Professional Documents

Culture Documents

Sab 4923

Uploaded by

Mohamed JalalaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sab 4923

Uploaded by

Mohamed JalalaCopyright:

Available Formats

FKA.B.PP.03 Ed.

UNIVERSITI TEKNOLOGI MALAYSIA FACULTY OF CIVIL ENGINEERING

FINAL EXAMINATION SEMESTER II, SESSION 2008/2009

COURSE CODE : SAB 4923

COURSE

ADVANCED WATER & WASTEWATER TREATMENT

PROGRAMME

SAW

DURATION

2 HOURS 30 MINUTES

DATE

APRIL 2009

INSTRUCTION TO CANDIDATES:

ANSWER ANY FIVE (5) QUESTIONS FROM SECTION A AND B

WARNING!

Students caught copying/cheating during the examination will be liable for disciplinary actions and the faculty may recommend the student to be expelled from the study.

THIS EXAMINATIONS QUESTIONS CONSISTS OF ( 8) PRINTED PAGES ONLY

SAB 4923 -1SECTION A

Q1

(a)

(i)

Discuss the importance of chemical oxidation reactions in water treatment. (4 marks)

(ii)

Discuss the importance of chemical oxidation in water treatment process. (4 marks)

(b)

(i)

Determine a packed tower height that is required to remove benzene from initial concentration of 100 g/L down to 5 g/L at 15oC for a water flow rate Q of 0.1 m3/s with a stripping factor R= 3.5, overall mass transfer constant of KLa benzene = 0.011 s-1 and tower diameter d = 1.17 m. (6 marks)

(ii)

Using the same number of transfer unit (NTU) from (i), the tower is used to remove chloroform with initial concentration of 80 g/L. Determine the stripping factor and the effluent concentration (Henrys constant Hu for choloroform = 0.569; overall mass transfer constant of KLa choloroform = 0.016 s-1; air to water ratio VG/VL = 26.3). (6 marks)

Q2

(a)

(i)

Specify three (3) different ways to remove metal ions from wastewater and briefly discuss the mechanism of treatment. (4 marks)

(ii)

Give three (3) factors need to be considered in advanced water treatment. (4 marks)

SAB 4923 -2(b) Consider a water softening work is conducted for raw water with the analysis shown below. Assume that the practical limit of hardness removal for CaCO3 is 30 mg/L and that of Mg(OH)2 is 10 mg/L as CaCO3. Ca2+ = 40.0 mg/L 7.32 mg/L 24.0 mg/L Na+ Cl= = 6.9 mg/L 7.1 mg/L

Mg2+ = SO42- =

Alk (HCO3-) = 110 mg/L as CaCO3 (i) Sketch a meq/L bar graph and list the hypothetical combinations of chemical compounds in solution

(Note: molar mass of Ca=40; Mg=24.4; C=12; Na=23; O=16; Cl=35.5; S=32)

(3 marks)

(ii)

Determine the most economic type of treatment to achieve the practical limits for hardness for the above particular case (give the reason) (3 marks)

(iii)

Calculate the lime dosage as CaO (3 marks)

(iv)

Sketch a bar graph for the softened water after recarbonation. Assume the alkalinity is in the form of HCO3- and CO3-2 (3 marks)

SAB 4923 -3Q3 (a) Briefly explain (use illustration) the adsorption process of the dissolved species (adsorbate) on porous carbon adsorbent. (5 marks)

(b)

Briefly explain the objective of carbon adsorption. (5 marks)

(c )

Langmuir isotherm equation model is commonly used to determine the maximum adsorbates/contaminants that can be adsorbed by activated carbon. A batch adsorption experiment is conducted at 25oC using Pb2+ as contaminant and GAC (Granulated Activated Carbon) as the adsorbent. The same lead amount (Pb2+) of 40 mg is equilibrated with various amount of GAC in 5 containers filled up with the same amount of 200 mL distilled water. After equilibration we found the concentration of lead in the solutions as follows:

Container A B C D E GAC (g) 0.3 1.46 2.30 2.34 3.53 Ce (eq. conc. of Pb2+, mg/L) 50.0 16.7 7.7 5.6 4.0

Calculate the maximum adsorption capacity and the equilibrium constant of the GAC? (Note: sketch the graph in the answer sheet) (10 marks)

SAB 4923 -4SECTION B

Q4

(a)

Membrane fouling always occurs during treatment processes. Membrane fouling is important consideration in the design and operation, since it can cause an additional cost if improper handling is applied. Give three (3) approaches that can control/reduce the membrane fouling. (4 marks) A reverse osmosis (RO) facility has been installed to treat 500 m3/hr of water for industrial cooling operations. With both recovery and rejection rates are equal to 92% and the concentration of the feed stream is 500 mg/L, calculate:

(b)

(i) (ii)

Concentrate stream flowrate (Qc) Total amount water to be processed (Qf), based on 4000 m3/day of RO water. Concentration of the permeate stream (Cp) Concentration of the concentrated waste stream (Cc) (8 marks)

(iii) (iv)

(d)

Typical seawater has salinity (TDS of 35,000 mg/L), of which 3,000 mg/L is NaCl. The generally accepted quality standards for drinking water are 500 mg/L of TDS and 200 mg/L of chloride. As requested by your government policy, state how Reverse Osmosis is more convenience than distillation for water drinking purposes. (8 marks)

SAB 4923 -5Q5. (a) Two rectangular clarifiers each 27 m long, 5.0 m wide and 3.8 m deep, settle 6000 m3/day. Total effluent weir length is 50 m. Calculate the detention time, overflow rate, and weir loading (6 marks)

(b)

Why must an activated sludge process be operated in the starvation stage (low F/M)? i. marks)

(c)

Explain aerobic, anoxic and anaerobic conditions in terms of the forms of oxygen present. Under which conditions does nitrification take place and why? i. marks)

(d)

Taman Impian Emass anaerobic digester produces 13 m3/d of sludge with a suspended solids concentration of 7.8%. What volume of they dispose of each year if their sand drying beds yield

sludge must

a solid concentration of 35%? (6 marks)

SAB 4923 -6Q6. (a) Water reuse and reclamation is the emergent technology that must be introduced in country. Many waste treatment plants have been struggled to invest and apply the concept of reusing water in their manufacturing. With ONE example (industry, wastewater recycled, etc.), define the concept of water reuse, water recycle and water reclaimation in terms of portable standard and criteria required for particular guidelines. (5 marks)

(b)

The following data in Table Q6 were reported during the operation of a wastewater treatment plant in Pasir Gudang: Table Q6 Constituent BOD5 Suspended Solids Phosphorus Oil and Grease (i) Influent (mg/L) 1500 500 50 300 Effluent (% removed) -85 -65 -45 -75

Calculate the effluent concentration for each of these constituents.

(ii)

Does the wastewater treatment plant meets the Standard A of Environmental Quality Act 1974?

(iii)

What type of treatment plant would produce such effluent? Draw a block diagram showing complete configuration of the treatment steps that would result in such performance. ii. marks)

SAB 4923 -7(c) You are designing an additional advanced treatment plant for local wastewater treatment to remove a bottleneck at the plant. In your design, the requirement of sludge treatment must be proposed to ensure the complete treatment of the wastewater. You have two options, Aerobic Digestion or Anaerobic Digestion. Your design selection must be based on cost-energy saving, duration of the treatment and desired environment-gained. Please state your decision. (5 marks)

(d)

Calculate the capacity required per population equivalent (PE) for a single-stage floating-cover digestion based on the following: 90 g of solids contributed per person, 4% solids content in raw sludge, 7% solids concentration in digested sludge, 40% total solids reduction during digestion, 30-day digestion period, and 90-day storage period for digested sludge

SAB 4923 -8FKA.B.PP.05.Ed.1

FACULTY OF CIVIL ENGINEERING UNIVERSITI TEKNOLOGI MALAYSIA

SEMESTER : II SESSION : 2008/2009 PROGRAMME : SAW COURSE CODE : SAB 4923

COURSE : ADVANCED WATER & WASTEWATER TREATMENT

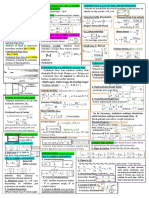

Membrane

product concentration 1 x 100% feedwater concentration

Re cov ery =

Qp Qf

x 100%

Qf = Qp + Qc

Cp = Cf (1 R)

Cc =

Q f C f Q pC p Qc

Sludge Digestion

V =

W W = s 100 p 100 100

V =

V1 + V2 T1 + V2 + T2 2

Vaverage = V1 2/3 (V1 V2) Vstored sludge = V2ts

Vdigesting sludge = Vavg * td Vt = 2Vs

Nitrification Denitrification Suspended

F Q BODload = M V MLSS

SRT =

MLSS V S e Qe + S w Qw

Aeration =

V Q

Chemical and Physical Treatment (c / c )( R 1) + 1 R ln i e NTU = h = (HTU) (NTU) R 1 R

1 1 1 1 = + X ab C b M

HTU =

VL K La

R=

H uVG VL

1 X = KC n M

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Book 1 PDFDocument85 pagesBook 1 PDFAditya Mehta67% (3)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Orifice Plate CalculationDocument10 pagesOrifice Plate CalculationkswaghmareNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Oil and LubricantsDocument95 pagesOil and LubricantspopescucvNo ratings yet

- XCMG Excavator Hydraulic Basics TrainingDocument129 pagesXCMG Excavator Hydraulic Basics TrainingBach Nguyen Xuan100% (4)

- Advanced Gas HandlingDocument2 pagesAdvanced Gas Handlingcamillo010No ratings yet

- Cryogenic Air Separation Safe Design and Operation of An ASUDocument18 pagesCryogenic Air Separation Safe Design and Operation of An ASUMohamed JalalaNo ratings yet

- Steam Ejector Pumps and Ejectors TheoryDocument5 pagesSteam Ejector Pumps and Ejectors TheorymahaveenNo ratings yet

- Leak Detection and RepairDocument12 pagesLeak Detection and RepairFredy Coral100% (1)

- Effect of Operating Conditions On COP of VCRDocument9 pagesEffect of Operating Conditions On COP of VCRSatheesh ChandranNo ratings yet

- Pipeline Design For Compressible Fluid FlowDocument42 pagesPipeline Design For Compressible Fluid FlowAruna JayamanjulaNo ratings yet

- Water Softening (IR)Document15 pagesWater Softening (IR)Iser100% (2)

- 9-Softning F11Document16 pages9-Softning F11Mohamed JalalaNo ratings yet

- SAB 4923 Chemical Precipitation - Student VersionDocument11 pagesSAB 4923 Chemical Precipitation - Student VersionMohamed JalalaNo ratings yet

- WWT 302 - 502 - Project - 2013Document2 pagesWWT 302 - 502 - Project - 2013Mohamed JalalaNo ratings yet

- Perancangan MenaraDocument18 pagesPerancangan Menaraogum_07No ratings yet

- Distillation ColumnDocument58 pagesDistillation Columnphoenix0467% (3)

- Chap1 4Document12 pagesChap1 4Mohamed JalalaNo ratings yet

- WK 10 TUTE 2012T Transient Diffusion and Convective Mass TransferDocument2 pagesWK 10 TUTE 2012T Transient Diffusion and Convective Mass TransferMohamed JalalaNo ratings yet

- Perancangan MenaraDocument18 pagesPerancangan Menaraogum_07No ratings yet

- Rhodes Solutions Ch11Document6 pagesRhodes Solutions Ch11Joson Chai100% (1)

- ChE 421 - Lect8Document30 pagesChE 421 - Lect8Mohamed JalalaNo ratings yet

- Computer Aided Design For Sustainable Industrial Processes: Specific Tools and ApplicationsDocument14 pagesComputer Aided Design For Sustainable Industrial Processes: Specific Tools and ApplicationsMohamed JalalaNo ratings yet

- Chap1 4Document12 pagesChap1 4Mohamed JalalaNo ratings yet

- DamsDocument9 pagesDamsRichard TagleNo ratings yet

- Chapter 3: Water Turbines Kaplan Turbine: Presented by Teaching Assistant Tu, Ioe Purwanchal CampusDocument16 pagesChapter 3: Water Turbines Kaplan Turbine: Presented by Teaching Assistant Tu, Ioe Purwanchal CampusMir Mustafa AliNo ratings yet

- PTEC 110 Lesson 11 ExerciseDocument7 pagesPTEC 110 Lesson 11 ExerciseFrancisca OrtizNo ratings yet

- Calculation of Hydrodynamic Pressures On Walls of Rectangular TankDocument7 pagesCalculation of Hydrodynamic Pressures On Walls of Rectangular Tankramesh chanderNo ratings yet

- 6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocument9 pages6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsdgkmurtiNo ratings yet

- ME2134cheatsheet PDFDocument1 pageME2134cheatsheet PDFbenNo ratings yet

- Septic Tank Purpose - FunctionDocument35 pagesSeptic Tank Purpose - FunctionMasnun Rahman100% (2)

- Fluid Mechanics Sample ExamDocument4 pagesFluid Mechanics Sample ExamNiña VictoriaNo ratings yet

- History and Development of Riparian and Water RightsDocument13 pagesHistory and Development of Riparian and Water RightsDennis McKinneyNo ratings yet

- 2007 PedersenDocument149 pages2007 Pedersenruchirsrivastav100% (1)

- Plumbing & Piping 19.06.08Document26 pagesPlumbing & Piping 19.06.08Kanupriya JainNo ratings yet

- Steam Jet Ejector: Can A Fit Your Vacuum Process?Document5 pagesSteam Jet Ejector: Can A Fit Your Vacuum Process?Tiến Mạnh NguyễnNo ratings yet

- Lec 16Document5 pagesLec 16Vimal KumarNo ratings yet

- Lab Report 123Document9 pagesLab Report 123Falcon Tech0% (1)

- SVL488 Stainless Steel Safety Valve For Clean Service ApplicationsDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service ApplicationsDanielNo ratings yet

- Tribo Assignment 4Document4 pagesTribo Assignment 4abdurhman suleimanNo ratings yet

- Temperature Control Trainer Flow Control TrainerDocument2 pagesTemperature Control Trainer Flow Control TrainerimmoNo ratings yet

- CYCLONES0000Document35 pagesCYCLONES0000Abdul HadiNo ratings yet

- Questions 11-20Document3 pagesQuestions 11-20Samuel Francisco SinagaNo ratings yet

- Course: Hydraulic Structures: Eng.M.M.QawdhanDocument25 pagesCourse: Hydraulic Structures: Eng.M.M.QawdhanJamaal MohamedNo ratings yet