document defines the objectives, the requirement for performance of the work, the limitation for the work and a description of the work to be performed.

Objectives

The objectives are to remove the QP jacket from the site, transport it to an inshore site and finally dismantle the structure. The removal will include the following: Preparation for removal Release from present secured condition Movement to a stable position for transport to shore Securing for transport to shore Transport from field to inshore Movement to stable position onshore Breaking and cutting up and disposal

The work shall be performed safely and in accordance with the relevant rules of national authorities. During the removal period the structure shall be maintained and repaired until removal takes place such that removal can be performed in a controlled and safe manner. The main objective is to perform the removal and disposal of the jackets with respect to the environment. The degree of reuse and recycling of the removed structure shall be optimized. It is, however, noted that the jacket structures will not be reused as such. Thus the structures may be subjected to permanent deformations during removal provided this will not lead to a functional or safety problem.

Date: 06.07.2004

Revision 01G

Page 5 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Definitions

includes all activities, required equipment necessary to fulfill the objectives DP1 jacket, appurtenances with all attachments including risers, J-tubes, caissons, boat landing, piles and pile cluster, anodes, etc and the relevant operative systems including navigation aids, safety equipment, NPD in Norway and Department of Energy in UK etc TOTAL E&P Norge AS and the Partners The corporation that is responsible for the execution of the contract and all the Subcontractors and vendors involved by the corporation in the execution of the contract. Independent institution responsible for the verification of Contractor method and calculation

Removal operation: Contract object: Authority: Company: Contractor: Third Part Verification:

Jacket Description

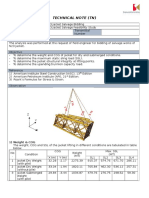

The DP1 platform which was launched in 1974, is located 800 m east southeast from TCP2. The main vertical rows are denoted as 1, 2, 3 and 4 where 2 and 3 are the launch frames; the longitudinal rows are named B and the east row A. The launch runners are located on row A. A general lay out drawing of the DP1 platform is shown in Figure 1. It is noted that the figure 1 is only indicative with regards to information given on drawing The jacket has been damaged during the launch operation. Due to collapse of the buoyancy tank the jacket has probably hit the sea bottom with the result of large damage at the lower part of the jacket. As a consequence of the mishap the installation of the jacket has never been completed (no pile) and the jacket has never been used. The water depth at the location is approximately 104 m.

Date: 06.07.2004

Revision 01G

Page 6 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Figure 4-1 General layout drawing of DP1 jacket

4.1

Main Data

The DP1 structure is an 8 legged jacket, launched installed. It should have been piled to the sea floor by 4 x 54 piles at the each corners and 4 insert piles ( 48) in the mid legs of Row 2 and Row 3. The jacket was built to support: 24 conductors, 2 production risers ( 26) One 8 5/8 kill line

Revision 01G Page 7 of 19

Date: 06.07.2004

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

One 4 condensate water riser One 8 5/8 electrical riser

The steel weight of jacket without pile is estimated to 6 480 tonnes.

4.1.1 Geometry

The dimensions of the jacket itself are given below. Top dimensions: 48.08 m by 25.10 m Dimensions at sea bed: 61.63 m by 43.28 mm at elevation 99.212 m Horizontal levels are located at elevations: 6.572 m, -11.861 m, -29.291 m, -50.606 m, -71.788 m and 97.993 m. The two launch frames are distant from each other with 18.288 m. Layout of the horizontal levels The conductor frames are located at the south end of the horizontal levels. The conductors are in two clusters of 12; 4 rows in south-north direction distant with 2005 mm and 3 rows in west-east direction distant with 2515 mm. A distance of 8000 mm segregates the two clusters. The square formed by the four mid legs is stiffened by a diamond brace system. At the corners 2 buoyancy tanks were installed for the launch operation (2 tanks with diameter 2540 mm). All risers are located along the mid legs. The North part of the horizontal levels is stiffened with a K bracing system. Steel layout for the longitudinal frames Simple diagonal braces stiffen the jacket. The dimensions of the braces vary from 1.575 m to 1.067 m and the wall thickness from 58 to 15 mm. The corner leg diameter varies from 3.048 m to 1.575 m while the thicknesses vary from 60 to 15.9 mm. Note that the leg nodes are heavily stiffened. The diameter of the launch legs is mainly 1.32 m while the thickness varies from 70 mm at the nodes to 25.4 mm. The launch legs in Row 2 and Row 3 (phase A) are fitted with launch running equipment. Steel layout for the transversal frames The transverse frames have an X bracing system. The diameter of the tubular braces varies from 1.219 m to 0.914 m while the thicknesses vary from 44.5 mm to 25.4 mm for the outside frames. At the launch frames the tubular braces have a diameter of 914 mm.

4.1.2 Foundation

No piles are installed. The soil conditions are shortly described in Table 4-1. A more comprehensive description of the upper layer is presented in NGI report Top Soil Conditions at Locations DP1, DP2 and QP (Ref 3).

Date: 06.07.2004

Revision 01G

Page 8 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Table 4-1 Soil conditions

Depth from mudline 0m7m 7 m 17 m 17m 41 m 41 m 47 m 47 m 77 m 77 m 120,5m

Soil Fine to medium sand, shell fragments Silty fine to medium sand, shell fragments silt and clay Very stiff to hard clay Silty fine sand, silt pockets Interbedded silty sand, sand silt and clayey silt Fine to medium sand

The jacket is supported by the lower frame. At the present time this frame is partly embedded into the soil. The penetration is to be determined.

4.2

Appurtenances

The jacket has been installed with several appurtenances: risers, J-tubes, caissons, instrumentations, anodes, bumpers, boat landing, walkways, ladders and stairs, guides for pile installation and buoyancy tanks and a launch runner frame. Most part of those appurtenances has been removed. The purpose of this section is to give an overall idea of the kind and the quantities of the different items. For more details and exact number the design drawings, as-build and inspection drawings have to be used.

4.2.1 Risers and J-tubes

Along the launch leg B2 the following risers are run: 8 kill line 26 production 26 production 4 condensate 8 electrical

Along launch leg B3 the following risers are run:

4.2.2 Caissons

No caissons

4.2.3 Anodes

The jacket is protected against corrosion by sacrificial anodes. The major part of the anodes is of stand of type. The total weight of the anodes at installation time was: 332 tonnes.

Date: 06.07.2004

Revision 01G

Page 9 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

4.2.4 Bumpers, Fenders and Boat landing

None

4.2.5 Walkways, Stairs and Ladders

The walkways installed on the jacket have been removed or has been destroyed by the wave action. At the present time only a small platform and access ladder for the navigation light remains.

4.2.6 Guides

At each horizontal elevation on the corner legs guides for installation of main piles are located. On the inside of the launch leg, 2 guides for the buoyancy tanks are supported. Only at-site inspection will verify if these guides are intact.

4.2.7 Instrumentation

None

4.2.8 Grout Lines and Inflation Lines

The lines for the air and the grout have been run for the pile cluster inside the leg, however for the launch leg they were located outside the leg. Packers are located at both ends of the piles sleeves

4.2.9 Valves

In connection with the upending operation the corner legs have been flooded. Valves and diaphragms are also installed on the legs.

4.2.10 Launch Runner

The launch runners are fixed on the two central legs on the east row of the jacket (legs A2 and A3). The present condition of the wooden part of the launch runner is not known.

Date: 06.07.2004

Revision 01G

Page 10 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

4.3

Special Areas

The data given in the above sections are based on the design drawings. The DP1 jacket has not been installed and secured as planed. After the mishap the jacket has been set down vertically on the seabed. No further action has been taken to stabilize the structure since this date. Due to the wave action the jacket has slightly moved out the vertical and some part of the lower frame has been buried into the sand at the seabed. Further some part of the structure has been damaged. The extent of those should be determinate based on a careful inspection of the structure. Note that the structure is covered with marine growth from seabed to the splash zone, this make the inspection difficult. Based on the inspection performed in the last year the following may be reported. 1. No conductor frames at the two upper levels. The upper one as probably never been installed, the second one has fallen down to the seabed. 2. The two lower levels are heavily damaged: several members are disconnected from the structure, some other damaged. 3. Lower part of the leg B2 is collapsed and has fallen to the seabed. 4. Lower part of leg B3 as collapsed. 5. One riser has been disconnected from the structure. 6. The jacket is somewhat tilted in longitudinal direction against the side without conductor-guides.

4.4

Materials

The jacket consists mainly of steel. Some components in the jacket are of other materials: Anodes: aluminum (Zn: 3.250.3%; Mg: 1.80.2%; In: 0.020.08%; Sn: 0.0070.003%) or zinc for reference anodes. Launch runners: wood.

The specifications for steel material used in the jacket are listed in the table below

Table 4-2 Steel materials used on DP1

Designation High Strength Steel HS 10

Steel Grade Acc. DIN 17 100 St 52-3N

Additional requirement Al-killed, max 0,07 Altot max 1,60 MN max 0,35 Si Max 0,035 P & S CE max < 0,46 CV transvers: Min average 41 J Min single 34 J At -10C

Typical Application Jacket braces and piles below El. 3m

High Strength Steel HS 20

Date: 06.07.2004

St 52-3N

As for HS 10 but CV at -20C

Revision 01G

Jacket braces and piles above el. 3m

Page 11 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Table 4-1 contd.

Designation Special High Strength steel SHS 10

Steel Grade Acc. DIN 17 100 St 52-3N

Additional requirement max 0,03 Altot max 1,60 Mn max 0,55 Si Max 0,020 P Max 0.015 S CE max < 0,46 CV transverse: Min average 41 J Min single 34 J At -10C

Typical Application Can section and overlapped heavy wall stubs below 3m

Special High Strength steel SHS 20 ML 0 ML 20

St 52-3N

As for SHS 10 but CV at 20C

Can section and overlapped heavy wall stubs above3m Conductor frames below 3m Conductor frame above 3m

St 37-3U St 37-3N

For the non-structural materials the steel quality is: For plates: DIN 17100/St 37-3U, ASTM A 285 Gr. C or ASTM A 36. For tubular: DIN 1629/BL.3 . St 35, API 5L Gr. B or ASTM A 53 Type E or S, grade B.

Limitations

The limiting boundaries of the jacket that shall be removed are: Top of jacket: No topside structure has been located at the top of jacket and no interface point exists Bottom of the jacket: No piles are installed but the jacket legs and the lower horizontal level has penetrated into the sea bed. Connections to sea lines (Risers, J-tubes and cables): No connections to sea lines are established for the jacket. All relevant HSE aspects must be considered during the removal work. A safe zone is defined as 500 m from the jacket that shall be removed.

Date: 06.07.2004

Revision 01G

Page 12 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

5.1

Information

The removal of the jacket will be regarded as finalized when: All objects / items are removed from the sea bottom All parts of the object has been disposed The sea bottom has been restored to its original configuration Any remaining structures are located at least 1 000 mm below the restored sea bottom. This shall be confirmed by a site survey taking place 3 years after the sea bottom restoring operation.

6

6.1

Cessation Risk Log

Introduction

Management of safety shall be an integral part of the cessation activity. As part of the Safety Management, an interim Risk Log has been developed. The Risk Log documents the hazards related to removal activities. All hazards that have been identified during Basic Engineering of the Frigg Field Cessation project are listed in the risk log. The Risk Log is a database file including all the platforms on the Frigg Field. Hazid sessions and a Risk Log Input/Update Form were used as tools to identify the hazards in a systematic manner. The Thesis software was chosen as the tool for supporting the systematic process to identify and evaluate any hazards and barriers. The Risk Log has been recorded into a Thesis database. Further Risk Log requirements and detailed information are found in the following documents: Risk Log, General Introduction. Risk Log, Thesis data for the Frigg Field.

The interim Risk Log will be made available to the contractor. The Contractor may adopt and update this interim Risk Log. The Contractor shall provide a Risk Log appropriate for his planned activities. The Risk Log shall be maintained within the Thesis Software, and the Contractor will be required to obtain a licence for own use and at own cost.

6.2

Main Hazard Findings

The hazards in the interim Risk Log that have been identified in Basic Engineering for DP2 are found in the Risk Log. A large number of the identified hazards are presented as Construction Industry General Hazards, some as Frigg Cessation special hazards and some (if identified) are presented as the specific platform/jacket special removal hazards.

Date: 06.07.2004 Revision 01G Page 13 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

(old 6.2 Reporting deleted)

7

7.1

Assumptions

Objects State

The DP1 platform is standing alone and do not support any topside. However, a navigation aids system will be still operating on the platform.

7.2

Provided Documentations

The contract objects structural status is described in the documents summarized in Table 7-1 below. More specific references are given in reference section.

Table 7-1 Structural status

Drawings: Design Documentation: Inspection reports: Inspection program Weight Summary: Soil Condition: Platforms and Lines General Layout Overall Removal Activities Description

Design drawings In place analysis (Ref 2), Installation Report Damaged member record, flooded member (Ref 7) Company schedule for jacket inspection for the remaining life time Weight estimate of the structure (Ref2) (indicative) General mapping of the top soil condition at the location DP1, DP2 and QP to 20 m below sea bed (Ref 3) Give the relative position of the platforms and the location of the pipelines. explains the total operation done at the Frigg field wherein the Removal is a part (Ref 1)

7.3

Interface

Since DP1 has not been used as a jacket, it has no interfaces towards topside or pipelines. The only interface will also be related to the operation as such. The work has to be coordinated with all other ongoing operations in the Frigg area.

Date: 06.07.2004

Revision 01G

Page 14 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Work Description

This section presents the activities that will be part of the removal. This list is not to be considerate as complete since it will be strongly depend on the method of execution of the work.

8.1

General

The main operations in the removal contract are defined in section 2. The release of the contract object from the sea floor is considered as one of the more complicated operation of the removal. During the operation the released object has to be stable. Also the structure must be able to sustain a given sea state without collapse after it has been disconnected from the sea floor or the rest of the jacket. A second concern is the presence of residual stresses and restrain in the structure. Those stresses may be the origin of accident under the cutting of members if no precaution is taken. This aspect is very important in the case of DP1 due to the particular history of this structure. The DP1 structure has not been correctly installed. The forces that have acted on the structure have not been the one expected during the design. The structural condition of the structure is therefore unknown and only careful inspection may give some indications. Some parts of the structure are damaged and are disconnected from the rest of the jacket. Further the method used has to take into account the load-in operation. The released object could be equipped as a self-floater, on a barge or on a vessel suitable to reach a harbor. The jacket is now resting almost vertically on the sea floor. The lower part is also embedded in the sand for a height of about 2 m. This explains partly the fact that the structure is now almost stable and has resisted the wave action. This implies that the soil has to be removed. But by doing so the stability of the jacket may be questioned, and shall be very carefully documented. Further it may be expected that the load on the members in the area around the mudline have been loaded in an unusual way, their strength should be also assessed. The method of removal has to address specifically those aspects. The weight of the jacket is also determining the choice of removal method. The steel weight can be determined very accurately by a careful weight take off based on the design drawing and the local inspection of the structure. In addition the weight of the appurtenances such as risers, J-tubes, caissons and airlines, vent lines and valves may be calculated in the same way. Water entrapped in the structure may be evaluated based on the inside volume of the legs and the results of a Flooded member Inspection. The last item to be estimated is he weight of the marine growth. Estimation of it may only be done by inspection of the whole structure. (Old 8.2 Verification of the correctness of the information deleted)

Date: 06.07.2004

Revision 01G

Page 15 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

8.2

Operative Systems

All systems required for the removal work shall be defined. The involved systems include but are not limited to: Navigation aids Power generation for the living quarter on QP Any shuttling system from QP to the work site

8.3

Maintenance

The removal period may be considerable. Within this period the jacket may need to be inspected. The inspection shall ensure that the strength of the structure is compatible with the adopted removal method. No lifetime studies (fatigue calculations) have been performed for the jacket after installation in 1976.

(Old 8.5 Removal Aids deleted). (Old 8.6 Temporary Structures deleted)

8.4

Secure Loose Items

Before any operation all items susceptible to fall or cause some injury during the removal operation shall be secured or removed. This implies a critical evaluation of all items attached to the removed object. The effort applied (wind, wave action, inertia load, etc) to all items during the removal operation shall also be determinate and the consequence evaluated. It is noted that a lot of structural debris is located around and also inside the DP1 structure. This has been verified through ROV inspections performed for the structure (Ref 7).

8.5

Transportation

The transport operation includes the seafastening of the object on the transportation vessel, the transportation itself, the cutting of the seafastening and the load-in of the object on the inshore site.

(Old 8.9 Decommissioning of System deleted)

Date: 06.07.2004

Revision 01G

Page 16 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

8.6

Sea Bed Restoration

In general no steel or remains of the contract object shall be found in the 1 000 mm upper layer of the soil.

8.7

Final Survey of Sea Bottom

A final survey of the area will be performed at the location of the removed object and at the location of the operating vessel(s).

8.8

Disposal

Onshore disposal of the DP1 jacket must be performed in accordance with relevant rules and regulations. Record of destination of all items shall be kept. This record shall be monthly communicated to Company in a format compatible to the Company own reporting system TEAMS (Ref 4).

8.9

Waste Treatment

Some of the material removed from the contract object will not be recycled. That is for example epoxy material used for tightening, grout, and rubber. Those materials shall be properly handled according to the Company requirements. All materials and quantities shall be recorded as well as the final disposal site. All information shall be transmitted to Company. Record of destination of all items shall be kept. This record shall be monthly communicated to Company in a format compatible to the Company own reporting system TEAMS.

8.10 Engineering

All activities necessary for the execution of the Work will be covered by engineering and include as a minimum: Contractor own vessels/lift equipment The contract object Temporary structures Maintenance systems Removal aids equipment

Revision 01G Page 17 of 19

Date: 06.07.2004

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

Seafastening and grillage Operation to be performed such as: lift, load-in, set-down for all relevant objects, etc.

The engineering activities shall be done in accordance to the principle given in the Design Basis for Jacket Removal. The engineering shall include all aspects: Instrumental / electrical for the system Marine Structural

Date: 06.07.2004

Revision 01G

Page 18 of 19

Doc. No.: CB-93-RE-00-695589

Frigg Field Cessaition BASIC ENGINEERING DP1 Jacket, Main BE Report

9

1 2 3 4 5 6 7

References

Frigg Field Cessation Plan, May 2003. DocsOpen no 677963. DP1 Jacket In place analysis, DocsOpen no 682398. Top Soil Conditions at Locations DP1, DP2 and QP; DocsOpen no 640888 TotalEnvironment Accounting and Management System, TEAMS. Risk Log, ref. CB-00-RE-07-635923 Risk Log database, ref. CB-00-RE-07-635924 Frigg DP1 Inspection Finding Report (subsea including 2004), DocsOpen no 695264

Date: 06.07.2004

Revision 01G

Page 19 of 19

You might also like

- PLEM Pile Drivability PDFDocument49 pagesPLEM Pile Drivability PDFTharach JanesuapasaereeNo ratings yet

- Berthing Load Test On Wharf - r3Document15 pagesBerthing Load Test On Wharf - r3surya ilhamNo ratings yet

- Great Waters - Business Track Record 2012-16Document16 pagesGreat Waters - Business Track Record 2012-16KK NairNo ratings yet

- Swamp DredgingDocument19 pagesSwamp Dredgingmaniacs14No ratings yet

- Appendix e (Sacs Output)Document6 pagesAppendix e (Sacs Output)Tran Van DaiNo ratings yet

- Analysis of offshore jacket platform responsesDocument8 pagesAnalysis of offshore jacket platform responsesrobert.johns1028No ratings yet

- Light Assessment Readings GMPDocument2 pagesLight Assessment Readings GMPloveson glariyansNo ratings yet

- LIMA-Z-PLA-1026 - Rev1 Personnel Transfer With Barge CraneDocument20 pagesLIMA-Z-PLA-1026 - Rev1 Personnel Transfer With Barge CraneCahya Adi YeftaNo ratings yet

- 01 March SHO Monthly Report PDFDocument6 pages01 March SHO Monthly Report PDFBuwanah Selvaaraj0% (1)

- 125 LayingDocument5 pages125 LayingmondelNo ratings yet

- HSE PLAN Generic RAaaaaaaaaaaDocument7 pagesHSE PLAN Generic RAaaaaaaaaaaテレブリコ ジェファーソンNo ratings yet

- Sample: Job Safety AnalysisDocument7 pagesSample: Job Safety AnalysisHesanRajaraniNo ratings yet

- TBDP-A-S-RPT-1020 - Substructure Inplace AnalysisDocument45 pagesTBDP-A-S-RPT-1020 - Substructure Inplace AnalysisViktor DươngNo ratings yet

- Dewatering Method Statement for Abu Dhabi International Airport ExpansionDocument6 pagesDewatering Method Statement for Abu Dhabi International Airport ExpansionDomie Neil Bucag SalasNo ratings yet

- Stability of Breakwater ReefsDocument16 pagesStability of Breakwater ReefsKandousi YassineNo ratings yet

- Wind Turbine Foundation Design StepsDocument9 pagesWind Turbine Foundation Design StepsRamachandran Sundararaman100% (1)

- OMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillDocument8 pagesOMAE2012-83522: Pipeline Stabilisation Using Pre-Trenching and Sand BackfillLucas FladinirNo ratings yet

- Back Filing JsaDocument10 pagesBack Filing Jsashahazam4uNo ratings yet

- Design Submission Programme - RevisedDocument8 pagesDesign Submission Programme - RevisedUmesgNo ratings yet

- Ae W-PQ 9601.1 en 4.0Document60 pagesAe W-PQ 9601.1 en 4.0Farrukh Javed100% (1)

- Front End Engineering Design (FEED) for Gas Lift Compression Project Pipeline DesignDocument14 pagesFront End Engineering Design (FEED) for Gas Lift Compression Project Pipeline Designsutomo rochmandaNo ratings yet

- Analyzing Static and Dynamic Lifting Process of Topside PlatformDocument63 pagesAnalyzing Static and Dynamic Lifting Process of Topside Platformpriyanka pertiwiNo ratings yet

- Task Specific PlanDocument2 pagesTask Specific PlanNathaniel BudikeyNo ratings yet

- List of Referenced Codes and StandardsDocument1 pageList of Referenced Codes and StandardsHaridevNo ratings yet

- Employee Competency Profile for Rigger/ScaffolderDocument13 pagesEmployee Competency Profile for Rigger/ScaffolderAnggit PermataNo ratings yet

- JO HSE 014 JSA (Greenfield) FormDocument5 pagesJO HSE 014 JSA (Greenfield) FormPT. ANUGRAH MIRAN MANDIRINo ratings yet

- Civil Structural Engineer - Onshore Offshore - v2Document3 pagesCivil Structural Engineer - Onshore Offshore - v2leodegarioporral100% (1)

- DANA-Technical Note (TN)Document8 pagesDANA-Technical Note (TN)Samsul Imran BahromNo ratings yet

- TOW Criteria - Singapore To Bombay High, Offshore West India - Departure - DecDocument2 pagesTOW Criteria - Singapore To Bombay High, Offshore West India - Departure - Decksangeeth2000No ratings yet

- Application assessment process for IMarEST Membership and Professional RegistrationDocument2 pagesApplication assessment process for IMarEST Membership and Professional RegistrationjeffreymacaseroNo ratings yet

- Pile Driving MethodDocument26 pagesPile Driving MethodTrinco JettyNo ratings yet

- Folsom Dam Modification Project - Approach ChannelDocument872 pagesFolsom Dam Modification Project - Approach ChannelFickleNo ratings yet

- Pedestal FootingDocument2 pagesPedestal FootingMarisela BurkeNo ratings yet

- CD CM Overrides For Report Conductor Shielding FactorDocument2 pagesCD CM Overrides For Report Conductor Shielding FactorRamesh SelvarajNo ratings yet

- CYD Comment On MSP-T-AK-CII-004 SHES Plan and HSE Control Procedure PDFDocument101 pagesCYD Comment On MSP-T-AK-CII-004 SHES Plan and HSE Control Procedure PDFFaizal FergusanNo ratings yet

- Jms Crane Lifting RGTP p20220019 Esb Con Jms 9243 0013 - A Code 2Document39 pagesJms Crane Lifting RGTP p20220019 Esb Con Jms 9243 0013 - A Code 2amir hakimNo ratings yet

- SACS Software Offshore Structures Design Rev1Document2 pagesSACS Software Offshore Structures Design Rev1Boonme ChinnaboonNo ratings yet

- Engineering data sheet anchorDocument2 pagesEngineering data sheet anchorRomawi Stevyandi100% (1)

- GoM Offshore Structures Design CriteriaDocument32 pagesGoM Offshore Structures Design CriteriaDonald.KNo ratings yet

- EMERGENCY RESPONSE MANUALDocument33 pagesEMERGENCY RESPONSE MANUALAnonymous i3lI9MNo ratings yet

- 00 UJ - C 51 121 002 (Rev.X3)Document230 pages00 UJ - C 51 121 002 (Rev.X3)Amr AbdeinNo ratings yet

- Lifting Analysis Report - Mahadi KurniawanDocument31 pagesLifting Analysis Report - Mahadi KurniawanDian SasNo ratings yet

- Skew Load Lift AnalysisDocument3 pagesSkew Load Lift AnalysisBolarinwadeNo ratings yet

- 21008-BAE-79100-NA-RP-0009 - Rev02 Gas and Crude Oil Riser Platform Design ReportDocument55 pages21008-BAE-79100-NA-RP-0009 - Rev02 Gas and Crude Oil Riser Platform Design ReportAnonymousNo ratings yet

- MRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestDocument1 pageMRL-HRM-IMSF-03.01C (01) Training Seminar Conference RequestFateh AliyaNo ratings yet

- DAILY INSPECTION CHECKLIST FOR MOBILE ELEVATING WORK PLATFORMSDocument6 pagesDAILY INSPECTION CHECKLIST FOR MOBILE ELEVATING WORK PLATFORMSJeremia SamosirNo ratings yet

- R1339 Rev.0 Metocean Study ReportDocument452 pagesR1339 Rev.0 Metocean Study ReportElias EliasNo ratings yet

- Pipeline Routing StudiesDocument11 pagesPipeline Routing StudiesGodwinNo ratings yet

- Case Study 2101 Jack Up Unit Helideck Strength Verification1Document1 pageCase Study 2101 Jack Up Unit Helideck Strength Verification1Moe LattNo ratings yet

- 012 Piling WorkDocument17 pages012 Piling WorkSarah HaiderNo ratings yet

- Ssec Profile 2010Document47 pagesSsec Profile 2010Syaiful AzliNo ratings yet

- Chapter 5 Rock Slope StabilizationDocument24 pagesChapter 5 Rock Slope StabilizationcannonlicaNo ratings yet

- Buzzard Field Development Structural Computer ModelDocument63 pagesBuzzard Field Development Structural Computer ModelneelcorNo ratings yet

- Offshore Pipeline Landfall PDFDocument112 pagesOffshore Pipeline Landfall PDFangga fajarNo ratings yet

- Subsee Suction Pile Installation AnalysisDocument11 pagesSubsee Suction Pile Installation AnalysisKen KennyNo ratings yet

- 1.3minute Meeting For Qms ReviewDocument1 page1.3minute Meeting For Qms ReviewStephen David GozunNo ratings yet

- Execution Plan For Shutdown Repair of Tanks 9C & 10CDocument14 pagesExecution Plan For Shutdown Repair of Tanks 9C & 10CEzette KennedyNo ratings yet

- Method Statement: 1. Project Details Ref: Revision: Contractor: Date: Site: Tasks: Prepared By: Signed: 2. GuidanceDocument19 pagesMethod Statement: 1. Project Details Ref: Revision: Contractor: Date: Site: Tasks: Prepared By: Signed: 2. GuidanceDaniel SarmientoNo ratings yet

- Construction Security Plan SampleDocument21 pagesConstruction Security Plan SampleKumar100% (15)

- Specifications of Concrete WorksDocument45 pagesSpecifications of Concrete Worksnicoleta_cristian4798No ratings yet

- Best English WordsDocument40 pagesBest English WordsRAJESH GANESANNo ratings yet

- SCHEENNNGGGG!!!Document42 pagesSCHEENNNGGGG!!!RAJESH GANESANNo ratings yet

- DerivativeMid Monthreport 19april2017Document11 pagesDerivativeMid Monthreport 19april2017RAJESH GANESANNo ratings yet

- A Single Economic Space-From Lisbon To VladivostokDocument28 pagesA Single Economic Space-From Lisbon To VladivostokRAJESH GANESANNo ratings yet

- 01 Adi Parva PDFDocument501 pages01 Adi Parva PDFRAJESH GANESANNo ratings yet

- Armenia and EEU - The View From YerevanDocument2 pagesArmenia and EEU - The View From YerevanRAJESH GANESANNo ratings yet

- The EU in Eastern Europe PDFDocument5 pagesThe EU in Eastern Europe PDFRAJESH GANESANNo ratings yet

- A Single Economic SpaceDocument4 pagesA Single Economic SpaceRAJESH GANESANNo ratings yet

- China's Silk Road StrategyDocument1 pageChina's Silk Road StrategyRAJESH GANESANNo ratings yet

- Balkans and Russian Foreign Cultural Policy - Prof Elena EltcDocument4 pagesBalkans and Russian Foreign Cultural Policy - Prof Elena EltcRAJESH GANESANNo ratings yet

- Brushless vs Brushed Motors: A 38-Character GuideDocument2 pagesBrushless vs Brushed Motors: A 38-Character GuideRAJESH GANESANNo ratings yet

- Agathiyar 2000 Part-1Document164 pagesAgathiyar 2000 Part-1Suresh ChintuNo ratings yet

- SOPDocument3 pagesSOPRAJESH GANESAN0% (1)

- Lessons India Can Learn From China - The Economic TimesDocument6 pagesLessons India Can Learn From China - The Economic TimesRAJESH GANESANNo ratings yet

- Ocr GCSE Vocab List German Print 14 To EndDocument52 pagesOcr GCSE Vocab List German Print 14 To Endwilliamack3611100% (1)

- Katrine PHD ThesisDocument207 pagesKatrine PHD ThesiszewhiteNo ratings yet

- Five Common Legal Errors of Start-Ups - The Economic TimesDocument3 pagesFive Common Legal Errors of Start-Ups - The Economic TimesRAJESH GANESANNo ratings yet

- Machinery Systems Inside A ShipDocument65 pagesMachinery Systems Inside A ShipviahulNo ratings yet

- Learning Maxsurf: ManualDocument169 pagesLearning Maxsurf: ManualRAJESH GANESANNo ratings yet

- Final Tamil ManualDocument23 pagesFinal Tamil Manualssunny_y2k100% (1)

- PrimaveraDocument5 pagesPrimaveraRAJESH GANESANNo ratings yet

- Doing Business in Russia 2012Document46 pagesDoing Business in Russia 2012RAJESH GANESANNo ratings yet

- Russian Military Reform (2013)Document33 pagesRussian Military Reform (2013)RAJESH GANESANNo ratings yet

- Lauinching Evaluation by Numerical Simulations: Stefan Krueger, TU Hamburg-Harburg, GermanyDocument9 pagesLauinching Evaluation by Numerical Simulations: Stefan Krueger, TU Hamburg-Harburg, GermanyRAJESH GANESANNo ratings yet

- Blau BoatDocument39 pagesBlau BoatRAJESH GANESANNo ratings yet

- Numerical Modeling of Launching Offshore JacketsDocument13 pagesNumerical Modeling of Launching Offshore JacketsRAJESH GANESANNo ratings yet

- ENERPO BrochureDocument20 pagesENERPO BrochureRAJESH GANESANNo ratings yet

- RR - UnrepDocument2 pagesRR - UnrepRAJESH GANESANNo ratings yet

- Off Struc ProbsDocument17 pagesOff Struc ProbsRAJESH GANESANNo ratings yet

- Chapter 6: Reliability Data Analysis: Complexity of The System Its EnvironmentDocument8 pagesChapter 6: Reliability Data Analysis: Complexity of The System Its EnvironmentendalkachewNo ratings yet

- Mod. 01 - Standard Specifications For Construction Works 2019Document20 pagesMod. 01 - Standard Specifications For Construction Works 2019Mahdi ARasoolNo ratings yet

- Finance Minor ProjectDocument2 pagesFinance Minor ProjectRaghav ChandakNo ratings yet

- Thomas Plummer-Living Your DreamDocument274 pagesThomas Plummer-Living Your Dreammehr6544100% (1)

- OHSAS 18001 2007 IntroductionDocument6 pagesOHSAS 18001 2007 IntroductionirfanahmarNo ratings yet

- Creative Writing1 Elements and Kinds of GenreDocument3 pagesCreative Writing1 Elements and Kinds of GenreKevin Dela CalzadaNo ratings yet

- Corporate CultureDocument25 pagesCorporate CultureZayiNo ratings yet

- PSAK 23, RevenueDocument15 pagesPSAK 23, Revenueapi-370878350% (2)

- Analyze Covid-19 Risk Using Arcgis ProDocument21 pagesAnalyze Covid-19 Risk Using Arcgis ProEl inocenteNo ratings yet

- Entrepreneurship SA1 (Question & Answer)Document12 pagesEntrepreneurship SA1 (Question & Answer)lovellmenezes100% (1)

- Natural Hazards and Disasters Earth Science Presentation in Colorful Line-Drawing StyleDocument37 pagesNatural Hazards and Disasters Earth Science Presentation in Colorful Line-Drawing StyleRenalyn VenzonNo ratings yet

- ACT1110 Fundamental Concepts of Risk ManagementDocument42 pagesACT1110 Fundamental Concepts of Risk ManagementHaidee Flavier SabidoNo ratings yet

- Ce MarkingDocument148 pagesCe MarkinghenhuangNo ratings yet

- Axioma World-Wide Equity Factor Risk Model UpdateDocument34 pagesAxioma World-Wide Equity Factor Risk Model UpdateorienteNo ratings yet

- Autocallable Contingent Income Barrier Notes: HSBC Usa Inc. $2,920,000Document19 pagesAutocallable Contingent Income Barrier Notes: HSBC Usa Inc. $2,920,000caslusNo ratings yet

- Police Officer SuicideDocument14 pagesPolice Officer SuicideLjubitelj SamNo ratings yet

- Ulrich Borgren Gardiner Lundin 2018Document15 pagesUlrich Borgren Gardiner Lundin 2018Amy VegaNo ratings yet

- Managerial Decision-Making TechniquesDocument18 pagesManagerial Decision-Making TechniquesNur Liza HazlinNo ratings yet

- (David L. Goetsch Stanley Davis) Introduction ToDocument196 pages(David L. Goetsch Stanley Davis) Introduction ToThyya Chemmuet100% (1)

- Work at Heights PermitDocument4 pagesWork at Heights Permitrashid zamanNo ratings yet

- Ma8025 Battery Eu enDocument42 pagesMa8025 Battery Eu enCLAUDIONo ratings yet

- Classic Cases: An Introduction To Information Systems in Organizations Coors Ceramics Revamps Information SystemsDocument12 pagesClassic Cases: An Introduction To Information Systems in Organizations Coors Ceramics Revamps Information SystemsRanoo MahajanNo ratings yet

- PgMP+Process+Group+ +ITTO 2Document11 pagesPgMP+Process+Group+ +ITTO 2Adeel Khan Leghari0% (1)

- NCPDocument17 pagesNCPShayne Jessemae AlmarioNo ratings yet

- Studying For The Cism Exam3Document6 pagesStudying For The Cism Exam3book checkerNo ratings yet

- CDP+ Version 10 (Guide)Document124 pagesCDP+ Version 10 (Guide)Pew IcamenNo ratings yet

- Financing Mining Projects PDFDocument7 pagesFinancing Mining Projects PDFEmil AzhibayevNo ratings yet

- EFS Presentation - ProfileDocument24 pagesEFS Presentation - ProfileHMNo ratings yet

- PDF ContentDocument212 pagesPDF ContentValentina TrujilloNo ratings yet

- FM 3Document13 pagesFM 3ganeshraokhande99No ratings yet