Professional Documents

Culture Documents

1 s2.0 S1110016811000093 Main

Uploaded by

Pavan KishoreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S1110016811000093 Main

Uploaded by

Pavan KishoreCopyright:

Available Formats

ORIGINAL ARTICLE

Optimum design of B-series marine propellers

M.M. Gaafary

*

, H.S. El-Kilani, M.M. Moustafa

Naval Architecture and Marine Eng. Dept., Faculty of Engineering, Port Said University, Egypt

Received 19 December 2009; accepted 24 July 2010

Available online 5 March 2011

KEYWORDS

Optimization;

Single objective;

B-Series propeller

Abstract The choice of an optimum marine propeller is one of the most important problems in

naval architecture. This problem can be handled using the propeller series diagrams or regression

polynomials. This paper introduces a procedure to nd out the optimum characteristics of B-series

marine propellers. The propeller design process is performed as a single objective function subjected

to constraints imposed by cavitation, material strength and required propeller thrust. Although

optimization software of commercial type can be adopted to solve the problem, the computer pro-

gram that has been specially developed for this task may be more useful for its exibility and pos-

sibility to be incorporated, as a subroutine, with the complex ship design process.

2011 Faculty of Engineering, Alexandria University. Production and hosting by Elsevier B.V.

All rights reserved.

1. Introduction

Naval architects can easily design an optimized propeller with

the theoretical propeller design methods (lifting-line/surface

theories) using a computer without the geometry constraints

seen in series propellers [1]. However, series propellers are still

valuable; they are still widely used in the preliminary design of

light or moderately loaded propellers [2]. Moreover, for those

who cannot afford lifting surface software, traditional series

propellers are good choices. Among the propeller series, the

B-series is one of the commonly used series.

In this study, a computer program has been specially devel-

oped to nd the optimum characteristics of any B-series pro-

peller. The propeller design process is handled as a single

objective function subjected to several constraints such as cav-

itation, material strength and the required propeller thrust.

2. Optimization problem

The main difculty in most optimization problems does not lie

in the mathematics or methods involved. It lies in formulating

the objective all the constraints.

The propeller design problem has been handled as a multi-

objective constrained optimization problem [14]. There are

two principal ways to handle multi-objective problems, both

leading to single objective optimization problems [5]:

one objective is selected and the other objectives are formu-

lated as constraints.

*

Corresponding author.

E-mail address: hebaelkilani@gmail.com (M.M. Gaafary).

1110-0168 2011 Faculty of Engineering, Alexandria University.

Production and hosting by Elsevier B.V. All rights reserved.

Peer review under responsibility of Faculty of Engineering, Alexandria

University.

doi:10.1016/j.aej.2011.01.001

Production and hosting by Elsevier

Alexandria Engineering Journal (2011) 50, 1318

Alexandria University

Alexandria Engineering Journal

www.elsevier.com/locate/aej

www.sciencedirect.com

a weighted sum of all objectives forms the optimization

objective function.

The rather arbitrary choice of weight factors makes the

optimization model obscure and the rst option is mostly

preferred [5]. In this study, the propeller design problem is han-

dled as a constrained optimization problem according to the

rst option.

Any constrained optimization problem can be handled

according to the optimization model shown in Fig. 1.

This optimization problem can be formulated as follows [6]:

Find X

x

1

x

2

.

.

.

x

m

_

_

_

_

1

which maximizes an objective function called f(X) subjected to

the following constraints:

g

j

X 6 0; j 1; 2; . . . ; q

and

j

X 0; j q 1; q 2; . . . ; p

_

_

2

where, g

j

(X) and

j

(X) are the inequality and the equality con-

straints, respectively.

3. B-series propeller

B-series propellers were developed in the Netherlands Ship

Model Basin, and the section of the blade was improved later.

For any B-series propeller, the thrust and torque coefcients

can be expressed as functions of the blade number (Z), blade

Nomenclature

A

E

propeller expanded area, m

2

A

O

propeller disk area, m

2

C

0.75R

blade chord length at 0.75R, m

C

mi

regression coefcient of torque coefcient

C

si

regression coefcient of thrust coefcient

D propeller diameter, m

H

PAP

height of propeller aperture, m

J advance coefcient

K

Q

torque coefcient

K

T

thrust coefcient

N propeller rotating speed, rpm N = 60 \ n

N

P

number of propellers

n propeller rotating speed, rps

M number of the design variables

P propeller blade pitch, m

P

CL

propeller immersion, m

P

D

developed power, kW

P

S

shaft power per blade, kW

P

O

static pressure at the centerline of the propeller

shaft, Pa

P

V

vapor pressure, Pa

P total number of constraints

q number of inequality constraints

Rn Reynolds number

R

T

ship total resistance, N

S

C

maximum allowable stress of the propeller

material, MPa

si exponent of (J) in K

T

equation

si

0

exponent of (J) in K

Q

equation

T propeller thrust, N

T

Cal

calculated propeller thrust, N

T

R

required propeller thrust, N

T propeller blade thickness, m

t

d

thrust deduction

ti exponent of (P/D) in K

T

equation

ti

0

exponent of (P/D)in K

Q

equation

t

min

minimum thickness of propeller blade, m

ui exponent of A

E

/A

O

in K

T

equation

ui

0

exponent of A

E

/A

O

in K

Q

equation

V

A

speed of advance, m/sec

V

S

ship speed, m/sec

Vi exponent of Z in K

T

equation

Vi

0

exponent of Z in K

Q

equation

w wake fraction

Z number of propeller blades

DK

Q

correction of torque coefcient

DK

T

correction of thrust coefcient

g propeller efciency

g

max

maximum propeller efciency

q water density, kg

m

/m

3

m water kinematic viscosity, m

2

/s

Start

New Design

Feasibility Check of the Design

Objective Function Evaluation

Analysis of the results

Optimum

Design Reached

No

Yes

End

Figure 1 Optimization model for constrained problems.

14 M.M. Gaafary et al.

area ratio (A

E

/A

O

), pitch ratio (P/D), and advance coefcient

(J) as follows:

K

T

39

i1

C

si

J

si

P

D

_ _

ti

A

E

A

O

_ _

ui

Z

vi

3

and,

K

Q

47

i1

C

mi

J

si

0 P

D

_ _

ti

0 _

A

E

A

O

_

ui

0

Z

vi

0

4

where, C

si

and C

mi

are the regression coefcients of the thrust

and torque coefcients, respectively. The values of the coef-

cients and exponents involved in Eqs. (3) and (4) are given in [7].

If Reynolds number of a propeller at 0.75R is greater than

2 \ 10

6

, corrections to the thrust and torque coefcients must

be taken into consideration [1].

Rn

0:75R

C

0:75R

V

2

A

0:75p n D

2

_

m

5

where, C

0.75R

is the blade chord length at 0.75R and V

A

is the

advance velocity (m/s).

3.1. Objective function

The most common objective function, for the optimum marine

propellers, is the propeller maximum efciency (g

max

) [8]. The

efciency of marine propellers can be computed as follows:

g

J

2p

K

T

K

Q

6

3.2. Constraints

3.2.1. Cavitation constraint

Cavitation could affect a propellers performance and needs to

be considered in the propeller design process. A simple way to

avoid cavitation is to increase blade area ratio. The minimum

blade area ratio required to avoid cavitation was suggested by

Keller [1] as follows:

A

E

A

O

_ _

min

1:3 0:3ZT

P

O

P

V

D

2

K 7

where, (A

E

/A

O

)

min

is the minimum expanded area ratio. The

coefcient K equals 0.1 for twin-screws ships, and 0.2 for sin-

gle-screw ships.

3.2.2. Strength constraint

To achieve adequate blade thickness and thus ensure material

strength, the following formula can be used to determine the

minimum ratio of blade thickness at 0.7R to the diameter [4]:

t

min

D

_ _

0:7R

0:0028 0:21

3183:87 1508:15P=DP

S

1266652:04nD

3

S

C

20:9D

2

n

2

8

where, (t

min

/D)

0.7R

is the minimum propeller blade thickness

ratio at 0.7R.

According to the B-series propeller geometry [7], the ratio

of maximum thickness of propeller blade at each section to

the propeller diameter is given as shown in Table 1.

As shown in table 1, the ratio of maximum thickness of pro-

peller blade at 0.7R to the diameter is given as follows:

t

D

_ _

0:7R

0:0171 for Z 3

0:0156 for Z 4

0:0141 for Z 5

_

_

9

Using Eq. (8) and the geometry of B-series propellers, the

required propeller blade thickness can be obtained as follows:

t

D

_ _

0:7R

P

t

min

D

_ _

0:7R

10

3.2.3. Thrust constraint

The calculated propeller thrust (T

Cal

) must be equal to the re-

quired thrust (T

R

). The propeller thrust can be calculated as

follows:

T

CAL

K

T

q n

2

D

4

11

T

R

R

T

N

P

1 t

d

12

where, R

T

is the ship total resistance, N

P

is the number of pro-

pellers and t

d

is the thrust deduction.

4. Developed computer program

A computer program has been specially developed to nd the

optimum characteristics of any B-series propellers. This pro-

gram starts with an initial feasible point and proceeds towards

the optimum point according to the steps shown in Fig. 1. The

detailed procedure of this program is summarized in the ow

chart shown in Fig. 2.

5. Case study

The problem is to nd the optimum characteristics (D, A

E

/A

O

,

P/D, J) of four bladed B-type propeller of a twin screw ship.

The propeller diameter (D) is restricted at specied value to

suit the ship lines and to provide acceptable hull clearances

to avoid hull vibration. Ship speed (V

S

) and corresponding

resistance (R

T

) are given for this design condition. Wake frac-

tion (w) and thrust deduction (t

d

) are given for this design con-

dition. This problem can be formulated as follows:

Table 1 Maximum blade thickness % of D for B-series

propellers.

r/R Max. blade thickness (% of D)

Z = 3 Z = 4 Z = 5

0.2 4.06 3.66 3.26

0.3 3.59 3.24 2.89

0.4 3.12 2.82 2.52

0.5 2.65 2.40 2.15

0.6 2.18 1.98 1.78

0.7 1.71 1.56 1.41

0.8 1.24 1.14 1.04

0.9 0.77 0.72 0.67

1.0 0.30 0.30 0.30

Optimum design of B-series marine propellers 15

Figure 2 Flow chart for B-series marine propellers design process.

16 M.M. Gaafary et al.

Use the input data which are shown in Table 2 to nd

(D, A

E

/A

O

, P/D, J) which maximize the propeller efciency

(g) when subjected to the following constraints:

Cavitation constraint: the expanded area ratio should be

larger than a minimum value in order to avoid cavita-

tion, (A

E

/A

O

) P(A

E

/A

O

)

min

where (A

E

/A

O

)

min

can be

calculated using Eq. (7).

Thrust constraint: the calculated propeller thrust (T

cal

)

has to match the design requirement, as follows:

T

cal

= T

required

.

Strength constraint: to ensure adequate material

strength, a minimum propeller blade thickness is

required, as shown in Eq. (8).

t

D

_ _

0:7R

>

t

min

D

_ _

0:7R

Boundary constraint: to obtain an optimum design

point, the design variables must lie in an acceptable

domain.

In this part, the problem under consideration is carried out

in details by using the following techniques:

Using the developed computer program.

Using a commercial software (Lingo).

Table 2 Input data.

Ship total resistance (R

T

) 35000.0

Ship speed (V

S

) 10.289

Number of propellers (N

P

) 2

Number of propeller blades (Z) 4

Height of propeller aperture (H

PAP

) 1.25

Propeller immersion (P

CL

) 2.0

Wake fraction (w) 0.20

Thrust deduction (t

d

) 0.15

Max. allowable stress of propeller material (S

C

) 260

Boundary constraint

Design variable Lower Limit Upper Limit

Propeller diameter (D) 0.25 0.8 \ H

PAP

Area ratio (A

E

/A

O

) 0.35 0.85

Pitch ratio (P/D) 0.7 1.5

Advance coe. (J) 0.3 1.5

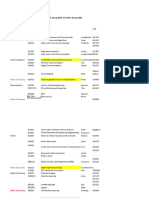

Figure 3 Output results of the developed computer program.

Figure 4 Open water diagram.

Figure 5 Output results of Lingo software.

Optimum design of B-series marine propellers 17

5.1. Using the developed computer program

The data which are shown in Table 2 are used to perform the

problem under consideration by using the developed computer

program. The output results of this program are shown in

Fig. 3.

The obtained optimum point is plotted on the open water

diagram for this design condition as shown in Fig. 4.

5.2. Using a commercial software (Lingo)

Lingo [9] is a comprehensive tool designed to make building

and solving linear, nonlinear and integer optimization models.

The problem under consideration is recalculated using LINGO

software [9] and the output results are shown in Fig. 5.

5.3. Analysis of the results

The output results obtained by the presented solutions are

shown in Table 3. It is clear that, the output results of Lingo

software are found in a good agreement with those obtained

by the developed program.

6. Conclusions

The design process of a series propeller by traditional calcu-

lation or chart methods is a tedious job due to the multiple

parameters and constraints involved.

To handle the multi-objective constrained problem of the

propeller design, one objective is selected and the other

objectives are formulated as constraints.

The developed computer program represents a tailored and

simple tool to nd the optimum characteristics of any B-ser-

ies marine propeller. It is more exible to use it as a subrou-

tine in global ship design problems than to use commercial

optimization

software.

References

[1] C. Jeng-Horng, S. Yu-Shan, Basic design of a series propeller

with vibration consideration by genetic algorithm, J. Mar. Sci.

Technol. 12 (2007) 119129.

[2] E. Benini, Multi-objective design optimization of B-screw series

propellers using evolutionary algorithm design, J. Mar. Sci.

Technol. 40 (2003) 229238.

[3] J.-B. Suen, J.-S. Kouj, Genetic algorithm for optimal series

propeller design, in: Proceeding of the Third International

Conference on Marine Technology, ORDA 99, Poland, 1999.

[4] M.M. Karim, M. Ikehata, A genetic algorithm (GA)-based

optimization technique for the design of marine propeller, in:

Proceeding of the Propeller/Shafting Symposium, Virginia Beach,

USA, 2000.

[5] H. Schneekluth, V. Bertram, Ship Design for Efciency and

Economy, Butterworth, Heinemann, 1998.

[6] S.S. Rao, Optimization Theory and Applications, second ed.,

Wiley Estern Limited, India, 1991.

[7] M.W.C. Oosterveld, V. Oossanen, Further Computer Analyzed

Data of The Wageningen B-series, I.S.P., vol. 23, July 1975.

[8] M.M. Gaafary, Computerized method for propeller design of

optimum diameter and rpm, in: 13th Congress of IMAM,

Istanbul, Turkey, October 2009.

[9] Lindo Systems Inc., Lingo Software, Version (9), <http://

www.lindo.com/>, April 2006.

Table 3 Output results.

Items Developed program Lingo

Objective: g

max.

0.620 0.62013

Design variables

D 1.00 1.00

A

E

/A

O

0.546 0.54456

P/D 1.075 1.082

J 0.78 0.784

[n] RPS 10.57 10.497

Coecients

K

T

0.1809 0.1823

K

Q

0.0362 0.0367

Power in kwatt

P

D

546.66 546.548

P

D

(Blade) 68.33 68.318

18 M.M. Gaafary et al.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- PanelDocument3 pagesPanelPavan KishoreNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- ANSYS Tutorial: Jake Blanchard January 2008Document24 pagesANSYS Tutorial: Jake Blanchard January 2008Joan HeviaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Auxiliary File FormatDocument133 pagesAuxiliary File FormatPavan KishoreNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 15746Document21 pages15746Pavan KishoreNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Engine 2018 BrochureDocument2 pagesEngine 2018 BrochurePavan KishoreNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Selection Procedure For Teaching PositionsDocument15 pagesSelection Procedure For Teaching PositionsPavan KishoreNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Call For PapersDocument7 pagesCall For PapersPavan KishoreNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Materials Methodology Stress FactorsDocument21 pagesMaterials Methodology Stress Factors538540No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- MosDocument2 pagesMosPavan KishoreNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Lesson Plan Subject: Engineering Mechanics (BME-101), Date Topics To Be CoveredDocument1 pageLesson Plan Subject: Engineering Mechanics (BME-101), Date Topics To Be CoveredPavan KishoreNo ratings yet

- MosDocument101 pagesMosPavan KishoreNo ratings yet

- Jsir 69 (9) 680-683 PDFDocument4 pagesJsir 69 (9) 680-683 PDFPavan KishoreNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Lab Consumables Requirement - 2018-19 A. Y.Document4 pagesLab Consumables Requirement - 2018-19 A. Y.Pavan KishoreNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 32 Forms of Lord Ganesh: Dr.S.KannanDocument1 page32 Forms of Lord Ganesh: Dr.S.KannanPavan KishoreNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Nonlinear Free Vibration Analysis of Single and Doubly Curved Composite Shallow Shell PanelsDocument29 pagesNonlinear Free Vibration Analysis of Single and Doubly Curved Composite Shallow Shell PanelsPavan KishoreNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- (Mechanical Engineering Series) Yuntao Song, Weiyue Wu, Shijun Du (Auth.) - Tokamak Engineering Mechanics-Springer-Verlag Berlin Heidelberg (2014)Document249 pages(Mechanical Engineering Series) Yuntao Song, Weiyue Wu, Shijun Du (Auth.) - Tokamak Engineering Mechanics-Springer-Verlag Berlin Heidelberg (2014)Pavan Kishore100% (1)

- IIPE faculty application deadline extended to June 10thDocument1 pageIIPE faculty application deadline extended to June 10thPavan KishoreNo ratings yet

- Stress Concentration Analysis Between Two Neighboring Circular Holes Under Internal Pressure of A Non-Explosive Expansion MaterialDocument12 pagesStress Concentration Analysis Between Two Neighboring Circular Holes Under Internal Pressure of A Non-Explosive Expansion MaterialPavan KishoreNo ratings yet

- Material Property DataDocument13 pagesMaterial Property DataKshitij SharmaNo ratings yet

- Notification ClarificationDocument1 pageNotification ClarificationPavan KishoreNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Propeller Blade Optimization Method for Cavitation Prevention at Multiple SpeedsDocument1 pagePropeller Blade Optimization Method for Cavitation Prevention at Multiple SpeedsPavan KishoreNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Heat ConductionDocument1 pageHeat ConductionPavan KishoreNo ratings yet

- 2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsDocument1 page2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsPavan KishoreNo ratings yet

- Analytical Methods in Conduction Heat TransferDocument242 pagesAnalytical Methods in Conduction Heat TransferMayank Sharma50% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- De DT K K K: 38 J.D. Anderson, JRDocument1 pageDe DT K K K: 38 J.D. Anderson, JRPavan KishoreNo ratings yet

- ACD2505-03 - Eqns of Fluid FlowDocument67 pagesACD2505-03 - Eqns of Fluid FlowPavan KishoreNo ratings yet

- Unsteady Heat ConductionDocument8 pagesUnsteady Heat ConductionRamesh KonakallaNo ratings yet

- 2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsDocument1 page2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsPavan KishoreNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- 2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsDocument1 page2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsPavan KishoreNo ratings yet

- EnergyDocument8 pagesEnergyPavan KishoreNo ratings yet

- Chapter 6 Assignment ModelDocument51 pagesChapter 6 Assignment ModelKlarence Corpuz LeddaNo ratings yet

- 2018 12 Dovico PDFDocument163 pages2018 12 Dovico PDFAshish K. GautamNo ratings yet

- Fast, Compact, Effi Cient. CONSIS Robotic DispensersDocument12 pagesFast, Compact, Effi Cient. CONSIS Robotic DispensersSergio Lorenzo Jaimes SolisNo ratings yet

- Boolean Functions - Theory, Algorithms, and Applications (Crama & Hammer 2011-05-16)Document711 pagesBoolean Functions - Theory, Algorithms, and Applications (Crama & Hammer 2011-05-16)Thabang ThemaNo ratings yet

- Aci HoDocument6 pagesAci HoLogin DumpNo ratings yet

- ANSYS Workbench 10Document1,192 pagesANSYS Workbench 10Nusret MeydanlikNo ratings yet

- User Manual A4.v.0.5.2 PDFDocument417 pagesUser Manual A4.v.0.5.2 PDFZe CabraNo ratings yet

- Mitchell TrussDocument16 pagesMitchell TrussvishalnalwarNo ratings yet

- CourseOfferingPlanGradF18 S20 20180106Document9 pagesCourseOfferingPlanGradF18 S20 20180106Anshum PalNo ratings yet

- Ensuring Control Accuracy - NEBYLOV PDFDocument254 pagesEnsuring Control Accuracy - NEBYLOV PDFLuiz Carlos da SilvaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Parameter Optimization of PI Controller by PSO For Optimal Controlling of A Buck Converter's OutputDocument7 pagesParameter Optimization of PI Controller by PSO For Optimal Controlling of A Buck Converter's OutputLIEW HUI FANG UNIMAPNo ratings yet

- Volume IIIDocument1,145 pagesVolume IIIathanasios niotisNo ratings yet

- Three Principles of Transportation Optimization JDA White PaperDocument4 pagesThree Principles of Transportation Optimization JDA White Paperismailhasan85No ratings yet

- Computers and Electrical EngineeringDocument14 pagesComputers and Electrical EngineeringChristiann HVNo ratings yet

- Sustainable Maritime Inventory Routing Problem With Time Window Constraints2017Engineering Applications of Artificial IntelligenceDocument19 pagesSustainable Maritime Inventory Routing Problem With Time Window Constraints2017Engineering Applications of Artificial Intelligencemajid yazdaniNo ratings yet

- COBIT 5-Self-Assessment TemplatesDocument262 pagesCOBIT 5-Self-Assessment Templatestania alejandra mendez50% (2)

- Ph.D. Thesis - OHAMDocument99 pagesPh.D. Thesis - OHAMManzoor HussainNo ratings yet

- Markdown Optimization 1.8 PDFDocument7 pagesMarkdown Optimization 1.8 PDFPerumalla Pradeep KumarNo ratings yet

- Operations ResearchDocument293 pagesOperations Researchtechnical saurabhNo ratings yet

- Cold-Formed Steel Design by Spreadsheet Program: Scholars' MineDocument19 pagesCold-Formed Steel Design by Spreadsheet Program: Scholars' MineRaineir PabiranNo ratings yet

- Renewable and Sustainable Energy Reviews: Anjukan Kathirgamanathan, Mattia de Rosa, Eleni Mangina, Donal P. FinnDocument17 pagesRenewable and Sustainable Energy Reviews: Anjukan Kathirgamanathan, Mattia de Rosa, Eleni Mangina, Donal P. FinnmaxmanfrenNo ratings yet

- Celestial Mechanics With MatlabDocument151 pagesCelestial Mechanics With MatlabEyjay Samson100% (2)

- Widiicioe Ea WW Vbudiiitia Iiiviiitay Pehl Iif: IiioebisDocument1,144 pagesWidiicioe Ea WW Vbudiiitia Iiiviiitay Pehl Iif: IiioebisMinahil FatimaNo ratings yet

- LMI optimization for fixed-order H-infinity controller designDocument13 pagesLMI optimization for fixed-order H-infinity controller designajitsatapthyNo ratings yet

- Aspentech Course Catalog Fy18Document27 pagesAspentech Course Catalog Fy18Waseem AkramNo ratings yet

- Prosper Software For Gas Lift System Design and SimulationDocument11 pagesProsper Software For Gas Lift System Design and SimulationRaunak AryanNo ratings yet

- Transportation Problems 5Document50 pagesTransportation Problems 5Anisha Gulia100% (1)

- Basic Operation Research ModelDocument15 pagesBasic Operation Research ModelShebin ThampyNo ratings yet

- Stratified Linear Systematic Sampling Based Clustering Approach For Detection of Financial Risk Group by Mining of Big DataDocument15 pagesStratified Linear Systematic Sampling Based Clustering Approach For Detection of Financial Risk Group by Mining of Big DataAPPNo ratings yet

- Tme 601Document14 pagesTme 601dearsaswatNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)