Professional Documents

Culture Documents

P91 Guidelines

Uploaded by

hboodhaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P91 Guidelines

Uploaded by

hboodhaiCopyright:

Available Formats

Guideline Procurement Specification (Reference AWS/ASME A/SFA 5.

01)

I. General

Suggested Procurement Detail Form per referenced document A. Quantity (lbs) B. AWS Specification C. AWS Classification D. Supplemental Designators E. Diameter F. Length G. Unit Package Type and Weight 1. Carton 2. Can 3. Other II. Certification and Testing A. Lot Classification B. Level of Testing III. Other Requirements A. Impring / Marking B. Stamping or Tagging C. Report Tensile/Yield Strength D. PWHT: 7600C, 2 hrs. min. E. Report Toughness @ Temp. Hydrotesting at 40oF to 72oF Hydrotesting at 72oF F. X-Factor (Bruscato No.) Note c G. Mn + Ni Content H. Mn/S Ratio I. CMTRs or 3.1B Required Notes: a.

Note d

See Table A2 To be noted A5.28 ER90S-B9 N/A To be noted To be noted

See Table A1 To be noted A5.5 E9015-B9 H4 To be noted To be noted To be noted To be noted

See Table A4 To be noted A5.23 EB9 N/A To be noted N/A

See Table A3 To be noted A5.29 E91T1-G {pending}

Note a

H4 or H8 Note b 0.045 N/A

To be noted

To be noted

To be noted

S1 H

C1 K

C1 H

T1 K

Heat No. & Classification Stamp Yes Yes 20 ft-lb min. at 40oF N/A < 15 <1.3% <50 Yes

Lot No. & Classification Stamp Yes Yes 20 ft-lb min. at 40oF N/A < 15 <1.3% <50 Yes

Label w/Heat No. & Classification Label N/A N/A 20 ft-lb min. at 40oF N/A < 15 <1.3% <50 Yes

Label w/Lot No. & Classification Label Yes Yes 20 ft-lb min. at 40oF 20 ft-lb min. at 70oF < 25 <1.3% <50 Yes

b.

c. d.

Where (-G) designation is used in the classification, chemical composition of the filler metal shall be as agreed to by purchaser and supplier. In this example, it is as follows: (Some Users Request: Meets the mechanical requirements of E9015-B 9, instead of using the -G designator). C 0.07-0.13% Cr 8.00-9.50% Ti <0.004% Cu <0.20% Mn 1.25% max. Ni 1.00% max. As <80ppm N2 0.03-0.07% Si* 0.20-0.50% Mo 0.80-1.10% Sb <30ppm Other <0.50% Total S* <0.010% Nb 0.02-0.10% Sn <30ppm P* <0.010% V 0.15-0.25% Al <0.04% *FCAW: Si = 0.50% max., S = 0.015% max., P = 0.020% max. See the applicable Welding Procedure Specification (WPS) or contact the applicable Corporate Welding Engineer in Construction Technology for the approved manufacturers and brand names of FCAW filler metals. Either H4 or H8 Diffusible Hydrogen Designator is acceptable; however, H4 is preferred. The Optional Diffusible Hydrogen Designator indicates that the diffusible hydrogen in the deposited weld did not exceed either 4.0 mL/100g (H4) or 8.0 mL/100g (H8) when tested in accordance with AWS A4.3 and A5.5 specifications. X-Factor (Bruscato Number) can be calculated using the following formula: where, X = (10P+5Sb+4Sn+As)/100, elements may be expressed in either % or ppm. Welding filler metal shall be purchased with CMTR (Certified Material Test Reports), for domestic manufactures or EN10204 3.1b for European manufacturers.

You might also like

- Solar Energy Basics - AssignmentDocument12 pagesSolar Energy Basics - AssignmenthboodhaiNo ratings yet

- Indications in Metallic MaterialsDocument32 pagesIndications in Metallic MaterialshboodhaiNo ratings yet

- Indications in Metallic MaterialsDocument32 pagesIndications in Metallic MaterialshboodhaiNo ratings yet

- NDTDocument64 pagesNDTmohamedyoussef1No ratings yet

- Shielded Metal Arc WeldingDocument29 pagesShielded Metal Arc WeldingobijistephenNo ratings yet

- API MethodologyDocument278 pagesAPI MethodologyRed_Wing100% (1)

- Role of Hydro TestDocument14 pagesRole of Hydro TestHazwan AizatNo ratings yet

- TP 77 Pap PDFDocument8 pagesTP 77 Pap PDFJaved MohammedNo ratings yet

- Hydrostatic Testing ReviewDocument1 pageHydrostatic Testing ReviewhboodhaiNo ratings yet

- Instructiuni La SuduraDocument36 pagesInstructiuni La SuduraAntohi CatalinNo ratings yet

- Arc WeldingDocument10 pagesArc Weldingmetals1358No ratings yet

- Stress Corrosion: CrackingDocument16 pagesStress Corrosion: CrackingvincrediableNo ratings yet

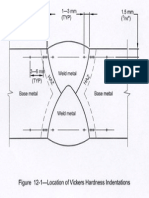

- Hardness Location001Document1 pageHardness Location001hboodhaiNo ratings yet

- Duplex Stainless Steels - A Simplified GuideDocument5 pagesDuplex Stainless Steels - A Simplified GuidehboodhaiNo ratings yet

- Chloride Stress Corrosion Cracking of 300 Series Stainless SteelDocument5 pagesChloride Stress Corrosion Cracking of 300 Series Stainless SteelhboodhaiNo ratings yet

- Welding & PWHT of P91 SteelsDocument4 pagesWelding & PWHT of P91 SteelshboodhaiNo ratings yet

- Joining Copper-Nickel Alloys GuideDocument9 pagesJoining Copper-Nickel Alloys GuidehboodhaiNo ratings yet

- Handling NineDocument10 pagesHandling NinehboodhaiNo ratings yet

- Grade T91Document5 pagesGrade T91anurag_4013No ratings yet

- Mechanical Finishing enDocument38 pagesMechanical Finishing enEric Halstead100% (1)

- Effects of Ni + MN On Ac1Document1 pageEffects of Ni + MN On Ac1hboodhaiNo ratings yet

- Controlling Heat Treatment of Welded P91 with Hardness TestingDocument3 pagesControlling Heat Treatment of Welded P91 with Hardness TestingyesimeonNo ratings yet

- P91 Temperature V HardnessDocument1 pageP91 Temperature V HardnesshboodhaiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Basic Specifications and Dimensions for Elenessa Series-AP ElevatorsDocument1 pageBasic Specifications and Dimensions for Elenessa Series-AP Elevatorsour143No ratings yet

- Lightning Protection SystemDocument4 pagesLightning Protection SystemBimadraj Sharan SinhaNo ratings yet

- Liquid Applied Waterproofing - ProtectowrapDocument3 pagesLiquid Applied Waterproofing - ProtectowrapYndia SorianoNo ratings yet

- Installation Manual - S200 Landing Door SystemDocument41 pagesInstallation Manual - S200 Landing Door SystemKhanh Huy Nguyen100% (1)

- Ward 5 Building Permits Issued 2.19.13 Thru 3.3.13 PDFDocument7 pagesWard 5 Building Permits Issued 2.19.13 Thru 3.3.13 PDFward5heartbeatNo ratings yet

- Form 6 (Daily Accomplishment)Document4 pagesForm 6 (Daily Accomplishment)Bendaña KHayeNo ratings yet

- Method Statement HT Switch GearDocument2 pagesMethod Statement HT Switch GearNasrul Syahmi100% (2)

- TP - Tool Hire Guide 2017Document81 pagesTP - Tool Hire Guide 2017Peter DavidsonNo ratings yet

- Introduction To Revit ArchitectureDocument99 pagesIntroduction To Revit ArchitectureOgunwusi Olubodun Samuel100% (1)

- Archiguide 2009Document75 pagesArchiguide 2009Constantin Dodon100% (1)

- Aquaria Grande residential tower in Borivali MumbaiDocument10 pagesAquaria Grande residential tower in Borivali MumbaiFaisal Nasim78% (9)

- Rule 14 - Photographic & X-Ray Films (Book Format)Document3 pagesRule 14 - Photographic & X-Ray Films (Book Format)Thea AbelardoNo ratings yet

- Boq PDFDocument12 pagesBoq PDFChandeshwor Shah0% (1)

- Durock Cement Board System Guide en SA932Document12 pagesDurock Cement Board System Guide en SA932Ko PhyoNo ratings yet

- Smoke Management Design Calculations for Nozha City CenterDocument29 pagesSmoke Management Design Calculations for Nozha City Centerhasanadel88No ratings yet

- Smoke Control and Day To Day Ventilation For Multi-Storey Residential BuildingsDocument20 pagesSmoke Control and Day To Day Ventilation For Multi-Storey Residential BuildingsThanh Nguyen Ngoc100% (1)

- Manual 162 PDFDocument47 pagesManual 162 PDFDeimer Jose Figueroa ManriqueNo ratings yet

- Ghastly Affair Location Catalogue CastleDocument35 pagesGhastly Affair Location Catalogue CastleAdam LaforetNo ratings yet

- ALHuxtable-Le Corbusier PessacDocument8 pagesALHuxtable-Le Corbusier PessacAnonymous Psi9GaNo ratings yet

- Assignment of PASSIVE VOICE Kelas AADocument2 pagesAssignment of PASSIVE VOICE Kelas AAHarum KartikasNo ratings yet

- Reinforced Concrete Design RefresherDocument5 pagesReinforced Concrete Design RefresherMark Neil Delgaco Gastilo100% (2)

- Quantity Takeoff: Dr. Ahmed ElyamanyDocument66 pagesQuantity Takeoff: Dr. Ahmed ElyamanysyampkNo ratings yet

- DUNHAM CASTLE: The Dunham Legacy in The Fox River ValleyDocument12 pagesDUNHAM CASTLE: The Dunham Legacy in The Fox River ValleyEd Chops FitzGerald100% (1)

- Alpha HB (BH12) - Manuel D'installation - GB - Du 10 05 01 (7657)Document200 pagesAlpha HB (BH12) - Manuel D'installation - GB - Du 10 05 01 (7657)hieroNo ratings yet

- Qcs 2010 Section 21 Part 7 Conduits and Conduit BoxesDocument8 pagesQcs 2010 Section 21 Part 7 Conduits and Conduit Boxesbryanpastor106No ratings yet

- English 6 Exam PrepDocument2 pagesEnglish 6 Exam Prepkhuyen phamNo ratings yet

- Elita Garden Vista-By Keppel Land, KolkataDocument12 pagesElita Garden Vista-By Keppel Land, Kolkatasourabh_sarkarNo ratings yet

- Vocabulary Prepositions There : Parts of A House Rooms Furniture NegativeDocument1 pageVocabulary Prepositions There : Parts of A House Rooms Furniture NegativeAMPARO BERISTAIN TENORIONo ratings yet

- Histoy 3 Lecture 005 - Architecture of Post IndependenceDocument63 pagesHistoy 3 Lecture 005 - Architecture of Post IndependenceEdmund ChuiNo ratings yet

- Thessaloniki. Hellenistic To Early Christian PeriodDocument25 pagesThessaloniki. Hellenistic To Early Christian PeriodLycophronNo ratings yet