Professional Documents

Culture Documents

KEYnote Address

Uploaded by

divya1587Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KEYnote Address

Uploaded by

divya1587Copyright:

Available Formats

1

The task of delivering a keynote address or any such talk on a public platform, which I had not taken up for almost 40 years, has surprisingly come to me. Anyhow I thank the concerned for such an opportunity. The most important component of an electric machine is the windings where the main energy conversion processes take place. The winding diagrams illustrate the operating principle of the windings, construction and arrangement of the entire winding element on the core as well as the connection in between. It is very difficult to carry out winding without periodically checking against a winding diagram. Therefore, such diagrams should always be drawn before the repairs. Necessity and developments has led to many types of winding satisfying the requirements. DC wave winding is the result of such a requirement. In 1890,B G Lamme was working on the design of a new railway motor with a view to improvement of the then existing motor. The older motor had a lap wound armature specially cross connected at the commutator for the purpose of eliminating all but two brush arms.One of Lammes desire was to design the winding so that cross connection would not be necessary and so that it would still be possible to operate the motor with two brush arms. He devised a winding that requires only two brush arms (The present day wave winding) irrespective of the number of poles. The winding was included in the new design. Question was raised regarding this new winding, when it was first proposed. Lamme had to swear up and down that it was absolutely correct in principle, even if it was new and untried. This is interesting in view of the fact that the same windings are used even today. An assembly drawing normally consists of All parts, drawn in their normal operation A parts list or bill of materials showing the detail number of each part, the quantity required for a single assembly, the description or name of the part, the catalog number if it is a standard part, and the company part number. Machining and assembly operations and critical dimensions related to these functions.

Sectional gives a general graphic description of the interior shape by passing a cutting plane through all or part of the assembly. Sectional assembly drawings are used for the manufacture and assembly of complicated devices. A detailed assembly drawing shows how all components are assembled and provides necessary details and joining techniques to fully assemble all or part of the project. What are the objectives of Electrical Drawing? Electrical drawing for a project serves three distinct functions. 1. Describes the electrical project in sufficient details to allow electrical contractors to use the drawings in estimating the cost of materials, labor, and services when preparing a contract bid.

2 2. Instructs and guides electricians in performing the required wiring and equipment installation while also warning them of potential hazards such as existing wiring, gas pipes, or plumbing systems. 3. Provides the owner with an as built record of the installed electrical wiring and equipment for the purposes of maintenance or planning for future expansion.

Computer aided drawing (CAD) has many benefits as compared to manual. Some of the benefits are, 1. Saving time in the preparation of all types of electrical drawing. 2. Eliminating the tedious task of lettering and drawing uniform lines and symbols. 3. Making rapid changes on completed and approved drawings to reflect field changes such as substation of different equipment. 4. Making rapid corrections of mistakes or oversights that have been discovered. 5. Permitting work to be done on a specific drawing by two or more persons at separate workstations within the same office or miles apart, because data can be transmitted over networks to master workstation. This permits two or more persons to participate in the design work in real time. 6. Accelerating the distribution of drawings to all concerned parities: owners, contractors, equipment manufacturers, and suppliers. Electrical CAD software: The basic AutoCAD has a menu structure that permits drawing lines, circles, arcs, rectangles, spline curves, hatching etc. It also permits generation of text, scaling, and dimensioning. The modifying commands include erase, copy, mirror, stretch, and array. The electrical drafting software has a library of hundreds of standard electrical symbols that can be accessed from a menu, downloaded, and dragged into position on the face of the screen as needed. The basic symbols can be modified to fulfill special requirements Logic inherent in the software monitors the use of the symbols and indicates possible errors. AutoCAD has special features to draw single line diagrams and also can do a lot when it comes assembly drawing. I congratulate the management, the Principal and the teaching staff of Department of Electrical and Electronics Engineering for the initiative taken to provide a platform for the exchange and enhancement of knowledge among the teaching fraternity. I wish the participants avail the benefit and transfer the same to students. I thank one and all of HKBK for having provided me an opportunity to be here in this capacity.

You might also like

- Subject: Ada Topic: To Find The Square Root of A Number by Nested Method (CYCLE 5)Document9 pagesSubject: Ada Topic: To Find The Square Root of A Number by Nested Method (CYCLE 5)divya1587No ratings yet

- Introduction To Matlab Application To Electrical EngineeringDocument98 pagesIntroduction To Matlab Application To Electrical EngineeringSindhu ReddyNo ratings yet

- Computer Techniques in Power System Analysis NotesDocument60 pagesComputer Techniques in Power System Analysis Notesdivya1587No ratings yet

- All Power System StabiltyDocument78 pagesAll Power System StabiltyShafeek GhreebNo ratings yet

- Lecture 1 Introduction To SimulinkDocument13 pagesLecture 1 Introduction To Simulinkdivya1587No ratings yet

- IIR Filter Design With MATLABDocument28 pagesIIR Filter Design With MATLABdivya1587No ratings yet

- Two-Port Network Parameters ExplainedDocument89 pagesTwo-Port Network Parameters Explainedphoenix2260% (1)

- 1 s2.0 S2212017313007342 Main PDFDocument6 pages1 s2.0 S2212017313007342 Main PDFdivya1587No ratings yet

- EC - II Course MeterialDocument44 pagesEC - II Course Meterialdivya1587No ratings yet

- Design of IIR FiltersDocument32 pagesDesign of IIR Filtersdivya1587No ratings yet

- Dims 22Document8 pagesDims 22divya1587No ratings yet

- Introduction To MATLAB and Simulink: Ravikiran B. A. Asst. Professor, Dept of ECE KssemDocument79 pagesIntroduction To MATLAB and Simulink: Ravikiran B. A. Asst. Professor, Dept of ECE Kssemdivya1587No ratings yet

- 1Document16 pages1Amita SinghNo ratings yet

- Implementation of Digital FiltersDocument15 pagesImplementation of Digital Filtersdivya1587No ratings yet

- Design of FIR FiltersDocument28 pagesDesign of FIR Filtersdivya1587No ratings yet

- Mathworks and The Freescale Cup Working With Matlab & SimulinkDocument26 pagesMathworks and The Freescale Cup Working With Matlab & Simulinkdivya1587No ratings yet

- MiP-PSCT LFA User Manual Load Flow Analysis GuideDocument119 pagesMiP-PSCT LFA User Manual Load Flow Analysis Guidedivya1587100% (1)

- Matlab Tutorial IsdDocument36 pagesMatlab Tutorial IsdRadha Devi PeriyasamyNo ratings yet

- Agribot: Vinay Kumar V Hoskoti AMC Engineering College Banglore-83 May 17, 2018Document2 pagesAgribot: Vinay Kumar V Hoskoti AMC Engineering College Banglore-83 May 17, 2018divya1587No ratings yet

- Bmsit PssmanualDocument64 pagesBmsit Pssmanualdivya1587No ratings yet

- Mathworks and The Freescale Cup Working With Matlab & SimulinkDocument26 pagesMathworks and The Freescale Cup Working With Matlab & Simulinkdivya1587No ratings yet

- ASEECircuitAnalysis in MATLAB and Simulink PDFDocument12 pagesASEECircuitAnalysis in MATLAB and Simulink PDFSuriyachakArchwichaiNo ratings yet

- Chapter - 2 Power Flow AnalysisDocument24 pagesChapter - 2 Power Flow AnalysisdivyaNo ratings yet

- MATLAB Sample Scripts: Shameer A KoyaDocument12 pagesMATLAB Sample Scripts: Shameer A Koyadivya1587No ratings yet

- Lecture Notes On: Bee 1711 Power System-IiiDocument88 pagesLecture Notes On: Bee 1711 Power System-IiiSatyanarayana GurramNo ratings yet

- The Application and Study of MATLAB in Electrical Engineering and Its AutomationDocument6 pagesThe Application and Study of MATLAB in Electrical Engineering and Its AutomationnpfhNo ratings yet

- Modern DSP Education: The Story of Three Greek Philosophers: Joseph Picone, Jonathan E. Hamaker, Robert BrownDocument22 pagesModern DSP Education: The Story of Three Greek Philosophers: Joseph Picone, Jonathan E. Hamaker, Robert Browndivya1587No ratings yet

- Pss Lab Questions, Programs &solutionsDocument29 pagesPss Lab Questions, Programs &solutionsdivya1587No ratings yet

- Pss ProgramsDocument76 pagesPss Programsdivya1587No ratings yet

- Vidya Vikas Institute of Engineering and Technology Departement of Electrical and Electronics Engineering Feedback Form For Even Semester 2014-2015Document1 pageVidya Vikas Institute of Engineering and Technology Departement of Electrical and Electronics Engineering Feedback Form For Even Semester 2014-2015divya1587No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

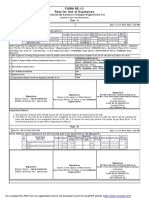

- PESO Online Explosives-Returns SystemDocument1 pagePESO Online Explosives-Returns Systemgirinandini0% (1)

- DELcraFT Works CleanEra ProjectDocument31 pagesDELcraFT Works CleanEra Projectenrico_britaiNo ratings yet

- Borello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceDocument10 pagesBorello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceaykutNo ratings yet

- Cold Rolled Steel Sections - Specification: Kenya StandardDocument21 pagesCold Rolled Steel Sections - Specification: Kenya StandardPEng. Tech. Alvince KoreroNo ratings yet

- NAT Order of Operations 82Document39 pagesNAT Order of Operations 82Kike PadillaNo ratings yet

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainNo ratings yet

- Modified Syllabus of Control SystemDocument2 pagesModified Syllabus of Control SystemDigambar PatilNo ratings yet

- Theory of Linear Programming: Standard Form and HistoryDocument42 pagesTheory of Linear Programming: Standard Form and HistoryJayakumarNo ratings yet

- TWP10Document100 pagesTWP10ed9481No ratings yet

- Mtle - Hema 1Document50 pagesMtle - Hema 1Leogene Earl FranciaNo ratings yet

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDocument2 pagesPradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalNo ratings yet

- Moor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsDocument4 pagesMoor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsIrene IturraldeNo ratings yet

- Honda Wave Parts Manual enDocument61 pagesHonda Wave Parts Manual enMurat Kaykun86% (94)

- Energy AnalysisDocument30 pagesEnergy Analysisca275000No ratings yet

- BIBLIO Eric SwyngedowDocument34 pagesBIBLIO Eric Swyngedowadriank1975291No ratings yet

- Mercedes BenzDocument56 pagesMercedes BenzRoland Joldis100% (1)

- Portfolio Artifact Entry Form - Ostp Standard 3Document1 pagePortfolio Artifact Entry Form - Ostp Standard 3api-253007574No ratings yet

- 2010 - Impact of Open Spaces On Health & WellbeingDocument24 pages2010 - Impact of Open Spaces On Health & WellbeingmonsNo ratings yet

- IoT BASED HEALTH MONITORING SYSTEMDocument18 pagesIoT BASED HEALTH MONITORING SYSTEMArunkumar Kuti100% (2)

- System: Boehringer Mannheim/Hitachi AnalysisDocument20 pagesSystem: Boehringer Mannheim/Hitachi Analysismaran.suguNo ratings yet

- Sharp Ar5731 BrochureDocument4 pagesSharp Ar5731 Brochureanakraja11No ratings yet

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDocument22 pagesStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasNo ratings yet

- QuickTransit SSLI Release Notes 1.1Document12 pagesQuickTransit SSLI Release Notes 1.1subhrajitm47No ratings yet

- Game Rules PDFDocument12 pagesGame Rules PDFEric WaddellNo ratings yet

- Evaluating MYP Rubrics in WORDDocument11 pagesEvaluating MYP Rubrics in WORDJoseph VEGANo ratings yet

- Wasserman Chest 1997Document13 pagesWasserman Chest 1997Filip BreskvarNo ratings yet

- (23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion SpringsDocument6 pages(23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion Springsstefan.vince536No ratings yet

- Three-D Failure Criteria Based on Hoek-BrownDocument5 pagesThree-D Failure Criteria Based on Hoek-BrownLuis Alonso SANo ratings yet

- IDocument2 pagesIsometoiajeNo ratings yet

- Case StudyDocument2 pagesCase StudyBunga Larangan73% (11)