Professional Documents

Culture Documents

PLC L

Uploaded by

chokamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PLC L

Uploaded by

chokamCopyright:

Available Formats

PLC Training Course [[ 5 ]]

Basic Program Designing Examples

Instructor:

Eng. Said Ibrahim Abu Al-Roos 03-03-2k9

Start, Stop and Latched

In some application events, we need to use the transient close/open buttons for the start and stop of an equipment. To maintain its continuous action, you have to design latched circuits.

Example 1: Stop first latched circuit

When the normally open contact X1 = On and the normally closed contact X2 = Off,Y1 will be On. If you make X2 = On at this time, Y1 will be Off. It is the reason why this is called stop first.

Location of Stop Switches

Location Of emergency switch

Example 2: Start first latched circuit

When the normally open contact X1 = On and the normally closed contact X2 = Off,Y1 will be On and latched. If you make X2 = On at this time, Y1 will continue to be On because of the latched contact. It is the reason why this is called start first.

Example 3: Latched circuit for SET and RST instructions

See the diagram in the right hand side for the latched circuit consist of RST and SET instructions. In the stop first diagram, RST is placed after SET. PLC executes the program from up to down, so the On/Off of Y1 will be determined upon its status in the end of the program. Therefore, when X1 and X2 are enabled at the same time, Y1 will be Off. It is the reason why this is called stop first. In the start first diagram, SET is placed after RST. When X1 and X2 are enabled at the same time, Y1 will be On. It is the reason why this is called start first.

Example 4: Power shutdown latched

The auxiliary relay M512 is latched. The circuit can not only be latched when the power is on, but also keep the continuity of the original control when the power is shut down and switched on again.

Example 5: Conditional control

X1 and X3 enables and disables Y1; X2 and X4 enables and disables Y2, and all are latched. Due to that the normally open contact of Y1 is connected to the circuit of Y2 in series, Y1 becomes an AND condition for Y2. Therefore, only when Y1 is enabled can Y2 be enabled.

Example 6: Interlock control

Which of the X1 and X2 is first enabled decides either the corresponding output Y1 or Y2 will be enabled first. Either Y1 or Y2 will be enabled at a time, i.e. Y1 and Y2 will not be enabled at the same time (the interlock). Even X1 and X2 are enabled at the same time, Y1 and Y2 will not be enabled at the same time due to that the ladder diagram program is scanned from up to down. In this ladder diagram, Y1 will be enabled first.

Example 7: Sequential control

If we serially connect the normally closed contact of Y2 in example 5 to the circuit of Y1 as an AND condition for Y1 (as the diagram in the left hand side), the circuit can not only make Y1 as the condition for Y2, but also allow the stop of Y1 after Y2 is enabled. Therefore, we can make Y1 and Y2 execute exactly the sequential control.

Example 8: Oscillating circuit

An oscillating circuit with cycle T+T

The ladder diagram above is a very simple one. When the program starts to scan the normally closed contact Y1,Y1 will be closed because coil Y1 is Off. When the program then scan to coil Y1 and make it On, the output will be 1. When the program scans to the normally closed contact Y1 again in the next scan cycle, because coil Y1 is On, Y1 will be open and make coil Y1 Off and output 0. The repeated scans will result in coil Y1 outputs oscillating pulses by the cycle T(On)+T(Off). An oscillating circuit with cycle nT+T

The ladder diagram program controls the On time of coil Y1 by timer T0 and disable timer T0 in the next scan cycle, resulting in the oscillating pulses in the output of Y1. n refers to the decimal set value in the timer and T is the cycle of the clock.

Example 9: Flashing circuit

The ladder diagram is an oscillating circuit which makes the indicator flash or enables the buzzer alarms. It uses two timer to control the On/Off time of coil Y1. n1 and n2 refer to the set values in T1 and T2 and T is the cycle of the clock.

Example 10: Trigger circuit

The rising-edge differential instruction of X0 makes coil M0 generate a single pulse of T (one scan cycle). Coil Y1 will be On during this scan period. In the next scan period, coil M0 will be Off and the normally closed contact M0 and Y1 will all be closed, making coil Y1 continue to be On until another rising-edge arrives in input X0, making coil M0 On for another scan period and Y1 Off. Such kind of circuit relies on an input to make two actions execute interchangeably. Also from the timing diagram on the last page, we can see that input X0 are square pulse signals of the cycle T and coil Y1 output are square pulse signals of the cycle 2T.

Example 11: Delay circuit

When input X0 is On, due to that its corresponding normally closed contact is Off, time T10 will be Off and the output coil Y1 will be On. T10 will be On and start to count until input X0 is Off. Output coil Y1 will be delayed for 100 seconds (K1,000 0.1 sec = 100 secs) and be Off. See the timing diagram above.

Time base: T = 0.1 sec

Example 12: Output delay circuit

The output delay circuit is the circuit composed of two timers. When input X0 is On and Off, output Y4 will be delayed.

Example13: Timing extension circuit

The total delay time from input X0 is closed to output Y1 is On = (n1+n2)* T. T refers to the clock cycle.

Example 14: How to enlarge the counting range

The counting range of a 16-bit counter is 0 ~ 32,767. Using two counters can increase the counting range to n1*n2. When the counting of counter C5 reaches n1, C6 will start to count for one time and reset for counting the pulses from X13. When the counting of counter C6 reaches n2, the pulses from input X13 will be n1*n2.

Case Study I Traffic Light Control

Timing Diagram:

You might also like

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- EXP1-Basic Contro Circuit-2020Document8 pagesEXP1-Basic Contro Circuit-2020Shahidan KirkukyNo ratings yet

- Sample PLC Exam ProblemsDocument5 pagesSample PLC Exam Problemsknbaluvlsi90% (10)

- Timer Design Examples GuideDocument28 pagesTimer Design Examples GuideghanNo ratings yet

- A Multi Vibrator Is An Electronic Circuit Used To Implement ADocument5 pagesA Multi Vibrator Is An Electronic Circuit Used To Implement AbulkSoftNo ratings yet

- Edc Project ReportDocument9 pagesEdc Project ReportbilalsimpleNo ratings yet

- Timer Ic Switch Using 555: Experiment #4Document7 pagesTimer Ic Switch Using 555: Experiment #4Zeeshan RafiqNo ratings yet

- EE301 - Inductor Transient Analysis ExplainedDocument6 pagesEE301 - Inductor Transient Analysis ExplainedAhmad BaseerNo ratings yet

- PLC Excercises (Module 1-3) PDFDocument101 pagesPLC Excercises (Module 1-3) PDFAnonymous 324QXtcuxoNo ratings yet

- Chapter 8: PLC Programming Language - Basic InstructionsDocument57 pagesChapter 8: PLC Programming Language - Basic InstructionsNguyễn Tuấn HòaNo ratings yet

- How To Configure A 555 Timer ICcdDocument2 pagesHow To Configure A 555 Timer ICcdJose C. Lita JrNo ratings yet

- Definition of Timing FunctionsDocument3 pagesDefinition of Timing FunctionsMuhammad FarisNo ratings yet

- Technological Studies: Applied Electronics (AH) Sequential Logic DevicesDocument116 pagesTechnological Studies: Applied Electronics (AH) Sequential Logic DevicesPham PunNo ratings yet

- PLC Basic Exercises For DeltaDocument3 pagesPLC Basic Exercises For DeltaYasirSwatiNo ratings yet

- 023 PLC Basic Exercises Sheet UnsolvedDocument3 pages023 PLC Basic Exercises Sheet UnsolvedDoğan YolluNo ratings yet

- Flip-Flop Excitation Table and IC 555 MultivibratorDocument6 pagesFlip-Flop Excitation Table and IC 555 MultivibratorDavidNo ratings yet

- Flip-Flop Excitation Table and IC 555 MultivibratorDocument6 pagesFlip-Flop Excitation Table and IC 555 MultivibratorDavidNo ratings yet

- How To Configure A 555 Timer ICDocument9 pagesHow To Configure A 555 Timer ICHebert Danilo Auccapure CusiNo ratings yet

- Department of Electrical Engineering: Instrumentation Lab EE-702Document5 pagesDepartment of Electrical Engineering: Instrumentation Lab EE-702Saurav SumanNo ratings yet

- Report.... 555ic and Stepper MotorDocument73 pagesReport.... 555ic and Stepper MotorJenielyn IparbaNo ratings yet

- Assignment 9 Landing GearDocument7 pagesAssignment 9 Landing GearAfrina PutraNo ratings yet

- 555 Timer Monostable OperationDocument13 pages555 Timer Monostable OperationGrigore ManNo ratings yet

- Assignment - PLCs & Control SystemsDocument6 pagesAssignment - PLCs & Control SystemsSaud Ahmed NizamiNo ratings yet

- Appliance Timer: Working of The CircuitDocument5 pagesAppliance Timer: Working of The CircuitMamon GhoshNo ratings yet

- A05 Op-Amp Take-HomeDocument3 pagesA05 Op-Amp Take-HomeDion BrownNo ratings yet

- 2.1 Conditional Logic: Ladder ProgrammingDocument10 pages2.1 Conditional Logic: Ladder ProgrammingLuka NikitovicNo ratings yet

- Please Understand That I Need To Understand That You Understood The SolutionDocument3 pagesPlease Understand That I Need To Understand That You Understood The SolutionArslan AhmadNo ratings yet

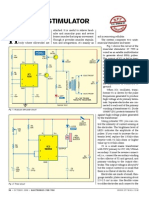

- Muscular Stimulator Circuit Generates Pulses to Relieve PainDocument2 pagesMuscular Stimulator Circuit Generates Pulses to Relieve PainDumitrescu Leonard CezarNo ratings yet

- Project Report-Seismic SensorDocument4 pagesProject Report-Seismic Sensorshantanukotkar91100% (1)

- CPSC 121: Models of Computation Lab #5: Flip-Flops and Frequency DivisionDocument8 pagesCPSC 121: Models of Computation Lab #5: Flip-Flops and Frequency DivisionJason RichardsNo ratings yet

- Industrial Electric RelayDocument26 pagesIndustrial Electric Relaysyed muazzam shah putraNo ratings yet

- Muscular StimulatoryDocument3 pagesMuscular StimulatoryIskcon GunturNo ratings yet

- PLC CH4 ADocument29 pagesPLC CH4 Aahmad qadiNo ratings yet

- Muscular Stimulator Project - Detailed Circuit Diagram AvailableDocument3 pagesMuscular Stimulator Project - Detailed Circuit Diagram AvailableAjay J VermaNo ratings yet

- Auxxilyary Switch ControlDocument4 pagesAuxxilyary Switch ControlMilan StefanovicNo ratings yet

- PN-2500 NewDocument50 pagesPN-2500 NewcresjohnNo ratings yet

- Time Relays: Understanding On-Delay, Off-Delay, and Other FunctionsDocument20 pagesTime Relays: Understanding On-Delay, Off-Delay, and Other Functionsmazen banatNo ratings yet

- XT 351 IcDocument4 pagesXT 351 IcbansalrNo ratings yet

- Introduction to Astable Multivibrators and the 555 Timer ICDocument15 pagesIntroduction to Astable Multivibrators and the 555 Timer ICTēmptēd Êģŏişitiç ßērrýx ÐxNo ratings yet

- Single Phase Series InverterDocument9 pagesSingle Phase Series InverterDhivya NNo ratings yet

- IC Families Comparison & Logic Gate CharacteristicsDocument11 pagesIC Families Comparison & Logic Gate CharacteristicsAlapati RajasekharNo ratings yet

- Understanding Time Delay Relay FunctionsDocument6 pagesUnderstanding Time Delay Relay FunctionsAndrew BullNo ratings yet

- Eel1166 CK1Document11 pagesEel1166 CK1Shafiq HafizullahNo ratings yet

- Introduction To Timer IC 555 & Its ApplicationsDocument13 pagesIntroduction To Timer IC 555 & Its ApplicationsSamuditha YatiwellaNo ratings yet

- Motor Control IntroDocument30 pagesMotor Control Introrandolf elmidoNo ratings yet

- Muhammad Asyraaf Syahmi - Electro-Pneumatic System (Jobsheet 2)Document13 pagesMuhammad Asyraaf Syahmi - Electro-Pneumatic System (Jobsheet 2)Muhammad Asyraaf Syahmi bin YazidNo ratings yet

- 4 Bit Shift RegisterDocument6 pages4 Bit Shift Registerpenchal_chinniNo ratings yet

- Quizz Based Buzzure by Sidharth KumarDocument15 pagesQuizz Based Buzzure by Sidharth KumarRahul KumarNo ratings yet

- CIM & Automation Technology Lecture on Electropneumatics and Automatic CyclingDocument5 pagesCIM & Automation Technology Lecture on Electropneumatics and Automatic Cyclingbaboiu electricNo ratings yet

- MneomonicsDocument62 pagesMneomonicsAbhishek TanguturiNo ratings yet

- Circuit Ideas Time SwitchDocument1 pageCircuit Ideas Time Switchs_subbulakshmiNo ratings yet

- Humidity ControllerDocument12 pagesHumidity ControllerPooja GautamNo ratings yet

- PLC Application Exercise - LDDocument33 pagesPLC Application Exercise - LDMazarel AurelNo ratings yet

- Understanding Time Delay Relay Functions - MacromaticDocument3 pagesUnderstanding Time Delay Relay Functions - Macromaticadak avijitNo ratings yet

- DC 6-40v Carregador de Bateria DescarregadorDocument5 pagesDC 6-40v Carregador de Bateria DescarregadorNemesio FilhoNo ratings yet

- PLC Applications Workbook - Dayanand, RickyDocument240 pagesPLC Applications Workbook - Dayanand, RickyPeter Nomikos100% (1)

- Blade Element TheoryDocument5 pagesBlade Element TheoryfleigenNo ratings yet

- DefDocument13 pagesDefmihai37No ratings yet

- AutoCAD 3D Course ManualDocument166 pagesAutoCAD 3D Course ManualJed Tedor98% (47)

- Moeller Datasheet MCS4 019711Document5 pagesMoeller Datasheet MCS4 019711mihai37No ratings yet

- DefDocument13 pagesDefmihai37No ratings yet

- Api 551Document1 pageApi 551mihai3750% (2)

- CGI Catalog 2010 v16Document25 pagesCGI Catalog 2010 v16mihai37No ratings yet

- New Product Release CGI - Rev7Document16 pagesNew Product Release CGI - Rev7mihai37No ratings yet

- DefDocument13 pagesDefmihai37No ratings yet

- Help For Calculating The Impeller Tip Speed To Avoid Excessive Erosion Due To Suspended ParticlesDocument22 pagesHelp For Calculating The Impeller Tip Speed To Avoid Excessive Erosion Due To Suspended Particlesmihai37No ratings yet

- Acdmac 2013 Autolisp Developers GuideDocument178 pagesAcdmac 2013 Autolisp Developers GuideAlexandru Stefan BothNo ratings yet

- PD Pump FundamentalsDocument138 pagesPD Pump Fundamentalsmihai37No ratings yet

- Help For Calculating The Impeller Tip Speed To Avoid Excessive Erosion Due To Suspended ParticlesDocument22 pagesHelp For Calculating The Impeller Tip Speed To Avoid Excessive Erosion Due To Suspended Particlesmihai37No ratings yet

- Da 7Document37 pagesDa 7mihai37No ratings yet

- Engineering Risk Benefit Analysis ERBADocument6 pagesEngineering Risk Benefit Analysis ERBAmihai37No ratings yet

- MIT15 075JF11 Exam01 SolnDocument6 pagesMIT15 075JF11 Exam01 Solnmihai37No ratings yet

- Engineering Risk Benefit AnalysisDocument22 pagesEngineering Risk Benefit Analysismihai37No ratings yet

- Sen Advances in Stochastic Mixeda Integer ProgrammingDocument58 pagesSen Advances in Stochastic Mixeda Integer Programmingmihai37No ratings yet

- Engineering Risk Benefit Analysis: Rpra 3. Probability Distributions in RPRADocument40 pagesEngineering Risk Benefit Analysis: Rpra 3. Probability Distributions in RPRAmihai37No ratings yet

- Engineering Risk Benefit AnalysisDocument26 pagesEngineering Risk Benefit Analysismihai37No ratings yet

- Da 6Document14 pagesDa 6mihai37No ratings yet

- Da 6Document14 pagesDa 6mihai37No ratings yet

- Engineering Risk Benefit AnalysisDocument14 pagesEngineering Risk Benefit AnalysisRiki MandolNo ratings yet

- Rpra 4Document13 pagesRpra 4mihai37No ratings yet

- Engineering Risk Benefit Analysis: Rpra 2. Elements of Probability TheoryDocument33 pagesEngineering Risk Benefit Analysis: Rpra 2. Elements of Probability Theorymihai37No ratings yet

- Da 7Document37 pagesDa 7mihai37No ratings yet

- Engineering Risk Benefit AnalysisDocument26 pagesEngineering Risk Benefit Analysismihai37No ratings yet

- Engineering Risk Benefit AnalysisDocument27 pagesEngineering Risk Benefit Analysismbajpai07No ratings yet

- Engineering Risk Benefit Analysis ComparisonDocument46 pagesEngineering Risk Benefit Analysis Comparisonmihai37No ratings yet

- Engineering Risk Benefit Analysis: CBA 4. Including UncertaintyDocument39 pagesEngineering Risk Benefit Analysis: CBA 4. Including Uncertaintymihai37No ratings yet