Professional Documents

Culture Documents

Effects of Calcium Addition On Properties of MG Alloys: A Review

Uploaded by

Gunabalan SellanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of Calcium Addition On Properties of MG Alloys: A Review

Uploaded by

Gunabalan SellanCopyright:

Available Formats

Effects of Calcium Addition on Properties of Mg Alloys: A Review

Effects of Calcium Addition on Properties of Mg Alloys: A Review

1. S.Gunabalan, 2. Dr. R. Elansezhian 1. Ph.D. (Research Scholar), 2. Associate Professor, Dept. of Mechanical Engineering, Pondicherry Engineering College, Puducherry.

Abstractthe Magnesium alloys attract the automobile, aerospace and electronic equipments manufacturing industries with its superior specific strength, processability and electromagnetic shielding. Aluminium alloys and polymer matrix composites are the strong contenders for magnesium alloys. Alloying is the way to improve the properties of the magnesium to defend its position as a structural material. Calcium one of the low cost alloying elements which improves the mechanical properties, provides thermal stability and enhances the formation of a thin and uniform oxide layer and thus improves the oxidation resistance and also increases the ignition temperature with a decrease in elongation and loss of fluidity. This article summarizes the effects of Calcium addition on the properties of magnesium alloys. Index TermsMg-Ca alloys, creep resistance, strengthening mechanism, corrosion.

I. INTRODUCTION A wide spectrum of materials is presently available for the innovative product designer. Although the versatility of the various engineering plastics especially fiber reinforced plastics has made a strong impact on material utilization, the metals have defended their strong position as materials for high performance, loaded structures [1]. Magnesium, a density of 2/3 that of aluminium, and little higher than fiber reinforced plastics, combined with excellent mechanical and physical properties as well as processability and recyclability, make magnesium alloys an obvious choice when designing for light weight. Magnesium and its alloys are becoming widely recognized in automotive, aircraft, and also in electronic consumer products with its good electromagnetic shielding characteristics [1],[2]. Commercial cast magnesium alloys for automotive applications are AZ and AM series alloys (AZ91D, AM50A, and AM60B). These alloys offer an excellent combination of

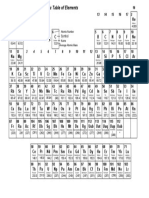

mechanical properties, corrosion resistance, machinability and die-castability. But, they have poor creep resistance above 125 , which makes them inadequate for major powertrain applications. A new improved high performance magnesium alloys, could well be used in the automatic transmission cases, which can operate up to 175 , engine blocks where up to 200 , and engine pistons where even higher than 300 . Creep resistance is a major requirement for use of magnesium in automotive powertrain components that are currently made up of aluminium or cast iron [2]. Present consumption of aluminium and magnesium in passenger cars is 120-140 kg and approximately 5 kg per vehicle respectively [3]. Magnesium in pure form is soft and can only be hardened by deformation. For structural applications a variety of magnesium alloys have been developed. The alloying elements are added both to secure adequate processability of the metal, and to obtain the performance required by the applications [1]. Magnesium is classified as an alkaline earth metal. It is found in Group three of the periodic table. It possesses a similar electronic structure to Beryllium (Be), Calcium (Ca), Strontium (Sr), Barium (Ba) and Radium (Ra) [4]. The alloy elements used for enhancing thermal stability of magnesium alloy mainly consists of rare-earth elements, the alkali soil elements (Ca, Sr, Ba) and the IV,V Race elements such as silicon (Si), tin (Sn), antimony (Sb), bismuth (Bi). These elements can form high melting point compounds with Mg, Al and other alloying element (for example, Zn, Mn, Zr) to realize good thermal stability by dispersion strengthening of alloys [5]. Alloying with Ca in the range from 0.01 to 3% is becoming more common in the development of cheap creep resistant magnesium alloys essentially to replace -Mg17Al12 phase in Mg-Al alloys [4]. Fig.1. shows the direction of new magnesium alloys development based on the required properties for different performance range. This grouping clearly shows that the Ca containing magnesium alloys 88

ISBN: 978-1-4673-4948-2 2013 IEEE

IEEE - International Conference on Research and Development Prospects on Engineering and Technology (ICRDPET 2013) March 29,30 - 2013 Vol.1

participate in many groups such as creep resistance, diecastability and wrought Magnesium alloys [6]. This is the indication of importance of calcium in development of new magnesium alloys.

The ultimate tensile strength and elongation of ZA104 + 0.3Ca alloy are superior to those of ZA104 + 0.6Ca alloy. Tensile properties of ZA104 + 0.3Ca die-casting alloy are comparable to those of AZ91D alloy. Ultimate tensile strength and fracture strain of the two ZA experimental alloys decrease while calcium content increases [8]. III. CREEP PROPERTIES The creep properties of magnesium alloys are mainly related to the structure stability at high temperatures. The creep properties of the Ca-containing Mg-5Zn-5Sn alloys are possibly related to the formation of eutectic and/or primary CaMgSn phase with high thermal stability. With the Ca amount increasing from 0.5% to 1.5%, the amount and size of the CaMgSn phase increase gradually. Ca addition to the Mg5Zn-5Sn alloy does not significantly change the fracture mode of the alloy. The tensile rupture of the experimental alloys occurs along inter-granular boundary, but the cracks seem to extend easily along the interfaces between the coarse primary CaMgSn particle and -Mg matrix which possibly results in the relatively poor mechanical properties of the Mg-5Zn-5Sn1.0Ca and Mg-5Zn-5Sn-1.5Ca alloys [7]. Mg-3Sn-2Ca alloy has more potential as elevated temperature magnesium alloy due to its higher creep properties as compared to Mg-3Sn-1Ca alloy [9]. The microstructure of the Mg-Ca alloys is characterized by the discontinuously distributed primary magnesium phase and Mg2Ca phases. Increase in calcium content decreases the volume fraction of the primary magnesium phase. Mg2Ca is the reason for the creep resistance [10]. In Mg-Al based alloys Mg17Al12 phase is the reason for the poor creep property. Ca suppresses Mg17Al12 phase in AC515 alloy due to the suppression of its generation caused by a strong combination with Ca and Al atoms [11]. The Ca added to AZ91D + 3% Ca alloys forms insoluble Al 2Ca which decreases the amount of Mg17Al12 phase in the matrix. In AZ91D + 5% Ca, Mg17Al12 is not detected, but Al2Ca detected. In AZ91D + 1% CaO alloy Mg17Al12 is detected as the minor phase. In the case of the AZ91D + 10% CaO alloy only -Mg and Al2Ca are detected as the matrix phases [12]. IV. STRENGTHENING MECHANISM Grain refinement is the most desirable strengthening mechanism. The strengthening mechanism of Ca-containing Mg-5Sn-5Zn alloy is mainly attributed to the microstructure refinement and/or the formation of the CaMgSn phase [7]. With the combined addition of 0.5% Ca and 1.0% Y to AZ91 alloy, the grain size in microstructure decreases. Further increasing Ca content can cause the change of microstructure 89

Fig.1. Direction of Mg alloy development to improve the performance [6]

II. MICRO STRUCTURE AND MECHANICAL PROPERTIES The mechanical properties of the pure magnesium can be improved by the addition of alloying elements. Ca addition from 0.5% to 1.5% (mass fraction) in Mg-5Zn-5Sn system increases the yield strength and creep properties of the Cacontaining Mg-5Zn-5Sn alloys. As-cast Mg-5Zn-5Sn alloys are mainly composed of -Mg, CaMgSn, MgZn and Mg2Sn phases. The CaMgSn intermetallics is more easily formed due to the higher electronegative difference value between Ca and Sn elements, while the Mg2Ca intermetallics is less easily formed due to the lower electronegative difference value between Mg and Ca elements. The CaMgSn compound which has a high thermal stability can possibly restrict the growth of -Mg primary phase and secondary solidification phases during solidification. Consequently, the Ca-containing Mg5Zn-5Sn alloys obtain finer microstructures than the Mg-5Zn5Sn alloy. This improves the tensile properties both at room temperature and at 150 , which is beneficial to the creep properties. Among the Ca-containing Mg-5Zn-5Sn alloys, the alloy added 1.5% Ca exhibits the optimum yield strength and creep properties, however, the maximum ultimate tensile strength of 174.7MPa and elongation of 4.79% at room temperature and ultimate tensile strength of 147.9MPa and elongation of 14.21 % at 150 are achieved in the alloy added with 0.5% Ca [7]. Mg-3Sn-1Ca alloy shows higher ultimate tensile strength and elongation at room temperature (138MPa) and at 150 (120MPa) than Mg-3Sn-2Ca alloy with 127MPa at room temperature and 116MPa at 150 . However, the yield strength of the Mg-3Sn-1Ca alloy is 101MPa at room temperature and 82MPa at 150 , which is lower than that of Mg-3Sn-2Ca alloy having yield strength of 112MPa and 104MPa respectively [9].

ISBN: 978-1-4673-4948-2 2013 IEEE

Effects of Calcium Addition on Properties of Mg Alloys: A Review

from dentritic to equiaxed. When 1.5% Ca and 1.0% Y are added to AZ91 alloy, the grains are remarkably refined, and the average grain size is 2030 m. the grain refinement may be the result of the formation of new particles that can act as potent nucleation sites for magnesium [13]. Micro-hardness of Mg-Zn-Ca system increases with the increase in Ca content and age hardening occurs after aging at 200 in the flakes probably due to the precipitation strengthening of the fine precipitates Mg2Ca and Ca2Mg6Zn3[14]. The combined addition of Y and Ca can refine the as-diecast microstructure, result in the formation of Al2Ca phase and Al2Y phase, and inhibit the precipitation of Mg17Al12 phase. The combined addition of Y and small amount of Ca has little influence on the ambient temperature tensile properties, but increasing the content of Ca can improve significantly the tensile strength at both ambient and elevated temperatures. In AZ91-1Y alloy, formation of coarse block and rod-like Al2Y phase are seen. The increase of ambient ultimate tensile strength of AZ91-1Y-1.5Ca alloy is due to microstructure improvement, refinement of Al2Y phases and dispersion strengthening with Al2Ca phases and Al2Y phases. Unfortunately, the combined addition of Y and Ca can decrease the elongation at 150 [13]. V. CORROSION In spite of the great advantages of magnesium alloys, their application as engineering material is still restricted by their high susceptibility to corrosion [15]. Magnesium is highly resistant to alkalies, chromic and hydrofluoric acids. But it is less resistant to other acidic or salt-laden environments. Magnesium is anodic to any other structural metal and will be preferentially attacked in the presence of an electrolyte [16]. Adding Ca to AZ91 magnesium can refine the microstructure, improve the elevated temperature properties and the corrosion resistance of magnesium alloys [17]. AsCast AZ91 magnesium alloy containing 0.14 wt.% Ca consists of -Mg17Al12, Mg17Al8Ca0.5 and Mg2Ca. When the alloys are exposed to 3.5% NaCl solution no corrosion attack is observed in Mg17Al8Ca0.5 and Mg2Ca phases [18]. On other hand addition of calcium to the Mg6% Zn1% Mn5% Si alloy decreases the corrosion resistance [19]. VI. DAMPING PROPERTIES The structural materials required to withstand the intended load and also required to absorb shock load occasionally. Pure magnesium has the better damping properties among various metallic materials. As-cast Mg1 wt%Ca binary alloy exhibits good damping capacities. The damping curve of Mg1 wt%Ca

alloy is close to high damping pure magnesium, while it is much higher than AZ91D alloy, which indicates that Mg1 wt%Ca alloy exhibits good damping capacity. Mg1 wt%Ca alloy could be considered as a potential candidate for high damping magnesium alloy. But further increase in Ca content in MgCa binary alloy exhibits the lower damping capacities [20]. VII. CAST ABILITY

Magnesium alloys, especially those with aluminium as a major alloying element show a very good castability [6]. In magnesium alloy casting, the viscosity of the molten metal is increases clearly with increasing the amount of Ca addition and firmer surface oxide film is formed by Ca addition. The flow length is shortened by Ca addition on the effect of the above factors [11]. Ca can be introduced in magnesium alloy casting as Mg-Ca master alloy. Mg-Ca master alloys are commercially available in 15, 20 and 30% Ca. Recommended addition temperatures for these master alloys depend on the Ca content and range from 680 720C. Dissolution or mixing time of 1530 minutes after the addition is recommended. Recoveries are quite high around 8090% under fluxless alloying conditions. As mentioned above, standard magnesium fluxes react with calcium so flux free melt protection is the preferred method for Ca addition [4]. Ca addition to the Mg-5Zn-5Sn alloy can result in the micro structural refinement of the alloy. It is well known that the Ca atom has a larger atomic radius than the Zn and Sn atoms (Ca: 0.197 nm; Zn: 0.131 nm; Sn: 0.141 nm), with the Ca addition to the Mg-5Zn-5Sn alloy, the Ca element is mainly rich in the solid-liquid interface during solidification [7]. More than about 1% Ca addition to AM50 alloy significantly improves creep resistance. It is accompanied by a tendency to hot cracking. By the addition of approximately 0.2%Sr, such casting cracks are significantly suppressed, and besides the enhancement in creep resistance and mechanical properties. The improvement of creep resistance by Sr addition seems to be attributed to the suppression of grain boundary sliding due to the creation of thermally stable Al-Sr compound along the grain boundary and the suppression of discontinuous precipitation of Mg17Al12 phase [4],[11].

VIII. OXIDATION AND IGNITION RESISTANCE A. Oxidation The interaction of oxygen with base metal forms the oxide layer. PillingBedworth principle of oxidation is the condition of oxidation film on the surface of the oxidizing metal. The PillingBedworth ratio () is the ratio of the oxide volume to 90

ISBN: 978-1-4673-4948-2 2013 IEEE

IEEE - International Conference on Research and Development Prospects on Engineering and Technology (ICRDPET 2013) March 29,30 - 2013 Vol.1

the volume of the original metal which is consumed to form the oxide. When > 1, oxide can expand to bring compressive stress, under the action of which the oxidation film becomes tightly coherent. The value of magnesium is 0.81, so the MgO film is loose and there are a lot of small holes on oxidation film which allows oxygen infiltrating into the molten alloy [21],[22],[23]. The surface changes, of pure magnesium during casting and solidification under ambient atmosphere without any protective gas, are seen such as severe oxidation begins and tarnished surface appears in 10 seconds just after being poured. Severe burning starts in 10 seconds and continues even with white flame to the point when all melts [5]. Ca strongly improves oxidation performance. As little as 1% of Ca is enough to reduce the oxidation rate to extremely low values, even for longer oxidation times. Rare earths (added in the form of mischmetal) are not as effective as Ca, and slightly higher contents are necessary to achieve similar performance [15]. Elements with high affinity to oxygen such as Ca, Sr or Zr enhance the formation of a thin and uniform oxide layer and prevent growth of thick nodular oxide features [24]. B. Ignition The lowest temperature associated with the observation of a flame is called Ignition temperature. Ignition also defined as the temperature at which an exothermic oxidation reaction becomes self-sustaining at a rate which causes a significant temperature increase. The ignition temperature measurement is critical when the heat accumulates in the specimen [25], [26]. In the case of magnesium machining, most of the energy put into cutting processes is converted into heat, this leads to a risk of fire due to chip ignition [4]. Surface changes, of Mg alloy with 0.3wt% CaO during casting and solidification under ambient atmosphere without any protective gas, see no burning appears and shiny surfaces are maintained even after the solidification is completely stopped. The similar phenomena occurs in AZ310.27wt%CaO, AM50-0.27wt%CaO, AM60-0.3wt%CaO, and AZ91-0.27wt%CaO magnesium alloys [5]. The ignition point of AZ91 alloy increases linearly with the increase of Ca content. The data of ignition points of Cabearing AZ91 alloys can be fit as a linear equation: (1) Where is the ignition point in and x is the analyzed content of Ca (mass fraction, %) in AZ91 alloy. Ca-bearing AZ91 alloys are in agreement with linear equation when the

content of Ca is lower than 1.3% (analyzed content). When the content is higher than 1.3%, the ignition temperature is unstable. The minimum ignition temperature is higher than 770 and some of the alloys do not burn up to 900 . The testing results of ignition points of Ca-bearing AZ91 alloys imply that the proper addition of Ca is effective to improve the ignition point of AZ91 alloy up to 770 , but at a higher temperature the ignition of AZ91 cannot entirely be inhibited by addition of Ca [27]. The ignition point of Mg-5Ca alloy is about 1,030 .The average ignition point of Mg-5Ca powder in the size range of 150-250 m, is 685 , this average ignition temperature increases with the increasing particle size [11]. IX. DEVELOPMENT OF ECO MAGNESIUM ALLOY As environmental benefits provided by lightweight, being unlimited, and recyclable, magnesium alloys have the potential to grow significantly in the future by Eco-Mg (Environment Conscious Magnesium) approach. The simple and plain approach of Eco-Mg alloy is to introduce CaO particles in the range of 0.3wt% to 0.7wt% as an ingredient into conventional cast and wrought magnesium alloys for (1) nonSF6 process, (2) Be elimination, (3) improved melt cleanliness, (4) ensured original process adjustability for casting, forming, joining as well as surface treatment, (5) improved mechanical property by grain refinement and internal soundness, (6) ensured safety during manufacturing and application by raising oxidation and ignition resistances of machined chips and products, and (7) improved recyclability. CaO of over 0.5~0.7wt% can be introduced for special purposes to develop creep-resistant, fire-retardant or fire-proof magnesium alloys [5]. It is confirmed that CaO is reduced to Ca through phase analysis. Mg2Ca phase is formed even in 0.07% CaO added pure magnesium by reduction, while Mg2Ca phase is formed over 1.35% in Ca added magnesium. With respect to CaO content, the hardness of CaO added pure magnesium increased by grain refinement [28]. X. RECYCLABILITY Ca content in magnesium alloys disappears during recycling due to the reaction of Ca with the fluxes so flex free melt protection is recommended for Ca addition[4]. In a fluxed magnesium melting process, a suitable flux also can minimize the reduction of Ca content during recycling for Ca added magnesium alloys. KCl and NaCl are the suitable fluxes for magnesium alloys with Mg2Ca or Al2Ca phases without Ca content loss [5]. XI. SUMMARY AND CONCLUSIONS The research in the area of Ca addition on Properties of 91

ISBN: 978-1-4673-4948-2 2013 IEEE

Effects of Calcium Addition on Properties of Mg Alloys: A Review

magnesium alloy is summarized as follows: 1) In Mg-Al based alloys Mg17Al12 phase is the reason for the poor creep property. Ca suppresses Mg17Al12 phase in AC515 and AZ91D + 3% Ca alloys forms insoluble Al2Ca which decreases the amount of Al12Mg17 phase in the matrix. 2) Ca addition from 0.5% to 1.5% (mass fraction) increases the yield strength and creep properties of the Cacontaining Mg-5Zn-5Sn alloys. The maximum ultimate tensile strength of 174.7MPa and elongation of 4.79% at room temperature and ultimate tensile strength of 147.9MPa and elongation of 14.21% at 150 are achieved in the alloy added with 0.5% Ca. 3) Increasing Ca content in magnesium alloys enhances the grain refinement and also change of microstructure from dentritic to equiaxed. When 1.5% Ca and 1.0% Y are added to AZ91 alloy, the grains are remarkably refined, and the average grain size is 2030 m. 4) Ca addition of more than about 1% to AM50 alloy significantly improves creep resistance but increases the cast cracking tendency. By the addition of approximately 0.2%Sr, casting cracks are significantly suppressed, and besides increasing the creep resistance and mechanical properties. 5) The fluidity of the molten metal decreases with increasing the amount of Ca addition. 0.07% CaO added pure magnesium is reduced to Ca forming Mg2Ca phase, while Mg2Ca phase is formed over 1.35% in Ca added magnesium. So Ca can be effectively added to magnesium alloys in the form of CaO. REFERENCES

[1] H. WESTENGEN, Magnesium alloys for structural applications ; recent advances, J. Phys. IV France, vol. 03, no. C7, pp. C7 -491C7501, 1993. Z. YANG, J. LI, J. ZHANG, G. LORIMER, and J. ROBSON, Review on Research and Development of Magnesium Alloys, Acta Metallurgica Sinica (English Letters), vol. 21, no. 5, pp. 313 328, 2008. T. Ramachandran, P. Sharma, and K. Balasubramanian, Grain Refinement of Light Alloys, 68th WFC - World Foundry Congress, pp. 189193, 2008. B.L. Horst E.Friedrich, Ed, Magnesium Technology: Metallurgy, Design Data,Applications, 2006. Frank Czerwinski, Ed, Magnesium Alloys - Design, Processing and Properties, 2011. Blawert, C., Hort, N., and Kainer, K., AUTOMOTIVE APPLICATIONS OF MAGNESIUM AND ITS ALLOYS, Trans. Indian Inst. Met., vol. 57, no. 4, pp. 397 408, 2004. M. YANG, L. CHENG, and F. PAN, Effects of calcium addition on as cast microstructure and mechanical properties of Mg-5Zn-5Sn alloy, Transactions of Nonferrous Metals Society of China, vol. 20, no. 5, pp. 769775, 2010. Zhang, Z., Tremblay, R., and Dub, D., Microstructure and mechanical properties of ZA104 (0.3 0.6Ca) die-casting magnesium alloys,

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[2]

[23]

[3]

[4] [5] [6]

[24]

[25]

[7]

[26]

[8]

Materials Science and Engineering: A, vol. 385, no. 1-2, pp. 286291, 2004. M.YANG, L.CHENG, and F.PAN, Comparison of as -cast microstructure, tensile and creep properties for Mg-3Sn-1Ca and Mg3Sn-2Ca magnesium alloys, Transactions of Nonferrous Metals Society of China, vol. 20, no. 4, pp. 584 589, 2010. Shibayama, Y. Terada, Y. Mura ta, and M. Morinaga, Creep Behavior of Hypoeutectic Mg-Ca Binary Alloys, MATERIALS TRANSACTIONS, vol. 51, no. 12, pp. 2284 2288, 2010. T. Dunqiang, Y. Xiaoxia, Z. Yijie, and X. Dongfei, On ignition point of Mg-Ca alloy under nitrogen atmosphere, CHINA FOUNDRY, vol. 8, no. 3, pp. 282285, 2011. D.B. Lee, L.S. Hong, and Y.J. Kim, Effect of Ca and CaO on the High Temperature Oxidation of AZ91D Mg Alloys, MATERIALS TRANSACTIONS, vol. 49, no. 5, pp. 1084 1088, 2008. F. WANG, Y. WANG, P. MAO, B.Y. YU, and Q .Y. GUO, Effects of combined addition of Y and Ca on microstructure and mechanical properties of die casting AZ91 alloy, Transactions of Nonferrous Metals Society of China, vol. 20, pp. s311 s317, 2010. T. Zhou, D. CHEN, and Z.H. CHEN, Microstructures a nd properties of rapidly solidified Mg-Zn-Ca alloys, Transactions of Nonferrous Metals Society of China, vol. 18, no. 1, pp. s101 s106, 2008. D. Eliezer and H. Alves, CORROSION AND OXIDATION OF MAGNESIUM ALLOYS, in Handbook of materials selection, M. Kutz, Ed, New York, N.Y: Wiley, 2002, pp. 267 291. Robert S. Busk, MAGNESIUM AND ITS ALLOYS, 2002. In Handbook of materials selection, ed. Myer Kutz, 259 65. New York, N.Y: Wiley. SUN Yang-shan, ZHANG Wei-min, MIN Xue-gang. Tensile strength and creep resistance of Mg-9Al-1Zn based alloys with calcium addition [J]. Acta Metallurgica Sinica, 2001, 14(5): 330334. Zhou, W., Aung, N. N., and Sun, Y., Effect of antimony, bismuth and calcium addition on corrosion and electrochemical behaviour of AZ91 magnesium alloy, Corrosion Science, vol. 51, no. 2, pp. 403408, 2009. Ben-Hamu, G., Eliezer, D., and Shin, K., The role of Si and Ca on new wrought MgZnMn based alloy, Materials Science and Engineering: A, vol. 447, no. 1-2, pp. 3543, 2007. Wan, D., Wang, J., Lin, L., Feng, Z., and Yang, G., Damping properties of MgCa binary alloys, Physica B: Condensed Matter, vol. 403, no. 13-16, pp. 24382442, 2008. J. Rao and H. Li, Oxidation and ignition behavior of a magnesium alloy containing rare earth elements, In t J Adv Manuf Technol, vol. 51, no. 1-4, pp. 225231, 2010. J.S. Rao, H.J. Li, and H.S. Xue, Ignition -proof mechanism of ZM5 magnesium alloy added with rare earth, J. Cent. South Univ. Technol, vol. 17, no. 1, pp. 28 33, 2010. F. Czerwinski, THE OXIDAT ION OF MAGNESIUM ALLOYS IN SOLID AND SEMISOLID STATES, in Magnesium technology 2003: Proceedings of the jointly sponsored by the Magnesium Committee of the Light Metals Division (LMD) and the Solidification Committee of the Materials Processing and Manufacturing Division of TMS (the Minerals, Metals & Materials Society) with the International Magnesium Association held during the 2003 TMS Annual Meeting in San Diego, California, U.S.A, March 2-6, 2003, Warrendale Pa: TMS, 2003, pp. 39 42. F. Czerwinski, T he early stage oxidation and evaporation of Mg 9%Al1%Zn alloy, Corrosion Science, vol. 46, no. 2, pp. 377386, 2004. Ravi Kumar, N., BLANDIN, J., SURY, M., and Grosjean, E., Effect of alloying elements on the ignition resistance of magnesium alloys, Scripta Materialia, vol. 49, no. 3, pp. 225 230, 2003. Prasad, A., Shi, Z., and Atrens, A., Influence of Al and Y on the ignition and flammability of Mg alloys, Corrosion Science, vol. 55, pp. 153163, 2012.

92

ISBN: 978-1-4673-4948-2 2013 IEEE

IEEE - International Conference on Research and Development Prospects on Engineering and Technology (ICRDPET 2013) March 29,30 - 2013 Vol.1

[27] S. CHENG, G. YANG, J.F. FAN, Y.J. LI, and Y.H. ZHOU, Effect of Ca and Y additions on oxidation behavior of AZ91 alloy at elevated temperatures, Transactions of Nonferrous Metals Society of China, vol. 19, no. 2, pp. 299304, 2009. [28] S.H. Ha, J.K. Lee, and S.K. Kim, Effect of CaO on Oxidation Resistance and Microstructure of Pure Mg, MATERIALS TRANSACTIONS, vol. 49, no. 5, pp. 1081 1083, 2008.

93

ISBN: 978-1-4673-4948-2 2013 IEEE

You might also like

- Machine Drawing Question Paper 2011 AprDocument4 pagesMachine Drawing Question Paper 2011 AprGunabalan SellanNo ratings yet

- Advance Welding TechniqueDocument4 pagesAdvance Welding TechniqueGunabalan SellanNo ratings yet

- Machine Drawing Question Paper 2012 NovDocument3 pagesMachine Drawing Question Paper 2012 NovGunabalan SellanNo ratings yet

- Machine Drawing Question Paper 2013 AprDocument3 pagesMachine Drawing Question Paper 2013 AprGunabalan SellanNo ratings yet

- Machine Drawing Question Paper 2012 AprDocument3 pagesMachine Drawing Question Paper 2012 AprGunabalan SellanNo ratings yet

- Machine Drawing Question Paper 2014 AprDocument3 pagesMachine Drawing Question Paper 2014 AprGunabalan SellanNo ratings yet

- 04 Part1 General Thermodynamic PropertiesDocument20 pages04 Part1 General Thermodynamic PropertiesGunabalan SellanNo ratings yet

- Concepts in Machine DrawingDocument12 pagesConcepts in Machine DrawingGunabalan SellanNo ratings yet

- Machine Drawing Question Paper 2009-AprDocument2 pagesMachine Drawing Question Paper 2009-AprGunabalan SellanNo ratings yet

- 05 Part2 Steady Flow Analysis of Reacting MixturesDocument12 pages05 Part2 Steady Flow Analysis of Reacting MixturesGunabalan SellanNo ratings yet

- 05 Part3 Heating ValueDocument5 pages05 Part3 Heating ValueGunabalan SellanNo ratings yet

- 04 Thermodynamic RelationDocument1 page04 Thermodynamic RelationGunabalan SellanNo ratings yet

- Pondicherry University Big Questions in Machine DrawingDocument8 pagesPondicherry University Big Questions in Machine DrawingGunabalan SellanNo ratings yet

- 05 Part1 Combustion ReactionsDocument19 pages05 Part1 Combustion ReactionsGunabalan SellanNo ratings yet

- 02 Part3 Work Heat Transfer First LawDocument43 pages02 Part3 Work Heat Transfer First LawGunabalan SellanNo ratings yet

- 03 Part2 Charging and Discharging RigidDocument33 pages03 Part2 Charging and Discharging RigidGunabalan SellanNo ratings yet

- 03 Part3 Availability IrreversibilityDocument23 pages03 Part3 Availability IrreversibilityGunabalan SellanNo ratings yet

- 02 Part5 Energy BalanceDocument17 pages02 Part5 Energy BalanceGunabalan SellanNo ratings yet

- 02 Part6 Energy BalanceDocument28 pages02 Part6 Energy BalanceGunabalan SellanNo ratings yet

- 02 Part7 Second Law ThermodynamicsDocument12 pages02 Part7 Second Law ThermodynamicsGunabalan SellanNo ratings yet

- 02 Part2 Thermo Laws First LawDocument5 pages02 Part2 Thermo Laws First LawGunabalan SellanNo ratings yet

- 02 Part1 Thermo Laws Zeroth LawDocument14 pages02 Part1 Thermo Laws Zeroth LawGunabalan SellanNo ratings yet

- 05 Combustion ReactionDocument2 pages05 Combustion ReactionGunabalan SellanNo ratings yet

- 03 Part1 General Conservation of Energy and Mass Principles For Control VolumeDocument19 pages03 Part1 General Conservation of Energy and Mass Principles For Control VolumeGunabalan SellanNo ratings yet

- 02 Part4 Work Heat Transfer First Law ProbDocument10 pages02 Part4 Work Heat Transfer First Law ProbGunabalan SellanNo ratings yet

- 02 Laws ThermodynamicsDocument4 pages02 Laws ThermodynamicsGunabalan SellanNo ratings yet

- 03 Irreversibility AvailabilityDocument1 page03 Irreversibility AvailabilityGunabalan SellanNo ratings yet

- APPLIED THERMODYNAMICS - Definitions-Unit - I - Ideal and Real Gas EquationDocument2 pagesAPPLIED THERMODYNAMICS - Definitions-Unit - I - Ideal and Real Gas EquationGunabalan SellanNo ratings yet

- 01-Properties of Pure SubstancesDocument2 pages01-Properties of Pure SubstancesGunabalan SellanNo ratings yet

- 01-Ideal and Real Gas EquationDocument3 pages01-Ideal and Real Gas EquationGunabalan SellanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Which Element Am I? Directions: ArgentumDocument3 pagesWhich Element Am I? Directions: ArgentumdianaNo ratings yet

- Metals and Non-Metals Assignment (Solved)Document4 pagesMetals and Non-Metals Assignment (Solved)Hitesh Alwadhi0% (1)

- UTP MaintenanceDocument28 pagesUTP MaintenanceAnonymous PkAjjOZBNo ratings yet

- Aluminium Alloy 5083H111 Data SheetDocument1 pageAluminium Alloy 5083H111 Data Sheetpvssrh9929No ratings yet

- Investment Opportunities in Exploration & Production - Strategic and Critical MineralsDocument34 pagesInvestment Opportunities in Exploration & Production - Strategic and Critical MineralsCenk GultekinNo ratings yet

- PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaDocument2 pagesPT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaReksiNo ratings yet

- Home Made Concrete StainDocument4 pagesHome Made Concrete StainAmir Shaik100% (1)

- Week 4 ExerciseDocument3 pagesWeek 4 ExerciseJohnNo ratings yet

- 2009 H2 Chemistry Paper 2 (MCQ) + AnsDocument11 pages2009 H2 Chemistry Paper 2 (MCQ) + AnsIliyana IliNo ratings yet

- Phosphoric AcidDocument3 pagesPhosphoric AcidhussainNo ratings yet

- A890 4A, A995 4A, CD3MN - Alloy Casting FoundryDocument3 pagesA890 4A, A995 4A, CD3MN - Alloy Casting FoundrySwapnil ShahNo ratings yet

- Balancing Equations: Practice ProblemsDocument10 pagesBalancing Equations: Practice ProblemsSheryl Nishmae Bernardo SantosNo ratings yet

- ChemDocument17 pagesChemTiviya Tarini ManiamNo ratings yet

- Study of Constituents of An AlloyDocument9 pagesStudy of Constituents of An AlloyShrikant ShendyeNo ratings yet

- General Chemistry/Principles of General: Final ExaminationDocument10 pagesGeneral Chemistry/Principles of General: Final Examinationmuhammad safuanNo ratings yet

- Etching SolutionsDocument4 pagesEtching SolutionsedhykoesNo ratings yet

- Jadual Berkala UnsurDocument1 pageJadual Berkala Unsurkhadijah madhadzirNo ratings yet

- The Identification of Unknown Compound Lab ReportDocument5 pagesThe Identification of Unknown Compound Lab Reportwgoodin0% (1)

- Extracting Bromine From Sea WaterDocument4 pagesExtracting Bromine From Sea WaterRaja Ji100% (2)

- Argon Recovery From Silicon Crystal FurnaceDocument7 pagesArgon Recovery From Silicon Crystal FurnaceasdfqwerNo ratings yet

- Merck Photocatalysis ChartDocument1 pageMerck Photocatalysis ChartRagav GNo ratings yet

- Chapter 5 and 6 TestDocument9 pagesChapter 5 and 6 Testshahinazs100% (1)

- Inventario A 30 SeptiembreDocument6 pagesInventario A 30 SeptiembreAlexandra LopezNo ratings yet

- Afrox Subarc 347: Back To Section 12Document2 pagesAfrox Subarc 347: Back To Section 12Branko FerenčakNo ratings yet

- Pasivasi: Dr. ISMOJO, S.T., M.TDocument7 pagesPasivasi: Dr. ISMOJO, S.T., M.TIndra SuryaNo ratings yet

- Smarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaDocument251 pagesSmarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaAvinash SiwachNo ratings yet

- Kyambogo UniversityDocument16 pagesKyambogo UniversityAodi NabothNo ratings yet

- Worksheet LR - ERDocument3 pagesWorksheet LR - ERTanvi GandhiNo ratings yet

- Chemical Analysis of Steels: Indian Standard " Methods ForDocument5 pagesChemical Analysis of Steels: Indian Standard " Methods ForMuthusamy ArumugamNo ratings yet

- CN 15 en 05Document19 pagesCN 15 en 05Toni D.No ratings yet