Professional Documents

Culture Documents

Crane Engineering Principles of Fluid Mixing

Uploaded by

Suphi YükselOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crane Engineering Principles of Fluid Mixing

Uploaded by

Suphi YükselCopyright:

Available Formats

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

TABLE OF CONTENTS

Types of Mixers 8.1 Mixer Terminology 8.3 D/T and Z/T 8.7 8.8

Axial Flow and Radial Flow

Flow and Shear 8.9 Horsepower (Work, Power, Shaft) Reynolds Numbers 8.10

8.12

Pumping Capacity or Flow 8.14 Torque 8.15 Shaft Terminology 8.16 Critical Speed . 8.17 Impeller Effect on Critical Speed 8.18 Nomenclature 8.19

Copyright 2003 BRAWN Mixer, Inc.

Page 8-i

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

TYPES OF MIXERS

Many types of mixers are available. Some mixers are designed specifically for one special application, while others are more versatile with many options such as variable speed, changeable impellers and shafts, plus a wide range of motor horsepower. This data sheet will clarify some of the designations commonly used when discussing mixers. Aerator: A mixer or other device used to dissolve air into water, usually for biological waste treatment. It may operate at the surface by splashing, or submerged with a pipe, or with a sparge providing air to the impeller. A mixer with a motor which uses compressed air instead of electricity is sometimes called an air mixer or air-drive mixer, or pneumatic mixer. A mixer whose drive is mounted to the bottom head of a vessel. The mixer shaft enters through the tank bottom therefore must be equipped with some type of shaft seal. A direct drive has an output shaft, which rotates at the same speed as the motor. Direct-drive mixers are relatively simple and offer a higher component of shear to the process. A special purpose high-shear mixer or just the blade or impeller. Typically, a high-speed device often with sharp edges (some look like circular saw blades with bent teeth) used to break up powders or particles to dissolve or suspend them. (See Rotor Stator definition also.) A relatively slow-RPM mixer, which is used to enhance the contact of particles in suspension to agglomerate them for easier settling or separation. A mixer with an output shaft that has a speed lower than the motor speed because of a gear reducer between the motor and output shaft. This mixer transmits higher torque and has higher pumping efficiency per horsepower. A very high-speed mixer used to blend immiscible phases of a solution into a cream or emulsion. One whose shaft and impeller is driven by a magnet. The internal mixer shaft is driven by a magnetic field. The driven shaft does not penetrate the vessel affording seal less mixing. These mixers are relatively easily moved from tank to tank and mounted to tank walls with a C-clamp or adjustable plate mount.

Air Mixer: Bottom Entry:

Direct Drive:

Disperser:

Flocculator: Gear Drive:

Homogenizer: Magnetic Drive Mixer:

Portable Mixers:

__________________________________________________________________________________

Copyright 2003 BRAWN Mixer, Inc. Page 8-1

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

TYPES OF MIXERS

(continued)

Rotor Stator: Sanitary Mixers:

A type of high shear mixer which utilizes a rotating head/impeller inside a stationary shroud or cage. A mixer whose drive components (motor, gearbox) are made from stainless steel or other approved materials. These are used in sanitary and washdown environments, as well as highly corrosive atmospheres. Mixers mounted on a flange through the side of a tank or chest. Often used for very tall tanks to reduce capital cost. These are pipes with specially-designed baffles inside which blend fluids as they flow through. These mixers do not have any moving parts. Mixers mounted on the rim, on beams, or on a flange entering from the top of the tank.

Side-Entry Mixers: Static Mixers: Top-Entry Mixers:

Copyright 2003 BRAWN Mixer, Inc.

Page 8-2

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

MIXER TERMINOLOGY

Axial Flow: Baffles: Bending Moment: Fluid flow directed axially along the mixer shaft from top to bottom (downpumping), or from bottom to top (up-pumping) is called axial flow. Structures attached to an inside tank straight side, either directly or on tabs to direct the fluid flow vertically in the tank preventing swirl and vortexing. The product of force times distance. Fluid forces are exerted on a mixer shaft at each impeller. The force (lbs) times the distance from the impeller to the lowest shaft bearing (in) is the bending moment (in lb). For multiple impellers, the shaft bending moment is the sum of the individual bending moments.

Bulk Fluid Velocity: The primary pumping rate of a mixer divided by the plan, cross sectional area of the mixed vessel. Example: Ft3/min Ft2 = Ft/min. Case Size: Speed reducer size on gear-driven mixers. When torque design limits are reached, or when a larger diameter shaft is required to meet other design criteria, the next larger size gear box (case size) must be used. A given case size may accommodate many various horsepower and input/output speed combinations, but carries the same torque and shaft size. The distance between the impeller and the liquid surface. Typical optimum coverage is equal to twice the impeller diameter. Insufficient coverage may cause vortexing and/or air entrainment. A rotational speed (rpm) of a mixer shaft which is operating at the shafts natural vibration frequency (cycles/min). Operating a shaft at critical speed may amplify vibrations leading to shaft failure by excessive deflection. The ratio of impeller diameter (D) to tank diameter (T). A vertically-mounted mixer which utilizes a gear drive that has an oil dam called a dry well around the output shaft. The oil dam extends above the oil level of the gearbox so that the oil cannot run out of the gearbox during operation.

Coverage:

Critical Speed:

D/T: Dry Well Mixer:

Equivalent Weight: A calculated value representing the combined impeller weight at the shaft end when several impellers are installed on a shaft. Entrainment: The result of the drawing force produced by a flowing fluid, which drags additional fluid (entrained flow) or air (air entrainment) along with the pumped fluid.

Copyright 2003 BRAWN Mixer, Inc.

Page 8-3

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

MIXER TERMINOLOGY

(continued) Flow: One of two components resulting from the action of a mixer impeller (see Shear). The bulk movement of the fluid. Primary impeller pumping rate measured in gallons per minute is often referred to as flow. The forces exerted on a mixer shaft through the impeller as a result of the fluid motion in the tank. Fluid forces are calculated for each impeller and used to calculate the shaft bending moment. Relating to the physical size of a motor. Frame size is dependent on motor HP, enclosure, speed, power supply voltage and phase. Example: HP, 1800 RPM, 230/460V has a NEMA 56 frame; 3 HP, 1800 RPM, 230/460V has a NEMA 182 frame. The distance from the liquid surface to the top of a tank. This distance must be taken into account when sizing a mixer shaft to ensure adequate coverage. The unobstructed flow of a fluid. Mixer characteristics, such as pumping capacity and power requirement, are based on the assumption that no obstructions or flow constrictions are present. A unit for measuring the power of motors, equal to 746 Watts. applications, horsepower may be expressed as shaft HP or motor HP. In mixer

Fluid Force:

Frame Size:

Freeboard: Free Flow/ Plug Flow:

HP (Horsepower): Impeller:

The device responsible for the actual mixing action in a process. The rotating impeller is responsible for flow and shear imparted to the fluid as it rotates.

MHP (Motor Horsepower): The actual shaft horsepower, divided by motor efficiency, determines the required motor nameplate horsepower. Np: Power number. A constant, unique to each type of mixing impeller, used to calculate power draw. Power number varies with Reynolds number, but may be treated, as a constant if the Reynolds number is sufficiently high. Flow number. A constant, derived empirically for each unique geometric shape of mixing impeller, used to calculate flow or pumping rate. The distance from the impeller to the tank bottom. Typically, the off-bottom is between one to two times the impeller diameter.

NQ: Off Bottom:

Copyright 2003 BRAWN Mixer, Inc.

Page 8-4

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

MIXER TERMINOLOGY

(continued) Prandl Number: A dimensionless number used to estimate the boundary layer film co-efficient in heat transfer calculations. In fluids, Prandl Numbers cannot be estimated accurately and therefore must be derived experimentally. Flow or pumping rate, measured in gallons per minute, which is the actual discharge rate of a specific size and type of mixing impeller. Impellers that draw from above and below the impeller and discharge it toward the tank wall, perpendicularly from the mixer shaft, are radial flow impellers. This type of flow is called radial flow.

Q: Radial Flow:

Reynolds Number: A dimensionless number used to indicate the type of fluid motion being produced. The value of this number determines the value of the power number, which affects the HP draw. Reynolds numbers below 1,000 are considered laminar; above 2,500 is turbulent flow. Right-Angle Mixer: A mixer with the motor shaft input perpendicular to the gearbox output shaft. The motor suspends off the side of the gearbox, keeping the required headroom to a minimum. Service Factor: Equipment having a service factor of 1.0 for a given level of performance is designed to operate without excessive wear or failure over its lifetime at that performance level. For instance, a 1 HP motor rotating at 1725 RPM with a service factor of 1.0 will operate for many years under a 1 HP load. A gearbox designed to transmit 1 HP has a service factor of 1.0 when loaded to 1 HP. If, however, that same gearbox is loaded to only HP, it now has a service factor of 2.0, indicating that it is capable of heavier duty than the current use and should have a longer service life. The intensity of the straining force on a mixer shaft that tends to deform its shape or cause it to fracture. It is usually expressed in PSI. Shaft stress is calculated from the bending moment. Stress limits are known for various materials under static loads. For mixer shafts which are subjected to alternating stresses because of their rotation, a fatigue stress limit must be established which is much less than the static limit. Mixers should not be designed with a shaft stress higher than 15,000 PSI. One of two components resulting from the action of a mixer impeller (see Flow). Different velocities existing simultaneously (velocity gradient = shear rate) which produce stresses on the fluid. Shear rate X viscosity = shear stress in PSI. Shear stress is responsible for small scale fluid intermixing.

Shaft Stress:

Shear:

Copyright 2003 BRAWN Mixer, Inc.

Page 8-5

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

MIXER TERMINOLOGY

(continued) SHP (Shaft Horsepower): The actual power required to drive the mixer impeller in the specific process fluid at the rotational speed supplied to the mixer shaft. Specific Gravity: T: Tip Speed: The ratio of fluid density E.G. (lb/gal) to the density of water (8.33 lb/gal @ 25C, 1 atm pressure) under current conditions. Tank diameter. The peripheral speed of a rotating impeller. Tip speed is something used to estimate the shear applied to a fluid. Tip Speed = RPM X D X . The twisting force that is created by a motor and/or gearbox to produce rotation of a mixer shaft. For the mixer concepts presented in these data sheets, velocity head and shear have the same meaning. (See Shear). Internal fluid friction. The property of a fluid that enables it to develop and maintain an amount of shearing stress dependent upon the velocity of flow and then to offer continued resistance to flow. The designation used to signify the liquid level or height in a tank.

Torque: Velocity Head: Viscosity:

Z:

Copyright 2003 BRAWN Mixer, Inc.

Page 8-6

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

D/T and Z/T TANK DESIGN CONSIDERATIONS

Other than the mixer itself, the mixing tank design is the single most important factor in successful process result. In order for a mixing impeller to perform optimally, correct location and liquid coverage is essential. Incorrect position of mixing impeller may hamper mixing performance and be detrimental to the performance life of the mixer drive. D/T is the ratio of impeller diameter to tank diameter. For most mixing applications, it ranges from 0.20 to 0.60. A D/T that is too small may leave areas unmixed. A D/T too large may choke off the upflow between the impeller and the tank wall. Mixer sizing for general blending starts with a D/T of 0.25. The impeller diameter is then adjusted to fit the most economical drive selection. A smaller D/T may be offset by high flow created by turning at higher RPM. Z/T is the ratio of liquid height to tank diameter. When this ratio exceeds 1.2, dual impellers should be used.

Illustration No. 1

Off-bottom distance is normally 1 to 2 impeller diameters. Coverage is typically 2 to 4 impeller diameters.

Typical Baffle Arrangements

Four (4) baffles, 90 apart. Baffle width 1/12 the tank diameter; length is from the liquid level down to 6 inches off bottom. Three (3) baffles, 120 apart. Baffle width 1/12 the tank diameter; length is from the liquid level down to 6 inches off bottom.

Copyright 2003 BRAWN Mixer, Inc.

Page 8-7

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

AXIAL FLOW and RADIAL FLOW

Illustration No. 2

Illustration No. 3

Most open impeller mixing applications operate in the turbulent regime (meaning low viscosity). Applications requiring high flow are generally best performed with axial flow impellers. If high shear is required, radial flow impellers may be preferred. Close clearance impellers including those which scrap the tank interior work best in laminar flow (high viscosity) conditions.

Copyright 2003 BRAWN Mixer, Inc.

Page 8-8

PRINCIPLES OF FLUID MIXING

3389 128th Avenue Holland, MI 49424 USA

Phone: 616/399-5600 Fax: 616/399-3084

FLOW and SHEAR

Constant Horsepower Impeller Type Rake/Picket Fence Helix Hydrofoil Propeller Axial-Flow Turbine

Flow Q

In general, a mixer with a small diameter impeller, turning at a high speed, will result in the fluid seeing the applied power as mostly shear. This is represented by the bottom of the impeller spectrum above. Conversely, a low-speed mixer with a larger diameter impeller will discharge a higher volume of fluid, resulting in high flow. The required ratio of these components is determined according to the application requirement. Homogenizers are relatively small-bladed, very high RPM mixers, which produce tremendous amounts of shear for dispersing two phases into an emulsion. Flocculators, by way of contrast, are typically slow moving, large diameters, which gently push liquid around a tank to build large particles from smaller ones with the aid of chemical addition. An impeller which produces high flow would have little effect in a process requiring dispersion. Shear in flocculation would have a negative effect. The importance of understanding this principle lies mainly in recognizing that equal power does not mean equal mixing result. The process result is always a function of impeller type AND speed and diameter. In Section 8.1 we will further discuss how it is feasible to change the effect of mixing performance without changing impeller type while maintaining a constant horse power. Mixing processes such as blending, dissolving and solids suspension are 'flow or pumping-controlled' and make up most mixing applications. If high shear is not an essential component in achieving your result, you should select a mixer with lower speed, and larger diameter impellers. This will produce more flow per utility dollar.

Radial-Flow Turbine Bar Turbine Sawtooth Impeller & Stator Homogenizer Illustration No. 4 (Impeller Spectrum): The list of impellers at the left of our impeller spectrum is a sampling which illustrates that different impeller shapes produce different ratios of flow and shear.

Shear S (Velocity Head)

The energy which a mixer transmits to the fluid results in two effects - flow and shear (or velocity head) - by the following relationship: P oc Q x S x S.G. P = Power Q = Flow S = Shear (head) S.G. = Specific Gravity

where:

For a given power level, a mixture can be designed so that either the shear component or the flow component represents most of the power applied.

Copyright 2003 BRAWN Mixer, Inc.

Page 8-9

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424 U.S.A.

th

Tel: 616/399-5600 Fax: 616/399-3084

HORSEPOWER

The power consumed by a rotating impeller in a process fluid is easily measured. The units we typically express this power in is horsepower. It is common to relate mixer performance to horsepower. However, there are problems associated with this tendency. Horsepower can be calculated for most mixer (turbulent flow) applications as follows: SHP NP N D S.G. 1.53 x 1013 = = = = = = Np N3 D5 S.G. 1.53 x 1013 Power Number of impeller Impeller speed (RPM) Impeller diameter (IN) Specific Gravity Conversion factor

As can be seen from this formula, changes in RPM or impeller diameter have a major impact on required horsepower to operate your mixer. When we examine this horsepower effect closely and tie it together with the formula for pumping capacity(see Pumping Capacity, page 8) we can derive the following: QHP QHP D K = = = = D4/3K Flow at constant HP Impeller Diameter (inches) A Constant

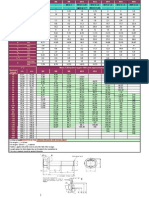

What this means is, if horsepower is constant and we increase impeller diameter, (RPMs must go down) and hence increase D/T, we receive a disproportional gain in flow. The following table illustrates this:

2HP Mixers

Model BD200 BGM200 BGM200-233 3BTO2-68

Copyright 2003 BRAWN Mixer, Inc.

RPM 1725 350 233 68

Max AF3 Diameter 7.24 18.85 24.05 50.4

Q(gpm) 1559 5582 7717 20,727

Page 8-10

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424 U.S.A.

th

Tel: 616/399-5600 Fax: 616/399-3084

HORSEPOWER (Continued)

Viscosity Effect: As described in section 8-12 on Reynolds Number, as viscosity increases, impeller power number may begin to increase. This becomes important in the HP calculations because as power number begins to go up so does the horsepower required to drive the mixer. Simply increasing the input horsepower may be the answer, but one must bear in mind that this change reduces the service factor of the mixer drive, hence a bigger mixer may be required. Viscosity increase also effects the flow characteristics of fluid as compared to water. A correction factor may be obtained from a qualified mixer application engineer. However, most viscons fluids should be checked in the lab to obtain a predictable viscosity profile. Multiple Impellers: More than one impeller may be required for some processes. This may be due to tank geometry or fluid characteristics. Regardless of how many impellers are required or why, it is important to realize the multiple effect on horsepower required.

Copyright 2003 BRAWN Mixer, Inc.

Page 8-11

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424

th

Tel: 616/399-5600 Fax: 616/399-3084

REYNOLDS NUMBERS

Viscosity Effect on Mixing Performance

Reynolds Number is a dimensionless number that can be derived as follows: Nre visc. = = 10.75 N D2 S.G. Viscosity fluid viscosity (cPs)

Power number is constant for each impeller type, as long as the Reynolds number is sufficiently high. Power number is a function of Reynolds Number. The Reynolds number is the indicator of the type of mixing fluid regime your mixer will operate in, in the process fluid. If the Reynolds Number is above 2,000, you are generally operating in the fluid regime where the power number is constant (turbulent flow). When the Reynolds Number you calculate is less than 1,000 (laminar flow), then the Power Number increases as the Reynolds Number decreases (see Illustration No. 5). Consequently, the shaft horsepower you calculate must be based on the corrected power number. In this case, you will need to obtain an Np (Power Number) vs Nrey (Reynolds Number) curve from the impeller manufacturer or by experimentation. The Illustration shows how the Power Number for each impeller varies with changes in Reynolds Number. The Illustration below shows that, as Reynolds Number drops, we reach a point where the power number begins to increase sharply. This point depends on the type of impeller in use. Reynolds Numbers or Nrey between 1000 and 2000 are generally considered in transition.

A1 A2

Illustration No 5 Copyright 2003 BRAWN Mixer, Inc. Page 8-12

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424

th

Tel: 616/399-5600 Fax: 616/399-3084

POWER NUMBERS

Each impeller of constant geometric design demonstrates a uniform Power Number curve. By knowing the impeller speed and diameter, the fluid specific gravity, and measuring the shaft horsepower, we can calculate the impeller Power Number with the following formula: Np SHP N D S.G. = = = = = 1.53 x 1013 SHP N3 D5 S.G. Shaft horsepower (HP) Speed (RPM) Impeller diameter (INCHES) Specific Gravity

Impeller Power Numbers are generally derived in water-like fluids. Notice that, for very high Reynolds Numbers, (low viscosity) the Np curve is flat. This indicates that the Power Number is constant. Calculating horsepower with this constant Np can be accomplished using the equation as shown in the HORSEPOWER (Work, Power Shaft) section. Many open impeller mixing applications are what we commonly refer to as flow controlled applications. This means that the process result is a direct result of the mixer pumping rate or flow. This concept can be seen in Illustration 6 on page 8-15.

Copyright 2003 BRAWN Mixer, Inc.

Page 8-13

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424

th

Tel: 616/399-5600 Fax: 616/399-3084

PUMPING CAPACITY OR FLOW

Pumping capacity is the measure of fluid discharged by a rotating impeller. This flow produced directly by the impeller and through the impeller area is known as primary flow. In addition to primary flow, liquid is drawn by and pushed by the primary flow to produce induced flow. The primary and induced flow together make up the total flow. Total flow is difficult to calculate, but can be measured in the laboratory. Total flow is typically several times higher than primary flow. This distinction is very important when comparing mixer performance and efficiency. Mixers should be compared using primary pumping capacity. Total flow may be estimated by the mixer manufacturer, but should not be used for comparison purposes. For simplicity, pumping capacity calculations assume free flow or plug flow where the impeller is not too close to the tank bottom and flow is not hindered by other constrictions. Water is used as the standard liquid, with a specific gravity of 1.0 and a viscosity of 1.0 centipoise. The result is generally referred to as the water pumping capacity, since pumping capacity for the actual conditions can also be calculated by adjusting the flow number for the fluid characteristics and tank geometry. The following equation is used to calculate PRIMARY pumping capacity: Q Q Nq N D 231 = = = = = Nq N D3 231 Flow in gallons per minute (GPM) Flow number for impeller Mixer speed (RPM) Impeller diameter (IN) Conversion factor

Nq, the flow number, is determined empirically for each impeller type (geometry). It is constant for the impeller under standard conditions (water, free flow). The impeller manufacturer can supply this number to you if you are calculating pumping capacity. Dual Impellers: Depending on how the impellers are spaced, the fluid characteristics, tank geometry and other variables, multiple impellers will pump somewhat more than one impeller at like speed and horsepower. While this pumping capacity is a very useful concept for comparing mixers, caution must be exercised when using it as a sizing criteria, since the same liquid in one small area of the tank may be pumped over and over, while other areas do not get mixed. D/T, off-bottom distance, number and location of impellers must also be correct.

Copyright 2003 BRAWN Mixer, Inc.

Page 8-14

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424

th

Tel: 616/399-5600 Fax: 616/399-3084

TORQUE

Torque is the twisting or turning force acting to produce rotation on the mixer shaft. Torque = HP x 73025 RPM

In flow-controlled mixing processes, torque = mixer flow X a constant, which is, in turn, equal to process result. Also, higher torque (not necessarily higher HP) = higher mixer cost. Mixer torque per unit volume may be an important scale-up criteria. The torque required for any mixing process will effect the size and type of mixer drive and also have a direct impact on mixer shaft design.

Process Result Flow Torque

Flow

Torque (K)

$ (Capital Cost)

Illustration No. 6: Flow Controlled Applications

Copyright 2003 BRAWN Mixer, Inc.

Page 8-15

PRINCIPLES OF FLUID MIXING

Phone: 616/399-5600 Fax: 616/399-3084

SHAFT TERMINOLOGY

Copyright 2003 BRAWN Mixer, Inc.

Page 8-16

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424

th

Phone: 616/399-5600 Fax: 717/399-3084

CRITICAL SPEED

Natural Frequency & Rotational Frequency

A rigid body, like a mixer shaft, vibrates when subjected to outside forces. Like a tuning fork, it has a predetermined vibrational frequency (harmonic), which remains constant as long as the composition of the shaft and the shaft-impeller relationship is not altered. This vibrational frequency is called natural frequency. Unlike a tuning fork however, a mixer shaft must also deal with the forces of rotation. The rotational frequency is the number of turns or revolutions the shaft makes over a period of time seconds, minutes, etc. We typically measure rotational frequency in revolutions per minute (RPM). If you could adjust the shaft speed so the rotational frequency exactly matched the natural frequency of the shaft, you would achieve critical speed, represented by Ncr in our equation (Illustration No. 9). Additional critical speeds actually occur at several multiples of the first critical speed. Critical Speed Can Be Dangerous These speeds (vibration and rational) are called critical because they are the speeds at which the two frequencies reinforce one another. This condition has the potential to set up destructive force. The relationship of shaft length and impeller weight to critical speed is given by the following equation. This equation calculates the first natural, or vibrational, frequency of the shaft.

d l a We E

= = = = = =

Shaft diameter (IN) Shaft length (IN) Bearing spacing (IN) Density (LB/CU. IN) Weight or equivalent of impeller(s) Modulus of elasticity

Illustration No. 7

Some mixers are designed to operate above first critical speed. When designed this way the shaft passes through critical speed with nothing more than a slight tremor at start up or shutdown. Generally speaking, it is good design practice to stay below the first critical speed by 20% or more. The ratio of operating speed to critical speed (N/Ncr) is called the critical speed ratio. A critical speed ratio of 0.8 would indicate that the operating speed is 20% below the critical speed. A ratio of 1:2 indicates the operating speed is 20% above critical speed.

Copyright 2003 BRAWN Mixer, Inc. Page 8-17

PRINCIPLES OF FLUID MIXING

3389 128 Ave Holland, MI 49424

th

Phone: 616/399-5600 Fax: 616/399-3084

IMPELLER EFFECT ON CRITICAL SPEED

Weight and Equivalent Weight

Impeller weight can be calculated, knowing the material density and the dimensions of all the impeller components, but this weight is only directly useful if there is only one impeller on a shaft, located at the very end of a shaft. For shaft design calculations, we are concerned with the effect of the weight or equivalent weight of multiple impellers on the end of the shaft. The equivalent weight is the apparent weight of all the impellers and is calculated using the following formula.

We W1,2,3 L1, 2, 3

Illustration No. 8

= = =

Equivalent weight (LB) Weights of impellers 1, 2, 3 (LB) Length (IN)

When impellers are made adjustable, they must be safe at all operating conditions. The simple way to assume all the impellers are at their lowest possible position, calculate the equivalent weight and critical speed under this worst-case scenario. If your result is below the maximum critical speed ratio, the impellers are safe at any position. The equivalent weight calculated for two or more impellers can be directly input into the critical speed equation (see SHAFT LENGTH and CRITICAL SPEED).

Copyright 2003 BRAWN Mixer, Inc.

Page 8-18

PRINCIPLES OF FLUID MIXING

3389 128 Avenue Holland, MI 49424

th

Phone: 616/399-5600 Fax: 616/399-3084

NOMENCLATURE The following terms are used in the sizing and selection of mixers, as well as the design and installation of these mixers: A, a, BRSPC d, SD D E, MOD F, FF HP L, L1 MHP N Ncr, NCR Np Nq NRE, Nre NUMI P MB, Mb bearing space (inches) shaft diameter (inches) impeller diameter (inches) modulus of elasticity fluid forces (LB) horsepower (HP) length, length of distance 1 (inches) bending moment (IN-LB) motor horsepower (HP) speed (RPM) critical speed (RPM) impeller power number impeller flow number Reynolds Number number of impellers on shaft power (HP) PC, Q Q S SD, d SHP SS T T TS V VISC We Z

, DENS

pumping capacity (GPM) flow shear shaft diameter (inches) shaft horsepower (HP) specific gravity shaft stress (PSI) torque (IN-LB) tank diameter tip speed (FT/SEC) volume (liters) (gallons) viscosity (cP) (centipoise) equivalent weight (LB) liquid level (inches)

density (LB/CU.IN)

SPGR, Sp. Gr., S.G.

W, W1 weight, weight of impeller 1 (LB)

Copyright 2003 BRAWN Mixer, Inc.

Page 8-19

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Fransız Elektrot Firması Seçim TablosuDocument60 pagesFransız Elektrot Firması Seçim TablosuSuphi Yüksel100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Document108 pagesGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Suphi YükselNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Thread Size Chart for Metric Hex Nuts (M6 to M20Document1 pageThread Size Chart for Metric Hex Nuts (M6 to M20Suphi YükselNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- DIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertDocument1 pageDIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertSuphi YükselNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 10512Document1 page10512Suphi YükselNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- M8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Document1 pageM8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Suphi YükselNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Fiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Document1 pageFiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Suphi YükselNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Einschlaganker Drop in Anchor: Çakma DübelDocument16 pagesEinschlaganker Drop in Anchor: Çakma DübelSuphi YükselNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- EN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadDocument1 pageEN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadSuphi YükselNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- DIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsDocument1 pageDIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsSuphi YükselNo ratings yet

- DIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Document1 pageDIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Suphi YükselNo ratings yet

- DIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Document1 pageDIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Suphi YükselNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Outokumpu Stainless Steel HandbookDocument92 pagesOutokumpu Stainless Steel HandbookcutefrenzyNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- DIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarDocument1 pageDIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarSuphi YükselNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- P B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinDocument1 pageP B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinSuphi YükselNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- P (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeDocument1 pageP (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeSuphi YükselNo ratings yet

- Thread Size Chart for Metric Bolts M5 to M16Document1 pageThread Size Chart for Metric Bolts M5 to M16Suphi YükselNo ratings yet

- 34801Document1 page34801Suphi YükselNo ratings yet

- 1665Document1 page1665Suphi YükselNo ratings yet

- 6921Document1 page6921Suphi YükselNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadDocument1 pageMass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadSuphi YükselNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinDocument1 pageMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselNo ratings yet

- Thread Size Dimensions Chart for M12, M16, M20 BoltsDocument1 pageThread Size Dimensions Chart for M12, M16, M20 BoltsSuphi YükselNo ratings yet

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinDocument1 pageMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- A Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Document1 pageA Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Suphi YükselNo ratings yet

- SMAW PowerpointDocument28 pagesSMAW PowerpointShankar Gurusamy100% (3)

- Ref. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinDocument1 pageRef. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinSuphi YükselNo ratings yet

- Solutions Guide: The Choice of Master CraftsmenDocument20 pagesSolutions Guide: The Choice of Master CraftsmenSuphi YükselNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Storage Tanks Made of SteelDocument6 pagesStorage Tanks Made of SteelHakan Şahinoğlu100% (1)

- SKF Bearing Installation and MaintenanceDocument146 pagesSKF Bearing Installation and MaintenanceDefinal ChaniagoNo ratings yet

- (Jf613e) CVT Renault-Nissan PDFDocument4 pages(Jf613e) CVT Renault-Nissan PDFJhoanny RodríguezNo ratings yet

- Java MCQ questions and answersDocument65 pagesJava MCQ questions and answersShermin FatmaNo ratings yet

- Cantilever Retaining Wall AnalysisDocument7 pagesCantilever Retaining Wall AnalysisChub BokingoNo ratings yet

- Personal InsuranceDocument11 pagesPersonal InsuranceSumit Kumar SharmaNo ratings yet

- Lea 201 Coverage Topics in Midterm ExamDocument40 pagesLea 201 Coverage Topics in Midterm Examshielladelarosa26No ratings yet

- SC invalidates Ordinance allowing oil depots in Pandacan due to population densityDocument2 pagesSC invalidates Ordinance allowing oil depots in Pandacan due to population densityMigs Raymundo100% (1)

- Process ValidationDocument116 pagesProcess ValidationsamirneseemNo ratings yet

- Vydyne® R533H NAT: Ascend Performance Materials Operations LLCDocument4 pagesVydyne® R533H NAT: Ascend Performance Materials Operations LLCJames FaunceNo ratings yet

- (NTA) SalaryDocument16 pages(NTA) SalaryHakim AndishmandNo ratings yet

- Leyte Geothermal v. PNOCDocument3 pagesLeyte Geothermal v. PNOCAllen Windel BernabeNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Using The Marketing Mix Reading Comprenhension TaskDocument17 pagesUsing The Marketing Mix Reading Comprenhension TaskMonica GalvisNo ratings yet

- Intermediate Accounting Testbank 2Document419 pagesIntermediate Accounting Testbank 2SOPHIA97% (30)

- Joint Memorandum Circular (JMC) No. 2021Document49 pagesJoint Memorandum Circular (JMC) No. 2021Nicey RubioNo ratings yet

- Triblender Wet Savoury F3218Document32 pagesTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- For-tea Tea Parlour Marketing Strategy Targets 40+ DemographicDocument7 pagesFor-tea Tea Parlour Marketing Strategy Targets 40+ Demographicprynk_cool2702No ratings yet

- Stage 1 Isolating Boiler Feed Pump 1. PurposeDocument3 pagesStage 1 Isolating Boiler Feed Pump 1. Purposejoseph kamwendoNo ratings yet

- Vitamin D3 5GDocument7 pagesVitamin D3 5GLuis SuescumNo ratings yet

- Fall Protection ANSIDocument5 pagesFall Protection ANSIsejudavisNo ratings yet

- Mechanical PropertiesDocument30 pagesMechanical PropertiesChristopher Traifalgar CainglesNo ratings yet

- AB InBev Code of Business Conduct PDFDocument10 pagesAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiNo ratings yet

- (Lesson 10-1) - Quality Assurance, Hemocytometry, Thoma PipetsDocument22 pages(Lesson 10-1) - Quality Assurance, Hemocytometry, Thoma PipetselleNo ratings yet

- Examination: Subject CT5 - Contingencies Core TechnicalDocument7 pagesExamination: Subject CT5 - Contingencies Core TechnicalMadonnaNo ratings yet

- Capran+980 CM en PDFDocument1 pageCapran+980 CM en PDFtino taufiqul hafizhNo ratings yet

- GSM Multi-Mode Feature DescriptionDocument39 pagesGSM Multi-Mode Feature DescriptionDiyas KazhiyevNo ratings yet

- Article 4Document31 pagesArticle 4Abdul OGNo ratings yet

- Iqvia PDFDocument1 pageIqvia PDFSaksham DabasNo ratings yet

- Frequency Meter by C Programming of AVR MicrocontrDocument3 pagesFrequency Meter by C Programming of AVR MicrocontrRajesh DhavaleNo ratings yet

- WPB Pitch DeckDocument20 pagesWPB Pitch Deckapi-102659575No ratings yet

- BUSN7054 Take Home Final Exam S1 2020Document14 pagesBUSN7054 Take Home Final Exam S1 2020Li XiangNo ratings yet

- 59 - 1006 - CTP-Final - 20200718 PDFDocument11 pages59 - 1006 - CTP-Final - 20200718 PDFshubh.icai0090No ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)