Professional Documents

Culture Documents

EC3-751 Condenser Controller With LON Interface

Uploaded by

Maria DazaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EC3-751 Condenser Controller With LON Interface

Uploaded by

Maria DazaCopyright:

Available Formats

EC3-751 Condenser Controller with LON Interface

Operating Instructions

GB

Contents: Safety instructions: Technical data: Mounting Electrical Installation Setup and Parameter Modification using the Keypad Temporary Display of Data:

1 1 1 2 2 2

Load Default Parameters: Special Functions Indications On The Display Alarm Codes and Messages Parameter List Visualising Data

2 2 2 2 3 4

Technical Data EC3 Series Controller Power supply Power consumption Communication Plug-in connector size Temperature storage operating

24VAC 10%; 50/60Hz; Class II 6.3mm spade earth connector 20VA max. LON FTT10 Removable screw terminals wire size 0.14 1.5 mm2 -20 +65C 0 +60C 080% r.h. non condensing IP20 24VDC, 4...20mA NTC 10 k @ 25C, -50 +50C 24VDC, 4...20mA, 2 wires 24VAC/DC or 230VAC Inductive (AC15) 250V/2A Resistive (AC1) 250V/8A 250V AC, max. 2A

Note: This document contains short form instructions for experienced users. Use last column in List of Parameters to document your individual settlings. More detailed information can be found in the User Manual.

Humidity Protection class Pressure transmitter inputs 2 Temp. inputs for Ambient and Control Temperature (1) Humidity transmitter input (2) Digital Inputs Fan output relays (6x) + General alarm output + Heat recovery output Triac rating

ECD-000 Display Unit Power Supply From EC3-751 via connecting cable Display The EC3-751 condenser controller is a digital controller for air cooled condensers. The condenser may consist of up to 6 fans, one of which is continuously speed controlled. The control target is to maintain the condensing pressure at a defined value by varying the available fan capacity. LED indicators Temp & Humidity Protection class Connecting cable 2-digit red LED with decimal point reversible between C and F Controller 1, Controller 2, p bar, Alarm, IR status Identical to EC3-751 specifications above IP65 (front protection with gasket) ECC-N10 (1m), ECC-N30 (3m), ECC-N50 (5m) or CAT5 cable with RJ45 connectors

Mounting The EC3-751 can be mounted onto a standard DIN rail.

For the measurement of the condensing pressure, a PT4 pressure sensor (3) with 4 20 mA interface can be connected to the controller. The condenser controller has eight relay outputs, six to command the fans (7), one for the heat recovery solenoid (9) and one for General Alarm. Eight digital inputs for 24V AC/DC or 230V AC are available, six for fan serial alarm (4), one for high pressure alarm (5) and one for heat recovery demand (6). The first fan (8) can be continuously speed controlled by the analogue output 0 to 10V with an ALCO FSP Fan Speed Controller or directly with the onboard TRIAC. The fan power supply must be connected to the Triac. To meet the EMC compliance in this case, an external filter must be fitted. Two analogue inputs (1) can be used to measure a control temperature and the ambient temperature. A 420mA input (2) is reserved for the relative humidity sensor. The optional ECD-000 Display Unit can be connected to the EC3-751 for local display of control parameters and for controller setup without the use of a PC. Because the EC3-751 is fully functional without display unit the ECD-000 may be removed at any time.

The ECD-000 can be mounted in panels with a 71x29 mm cutout. See dimensional drawing below for space requirements including rear connectors. Push controller into panel cutout. (1) Make sure that mounting lugs are flush with outside of controller housing Insert allen key into front panel holes and turn clockwise. Mounting lugs will turn and gradually move towards panel (2) Turn allen key until mounting lug barely touches panel. Then move other mounting lug to the same position (3) Tighten both sides very carefully until display is secured. Do not over tighten as mounting lugs will break easily.

Safety instructions: Read installation instructions thoroughly. Failure to comply can result in device failure, system damage or personal injury. It is intended for use by persons having the appropriate knowledge and skill. Ensure electrical ratings per technical data are not exceeded. Disconnect all voltages from system before installation. Keep temperatures within nominal limits. Comply with local electrical regulations when wiring

EC3-751_65087_EN_R04.doc

Replacement for R03

1/5

DWG Nr.: 864 915

26.09.2007

EC3-751 Condenser Controller with LON Interface

Operating Instructions Electrical Installation Refer to the electrical wiring diagram (below) for electrical connections. A copy of this diagram is labeled on the controller. Use connection wires/cables suitable for 90C operation (EN 60730-1). Ground the metal housing with a 6.3mm spade connector. Important: Keep controller and sensor wiring well separated from mains wiring. Minimum recommended distance 30mm.. Warning: Use a class II category transformer for 24VAC power supply (EN 60742). Do not ground the 24VAC lines. We recommend to use one transformer per EC3 controller and to use separate transformers for 3rd party controllers, to avoid possible interference or grounding problems in the power supply. Connecting any EC3 inputs to mains voltage will permanently damage the EC3. Setup and Parameter Modification Using the Keypad of the ECD-000 For convenience, an infrared receiver for the optional IR remote control unit is build-in, enabling quick and easy modification of the system parameters when a computer interface is not available. Alternatively, the parameters can be accessed via the 4-button keypad. The configuration parameters are protected by a numerical password. The default password is 12. To select the parameter configuration: Press the PRG button for more than 5 seconds A flashing 0 is displayed Press or until 12 is displayed; (password) Press SEL to confirm password The first modifiable parameter code is displayed (/1). To modify parameters see Parameters modification below. Parameter Modification: Procedure Press or to show the code of the parameter that has to be changed; Press SEL to display the selected parameter value; Press or to increase or decrease the value; Press SEL to temporarily confirm the new value and display its code; Repeat the procedure from the beginning "press or to show..." To exit and save the new settings: Press PRG to confirm the new values and exit the parameters modification procedure. To exit without modifying any parameter: Do not press any button for at least 60 seconds (TIME OUT). Press ESC on IR remote control. Neuron Id / Service Pin: The service pin is available on ECD display and on the controller. It is only needed, when using controller in a LON network. Display:

GB

Special Functions: The Clear Alarm function has been replaced by the Special Functions mode. The Special Functions can be activated by: Press and together for more than 5 seconds. A flashing 0 is displayed. Press or until the password is displayed (default = 12). If password was changed, select the new password. Press SEL to confirm password A 0 is displayed and the Special Function mode is activated. Press or to select the function. The number of special functions is dynamic and controller dependent. See list below. Press SEL to activate the function without leaving the special function mode. Press PRG to activate the function and leave the special function mode. Most of the Special Functions work in a toggle mode, the first call activates the function, and the second call deactivates the function. The indication of the function can only be displayed after exiting the special function mode. 0: Display test function 1: Resets all parameters to the factory default setting. The controller will indicate oF during the reset. Display of Data: The data to be permanently shown on the display can be selected by the user (parameter /1). In case of an alarm, the alarm code is displayed alternately with the selected data. The user can inhibit the alarm code. It is possible to temporarily display these values. This is a useful feature when initially setting-up the system without the aid of the WebPages. Press the SEL button to scroll through all possible displayable data.. The display will show for one second the numerical identifier of the data (see /1 parameter) and then the selected data. After two minutes the display will return to the by parameter /1 selected data. This action is only valid when parameter H2 = 3 IR LED Fan 1 On Fan 7 On Controller LED Service LED Press. Sensor LED Pressure LED Alarm LED Fan 6 On Fan 5 On Fan 3 On Fan 4 On Fan 2 On

button for app. 1 second to send the Neuron ID. An LED (Service) in Press the the left upper corner will indicate the transmission of the Neuron ID.

ECD-001

Controller: There is a small hole left of the network connector. Use a small pen or screwdriver to press the switch behind the hole. An LED close to the switch will light to indicate the transmission of the Neuron ID.

Load Default Parameters: Use a small pen or screwdriver to press the service pin switch on the controller and switch on the power supply on. The EC3-751 will be reset to its default settings.

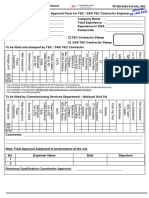

Wiring Diagram (controller label)

EC3-751_65087_EN_R04.doc

Replacement for R03

2/5

DWG Nr.: 864 915

26.09.2007

EC3-751 Condenser Controller with LON Interface

Operating Instructions

GB

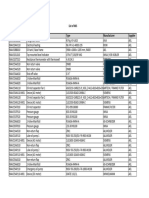

List of Parameters / DISPLAY PARAMETERS Min Max Unit /1 Value to show 0 3 0 = fans states 1 = condensing pressure (bar) 2 = saturation temperature from condensing pressure (C) 3 = medium temperature (Contr. Tmp.) P SET-POINT PARAMETERS P0 Condensing setpoint For unit see control strategy (c7) P1 Condensing band For unit see control strategy (c7) P2 Condensing setpoint 2 P3 Condensing recovery min P4 Condensing shift (0 = off, 1 = on) P5 Condensing shift max P6 Condensing shift temp min P7 Condensing shift temp max P8 Condensing recovery max t TIME PARAMETERS t1 Condensing request on time t2 Condensing request off A A1 A2 A3 A4 A5 A8 A9 ALARM-PARAMETERS Alam delay HP Condensing alarm limit min Condensing alarm limit max Alarm delay condensing limit min Alarm delay condensing limit max Alarm delay serial alarm fan Service interval Def. Individ. 0 c APPLICATION PARAMETERS Min Max Unit Def. c1 Number of fans 1 6 3 c4 First fan 0 2 0 0 = in standard control loop, 1 = act as base load fan, 2 = act as modulating capacity; single stage; 010V for inverter command or TRIAC output c5 Fan rotation 0 1 0 0 = FILO logic (First In, Last Out) 1 = FIFO logic (First In, First Out) c6 Sensor fail (number of fans in case of 0 7 0 sensor failure) c7 Control strategy 0 2 0 0 = control on discharge pressure 1 = control on difference between saturated discharge temp. and ambient temperature sensor 2 = control on contr. tmp. sensor r r3 r4 r5 r6 SENSOR PARAMETERS Condensing sensor 0% Condensing sensor 100% Condensing sensor offset Refrigerant 0 = R 22 3 = R 404A 1 = R 134a 4 = R 407C 2 = R 507 5 = R 410A Individ.

-1 0.0 -1.0 -9.9 0 0.0 -50 -50 -9.9

50 Bar,K,C 14.0 50 Bar,K,C 50 50 1 3.0 50 50 50 bar bar bar C C bar 4.0 14.0 -9.9 0 3.0 25C 15C 50.0

0 0

99 99

10 sec(1) 10 sec(1)

3 3

0 -1.0 -1.0 0 0 0 0

99 50 50 99 99 99 99

10 sec(1) 0 bar 10.0 bar 27 10 sec(1) 0 10 sec(1) 0 10 sec(1) 0 0 10 000 hr(2)

-1.0 50 -1.0 50 -1.0 1.0 0 7 6 = R 124 7 = R 744

bar bar bar -

0.0 30 0.0 4

F MODULATING PARAMETERS F2 Fan 1 min speed (if modulated) 0.0 100 % F3 Fan 1 max speed (if modulated) 0.0 100 % F4 Fan 1 min on (0 = fan off, 1 = 0 1 maintain fan 1 on at minimum value) F7 Modulation type for fan 1 0 1 0 = analogue output 0 10 V for FSP 1 = phase cutting with TRIAC (direct fan speed control) 0.0 100 0 0

u STEP ENABLE PARAMETERS u0 Reset 0 = do nothing 1 = reset operating time fan 1 2 = reset operating time fan 2 3 = reset operating time fan 3 4 = reset operating time fan 4 5 = reset operating time fan 5 6 = reset operating time fan 6 7 = reset operating time all fans u1 Fan enable 1 (0=disable, 1=enable) u2 Fan enable 2 (0=disable, 1=enable) u3 Fan enable 3 (0=disable, 1=enable) u4 Fan enable 4 (0=disable, 1=enable) u5 Fan enable 5 (0=disable, 1=enable) u6 Fan enable 6 (0=disable, 1=enable)

0 0 0 0 0 0

1 1 1 1 1 1

1 1 1 1 1 1

H OTHER PARAMETERS H2 ECD Display access 0 3 3 0 = all disabled (Caution, access to controller only via LON network possible) 1 = Keyboard enabled 2 = IR remote control enabled 3 = Keyboard and IR rem. contr. enabled H3 IR access code 0 199 0 H5 Password 0 199 12 Note: Concerning the indicated parameters, it is recommended to check, before installing, if the factory value is suitable for the required use.

(1) (2)

Resolution of the local ECD-000 display is 10sec. E.g. value 2 means 20sec. Resolution of the local ECD-000 display is 10 000h. E.g. value 2 means 20 000h. EMS allows data entry in sec / 1000hr

EC3-751_65087_EN_R04.doc

Replacement for R03

3/5

DWG Nr.: 864 915

26.09.2007

EC3-751 Condenser Controller with LON Interface

Operating Instructions ALARMS AND MESSAGES ALARM CODES HP External high-pressure alarm High pressure signal from digital input hP High pressure alarm Condensing pressure higher than the maximum limit lP Low pressure alarm Condensing pressure lower than the minimum limit EP Error pressure Condensing pressure sensor failure hr High discharge pressure alarm High discharge (condensing) pressure recovery E1 Feedback alarm 1 Digital input associated with fan 1 has changed into alarm state (safety chain) E2 Feedback alarm 2 Digital input associated with fan 2 has changed into alarm state (safety chain) E3 Feedback alarm 3 Digital input associated with fan 3 has changed into alarm state (safety chain) E4 Feedback alarm 4 Digital input associated with fan 4 has changed into alarm state (safety chain) E5 Feedback alarm 5 Digital input associated with fan 5 has changed into alarm state (safety chain) E6 Feedback alarm 6 Digital input associated with fan 6 has changed into alarm state (safety chain) n1 Service alarm 1 Fan 1 operating time higher than run limit n2 Service alarm 2 Fan 2 operating time higher than run limit n3 Service alarm 3 Fan 3 operating time higher than run limit n4 Service alarm 4 Fan 4 operating time higher than run limit n5 Service alarm 5 Fan 5 operating time higher than run limit n6 Service alarm 6 Fan 6 operating time higher than run limit Er Data error Data send to the display is out of range MESSAGES

GB

--No data The display will show an --- at node start up, when no data is send to the display or when the display is disabled. In Configuration data initialization The display will show an In when the configuration data are initialized with the factory default values. Id Wink request received The display will show a flashing Id when the wink request was received. The node will receive the flashing Id will be shown on the display until the service button will be pressed, or a 30 min delay timer will expire or a second wink request. OF Offline The node is offline: no application is running. This is the result of a network management command an will happen - -- --Controller disabled, waiting for restart After a major change of the configuration parameter, the condenser controller is disabled for 20 seconds. After this delay the controller restart automatically. The condenser controller is disabled (with object status or with the network variable nviContEnable). N.B. When cleaning the display use damp cloth and neutral detergent. Visualising Data: LON Monitoring Server The EC3-751 has a LON communication interface enabling the controller to be directly connected to a Monitoring Server or a LON network. Neuron ID / Service PIN: The service pin is available on the ECD display. It is used to identify the controller in a LON network. Press the button for app. 1 second to send the Neuron ID. The LED in the left upper corner will indicate the transmission of the Neuron ID. The default settings may be modified remotely from the Monitoring Server via the LON network. Consult the EMS__64074 user manual for more information. It is also possible to display live graphical data on the server or to log data containing the control temperature at defined intervals. Recommended cable types Cable type / AWG Belden 85102 Belden 8471 Level IV 22 AWG JY ( ST) 2x2x0,8 TIA 568A CAT 5 1,3 mm / 16 1,3 mm / 16 0,65 / 22 0,8 / 20,4 0,51 / 24

LonWorks Interface FTT10 Structure free topology Termination RC Network Medium Twisted pair, 2-wires Connection 11, 12 Data - 13 free Nodes/ 64 Units Segment Transfer rate 78 kbits / s

R / km 28 28 106 73 168

C nF / km 56 72 49 98 46

V % of c 62 55 67 41 58

FTT10 max. length in m 2700 2700 1400 900 900

For more details see the Echelon LonMark documentation

technical knowledge of today. It is intended only for use by persons having the Emerson Electric GmbH & Co OHG is not to be held responsible for erroneous appropriate technical knowledge and skills, at their own discretion and risk. Since literature regarding capacities, dimensions, applications, etc. stated herein. conditions of use are outside of ALCO'S control we cannot assume any liability Products, specifications and data in this literature are subject to change without for results obtained or damages occurred due to improper application. notice. The information given herein is based on technical data and tests which This document replaces all former versions ALCO CONTROLS believes to be reliable and which are in compliance with Emerson Electric GmbH & Co OHG - Postfach 1251 - Heerstrae 111 - D-71332 Waiblingen - Germany - Phone .49-(0)7151-509-0 - Fax .49-(0)7151-509-200 www.eCopeland.com/alcoliterature.cfm

EC3-751_65087_EN_R04.doc Replacement for R03 4/5 DWG Nr.: 864 915 26.09.2007

You might also like

- H Im LK Medpro AddDocument2 pagesH Im LK Medpro AddMaria DazaNo ratings yet

- Phasec2d Data SheetDocument2 pagesPhasec2d Data SheetMaria DazaNo ratings yet

- H Im PSMDocument28 pagesH Im PSMMaria DazaNo ratings yet

- H Im SDKDocument2 pagesH Im SDKMaria DazaNo ratings yet

- H Im PCSDocument36 pagesH Im PCSسامح الجاسمNo ratings yet

- Locator 3s Phasec 2s Phasec 2d: Technical Reference and Operating ManualDocument136 pagesLocator 3s Phasec 2s Phasec 2d: Technical Reference and Operating ManualMaria DazaNo ratings yet

- H Im BeaconDocument36 pagesH Im BeaconMaria DazaNo ratings yet

- H Im pcs1Document42 pagesH Im pcs1Maria DazaNo ratings yet

- H Im HGDDocument64 pagesH Im HGDMaria DazaNo ratings yet

- H Im CuDocument24 pagesH Im CuMaria DazaNo ratings yet

- H Im EcmotorsDocument4 pagesH Im EcmotorsMaria DazaNo ratings yet

- H Im 65BDocument16 pagesH Im 65BMaria DazaNo ratings yet

- H Im BN Medpro AddDocument2 pagesH Im BN Medpro AddMaria DazaNo ratings yet

- H Im 77DDocument16 pagesH Im 77DMaria DazaNo ratings yet

- H Im 711C.1Document48 pagesH Im 711C.1Maria DazaNo ratings yet

- H Im 711CDocument48 pagesH Im 711CMaria DazaNo ratings yet

- H Im 80DDocument28 pagesH Im 80DMaria DazaNo ratings yet

- H Im 81eDocument28 pagesH Im 81eMaria DazaNo ratings yet

- H Im 82CDocument26 pagesH Im 82CMaria DazaNo ratings yet

- H Im 76Document8 pagesH Im 76Maria DazaNo ratings yet

- H Im 68Document12 pagesH Im 68Maria DazaNo ratings yet

- H Im 67GDocument52 pagesH Im 67GMaria DazaNo ratings yet

- H Im 90Document20 pagesH Im 90Maria DazaNo ratings yet

- H Im 79eDocument36 pagesH Im 79eMaria DazaNo ratings yet

- Bonh 1Document38 pagesBonh 1Maria DazaNo ratings yet

- H Im 64LDocument48 pagesH Im 64Lسامح الجاسمNo ratings yet

- 90514937, BDBN1202 1802Document32 pages90514937, BDBN1202 1802Maria DazaNo ratings yet

- Reach-In Unit Coolers: Technical GuideDocument12 pagesReach-In Unit Coolers: Technical GuideMaria DazaNo ratings yet

- BN TB Uc Co2Document16 pagesBN TB Uc Co2Maria DazaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IOMAX Archangel Brochure 2018Document9 pagesIOMAX Archangel Brochure 2018Francois MNo ratings yet

- Comparison Between RISC and CISCDocument1 pageComparison Between RISC and CISCShubham BagalNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Controlli e RegistrazioniDocument4 pagesEngine Valve Lash - Inspect/Adjust: Controlli e RegistrazionijamcaNo ratings yet

- Atmel 2508 Zero Cross Detector ApplicationNote AVR182Document11 pagesAtmel 2508 Zero Cross Detector ApplicationNote AVR182armando nolasco rodriguezNo ratings yet

- Seminar ReportDocument17 pagesSeminar ReportG-1076-Sudhansu AwasthiNo ratings yet

- Check List For Review of Afbc P&Id Air&Flue Gas System: ProjectDocument2 pagesCheck List For Review of Afbc P&Id Air&Flue Gas System: Projectctraminst_81No ratings yet

- Design and Fabrication of An AUTOMATIC BLACK BOARD CleanerDocument21 pagesDesign and Fabrication of An AUTOMATIC BLACK BOARD CleanerNAGARAJNo ratings yet

- Delimon Master CatalogDocument445 pagesDelimon Master Cataloggruf100% (1)

- Craftsman ManualDocument28 pagesCraftsman ManualAlex Perez100% (1)

- Equipment TP MAV AEL Oil Supply UnitDocument1,392 pagesEquipment TP MAV AEL Oil Supply UnitMuhammad Hasbi AsidiqiNo ratings yet

- TP-NG-6450-010-003 Pre-Qualification Approval Form For T&C SAS - T&C Contractor Engineer Rev02Document1 pageTP-NG-6450-010-003 Pre-Qualification Approval Form For T&C SAS - T&C Contractor Engineer Rev02karthikNo ratings yet

- Fig. 1 Type 3701-01 Solenoid ValveDocument4 pagesFig. 1 Type 3701-01 Solenoid Valveparthibanemails5779No ratings yet

- CX2032MM Rev1Document301 pagesCX2032MM Rev1totalofficesupportNo ratings yet

- Power 6393: Power 6393, Modular Power SupplyDocument2 pagesPower 6393: Power 6393, Modular Power Supplyghhg ioiiNo ratings yet

- Af 6atsp0h Iso PV 360019 01 001 C07Document1 pageAf 6atsp0h Iso PV 360019 01 001 C07Rashad AlasgarovNo ratings yet

- PIR Sensor Based Security System, Circuit Diagram, Working, ApplicationsDocument13 pagesPIR Sensor Based Security System, Circuit Diagram, Working, ApplicationsAlan A. TorresNo ratings yet

- Helipath InstructionsDocument4 pagesHelipath InstructionsRobert Soto100% (1)

- Mahindra 575 Tractor Spare Parts CatalogueDocument2 pagesMahindra 575 Tractor Spare Parts CatalogueThissa KumaraNo ratings yet

- Textile Fabrics & Clothing: 1. Abduselam AbdulkadirDocument5 pagesTextile Fabrics & Clothing: 1. Abduselam AbdulkadirCE CERTIFICATENo ratings yet

- Solaron Price ListDocument9 pagesSolaron Price ListShem Cauley CabanayanNo ratings yet

- Active Active: WithdarwnDocument4 pagesActive Active: Withdarwnpugal80No ratings yet

- Jeep Parts List 1998 ZJDocument370 pagesJeep Parts List 1998 ZJlilfroger0% (1)

- Bert Rowe's Mercedes Benz 'A' Class InfoDocument26 pagesBert Rowe's Mercedes Benz 'A' Class InfoeliahNo ratings yet

- ATX Power Supply Pinout TablesDocument4 pagesATX Power Supply Pinout TablesElectrical EEENo ratings yet

- LPKF Protomat S64Document124 pagesLPKF Protomat S64Rodrigo de Carvalho VieiraNo ratings yet

- Light Emiting Polymers Seminar ReportDocument23 pagesLight Emiting Polymers Seminar ReportitsmemonuNo ratings yet

- Aleph J ManualDocument6 pagesAleph J ManualasenmtNo ratings yet

- Calculate Size of Contactor, Fuse, C.B, Over Load Relay of DOL StarterDocument5 pagesCalculate Size of Contactor, Fuse, C.B, Over Load Relay of DOL Startererson1981No ratings yet

- Mini Project 1 - 1Document9 pagesMini Project 1 - 1Sameer BaraNo ratings yet

- Data SheetDocument23 pagesData SheetMan TheNo ratings yet