Professional Documents

Culture Documents

What Is Ram-Maros

Uploaded by

peach5Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Ram-Maros

Uploaded by

peach5Copyright:

Available Formats

WHAT IS RAM

A well-designed and properly implemented asset optimisation program can save your projects bottom line thousands and even millions of dollars. RAM modeling assesses a production systems capabilities, whether it be operation or still in design phase. The results from RAM modelling will identify possible causes of production losses and can examine possible system alternatives.

Solution What is RAM Modeling? RAM modelling can simulate the configuration, operation, failure, repair and maintenance of equipment. The inputs to RAM modelling will include the physical components and maintenance schedules in a system and the outputs can determine how productive the system can be over the plant life. RAM studies will generate sufficient data to base decisions for possible systems changes that may increase system efficiency and hence project profits. Our Approach Our reliability engineers will liaise with the client to identify their needs and develop the basis for the RAM model. Once the basis is agreed a model of the system is created and run in Optimise. Analysis of the model generates results and recommendations for improvement of the design or of the operating results. Communication throughout all stages with the client and the reliability engineers is continuous and ensures maximum results. What are the key benefits? The key benefits of RAM modeling includes: - detecting failures in the early part of design; - optimising maintenance schedules; - adequately allocating the spares inventory; - increasing the effectiveness of logistics; and - identifying equipment priorities on failure.

Maros, a RAM tool, is used for assessing upstream asset performance with Maintainability, Availability, Reliability and Operability Simulation. MAROS, which stands for Maintainability, Availability, Reliability, Operability, Simulation, is an advanced RAM tool with extensive features for modelling networks, maintenance, operations and demand scenarios which includes powerful Boolean logic option. Key features of the Maros software

Discrete event driven simulation a very powerful platform Highly intuitive graphical user interface - Asset view, Reliability Block Diagram view, Table views and Symbol view Equipment catalogue - Build your own custom equipment catalogue for future studies Reservoir profiles over variable time periods - access/excel import facility Product demand profiles Compensation mechanisms (boosting, linepacking, storage, third party substitution) Multi-product (track primary, secondary and tertiary products through product ratios, which can vary over time) Tanker export facility (schedule or level in tank basis, berthing restrictions, round-trip delays) Conditional Logic powerful Boolean logic enables most operational scenarios to be modelled Process re-starts & production ramping Flaring analysis (Governmental type restrictions and impacts, i.e., Gulf of Mexico and North Sea) Maintenance and logistics Shift constraints Mobilisation delays Manpower Spares analysis Graphical and Tabular output Production statistics Efficiency statistics Criticality tables (hierarchical) Contract shortfalls analysis (size and frequency) Plant Shutdown analysis (size and frequency) Batch Run - to run multiple studies using each core of the multi core processor, suitable for Sensitivity Analysis

For the design stage the Maros software permits the development and comparison of systems by predicting their life-cycle behaviour pattern. Comparisons can be made of the most elementary concepts in the early stages of a design project when few details are fixed (or known), while at the other extreme complex systems can be optimized to yield maximum cost-efficiency. As the Maros acronym suggests the package encompasses well known 'types' of analyses which have been successfully integrated into a simulation algorithm and offered as a design aid. Application of the Maros software:

Equipment reliability and redundancy Establishing maintenance and intervention strategies System productivity and sales quota fulfilment System operability assessment Operations research

Benefits of the Maros software The Maros software is one of the worlds leading tool for RAM in the upstream Oil and Gas industry.

The Maros software is tailored to accommodate the very specific system configurations and operations present in the industry. Particular operational complexities supported are flaring, multiple products, timevarying reservoir profile and time-varying sales demands. The development team has a long history of working closely with advanced users, mainly the biggest Oil & Gas companies around the world, which ensures basic and advanced needs associated with availability analysis in oil and gas operations are met and supported by Maros

The Maros software is the most usable tool for RAM in the oil and gas industry

The user interface provides flexible ways for defining and manipulating input data to allow the user to focus less on input operations and more on using results to improve the performance of the system The study organisation reflects the real world and provides intuitive management of the system under analysis The results are presented with industry standard terminology and provide information on real world numbers that are easy to understand

The Maros software has great flexibility to handle complex configurations and situations outside the normal scope

The software has several features that allow the users to reflect situations not initially thought about in ways that seriously challenge the most powerful generic reliability simulation models

Maros software - Reliability Block Diagram (RBD) Purpose of the Maros software The Maros software was originally developed for the offshore oil and gas industry where it has been used extensively to design process facilities and transportation systems to exploit hydrocarbon reservoirs. As a general purpose systems design tool it is currently used in a wide range of applications including chemicals, power generation and distribution, manufacturing etc.

You might also like

- Analex RPDDocument16 pagesAnalex RPDpeach5100% (1)

- Barringer FMEA 11 17 09Document9 pagesBarringer FMEA 11 17 09peach5100% (1)

- Multi Plane Balancing of A Rotating Machine Using Run-Down DataDocument6 pagesMulti Plane Balancing of A Rotating Machine Using Run-Down Datapeach5No ratings yet

- Part 0. Program ScheduleDocument1 pagePart 0. Program Schedulepeach5No ratings yet

- Asme Boiler and Pressure Vessel Code, Section I Design GuideDocument11 pagesAsme Boiler and Pressure Vessel Code, Section I Design Guidepeach5No ratings yet

- Tips To Perform A Ram Study Webinar Presentation - tcm4-539661Document38 pagesTips To Perform A Ram Study Webinar Presentation - tcm4-539661Sivapriya SamyNo ratings yet

- Part 2. Basic Thinning Assessments - Shell & HeadDocument30 pagesPart 2. Basic Thinning Assessments - Shell & Headpeach5100% (2)

- API 570 Part 2 - Pipe DesignDocument34 pagesAPI 570 Part 2 - Pipe Designpeach5100% (10)

- Welcome To:: by Hazle Bin Ibrahim-Inspection & Maintenance Planning SectionDocument3 pagesWelcome To:: by Hazle Bin Ibrahim-Inspection & Maintenance Planning Sectionpeach5No ratings yet

- API 570 Part 3 - Pipe FabricationDocument21 pagesAPI 570 Part 3 - Pipe Fabricationpeach5100% (7)

- Application of Bayesian Methods For Age-Dependent Reliability Analysis Robertas Alzbutas, Tomas IešmantasDocument16 pagesApplication of Bayesian Methods For Age-Dependent Reliability Analysis Robertas Alzbutas, Tomas Iešmantaspeach5No ratings yet

- API 570 Part 1 - Pipe ComponentsDocument41 pagesAPI 570 Part 1 - Pipe Componentspeach5100% (18)

- 20 Pump Size CalculationsDocument20 pages20 Pump Size Calculationspeach5No ratings yet

- How To Take This Course: Recommended Steps in Taking CourseDocument3 pagesHow To Take This Course: Recommended Steps in Taking Coursepeach5No ratings yet

- Maintain Water Quality and Throughput: Cooling Tower Health MonitoringDocument3 pagesMaintain Water Quality and Throughput: Cooling Tower Health Monitoringpeach5No ratings yet

- About This CourseDocument2 pagesAbout This Coursepeach5No ratings yet

- Reduce Shutdowns and Fulfill Production Goals: Compressor Health MonitoringDocument4 pagesReduce Shutdowns and Fulfill Production Goals: Compressor Health Monitoringpeach5No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Enterprenureship DevelopmentDocument2 pagesEnterprenureship DevelopmentGãurãv SãndhãlNo ratings yet

- Plant Management TafskillsDocument4 pagesPlant Management TafskillsTHEOPHILUS ATO FLETCHERNo ratings yet

- Appointment CalendarDocument4 pagesAppointment CalendarVeronica G SchilloksNo ratings yet

- Invoice Payment RecordDocument155 pagesInvoice Payment RecordEvo HarmoniNo ratings yet

- Solution Manual For Managerial Economics Applications Strategies and Tactics 13th EditionDocument4 pagesSolution Manual For Managerial Economics Applications Strategies and Tactics 13th EditionMarjorie Gault100% (32)

- Business Credit Building Checklist 2020Document6 pagesBusiness Credit Building Checklist 2020Patrick Py100% (11)

- Accounting For Corporations: Mcgraw-Hill/Irwin1 © The Mcgraw-Hill Companies, Inc., 2006Document67 pagesAccounting For Corporations: Mcgraw-Hill/Irwin1 © The Mcgraw-Hill Companies, Inc., 2006Analou LopezNo ratings yet

- Challenger 3500Document54 pagesChallenger 3500Santiago Ro DaNo ratings yet

- Newlightmyanmar 02 01 2024Document15 pagesNewlightmyanmar 02 01 2024NickyNo ratings yet

- 4ec1 01Document20 pages4ec1 01CanioNo ratings yet

- De La Salle Montessori V de La Salle BrothersDocument2 pagesDe La Salle Montessori V de La Salle BrothersAleli BucuNo ratings yet

- Itext SoDocument512 pagesItext SoVancleuma Carvalho BrasilNo ratings yet

- Contact With Your Supplier PDFDocument3 pagesContact With Your Supplier PDFSufyan SafiNo ratings yet

- Sphinx Embedded & It SolutionsDocument8 pagesSphinx Embedded & It SolutionsJANANI COMPUTERSNo ratings yet

- Gmail Your CFA Exam Result 2Document1 pageGmail Your CFA Exam Result 2Scallion RiceNo ratings yet

- Tourism Paper3Document21 pagesTourism Paper3Nilanjana ChakrabartyNo ratings yet

- Amazon Fulfillment ProcessDocument1 pageAmazon Fulfillment ProcessRAHUL RNAIRNo ratings yet

- Accountant Services - Oceanx-CompressedDocument20 pagesAccountant Services - Oceanx-Compressedطراد الفنديNo ratings yet

- MU - Project Proposal Group 13 December 2016 V3Document21 pagesMU - Project Proposal Group 13 December 2016 V3mihiret lemmaNo ratings yet

- Jis g3462 Grade Stba 12 Tubes PDFDocument1 pageJis g3462 Grade Stba 12 Tubes PDFMitul MehtaNo ratings yet

- Fintech Final Lecture PPTDocument27 pagesFintech Final Lecture PPTParth100% (1)

- Castle Bay Restaurant Management System - Product & Sprint Backlogs Last Edit-2Document5 pagesCastle Bay Restaurant Management System - Product & Sprint Backlogs Last Edit-2Lahiru Ruhunage100% (1)

- A Surfers Guide To SustainabilityDocument85 pagesA Surfers Guide To SustainabilityEsteban Cedeño RodriguezNo ratings yet

- Customer AnalysisDocument2 pagesCustomer AnalysisAli Tariq Butt100% (1)

- AprilDocument4 pagesAprilkhanNo ratings yet

- Dealroom - Marketplaces 1H2022Document20 pagesDealroom - Marketplaces 1H2022Никита МузафаровNo ratings yet

- Investor Presentation On Right IssueDocument28 pagesInvestor Presentation On Right IssueSpy HanNo ratings yet

- Resume Khanh (Lisa), DuongDocument2 pagesResume Khanh (Lisa), DuongLisa DuongNo ratings yet

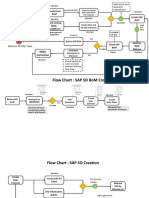

- SAP-SD-BOM-SO Creation Flow ChartDocument3 pagesSAP-SD-BOM-SO Creation Flow Chartshoohel ranaNo ratings yet

- AlwarDocument94 pagesAlwarSaurabh SrivastavaNo ratings yet