Professional Documents

Culture Documents

Decoction Mashing

Uploaded by

Baldev SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Decoction Mashing

Uploaded by

Baldev SinghCopyright:

Available Formats

Decoction Mashing, Part 1

Demystification of the Decoction Mash

By David Cordrey Of the three mashing methods Single Infusion, Step Infusion and Decoction, decoction mashing remains a mystery to many homebrewers. Single infusion mashing is by far the most common mashing technique and is employed by most all-grain homebrewers. Some homebrewers use a step infusion or temperature controlled mash which includes a protein rest, but few and far between are homebrewers that have ever tried to conduct a decoction mash. In this article, I'll attempt to demystify the decoction mash by explaining what decoction mashing is, what it's benefits are and what beer styles have traditionally used decoction mashing. In Part 2, I'll talk about how to successfully conduct a decoction mash in the homebrewery. Webster's defines:

"Decoct" 1) to extract the flavor of by boiling 2) boil down, concentrate "Decoction" 1) the act or process of decocting 2) the extract obtained by decocting

From these definitions it stands to reason that a decoction mash involves the boiling of the water/malt mixture, and that the intent is to extract and/or concentrate flavors. But how can that be? The first thing an all grain brewer learns is that if a mash is boiled, the precious amylase enzymes will be destroyed preventing starch conversion, and excessive amounts of tannins will be leached from the grain husks, leaving an undesirable astringent flavor. The answer to this paradox, as you'll soon see, is that careful technique overcomes these potential problems; indeed, a decoction mash when performed properly results in a beer with the highest malt flavor profile and highest extract yield of the three mashing techniques. Decoction mashing also results in less hot and cold break material, and reduces the mash pH naturally, without the addition of dark malts, lactic acid or other water treatments. In decoction mashing, a portion of the mash is removed from the mash tun and is transferred to a boiling pot. This portion is called the decoction, and it is heated slowly to bring it to a boil. After boiling for a period of time the decoction is added back to the main mash, thereby raising it's temperature. In this respect, the decoction mash is similar to the step mash or temperature controlled mash. For example, the initial mash temperature and volume of the decoction can be chosen so that the temperature rise goes from the protein rest temperature to the sacharification rest (starch conversion) temperature. This would be called a single decoction mash because only one decoction was made. An additional decoction can be made to raise the mash temperature again to mash out ( double decoction) or a total three decoctions (triple decoction) could be used to achieve an acid rest - protein rest - sacharification rest mash out profile. Long ago brewers had worked out the details of decoction mashing for beer making - even before the thermometer had been adopted by brewers. Proper strike water temperature was by achieved mixing measured volumes of boiling and ambient temperature water, and mash rest temperatures were achieved by mixing boiling and non boiling mash fractions. Through trial and error, good luck and patience these early brewers discovered the proportions of each needed to effectively step through the various temperatures to acidify the mash, degrade proteins, and convert the malts starch into the fermentable malt sugars. In fact, a simple infusion mash using the under modified malts of this period would have produced weak, hazy, inferior beer. Decoction mashing was an enabling technology for clear pale beers like those produced in Pilzn. You see, by boiling the grain, starches dissolve and insoluble proteins are denatured and coagulate as a scum on the top. The vital amylase enzymes are quite soluble, so if a "thick" decoction mash is pulled for boiling, the "thin" rest mash contains almost all of the enzymes where they are safe from heat degradation. When the decoction is added back, the dissolved starches are immediately available for the enzymes in the rest mash to go to work on, and the rest mash temperature is raised. The proteins that coagulate in the decoction are usually skimmed off the top before the decoction is added back to the rest mash, which improves wort clarity. Eventually, maltsters in Britain learned how to make higher modified malt, the thermometer was accepted as a brewing tool and infusion mashing was born. This technique enabled shorter brewing sessions, the use of less fuel and in general lowered the cost of beer; all good things considering beer sustained many a laborer during Britain's industrial revolution. Decoction mashing did not die. In fact, to this day most European lagers still use a decoction mash, even though their malts are now have a high degree of modification. And not just because they are steeped in tradition. Infusion mashing is not prohibited by the Reinheitsgebot. But, decoction mashing produces a richer malt profile with complex caramelized flavors that are the hallmarks of most continental European beer styles, particularly Pilsner, Marzen, Bock, and especially Dopplebock. The specific flavoring agents produced by decoction mashing have not been rigorously identified by chemical name, but it is presumed that they are the result of certain browning (melanoidin) reactions and caramelization. These are the same types of reactions that happen when you cook a roast in the oven. An analogy can be drawn between oven roasting vs. microwaving a roast and decoction vs. infusion mashing malt. The browning reactions require the presence of protein and sugars and carmelization requires a high sugar concentration. While carmelization does occur in the main boil, the concentration of sugars is generally higher in the mash so decoction mashing will give more carmelization than wort boiling. The browning reactions are not as prevelant in the boil because the wort has been separated from the grist, and there is not a sufficient amount of protein in clear wort to support them as much. These browning reactions, and high sugar content in the decoction also serve to lower the pH of the decoction so that leaching of tannins form the grains husk is not a problem. There has been a trend in continental Europe recently of brewers moving away from the triple and double decoctions as a matter of economics. Many are now using a single decoction, though rumors have it that a few are either using or experimenting with infusion mashes. Today's highly modified malts, the availability of large variety of specialty malts, superior milling, automated temperature control and superior water chemistry have all lessened the requirement for triple decoction mashes. However, even a single decoction will produce malt flavors unobtainable by any other means.

Hopefully the craft of decoction mashing won't be entirely lost among commercial brewers for economic reasons. As homebrewers we should be prepared to carry the torch and keep this historic and beneficial technique alive. In Part 2, I'll explain how to get started decoction mashing at home with a minimum investment.

Decoction Mashing, Part 2

Decoction Mashing at Home

By David Cordrey In Part 1 of this subject I described what decoction mashing is, extolled it's benefits, and gave a brief history of its origin and what styles showcase decoction mashing's added character. In Part 2 I'll describe the practical aspects of decoction mashing. This is a "How To" primer on the subject. You may ask yourself "Why on earth would I want to do a decoction mash at home?" - I make damn good beer using infusion mashes. I use highly modified quality 2-row malt, I don't need to decoct. I don't want to hassle with a bunch of extra process steps to make my beer. I'm afraid I'd screw up a batch by boiling grains. These are all valid points. But what if you wanted to make a killer Dopplebock? Adding Crystal and Munich malt to an infusion mash will help add sweetness, but just won't give the same perceived maltiness as a decoction mash. What if you wanted to replicate the procedure to make a Bohemian Pilsner? Authenticity would dictate a decoction mash. What if you were making a Pale Ale or Bitter or any other style using an infusion mash and you missed your mash temperature? A small decoction could get you back on track without thinning out the mash excessively by just adding more hot water. Decoction mashing is a technique that homebrewers should have in they're repertoire. And believe me, it is easy to master. Once you get used to the technique, you'll probably use it a lot! What To get started you'll need the following extra equipment: You'll Need:

A second stainless or enamel finished boiling pot at least one third the volume of your mash tun. A large long handled slotted spoon or strainer. A small approx. 1 to 2 quart size container (Tupperware works fine). A heat source for boiling the decoction.

Chances are you have everything you need at home already. I use the small 3 gallon pot I started brewing in, a big plastic slotted spoon from the kitchen, a thoroughly cleaned quart size yogurt container and my Cajun Cooker. How to Decoct The big question in decoction mashing is how much mash do you pull out for boiling? If you don't take enough mash the temperature rise will not be as great as desired; too much will result in overshooting your desired temperature. Fortunately there is a good "rule of thumb" to follow for decoction mashing:

Dough in using 1.33 qts. of water per pound of grain and stabilize at 122F. Use a thick portion of the mash consisting of 40% the quantity of grain in the decoction. Temperature gain will be approximately 28F per decoction.

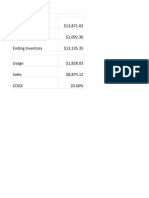

This rule of thumb is easy to remember, and fits the temperature profile for a single decoction nicely. If you want a different temperature gain, you can calculate the decoction fraction as follows: F = ( Tf - To ) / ( 212 - Tf- K ) Where: F is the fraction of the main mash to boil. (multiply by 100 to get %), To is the starting temperature in F, Tf is the desired final temperature in F, K is your temperature loss constant (17F for my system). The value for K can be adjusted a few degrees to fit your own results. When plotted in graphic format, the results look like this:

As can be seen, this formula predicts that as the starting temperature increases, a larger decoction needs to be pulled to result in the same temperature gain. I always try use 1.33 quarts of water per pound of grain for both single infusion and decoction mashes - just as a matter of convention, not because this is a magic ratio. Different ratios can be used, but will affect the temperature gain because water and grain have different specific heats. For water/grain ratios of 1.25 to 1.5 qts/lb the above rule is close, however, and can be accommodated by changing the "K" term. Detailed Procedure Definition of a "thick mash" is a little tricky. It is important to allow the gain to become fully hydrated (absorb all of the water it can) before pulling the decoction. Stir the mash well and let it soak for 5 to 10 minutes at the initial rest temperature. Then using your large slotted spoon, scoop out the wet grain into your quart size cup and transfer to the small (cold) boiling vessel. The grain should pile up in a ball in the pot. Scoop out a third of the grain. I've found my 1 qt. container holds very close to a pound of dry grain. If I'm mashing 15 lbs. total, one third of that would be 5 scoops for the decoction. Now pull out some liquid from the main mash in your container and slowly add it to the pot until the pile of grain begins to slump. Stir it up, it should resemble the consistency of thick oatmeal, with some liquid between clumps of grain. Don't forget to cover up and insulate the main mash. You don't want it to cool off while you're boiling the decoction! Start the fire under the decoction mash and heat it up slowly, stirring constantly to prevent scorching. As it nears boiling, it will appear to thin out some and a scum layer will form on top. Keep it on a low boil for as long as you want to conduct the initial main mash rest, scraping the scum off occasionally, and stirring frequently. I generally boil for 20 to 30 minutes. Be careful not to scorch or burn the grain, add a little more liquid from the main mash if this looks like it might happen. The longer the boil, the more the flavor impact it will have; I've gone as long as 45 minutes with the decoction boil. A short boil will net the same temperature rise, but with less flavor impact. Now carefully dump or scoop the decoction mash back into your mash tun. Try not to splash too much or spill it down the front of your shirt. If you wear glasses and can see Okay without them, take them off first. I've had a few near accidents when my glasses steamed up so bad I couldn't see at all. Once you have successfully transferred the decoction back to the mash tun, stir it all up thoroughly and cover to let the temperature stabilize. You should wait at least 5 minutes before checking the temperature. Everything should be Okay now, just continue this rest for the desired time. That's it for a single decoction mash. Just sparge and collect the wort like normal. Multiple Decoctions--The Ultimate Experience For multiple decoctions, just repeat the procedure to step through your temperature ranges. The 28F rise described in the previous section fits nicely with the temperature step profile that is desired for a single decoction mash. If you dough in to achieve a 122F first rest (protein rest), a single decoction will get you to the conversion rest temperature of ~150F. A second decoction would heat the mash to above 170F for a mash out. A triple decoction profile could be employed to rest at four different temperatures. The more decoctions you use will increase the number of melanoidin reactions and carmelization, and thus add more of the "malt character" that is associated with decoction mashing. The possibilities are virtually unlimited as far as temperature profiles you can create. Traditionally the rest temperatures that are used with decoction mashing are as follows:

95-110 F Acid / Gluconase Rest 120-127 F Protein Rest 145-159 F Sacharification (conversion rest) 170-178 F Mash out

Which rest temperatures you want to hit, will determine the number of decoctions you will use. The most common decoction mashing profiles are: Single Decoction: Mash in at the protein rest temperature. Use a single decoction to reach conversion temperature. Double Decoction Mash: Mash in at the protein rest temperature. Use one decoction to reach conversion temperature, then a second decoction to mash out. Typically used for sweeter beers with a higher conversion temperature. The "mash out" destroys any residual enzymes that might further break down any dextrins during sparging.

Triple Decoction Mash: Mash in for an acid or glucanase rest, then perform three separate decoctions to hit each of the temperature

ranges. An acid rest helps lower pH and thus starch conversion when using all pale malts and very soft water, such as might be the case when replicating a Bohemian Pilsner. These rest temperatures were developed over a long time by trial and error to fit the circumstances faced by brewers hundreds of years ago. The merits of each rest and impact of what temperature to hit in each range are often debated and hence are subjects for another article. There are plenty of books covering this subject in detail. Papazian's The New Complete Joy of Homebrewing is a good primer on this subject. Go For It! You now have all of the information you need to try decoction mashing on your very own. Go for it! Take the plunge. Really, your chance for failure is very, very small. Your chance for outstanding success is great. The temperature ranges are broad enough you're going to end up somewhere in the ballpark. My experience is that I have never overshot by more than 2F. When I err on the low side by 5F or more I just do an extra, small quick decoction to get back on track. Remember, proportionally smaller or larger decoction volumes will net lower or higher temperature rises. Short boil times will give the same temperature rise without affecting flavor or color very much. These facts are useful for making small temperature adjustments. So if you miss your target temperature in an infusion mash, use the formula or graph above and just pull a small decoction to boost it up a bit. For certain styles, decoction mashing is the only way to get the "malt character" that is required. Decoction mashing also can give a pleasing complexity in styles that don't traditionally use decoction mashes. Scotch Ales, for instance, can be easily given a malty finish through the use of a decoction mash. Decoction mashing is a technique that is well worth mastering. You may not use it for every batch, but it should be in your repertoire for making traditional lagers & bocks, correcting mash temperatures, or adding malt character to any beer.

You might also like

- Ancient Beer History: Origins Dating Back 7,000 YearsDocument8 pagesAncient Beer History: Origins Dating Back 7,000 YearsFarhaan MohammedNo ratings yet

- Cat's Meow Home Brewing 05 Stout PorterDocument48 pagesCat's Meow Home Brewing 05 Stout PorternawickNo ratings yet

- Make Yeast StarterDocument2 pagesMake Yeast StarterAlexandraNo ratings yet

- HTTP Winemaking Jackkeller Net Reques28 ASPDocument16 pagesHTTP Winemaking Jackkeller Net Reques28 ASPdedejotaNo ratings yet

- Beer Brewing ProcessDocument4 pagesBeer Brewing ProcessprodebmicrooNo ratings yet

- Ginger Beer Step by Step GuideDocument4 pagesGinger Beer Step by Step GuidemaximpashninNo ratings yet

- Brewing: Reported By: Relvis Josh DG. LauretaDocument11 pagesBrewing: Reported By: Relvis Josh DG. LauretamelalabsyouNo ratings yet

- Hand Out Home BrewingDocument9 pagesHand Out Home BrewingJuan Martin GiménezNo ratings yet

- Waste Water Treatment For Brewery and Winery IndustryDocument31 pagesWaste Water Treatment For Brewery and Winery IndustryNational WaterNo ratings yet

- Mangrove Jacks CatalogoDocument13 pagesMangrove Jacks CatalogolhcorreaNo ratings yet

- Brewing ScienceDocument36 pagesBrewing ScienceVohinh NgoNo ratings yet

- Faculty of MBChB Medical Biochemistry (BC2410) AMINO ACIDS REVISIONDocument27 pagesFaculty of MBChB Medical Biochemistry (BC2410) AMINO ACIDS REVISIONlucky mbaselaNo ratings yet

- Dry Yeast and Liquid Yeast Substitution ChartDocument7 pagesDry Yeast and Liquid Yeast Substitution ChartJuan ToledanoNo ratings yet

- Change in pH During Curd Formation from MilkDocument16 pagesChange in pH During Curd Formation from MilkYoezer PeldenNo ratings yet

- Topped With Hops Double IPADocument2 pagesTopped With Hops Double IPABautista John DexterNo ratings yet

- American IPA brewing data and calculationsDocument10 pagesAmerican IPA brewing data and calculationsGeoNo ratings yet

- Sustainable Brewing Concept Desalination ChemicalsDocument5 pagesSustainable Brewing Concept Desalination ChemicalsAndalusia Martha Novaline SiboroNo ratings yet

- National Homebrew Day Big Brew RecipesDocument1 pageNational Homebrew Day Big Brew RecipesYerco UrquizaNo ratings yet

- Brew House Process PDFDocument50 pagesBrew House Process PDFBerhe Dargo50% (4)

- Dry Fruits and VegetablesDocument15 pagesDry Fruits and VegetablesmeineanmeldungenNo ratings yet

- Yeast Farming - Yeast - Aussie Home BrewerDocument5 pagesYeast Farming - Yeast - Aussie Home Brewerietram12No ratings yet

- Brewing Fermentations More ProfitableDocument1 pageBrewing Fermentations More ProfitableSemana de Engenharia '2010No ratings yet

- Fermentation PracticeDocument5 pagesFermentation PracticeEyoel AwokeNo ratings yet

- Pat Macks Home Brewing Caps Recipe EbookDocument26 pagesPat Macks Home Brewing Caps Recipe Ebookgregoir4073No ratings yet

- Morebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemDocument2 pagesMorebeer! Beer Making Instructions: Morebeer! Personal Brewery Starter SystemTeddy Riaño AlarconNo ratings yet

- Brewing With WheatDocument16 pagesBrewing With WheatGustavo MicheliniNo ratings yet

- Malt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupDocument33 pagesMalt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupOleg Burlac100% (1)

- Brew Like A MonkDocument3 pagesBrew Like A MonkSonia Cireaşă0% (1)

- 15 American IPAs1Document17 pages15 American IPAs1JohnRykerNo ratings yet

- Malting Process PDFDocument9 pagesMalting Process PDFRay TaipeNo ratings yet

- Craft Brewery - Sanitation Procedure - KegsDocument1 pageCraft Brewery - Sanitation Procedure - KegsHau SinâuđaNo ratings yet

- Rehydrate vs. Gatorade ComparisonDocument1 pageRehydrate vs. Gatorade ComparisonClint100% (6)

- 2010 SOQ 3 Belgian StrongDocument5 pages2010 SOQ 3 Belgian StrongJoao Carlos MaximianoNo ratings yet

- Understanding YeastDocument1 pageUnderstanding YeastEmbdenNo ratings yet

- Home-Made MayonnaiseDocument1 pageHome-Made MayonnaisetryabcdefNo ratings yet

- CargillDocument8 pagesCargillbondo2011No ratings yet

- Sour PresentationDocument20 pagesSour PresentationPipo PescadorNo ratings yet

- Enzymes in BrewingDocument8 pagesEnzymes in BrewingAlexandru TarțianNo ratings yet

- BESTMALZ Malzbroschuere Malt Catalog ENDocument56 pagesBESTMALZ Malzbroschuere Malt Catalog ENPhilip Walker100% (1)

- Fermentedtreasures Ginger Beer BrewingDocument3 pagesFermentedtreasures Ginger Beer BrewingguennikNo ratings yet

- Brewing with Malt Extract: Fermentability, Hops, Water and Yeast RehydrationDocument4 pagesBrewing with Malt Extract: Fermentability, Hops, Water and Yeast RehydrationAsh88640% (1)

- Loma Brewing Company MenuDocument2 pagesLoma Brewing Company MenuEaterNo ratings yet

- Grains and Adjuncts Chart English Grain Malto PDFDocument7 pagesGrains and Adjuncts Chart English Grain Malto PDFDavide NicolisNo ratings yet

- Getting Started With Biab Brewing: A Start-To-Finish Guide For Home Brewing Your First BeerDocument23 pagesGetting Started With Biab Brewing: A Start-To-Finish Guide For Home Brewing Your First BeerDalibor DimkovskiNo ratings yet

- Ginger Beer: (Using Double Fermentation Based Loosely On La MéthodeDocument2 pagesGinger Beer: (Using Double Fermentation Based Loosely On La MéthodevelivolantNo ratings yet

- Leaflet - Milk FermentationDocument3 pagesLeaflet - Milk FermentationNoor SultanNo ratings yet

- How To Make YogurtDocument6 pagesHow To Make YogurtDewi ShintaNo ratings yet

- Food Preservation Techniques by WomenDocument15 pagesFood Preservation Techniques by WomenMoms Times100% (9)

- Kombucha Alcohol Study Finds Levels Vary in BCDocument30 pagesKombucha Alcohol Study Finds Levels Vary in BCsyahrilNo ratings yet

- 15 Classic Belgian Clone Recipes 2Document17 pages15 Classic Belgian Clone Recipes 2JohnRykerNo ratings yet

- Beer IndustryDocument23 pagesBeer IndustrySonit PaulNo ratings yet

- Bioreactor Configuration: Submitted To-Dr.R.S.Singh Submitted By-Benaf Kathuria MSC (Hon'S) Biotechnology Roll No-18010013Document35 pagesBioreactor Configuration: Submitted To-Dr.R.S.Singh Submitted By-Benaf Kathuria MSC (Hon'S) Biotechnology Roll No-18010013Jot SainiNo ratings yet

- Homemade Seasoning BlendsDocument4 pagesHomemade Seasoning BlendsJohnNo ratings yet

- Ferment IsDocument56 pagesFerment IsCarlos UriaNo ratings yet

- Cider Making Made EasyDocument6 pagesCider Making Made Easybartolomej7No ratings yet

- Recipes for Brewing Different Types of Beers and AlesFrom EverandRecipes for Brewing Different Types of Beers and AlesNo ratings yet

- Brew Beer Like A Yeti - Chapter Three: GrainDocument22 pagesBrew Beer Like A Yeti - Chapter Three: GrainChelsea Green PublishingNo ratings yet

- Beer and Wine ProductionDocument28 pagesBeer and Wine ProductionmoniqueNo ratings yet

- Road Construction Materials GuideDocument98 pagesRoad Construction Materials GuideFrimini BeatusNo ratings yet

- NHA CSR 2014 Rates for Sindh ProjectsDocument262 pagesNHA CSR 2014 Rates for Sindh ProjectsSohail Ahmed Khilji100% (1)

- Thread Gauge ISO1502 PDFDocument5 pagesThread Gauge ISO1502 PDFBaldev SinghNo ratings yet

- Abco L-Series Stainless Steel "Heat and Hold" Belt Blancher..Document3 pagesAbco L-Series Stainless Steel "Heat and Hold" Belt Blancher..Baldev SinghNo ratings yet

- Understanding Bearing Internal ClearanceDocument4 pagesUnderstanding Bearing Internal ClearanceBaldev SinghNo ratings yet

- Eternal Voice August 2009Document44 pagesEternal Voice August 2009Baldev SinghNo ratings yet

- SE50 VT Tamper Bar ScreedDocument1 pageSE50 VT Tamper Bar ScreedBaldev SinghNo ratings yet

- Handbook On Bio Methanation PlantDocument1 pageHandbook On Bio Methanation PlantBaldev SinghNo ratings yet

- Thread Rolling Machine GuideDocument2 pagesThread Rolling Machine GuideBaldev SinghNo ratings yet

- Can Thyroid Disease Be CuredDocument2 pagesCan Thyroid Disease Be CuredBaldev SinghNo ratings yet

- Profile On Processing of TurmericDocument13 pagesProfile On Processing of TurmericBaldev Singh100% (1)

- Thyroid Surgery (For Benign Thyroid Disease)Document12 pagesThyroid Surgery (For Benign Thyroid Disease)mzzzzmNo ratings yet

- Can Thyroid Disease Be CuredDocument2 pagesCan Thyroid Disease Be CuredBaldev SinghNo ratings yet

- Aim of LifeDocument3 pagesAim of LifeBaldev SinghNo ratings yet

- Rapid Thread Cutting SystemDocument4 pagesRapid Thread Cutting SystemBaldev SinghNo ratings yet

- Hydrostatic Force on Submerged PlatesDocument5 pagesHydrostatic Force on Submerged PlatesBaldev SinghNo ratings yet

- Difference Between Hydro Static Bearing and Hydrodynamic BearingDocument3 pagesDifference Between Hydro Static Bearing and Hydrodynamic BearingBaldev Singh80% (5)

- Difference Between Hydro Static Bearing and Hydrodynamic BearingDocument3 pagesDifference Between Hydro Static Bearing and Hydrodynamic BearingBaldev Singh80% (5)

- In The Bowl of The SkyDocument1 pageIn The Bowl of The SkyBaldev SinghNo ratings yet

- Taco Bamba DC Cocktail MenuDocument2 pagesTaco Bamba DC Cocktail MenuEaterNo ratings yet

- Beer CatalogDocument88 pagesBeer CatalogTonya SimsNo ratings yet

- Le Sherpa Wine MenuDocument1 pageLe Sherpa Wine Menusonam sherpaNo ratings yet

- Food Menu TemplateDocument14 pagesFood Menu TemplateG- WizNo ratings yet

- Summer 2017 Southern Oregon Wine SceneDocument69 pagesSummer 2017 Southern Oregon Wine SceneSouthern Oregon Wine SceneNo ratings yet

- Group 2 - Post Lab Activity 9 (Pcog Finals)Document10 pagesGroup 2 - Post Lab Activity 9 (Pcog Finals)Florence Lynn BaisacNo ratings yet

- The Influence of Ancient Rome On Wine History Research PaperDocument31 pagesThe Influence of Ancient Rome On Wine History Research PaperAnna Maria Dark100% (1)

- THESISDocument4 pagesTHESISMaiden GeeNo ratings yet

- Cox's Steakhouse, Bar & Restaurant - Dromod, Co. Leitrim - Drink's Menu 2018Document7 pagesCox's Steakhouse, Bar & Restaurant - Dromod, Co. Leitrim - Drink's Menu 2018Emmett CorcoranNo ratings yet

- Solidly Crafted Brilliantly Designed: Beverage TanksDocument2 pagesSolidly Crafted Brilliantly Designed: Beverage TanksHaries Bugarin GarciaNo ratings yet

- FVL2 - PracticeQuestionsExam - June 2016Document106 pagesFVL2 - PracticeQuestionsExam - June 2016nathalia100% (6)

- Excise Policy For Patiala Division For 2012-13Document24 pagesExcise Policy For Patiala Division For 2012-13Akhilesh YadavNo ratings yet

- Heineken N.V: Global Branding and AdvertisingDocument9 pagesHeineken N.V: Global Branding and AdvertisingAnik GuinNo ratings yet

- 1 - Beer Making ProcessDocument5 pages1 - Beer Making ProcessClarince Joyce Lao DoroyNo ratings yet

- Brettanomyces Bruxellensis, A Survivalist Prepared For The Wine Apocalypse and Other BeveragesDocument15 pagesBrettanomyces Bruxellensis, A Survivalist Prepared For The Wine Apocalypse and Other BeveragesOscar Díaz AcostaNo ratings yet

- Flavored Alcoholic Beverages 2015Document31 pagesFlavored Alcoholic Beverages 2015PublicaNo ratings yet

- Wset Level 4 SatDocument2 pagesWset Level 4 SatLNo ratings yet

- Smoked Beer Guide: History, Styles, Recipes & MoreDocument17 pagesSmoked Beer Guide: History, Styles, Recipes & MorediegobaraNo ratings yet

- Wine Spectator 12.15.2020 @enmagazine 0Document116 pagesWine Spectator 12.15.2020 @enmagazine 0Fernando ReisNo ratings yet

- Rate List PDFDocument12 pagesRate List PDFmaneesh_choudhary_pgp14100% (1)

- Essential Wine Vocabulary & Terms ExerciseDocument5 pagesEssential Wine Vocabulary & Terms ExercisePutu Rana JanendraNo ratings yet

- Thesis RsDocument22 pagesThesis RsS WaghNo ratings yet

- POLYGEL BH TDS EN 1120220 BEER ItalyDocument2 pagesPOLYGEL BH TDS EN 1120220 BEER ItalyyehNo ratings yet

- The Brew Your Own Big Book of Clone Recipe - Brew Your OwnDocument716 pagesThe Brew Your Own Big Book of Clone Recipe - Brew Your OwnFrederico Ribeiro67% (3)

- 7-3-364-232 GrapesDocument4 pages7-3-364-232 GrapesIlamurugu KrishnaswamyNo ratings yet

- Bài kiểm tra kết thúc Chương 4Document9 pagesBài kiểm tra kết thúc Chương 429Trương Minh NhânNo ratings yet

- Klosterneuburg ChorusDocument1 pageKlosterneuburg ChorusLeopoldimpNo ratings yet

- Fundamentals of Bar & Beverage KnowledgeDocument53 pagesFundamentals of Bar & Beverage KnowledgeAudrey RNo ratings yet

- The Science of Tella Production1Document15 pagesThe Science of Tella Production1Simon MehariNo ratings yet

- O'Briens Wine Festival BrochureDocument69 pagesO'Briens Wine Festival BrochureEdana CassidyNo ratings yet