Professional Documents

Culture Documents

ASPE PSD - Condensate Drains

Uploaded by

Niong DavidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASPE PSD - Condensate Drains

Uploaded by

Niong DavidCopyright:

Available Formats

CODE UPDATE

BY RAY MOORE, PE, CPD

Condensate Drains

As plumbing engineers, we must coordinate our systems with the heating and air-conditioning systems in a building, allowing for the needs of other trades. One issue that plumbing engineers must constantly deal with is condensate drainage. In an air-conditioning system, when the air is cooled, water is removed from the air. All cooling coils in an air-conditioning system must have a drain pan under the cooling coil to collect the condensed water (condensate). A path is required to allow this condensed water to discharge to the drainage system. e 2006 International Plumbing Code (IPC) has extensive requirements for collecting and discharging this condensed water. e 2006 Uniform Plumbing Code (UPC) has one simple requirement. Where do they di er? ABOUT CONDENSATE DRAINAGE Condensate drainage from air-conditioning equipment is extremely important. In humid climates, a lot of moisture is in the air. When the air is cooled through an air-conditioning process, this water is condensed out of the air. In dryer climates, only a little amount of water is condensed out of the air. In many jurisdictions located in dry climates, the condensate drain from rooftop air-conditioning equipment is discharged on the roof. However, I know of several jurisdictions where the condensate must be piped to the drainage system because algae tends to grow on the wet areas of the roof where the condensate drips, creating unhealthy conditions. Because the condensate drain piping is typically an indirect drain line, both the IPC and the UPC require the condensate piping from the air-conditioning unit to be trapped. In reality, the reason for the trap at air-conditioning equipment is a mechanical issue. e condensate drain pan, located under the cooling coil in the air-conditioning equipment, is under either positive pressure or negative pressure depending on the location of the cooling coil. On the outlet side of the fan, the drain pan is under positive pressure. On the suction pressure side of the fan, the drain pain is under negative pressure. e trap on the condensate drain from the air-conditioning unit prevents air from passing through the indirect piping. e trap seal of this trap is sized based on the negative or positive pressure of the fan. Typically, the trap seal is sized at 1 times the inlet or outlet pressure of the fan, whichever is greater. On large fan systems, the trap seal could be up to 12 inches deep. As a plumbing designer, you must coordinate the depth of the trap with the mechanical designer to ensure adequate space to install the trap. e downstream side of the trap should be vented to equalize the pressure in the piping, allowing the condensate water to ow from the trap. THE CODE REQUIREMENTS e piping from the condensate drain pan is an indirect waste pipe and must be sized and designed as an indirect waste pipe. e IPC requires indirect waste lines more than 4 feet total length or 2 feet horizontal length to be trapped. e UPC requires indirect waste lines more than 5 feet long to be trapped. e trap required on the condensate drain from the air-conditioning unit meets these requirements. An additional trap is not necessary. Table 8-2 of the UPC speci es the minimum pipe sizes for the condensate drain pipe. Section 314.2.2 of the IPC states that the minimize size of the pipe shall be inch, and where multiple units are connected, the piping shall be sized by an approved method. e IPC also requires horizontal sections of the drainpipe to be installed in a uniform alignment and at a uniform slope. Table 8-2 of the UPC shows that a -inch pipe can handle up to 20 tons of refrigeration. It is my experience that many manufacturers of air-conditioning equipment provide condensate drain connections that are larger than the -inch pipe size. It is my recommendation that the condensate drain line be the same size as the outlet connection on the air-conditioning equipment. e IPC speci es that the piping material for the condensate drainpipe should be cast iron, galvanized steel, copper, crosslinked polyethylene, polybutylene, polyethylene, ABS, CPVC, or PVC pipe or tubing. All components shall be selected for the pressure and temperature rating of the installation. e UPC speci es that the condensate drain piping shall be constructed of material speci ed in Chapter 7, which deals with sanitary drainage. erefore, all condensate drainage piping shall be the same as that for sanitary drainage. One problem with this is that the smallest drainage pipe is 1 inch, and many times the condensate drain pipe is inch or 1 inch. If this is the case, water tubing or pipe must be used. e IPC has some additional requirements for condensate drain pans that are not included in the UPC. Section 314 of the IPC is taken directly from the International Mechanical Code. Section 314 of the IPC requires that additional protection be provided in case the drain line gets plugged, and the condensed water overows the drain pan and damages building components. e IPC also requires that an auxiliary or secondary drain system be provided. ere are four di erent methods for compliance. e rst method is to provide a secondary drain connection on the primary drain pan. is secondary drain must drain to a place where occupants would notice if a stoppage existed in the main drainage system. e second method is to provide a condensate drainpipe from an auxiliary or secondary drain pan. e third and four methods listed in the IPC require a water level detector and shuts of the air-conditioning equipment to be provided so additional condensed water is not produced. Typically, this water level detector is a sensor or oat switch. As plumbing engineers, we need to work with the mechanical engineers in the design of the heating and air-conditioning systems to provide condensate drains from the air-conditioning equipment.

RAY MOORE is a principal with Professional Engineering Services in Salt Lake City, ASPE vice president, legislative, and chair of the Utah Building Codes Commission Plumbing Advisory Committee. For more information or to comment on this article, e-mail articles@psdmagazine.org.

12 Plumbing Systems & Design

MARCH/APRIL 2007

PSDMAGAZINE.ORG

You might also like

- The Story of Young Abraham Lincoln (Civil War Classics): The Early History of an American IconFrom EverandThe Story of Young Abraham Lincoln (Civil War Classics): The Early History of an American IconNo ratings yet

- Medgas Pipe Sizing 2021Document11 pagesMedgas Pipe Sizing 2021eimrehNo ratings yet

- A Method of Damper Control For Corridor Ventilation and Smoke ExtractionDocument15 pagesA Method of Damper Control For Corridor Ventilation and Smoke ExtractionrasheedillikkalNo ratings yet

- Seresco Natatorium Design Guide 2013Document36 pagesSeresco Natatorium Design Guide 2013Luis Giagante100% (1)

- ESP CAlDocument1 pageESP CAlMohammed Sayeem ShabuddinNo ratings yet

- PSD CEU 194dec12 PDFDocument22 pagesPSD CEU 194dec12 PDFCesar Muñoz OssesNo ratings yet

- VFD Domestic Water Booster Standard Sequence of Operation PDFDocument13 pagesVFD Domestic Water Booster Standard Sequence of Operation PDFCristianDumitruNo ratings yet

- AHU Condensate CollectionDocument7 pagesAHU Condensate CollectionAhamed Saleel C100% (1)

- Air Curtain Guide DesignDocument8 pagesAir Curtain Guide Designanton7786No ratings yet

- Chiller Flow Rates and Guidelines For Chilled Water System PipingDocument3 pagesChiller Flow Rates and Guidelines For Chilled Water System PipingTanveer Aziz100% (3)

- AHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetDocument17 pagesAHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetJagatjeetMNo ratings yet

- Hot Water Circulating Pump Cal2Document3 pagesHot Water Circulating Pump Cal2mansidaughtNo ratings yet

- Prima Usaha ACMV Duct Sizing Table 2017 LockedDocument1 pagePrima Usaha ACMV Duct Sizing Table 2017 LockedShaikh Tauseef100% (2)

- Chilled Beam App Guide - 2013Document12 pagesChilled Beam App Guide - 2013Santiago J. ramos jr100% (1)

- Water Sizing Fixture Units WorksheetDocument13 pagesWater Sizing Fixture Units Worksheetike4546No ratings yet

- Air Master Linear Bar Grille With Air Flow DataDocument0 pagesAir Master Linear Bar Grille With Air Flow Datamykel_dpNo ratings yet

- ASPE Greas Interceptor Sizing-2017EDDocument11 pagesASPE Greas Interceptor Sizing-2017EDEhab MohamedNo ratings yet

- Tyco Pre Action LimitsDocument13 pagesTyco Pre Action LimitsGrbayern Munchen100% (2)

- Duct DesignDocument49 pagesDuct DesignabianshbaralNo ratings yet

- Industrial VentilationDocument8 pagesIndustrial VentilationECRD100% (1)

- Condensate Drain Calculation - Lab AHU PDFDocument1 pageCondensate Drain Calculation - Lab AHU PDFAltaf KhanNo ratings yet

- Garage Ventilation System DesignDocument8 pagesGarage Ventilation System DesignDiego PovedaNo ratings yet

- Ductwork DesignDocument26 pagesDuctwork DesignHafiz Hassan100% (1)

- Heat Gain From Common Electrical EquipmentDocument4 pagesHeat Gain From Common Electrical EquipmentsauroNo ratings yet

- Smacna Duct LeakageDocument3 pagesSmacna Duct Leakageanton7786No ratings yet

- NBC vs. NFPADocument12 pagesNBC vs. NFPAMGHIRBI HAYKELNo ratings yet

- 78 Return Grille LocationsDocument2 pages78 Return Grille LocationsKyaw San OoNo ratings yet

- 2009 UPC PresentationDocument81 pages2009 UPC PresentationFarhsa Dhom Eemihahs DhomNo ratings yet

- High Velocity Duct Design Tips by TraneDocument50 pagesHigh Velocity Duct Design Tips by TraneInventor SolidworksNo ratings yet

- ASPE Cleveland Chapter Plumbing Handbook 2011-2012Document133 pagesASPE Cleveland Chapter Plumbing Handbook 2011-2012Edward Garcia100% (1)

- 201005CEU167Document7 pages201005CEU167Mohamed Mostafa AamerNo ratings yet

- AspeDocument8 pagesAspe185412No ratings yet

- High Performance Sequences of Operation For HVAC Systems: ASHRAE Addendum H To ASHRAE Guideline 36-2018Document26 pagesHigh Performance Sequences of Operation For HVAC Systems: ASHRAE Addendum H To ASHRAE Guideline 36-2018suhasNo ratings yet

- Ventilation - Electrical Rooms PDFDocument4 pagesVentilation - Electrical Rooms PDFvalentinlupascu33No ratings yet

- Secondary Loop Chilled Water in Super High Rise BLDGDocument11 pagesSecondary Loop Chilled Water in Super High Rise BLDGocean220220No ratings yet

- Practical Plumbing Design Guide by James C. ChurchDocument3 pagesPractical Plumbing Design Guide by James C. Churchali Zakria0% (1)

- Comfort and Critical Outdoor Design ConditionsDocument6 pagesComfort and Critical Outdoor Design ConditionshueyliewNo ratings yet

- HVAC - Overview of Space Heating Systems PDFDocument68 pagesHVAC - Overview of Space Heating Systems PDFFredie UnabiaNo ratings yet

- Systemair CatalogueDocument21 pagesSystemair CataloguePARVEZ AMEENNo ratings yet

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- Tech PDFDocument3 pagesTech PDFAwais JalaliNo ratings yet

- Double Regulating ValveDocument24 pagesDouble Regulating ValveMohamed Rady33% (3)

- Swimming Pool Heater SizingDocument1 pageSwimming Pool Heater SizingAmeer AbbasNo ratings yet

- Underfloor Heating SystemsDocument11 pagesUnderfloor Heating SystemsApurv GoyalNo ratings yet

- Ashrae Design Manual For Smoke ControlDocument6 pagesAshrae Design Manual For Smoke Controlist93993100% (2)

- Flue Sizing OptionsDocument2 pagesFlue Sizing OptionsMarco Antonio Camacho Tezanos-PintoNo ratings yet

- HVAC Chiller SystemsDocument65 pagesHVAC Chiller SystemsgaminirwNo ratings yet

- ASPE Design GuideDocument16 pagesASPE Design GuideJovenal TuplanoNo ratings yet

- CITY HVAC Design Guide AppendicesDocument41 pagesCITY HVAC Design Guide AppendicesSimon Law100% (1)

- Pharmaceutical Facility DesignDocument27 pagesPharmaceutical Facility Designmdalt9180No ratings yet

- SMACNADocument5 pagesSMACNAphil_sheridonNo ratings yet

- Doas DesignDocument4 pagesDoas DesignBill ChambersNo ratings yet

- Dehumidification Calcs AshraeDocument7 pagesDehumidification Calcs AshraeSujit RajanNo ratings yet

- Ashrae Pubcatalog 2016winterDocument16 pagesAshrae Pubcatalog 2016winterMohammed Bafakieh50% (2)

- Air Distribution Sys DesignDocument6 pagesAir Distribution Sys DesignpauloNo ratings yet

- Erv CatalogueDocument12 pagesErv CatalogueSaahil KhaanNo ratings yet

- PSD Ceu 198april13Document16 pagesPSD Ceu 198april13Niong DavidNo ratings yet

- Duct Presentation MaineDocument22 pagesDuct Presentation MaineCharmaine ManliguezNo ratings yet

- Ventilare Si Desfumare Parcaje - ModelDocument220 pagesVentilare Si Desfumare Parcaje - ModelalanatoraNo ratings yet

- Q105 - RSW#3 - Bautista, Aljon Mar, LDocument26 pagesQ105 - RSW#3 - Bautista, Aljon Mar, LaljonNo ratings yet

- Aurora Model 481 Pumps: Single-Stage Fire ServiceDocument1 pageAurora Model 481 Pumps: Single-Stage Fire ServiceNiong DavidNo ratings yet

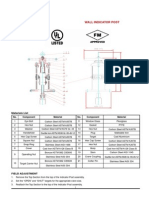

- 6 Rel-Pi-Wall Indicator PostDocument1 page6 Rel-Pi-Wall Indicator PostNiong DavidNo ratings yet

- 11-Car ModelsDocument27 pages11-Car ModelsNiong DavidNo ratings yet

- 08 08.pump Station - IfbDocument35 pages08 08.pump Station - IfbNiong DavidNo ratings yet

- Principles of Exterior DrainageDocument60 pagesPrinciples of Exterior DrainageSeshupower09No ratings yet

- FMDS0404NDocument5 pagesFMDS0404NStory LoveNo ratings yet

- Compressed Air Ref EngDocument118 pagesCompressed Air Ref Engchidambaram kasiNo ratings yet

- Manual 10 - Irrigation Scheme Operation and MaintenanceDocument55 pagesManual 10 - Irrigation Scheme Operation and MaintenanceNiong DavidNo ratings yet

- Electrical EngineeringElevator Safety SystemDocument13 pagesElectrical EngineeringElevator Safety SystemNiong DavidNo ratings yet

- Articles - Elevator Car SizesDocument5 pagesArticles - Elevator Car SizesNiong DavidNo ratings yet

- Basic Elevator Components - Part OneDocument16 pagesBasic Elevator Components - Part OneNiong DavidNo ratings yet

- Structures For Water Control and DistributionDocument76 pagesStructures For Water Control and Distributionnour100% (2)

- Manual 1 - Introduction To IrrigationDocument152 pagesManual 1 - Introduction To IrrigationNiong DavidNo ratings yet

- Manual 1 - Introduction To IrrigationDocument152 pagesManual 1 - Introduction To IrrigationNiong DavidNo ratings yet

- PSD Ceu 198april13Document16 pagesPSD Ceu 198april13Niong DavidNo ratings yet

- 43 00 00 - LPG InstallationDocument13 pages43 00 00 - LPG InstallationNiong David100% (1)

- Presentation5 EV ArchitectureDocument26 pagesPresentation5 EV ArchitectureJAYKUMAR MUKESHBHAI THAKORNo ratings yet

- Assignment 1Document2 pagesAssignment 1Alif Bukhari Imran NaimNo ratings yet

- International Marketing-Assignment No. 01Document36 pagesInternational Marketing-Assignment No. 01Faisal Shahzad60% (5)

- TribunaloLo Ex#6Document14 pagesTribunaloLo Ex#6Jaylou OpondaNo ratings yet

- Day 3 Polygons Lesson PlanDocument6 pagesDay 3 Polygons Lesson PlanBA RTNo ratings yet

- CISCO Router Software - Configuration PDFDocument408 pagesCISCO Router Software - Configuration PDFasalihovicNo ratings yet

- 20CB PDFDocument59 pages20CB PDFChidiebere Samuel OkogwuNo ratings yet

- Course 4 EDocument45 pagesCourse 4 ESzabolcs KovacsNo ratings yet

- InfoDocument18 pagesInfoKaran Verm'aNo ratings yet

- Best Approach: Compound AngleDocument8 pagesBest Approach: Compound AngleAbhiyanshu KumarNo ratings yet

- Hydrocarbon RecoveryDocument29 pagesHydrocarbon RecoveryAlekhya BandaruNo ratings yet

- 19 04 20 p2 PDFDocument32 pages19 04 20 p2 PDFGovind SajuNo ratings yet

- A B C D: Choose Only One Answer For Each QuestionDocument10 pagesA B C D: Choose Only One Answer For Each QuestionAchitt AchitNo ratings yet

- Rr410209 High Voltage EngineeringDocument7 pagesRr410209 High Voltage EngineeringSrinivasa Rao GNo ratings yet

- Gas Welding Equipment PowerpointDocument12 pagesGas Welding Equipment PowerpointChristian RexNo ratings yet

- Safe Bearing Capacity of Soil - Based On Is: 6403 Sample CalculationDocument1 pageSafe Bearing Capacity of Soil - Based On Is: 6403 Sample CalculationSantosh ZunjarNo ratings yet

- Ss 1 Further Mathematics Lesson 4Document7 pagesSs 1 Further Mathematics Lesson 4Adio Babatunde Abiodun CabaxNo ratings yet

- Assignment 1Document3 pagesAssignment 1Carolyn WangNo ratings yet

- 2nd Grading LAA Grade 10Document54 pages2nd Grading LAA Grade 10Urduja Kyle OdiacerNo ratings yet

- Python Unit 1Document18 pagesPython Unit 1Rtr. Venkata chetan Joint secretaryNo ratings yet

- PC - Section 1.3 - Worksheet PDFDocument2 pagesPC - Section 1.3 - Worksheet PDFAnabbNo ratings yet

- GTP For 1CX300sqmmDocument4 pagesGTP For 1CX300sqmmpriyanka236No ratings yet

- Product Bulletin N 6: Bearing Assemblies - Shaft VariationsDocument1 pageProduct Bulletin N 6: Bearing Assemblies - Shaft VariationsRANAIVOARIMANANANo ratings yet

- TM1 Rules White Paper Best Practice RulesDocument22 pagesTM1 Rules White Paper Best Practice RulesMax ChenNo ratings yet

- ASUS U47A Repair GuideDocument5 pagesASUS U47A Repair GuideCarlos ZarateNo ratings yet

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDocument5 pagesComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- Change LogDocument3 pagesChange Logyoga hendriyantoNo ratings yet

- Assignment - 1 Introduction of Machines and Mechanisms: TheoryDocument23 pagesAssignment - 1 Introduction of Machines and Mechanisms: TheoryAman AmanNo ratings yet

- The Power of Adventure in Your Hand: Product Catalog Volume 4 2019Document20 pagesThe Power of Adventure in Your Hand: Product Catalog Volume 4 2019Michael ShelbyNo ratings yet

- Application Note Usrp and HDSDR Spectrum MonitoringDocument14 pagesApplication Note Usrp and HDSDR Spectrum MonitoringcaraboyNo ratings yet