Professional Documents

Culture Documents

Ensat Self Tapping Inserts 303 Series

Uploaded by

Ace Industrial SuppliesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ensat Self Tapping Inserts 303 Series

Uploaded by

Ace Industrial SuppliesCopyright:

Available Formats

technologies for a reliable hold

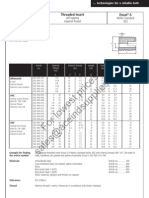

Thin-walled threaded insert

self-tapping, cutting slot

Application

Ensat-SD

Works Standard 303

Threaded insert Ensat with cutting slot in a special thin-walled and shortened version. Particularly suitable for plastic with thin residual walls and for light-weight constructions.

These versions are designed primarily for processing on thread tapping machines, as the pitch of the outside and Internal thread is identical.

Dimensions in mm Article no. Internal thread A External thread Length Guideline values for receiving hole dia. Soft plastics, hardwood L Hard, brittle plastics L

Minimum drill hole depth in case of blind holes

303 000 030 ... 303 000 035 ... 303 000 040 ... 303 000 050 ... 303 000 060 ... 303 000 080 ... 303 000 100 ...

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

M M M M M M M 3 3,5 4 5 6 8 10 4,5 5 6 7 8 10 12 0,5 0,6 0,7 0,8 1,0 1,25 1,5 6 6 6 8 10 12 15 4,0 4,5 5,3 6,3 7,1 8,6 10,6 to 4,1 to 4,6 to 5,4 to 6,4 to 7,2 to 8,8 to 10,8 4,1 4,6 5,5 6,5 7,3 8,9 10,9 to 4,2 to 4,7 to 5,6 to 6,6 to 7,5 to 9,2 to 11,2

T

8 8 8 10 13 15 18

Example for finding the article number

Self-tapping thin-walled insert Ensat-SD slot from Works Standard series 303 with internal thread A = M5 made of hardened, zinc-plated and yellow chromated steel: Ensat-SD 303 000 050.160

Materials, tolerances, thread see Works Standard 302, Page 8 and 9

Thin-walled threaded insert

Self-tapping, cutting bore

Ensat-SBD

P

Works Standard 347/348

Application

sa l

Threaded insert Ensat with three cutting bores in a special thinwalled and shortened version. Particularly suitable for plastic with thin residual walls and for lightweight constructions. These versions are designed primaArticle no.

rily for processing on thread tapping machines, as the pitch of the outside and Internal thread is identical. For processing thin-walled inserts in metals, the tensile strength / hardness of the base material is the determining factor. External thread

In critical cases, lubrication using suitable means is recommended in order to prevent breakage of the thin-walled inserts.

Dimensions in mm Length B Works standard Receiving hole dia. for plastics (guideline values) 348

8 8 10 12 14 18 22 24 24 4,6 5,4 6,0 7,4 9,3 11,1 13,1 15,0 17,0

Internal thread

Minimum drill hole depth T (blind holes) Works standard B B

10 10 13 15 17 22 26 28 28 7 8 9 10 11 13 15 17 17

A

3.. 000 035 ... 3.. 000 040 ... 3.. 000 050 ... 3.. 000 060 ... 3.. 000 080 ... 3.. 000 100 ... 3.. 000 120 ... 3.. 000 140 ... 3.. 000 160 ... M M M M M M M M M 3,5 4 5 6 8 10 12 14 16

E

5 6 6,5 8 10 12 14 16 18

P

0,6 0,7 0,8 1 1,25 1,5 1,75 2 2

347

5 6 7 8 9 10 12 14 14

L

to to to to to to to to to 4,7 5,6 6,1 7,6 9,5 11,3 13,3 15,2 17,2

Short design Long design Materials, tolerances, thread

Works Standard 347 Works Standard 348 see Works Standard 307/308, Page 10

11

Kerb-Konus-Vertriebs-GmbH P.O.Box 16 63 D-92206 Amberg Phone +49 9621 679-0 Fax +49 9621 679444

You might also like

- Wyckoff e BookDocument43 pagesWyckoff e BookIan Moncrieffe95% (22)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Caterpillar: Ripper ShanksDocument52 pagesCaterpillar: Ripper ShanksСергей Горовой100% (1)

- HeliCoil Aftermarket CatalogueDocument24 pagesHeliCoil Aftermarket CatalogueAce Industrial SuppliesNo ratings yet

- GPU Programming in MATLABDocument6 pagesGPU Programming in MATLABkhaardNo ratings yet

- Catalog Accesorii AEGDocument116 pagesCatalog Accesorii AEGGhiuli Aptisa100% (2)

- Plasterers AccessoriesDocument23 pagesPlasterers Accessoriespbrilhante0% (1)

- HeliCoil Product RangeDocument40 pagesHeliCoil Product RangeAce Industrial SuppliesNo ratings yet

- O-Ring (Metric Size)Document63 pagesO-Ring (Metric Size)Kamlesh DalavadiNo ratings yet

- Find specifications for ASTM A325 and A490 structural boltsDocument6 pagesFind specifications for ASTM A325 and A490 structural boltsalexortiz83No ratings yet

- Nitto Kohki Power Tools PDFDocument28 pagesNitto Kohki Power Tools PDFAnonymous E8YIWa4i6yNo ratings yet

- Clamping ToolsDocument190 pagesClamping ToolsИван РадивојевићNo ratings yet

- HeliCoil Screw Thread InsertsDocument36 pagesHeliCoil Screw Thread InsertsAce Industrial Supplies0% (1)

- Hazard Identification Priority Area Checklist Worksafe Gov AuDocument29 pagesHazard Identification Priority Area Checklist Worksafe Gov Aufh71100% (1)

- Flat Washers Standard MetricDocument4 pagesFlat Washers Standard MetricsivaNo ratings yet

- Math30.CA U1l1 PolynomialFunctionsDocument20 pagesMath30.CA U1l1 PolynomialFunctionsUnozxcv Doszxc100% (1)

- NETZSCH - Safety Valve - Brochure NdB672Document2 pagesNETZSCH - Safety Valve - Brochure NdB672Reivaj JavierNo ratings yet

- Broaches - Basic CharacteristicDocument5 pagesBroaches - Basic CharacteristicDhan CNo ratings yet

- Din 7500 enDocument10 pagesDin 7500 enCălin Bălăiţă100% (1)

- Cast Steel and Stainless Steel Y StrainersDocument13 pagesCast Steel and Stainless Steel Y StrainersNinad SherawalaNo ratings yet

- 132KV Siemens Breaker DrawingDocument13 pages132KV Siemens Breaker DrawingAnil100% (1)

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyNo ratings yet

- What Is PID - TutorialDocument5 pagesWhat Is PID - Tutorialsocrates19582405No ratings yet

- Ensat Self Tapping Inserts 302 Series MetricDocument1 pageEnsat Self Tapping Inserts 302 Series MetricAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 307 308 SeriesDocument1 pageEnsat Self Tapping Inserts 307 308 SeriesAce Industrial SuppliesNo ratings yet

- SmtdataDocument8 pagesSmtdataDaftDeveloperNo ratings yet

- Sheet Metal FastenersDocument15 pagesSheet Metal FastenersSudath KularathnaNo ratings yet

- Bollhoff Competence in MiniaturisationDocument8 pagesBollhoff Competence in MiniaturisationAce Industrial SuppliesNo ratings yet

- PEM Self Clinching Nuts CL SeriesDocument12 pagesPEM Self Clinching Nuts CL SeriesAce Industrial SuppliesNo ratings yet

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- PEM Self Clinching Standoffs SO, BSODocument12 pagesPEM Self Clinching Standoffs SO, BSOAce Industrial SuppliesNo ratings yet

- PEM Self Clinching Flush FastenersDocument4 pagesPEM Self Clinching Flush FastenersAce Industrial SuppliesNo ratings yet

- Grooved Pins Technical SpecsDocument8 pagesGrooved Pins Technical Specsjagan_san10No ratings yet

- PEM Self Clinching Floating FastenersDocument2 pagesPEM Self Clinching Floating FastenersAce Industrial SuppliesNo ratings yet

- Pentair 4003038 Industrial M88 LDocument4 pagesPentair 4003038 Industrial M88 LcatderNo ratings yet

- Elpress Catalog 2011Document149 pagesElpress Catalog 2011Mindaugas MockusNo ratings yet

- PEM Self Clinching Self Locking FastenersDocument4 pagesPEM Self Clinching Self Locking FastenersAce Industrial SuppliesNo ratings yet

- DS TM5301 GB 2133Document4 pagesDS TM5301 GB 2133Anonymous 4MwmDaNbNo ratings yet

- Pro Dec PlateDocument9 pagesPro Dec PlateAbe VoigNo ratings yet

- Haupa: Standard ProgramDocument12 pagesHaupa: Standard ProgramAgustine SetiawanNo ratings yet

- Stainless Steel Cable Ties and AccessoriesDocument5 pagesStainless Steel Cable Ties and AccessoriesAdelChNo ratings yet

- Kinkelder StandardDocument24 pagesKinkelder StandardJason StephensNo ratings yet

- Ejot FDSDocument20 pagesEjot FDSJacobNo ratings yet

- Metric Washer FlatDocument4 pagesMetric Washer Flatjontylee87No ratings yet

- GB TP0500 LRDocument20 pagesGB TP0500 LRGristarNo ratings yet

- Rothoblaas - Tbs.technical Data Sheets - enDocument6 pagesRothoblaas - Tbs.technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Ceratizit U DrillDocument8 pagesCeratizit U DrillJitendra BagalNo ratings yet

- PEM Self Locking Fasteners Nylon InsertDocument6 pagesPEM Self Locking Fasteners Nylon InsertAce Industrial SuppliesNo ratings yet

- ARNOLD - Thread Forming ScrewDocument4 pagesARNOLD - Thread Forming ScrewgirishawantiNo ratings yet

- Spiral Wound Gaskets PDFDocument4 pagesSpiral Wound Gaskets PDFSumit ChaurasiaNo ratings yet

- The Most Economical Solution For Drilling!: Indexable DrillDocument20 pagesThe Most Economical Solution For Drilling!: Indexable DrillapulavartyNo ratings yet

- 100059s Zvlnena Tesneni (W1A, W11A, W2A ... )Document4 pages100059s Zvlnena Tesneni (W1A, W11A, W2A ... )brkmechNo ratings yet

- PSI Casing End Seals Installation GuideDocument10 pagesPSI Casing End Seals Installation Guideanup_sahani100% (1)

- Alberg Cutting Tool 2002 PDFDocument28 pagesAlberg Cutting Tool 2002 PDFApichat1967No ratings yet

- Old - PADN-A0002-00 (TAPPING SCREW TYPE 304)Document1 pageOld - PADN-A0002-00 (TAPPING SCREW TYPE 304)Melih SENTURKNo ratings yet

- Rothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enDocument6 pagesRothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- EXPAMET - Builders - MetalworkDocument32 pagesEXPAMET - Builders - MetalworkMatthew AshworthNo ratings yet

- Pem NutsDocument0 pagesPem Nutsnaveen_talkinNo ratings yet

- Catalog 1066-1065-195 PDFDocument4 pagesCatalog 1066-1065-195 PDFDjordje VasicNo ratings yet

- Thread CoatingsDocument7 pagesThread CoatingsSumeet SainiNo ratings yet

- ETIN Tubing ClampsDocument8 pagesETIN Tubing ClampsVijenth VergheseNo ratings yet

- DSR PuneDocument16 pagesDSR Punedigvijayjagatap0% (1)

- Instructions For Fixing EtalbondDocument9 pagesInstructions For Fixing EtalbondAlket DhamiNo ratings yet

- JCP Resin Data SheetDocument2 pagesJCP Resin Data SheetgijimmyyoNo ratings yet

- HeliCoil Stud-Lock InsertsDocument2 pagesHeliCoil Stud-Lock InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless ApplicationsDocument2 pagesHeliCoil Tangless ApplicationsAce Industrial SuppliesNo ratings yet

- PowerCoil Screw Thread InsertsDocument103 pagesPowerCoil Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Self Tapping InsertsDocument4 pagesHeliCoil Self Tapping InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless Gall Resistant InsertsDocument2 pagesHeliCoil Tangless Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Stud-Lock ApplicationsDocument2 pagesHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs ImperialDocument1 pageHeliCoil Insert Specs ImperialAce Industrial SuppliesNo ratings yet

- HeliCoil Serrated Spark Plug InsertsDocument4 pagesHeliCoil Serrated Spark Plug InsertsAce Industrial Supplies100% (1)

- HeliCoil Insert Specs MetricDocument1 pageHeliCoil Insert Specs MetricAce Industrial SuppliesNo ratings yet

- HeliCoil Pipe Thread Inserts NPT ANPT NPSCDocument8 pagesHeliCoil Pipe Thread Inserts NPT ANPT NPSCAce Industrial SuppliesNo ratings yet

- HeliCoil Gall Resistant InsertsDocument2 pagesHeliCoil Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- Bollhoff Rivkle RivnutsDocument52 pagesBollhoff Rivkle RivnutsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UNDocument4 pagesHeliCoil NPT Inserts 8UNAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket KIts Sav-A-Thread HTDocument1 pageHeliCoil Aftermarket KIts Sav-A-Thread HTAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Oxygen SensorDocument1 pageHeliCoil Aftermarket Kits Oxygen SensorAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II InsertsDocument2 pagesHeliCoil Primer Free II InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II ApplicationsDocument2 pagesHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UN 2Document2 pagesHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- RivclinchDocument28 pagesRivclinchAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Catalogue 2Document24 pagesHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNo ratings yet

- Ripp Lock WashersDocument8 pagesRipp Lock WashersAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Head Bolt Thread RepairDocument1 pageHeliCoil Aftermarket Kits Head Bolt Thread RepairAce Industrial SuppliesNo ratings yet

- Rivkle ElasticDocument12 pagesRivkle ElasticAce Industrial SuppliesNo ratings yet

- Mercedes B-Class Accessories ListDocument34 pagesMercedes B-Class Accessories ListmuskystoatNo ratings yet

- FINC 301 MQsDocument40 pagesFINC 301 MQsMichael KutiNo ratings yet

- BS en 12951-2004Document26 pagesBS en 12951-2004Mokhammad Fahmi IzdiharrudinNo ratings yet

- Table of Forces For TrussDocument7 pagesTable of Forces For TrussSohail KakarNo ratings yet

- Panameterics GF 868 Flare Gas Meter PDFDocument8 pagesPanameterics GF 868 Flare Gas Meter PDFDaniel DamboNo ratings yet

- Convert MS Word Documents to LinuxDocument16 pagesConvert MS Word Documents to Linux8043 Nitish MittalNo ratings yet

- CS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationDocument28 pagesCS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationArdiansyah Mochamad NugrahaNo ratings yet

- Gilette Case - V3Document23 pagesGilette Case - V3Vidar Halvorsen100% (3)

- Moi University: School of Business and EconomicsDocument5 pagesMoi University: School of Business and EconomicsMARION KERUBONo ratings yet

- Term Paper Mec 208Document20 pagesTerm Paper Mec 208lksingh1987No ratings yet

- University of Cebu-Main Campus Entrepreneurship 100 Chapter 11 QuizDocument3 pagesUniversity of Cebu-Main Campus Entrepreneurship 100 Chapter 11 QuizAnmer Layaog BatiancilaNo ratings yet

- Environmental Pollution and Need To Preserve EnvironmentDocument3 pagesEnvironmental Pollution and Need To Preserve EnvironmentLakshmi Devar100% (1)

- Constitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Document3 pagesConstitutional Law of India-II CCSU LL.B. Examination, June 2015 K-2002Mukesh ShuklaNo ratings yet

- Kj1010-6804-Man604-Man205 - Chapter 7Document16 pagesKj1010-6804-Man604-Man205 - Chapter 7ghalibNo ratings yet

- Capital Asset Pricing ModelDocument11 pagesCapital Asset Pricing ModelrichaNo ratings yet

- E4PA OmronDocument8 pagesE4PA OmronCong NguyenNo ratings yet

- All India Corporate Photography Contest Promotes Workplace ArtDocument3 pagesAll India Corporate Photography Contest Promotes Workplace Artharish haridasNo ratings yet

- 2011 REV SAE Suspension Kiszco PDFDocument112 pages2011 REV SAE Suspension Kiszco PDFRushik KudaleNo ratings yet

- PNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawDocument3 pagesPNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawKelvin ZabatNo ratings yet

- MACROECONOMICSDocument95 pagesMACROECONOMICSClaudine Jeanne NillamaNo ratings yet

- NPTEL Web Course On Complex Analysis: A. SwaminathanDocument19 pagesNPTEL Web Course On Complex Analysis: A. SwaminathanMohit SharmaNo ratings yet

- VectorsDocument9 pagesVectorsdam_allen85No ratings yet

- WebquestDocument3 pagesWebquestapi-501133650No ratings yet

- Questions For ReviewDocument2 pagesQuestions For ReviewJoemar JavierNo ratings yet