Professional Documents

Culture Documents

Anchor Fastening Technology Manual: Rebar

Uploaded by

cart_thickOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchor Fastening Technology Manual: Rebar

Uploaded by

cart_thickCopyright:

Available Formats

Hilti HIT-HY 200 Post-installed rebar

Anchor Fastening Technology Manual

Hilti HIT-HY 200 post-installed rebar

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Hilti HIT-HY 200 post-installed rebar

Injection mortar system Hilti HITHY 200-R 330 ml foil pack (also available as 500 ml foil pack) Hilti HITHY 200-A 330 ml foil pack (also available as 500 ml foil pack) Benefits - HY 200-R version is formulated for best handling and cure time specifically for rebar applications - Suitable for concrete C 12/15 to C 50/60 - Suitable for dry and water saturated concrete - For rebar diameters up to 32 mm - Non corrosive to rebar elements - Good load capacity at elevated temperatures - Suitable for embedment length up to 1000 mm - Suitable for applications down to -10 C

Static mixer

Rebar

Concrete

Fire resistance

European Technical Approval

Corrosion tested

PROFIS Rebar design software

Service temperature range

Temperature range: -40 C to +80 C (max. long term t emperature +50 C, max. short term temperature +80 C) .

Approvals / certificates

Description Authority / Laboratory No. / date of issue ETA-12/0083 / 2012-02-06 (HIT-HY 200-R) ETA-11/0492 / 2011-12-23 (HIT-HY 200-A)

European technical approval a) Fire test report

DIBt, Berlin CSTB, Paris

26033756

a) All data given in this section according ETA-12/0083, issued 2012-02-06 and ETA-11/0492, issued 2011-12-23.

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Materials

Reinforcement bars according to EC2 Annex C Table C.1 and C.2N. Properties of reinforcement Product form Class Characteristic yield strength fyk or f 0,2k (MPa) Minimum value of k = (ft/fy)k Characteristic strain at maximum force, uk (%) Bendability Maximum deviation from nominal mass (individual bar) (%) Bond: Minimum relative rib area, fR,min Nominal bar size (mm) 8 >8 Nominal bar size (mm) 8 to 12 > 12 Bars and de-coiled rods B 400 to 600 1,08 5,0 Bend / Rebend test 6,0 4,5 0,040 0,056 C 1,15 < 1,35 7,5

Setting details

For detailed information on installation see instruction for use given with the package of the product.

Working time, curing timea)

Temperature of the base material -10 C to -5 C -4 C to 0 C 1 C to 5 C 6 C to 10 C 11 C to 20 C 21 C to 30 C 31 C to 40 C Temperature of the base material -10 C to -5 C -4 C to 0 C 1 C to 5 C 6 C to 10 C 11 C to 20 C 21 C to 30 C 31 C to 40 C HIT-HY 200-R Working time in which anchor Curing time before anchor can be inserted and adjusted twork can be fully loaded tcure 3 hour 20 hour 2 hour 7 hour 1 hour 3 hour 40 min 2 hour 15 min 1 hour 9 min 1 hour 6 min 1 hour HIT-HY 200-A Working time in which anchor Curing time before anchor can be inserted and adjusted twork can be fully loaded tcure 1,5 hour 7 hour 50 min 4 hour 25 min 2 hour 15 min 1 hour 7 min 30 min 4 min 30 min 3 min 30 min

a) Dry and water-saturated concrete, hammer drilling

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Bore hole drilling

Drill hole to the required embedment depth using a hammer-drill with carbide drill bit set in rotation hammer mode, or a compressed air drill.

Bore hole cleaning Just before setting an anchor, the bore hole must be free of dust and debris by one of two

cleaning methods described below b) Compressed air cleaning (CAC) For all bore hole diameters d0 and all bore hole depth h0 Blowing 2 times from the back of the hole with oil-free compressed air (min. 6 bar at 100 litres per minute (LPM)) until return air stream is free of noticeable dust. Bore hole diameter 32 mm the compressor must supply a minimum air flow of 140 m/hour. If required use additional accessories and extensions for air nozzle and brush to reach back of hole. Brushing 2 times with the specified brush size (brush borehole ) by inserting the round steel brush to the back of the hole in a twisting motion. The brush shall produce natural resistance as it enters the anchor hole. If this is not the case, please use a new brush or a brush with a larger diameter. Blowing 2 times again with compressed air until return air stream is free of noticeable dust.

a) Manual Cleaning (MC) As an alternative to compressed air cleaning, a manual cleaning is permitted for hammer drilled boreholes up to hole diameters d0 20mm and depths lv resp. le,ges. 160mm or 10 * d. The borehole must be free of dust, debris, water, ice, oil, grease and other contaminants prior to mortar injection.

4 strokes with Hilti blow-out pump from the back of the hole until return air stream is free of noticeable dust.

4 times with the specified brush size (brush borehole ) by inserting the round steel wire brush to the back of the hole with a twisting motion

4 strokes with Hilti blow-out pump from the back of the hole until return air stream is free of noticeable dust.

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Injection preparation

Observe the Instruction for Use of the dispenser. Observe the Instruction for Use of the mortar. Tightly attach Hilti HIT-RE-M mixing nozzle to foil pack manifold. Insert foil pack into foil pack holder and swing holder into the dispenser.

Discard initial adhesive. The foil pack opens automatically as dispensing is initiated. Depending on the size of the foil pack an initial amount of adhesive has to be discarded. Discard quantities are 2 strokes for 330 ml foil pack, 3 strokes for 500 ml foil pack, 4 strokes for 500 ml foil pack 5 C.

Inject adhesive from the back of the borehole without forming air voids

Injection method for borehole depth 250 mm: Inject the mortar from the back of the hole towards the front and slowly withdraw the mixing nozzle step by step after each trigger pull. Important! Use extensions for deep holes ( > 250 mm). Fill holes approximately 2/3 full, or as required to ensure that the annular gap between the rebar and the concrete is completely filled with adhesive over the embedment length. After injecting, depressurize the dispenser by pressing the release trigger (only for manual dispenser). This will prevent further mortar discharge from the mixing nozzle.

Piston plug injection for borehole depth > 250 mm or overhead applications: Assemble mixing nozzle, extension(s) and appropriately sized piston plug. Insert piston plug to back of the hole. Begin injection allowing the pressure of the injected adhesive mortar to push the piston plug towards the front of the hole. After injecting, depressurize the dispenser by pressing the release trigger. This will prevent further mortar discharge from the mixing nozzle. The proper injection of mortar using a piston plug HIT-SZ prevents the creation of air voids. The piston plug must be insertable to the back of the borehole without resistance. During injection the piston plug will be pressed towards the front of the borehole slowly by mortar pressure. Attention! Pulling the injection or when changing the foil pack, the piston plug is rendered inactive and air voids may occur.

HDM 330 HDM 500 HDE 500-A22

Manual dispenser (330 ml) Manual dispenser (330 / 500 ml) Electric dispenser (330 / 500 ml)

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Setting the element

Before use, verify that the element is dry and free of oil and other contaminants. Mark and set element to the required embedment depth until working time twork has elapsed.

After installing the rebar the annular gap must be completely filled with mortar. Proper installation can be verified when: Desired anchoring embedment is reached lv: Embedment mark at concrete surface. Excess mortar flows out of the borehole after the rebar has been fully inserted until the embedment mark. Overhead application: Support the rebar and secure it from falling till mortar started to harden. Observe the working time twork, which varies according to temperature of base material. Minor adjustments to the rebar position may be performed during the working time. After tcure preparation work may continue.

For detailed information on installation see instruction for use given with the package of the product.

Resistance to chemical substances

Chemical

Air Acetic acid 10% Acetone Ammonia 5% Benzyl alcohol Chloric acid 10% Chlorinated lime 10% Citric acid 10% Concrete plasticizer De-icing salt (Calcium chloride) Demineralized water Diesel fuel Drilling dust suspension pH 13,2 Ethanol 96% Ethylacetate Formic acid 10% Formwork oil + o 6

Resistance

+ + o + o + + + + + + + + +

Chemical

Gasoline Glycole Hydrogen peroxide 10% Lactic acid 10% Maschinery oil Methylethylketon Nitric acid 10% Phosphoric acid 10% Potassium Hydroxide pH 13,2 Sea water Sewage sludge Sodium carbonate 10% Sodium hypochlorite 2% Sulfuric acid 10% Sulfuric acid 30% Toluene Xylene

Resistance

+ o o + + o o + + + + + + + + o o

resistant resistant in short term (max. 48h) contact not resistant

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Electrical Conductivity HIT-HY 200 in the hardened state is not conductive electrically. Its electric resistivity is 15,5109 cm (DIN IEC 93 12.93). It is adapted well to realize electrically insulating anchorings (ex: railway applications, subway).

Drilling diameters

Drill bit diameters d0 [mm] Rebar (mm) 8 10 12 14 16 18 20 22 24 25 26 28 30 32 a) Max. installation length I = 250 mm. Hammer drill (HD) 12 (10) a) 14 (12) a) 16 (14) a) 18 20 22 25 28 32 32 35 35 37 40 Compressed air drill (CA) 17 17 20 22 26 28 32 32 35 35 35 40

Basic design data for rebar design according to ETA

Bond strength

Bond strength in N/mm according to ETA for good bond conditions

Rebar (mm) 8 - 32 Concrete class C25/30 C30/37 C35/45 2,7 3,0 3,4

C12/15 1,6

C16/20 2,0

C20/25 2,3

C40/50 3,7

C45/55 4,0

C50/60 4,3

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Minimum anchorage length

Minimum and maximum embedment depths and lap lengths for C20/25 according to ETA

Rebar Concrete temp. -10 C Concrete temp. 0 C lb,min* l0,min * lmax lmax Diameter ds fy,k [mm] [mm] [mm] [mm] [mm] [N/mm] 8 500 113 200 700 1000 10 500 142 200 700 1000 12 500 170 200 700 1000 14 500 198 210 700 1000 16 500 227 240 700 1000 18 500 255 270 700 1000 20 500 284 300 700 1000 22 500 312 330 700 1000 24 500 340 360 700 1000 25 500 354 375 700 1000 26 369 390 700 1000 500 28 500 397 420 700 1000 30 500 425 450 700 1000 32 500 454 480 700 1000 lb,min (8.6) and l0,min (8.11) are calculated for good bond conditions with maximum utilisation of rebar yield strength fyk = 500 N/mm and 6 = 1,0

02 / 2012

Hilti HIT-HY 200 Post-installed rebar Precalculated values

Example of pre-calculated values Rebar yield strength fyk = 500 N/mm, concrete C25/30, good bond conditions Anchorage length Design Mortar Anchorage Rebar lbd value NRd volume length lbd [mm] [mm] [kN] [ml] [mm] Design value Mortar NRd volume [kN] [ml] 2 or 5= 0,7 1=2=3=4=5=1,0 1 = 3 = 4 = 1,0 100 6,8 8 (3) 100 9,7 8 (3) 170 11,5 13 (6) 140 13,6 11 (5) 8 250 17,0 19 (8) 180 17,4 14 (6) 323 21,9 226 21,9 24 17 (8) 121 10,3 11 (5) 121 14,7 11 (5) 210 17,8 19 (9) 170 20,6 15 (7) 10 310 26,3 28 230 27,9 21 (10) 402 34,1 281 34,1 36 25 145 14,8 15 (7) 145 21,1 15 (7) 260 26,5 27 210 30,5 22 (10) 12 370 37,7 39 270 39,3 29 483 49,2 338 49,1 51 36 169 20,1 20 169 28,7 20 300 35,6 36 240 40,7 29 14 430 51,1 52 320 54,3 39 563 66,9 394 66,8 68 48 193 26,2 26 193 37,4 26 340 46,1 46 280 54,3 38 16 490 66,5 67 370 71,7 50 644 87,4 451 87,4 87 61 218 33,3 33 218 47,5 33 390 59,5 59 310 67,6 47 18 560 85,5 84 410 89,4 62 724 ** 110,5 507 110,6 109 76 242 41,1 51 242 58,6 51 430 72,9 91 350 84,8 74 20 620 105,2 131 460 111,5 98 805 ** 136,6 564 136,7 171 120 266 49,6 75 266 70,9 75 470 87,7 133 380 101,3 107 22 680 126,9 192 500 133,3 141 886 ** 165,3 620 165,3 251 175 * Values corresponding to the minimum anchorage length. The maximum permissible load is valid for good bond conditions as described in EN 1992-1-1. For all other conditions multiply by the value by 0,7. The volume of mortar correspond to the formula 1,2(d0-d)lb/4

** For installation temperature 0 C. For lower temperature l bd is limited to 700 mm

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Example of pre-calculated values for Rebar yield strength fyk = 500 N/mm, concrete C25/30, good bond conditions Anchorage length Design Mortar Anchorage Rebar lbd value NRd volume length lbd [mm] [mm] [kN] [ml] [mm]

Design value Mortar NRd volume [kN] [ml] 2 or 5= 0.7 1=2=3=4=5=1.0 1 = 3 = 4 = 1.0 290 59,0 122 290 84,3 122 520 105,9 220 420 122,1 177 24 740 ** 150,6 312 550 160,0 232 966 ** 196,7 676 196,6 408 285 302 64,0 114 302 91,5 114 530 112,4 199 440 133,3 165 25 770 ** 163,3 290 570 172,7 214 1000 ** 212,1 704 ** 213,3 376 265 314 69,2 162 314 98,9 162 540 119,1 279 450 141,8 233 26 770 ** 169,8 398 590 185,9 305 1000 ** 220,5 733 ** 230,9 517 379 338 80,3 140 338 114,7 140 560 133,0 233 490 166,3 204 28 780 ** 185,3 324 640 217,1 266 1000 ** 237,5 789 ** 267,7 416 328 363 92,4 160 363 132,0 160 580 147,6 256 520 189,0 230 30 790 ** 201,0 349 680 247,2 301 1000 ** 254,5 845 ** 307,2 442 374 387 105,0 210 387 150,1 210 590 160,1 320 560 217,1 304 32 800 ** 217,1 434 730 ** 283,1 396 1000 ** 271,4 902 ** 349,8 543 490 * Values corresponding to the minimum anchorage length. The maximum permissible load is valid for good bond conditions as described in EN 1992-1-1. For all other conditions multiply by the value by 0,7. The volume of mortar correspond to the formula 1,2(d0-ds)lb/4 for hammer drilling

** For installation temperature 0 C. For lower temperature l bd is limited to 700 mm

10

02 / 2012

Hilti HIT-HY 200 Post-installed rebar

Example of pre-calculated values for overlap joints Rebar yield strength fyk = 500 N/mm, concrete C25/30, good bond conditions Anchorage length Design Mortar Anchorage Rebar lbd value NRd volume length lbd [mm] [mm] [kN] [ml] [mm]

Design value Mortar NRd volume [kN] [ml] 2 or 5= 0,7 1=2=3=5=6=1,0 1 = 3 = 6 = 1,0 200 13,6 15 (7) 200 19,4 15 (7) 240 16,3 18 (8) 210 20,4 16 (7) 8 280 19,0 21 220 21,3 17 (7) 323 21,9 226 21,9 24 17 (8) 200 17,0 18 (8) 200 24,2 18 (8) 270 22,9 24 230 27,9 21 (10) 10 330 28,0 30 250 30,3 23 (10) 402 34,1 281 34,1 36 25 200 20,4 21 (10) 200 29,1 21 (10) 290 29,5 31 250 36,4 26 (12) 12 390 39,7 41 290 42,2 31 483 49,2 338 49,1 51 36 210 24,9 25 210 35,6 25 330 39,2 40 270 45,8 33 14 450 53,4 54 330 56,0 40 563 66,9 394 66,8 68 48 240 32,6 33 240 46,5 33 370 50,2 50 310 60,1 42 16 510 69,2 69 380 73,7 52 644 87,4 451 87,4 87 61 270 41,2 41 270 58,9 41 420 64,1 63 350 76,3 53 18 570 87,0 86 430 93,8 65 724 ** 110,5 507 110,6 109 76 300 50,9 64 300 72,7 64 470 79,7 100 390 94,5 83 20 640 108,6 136 480 116,3 102 805 ** 136,6 564 136,7 171 120 330 61,6 124 330 88,0 93 520 97,0 147 430 114,6 122 22 700 130,6 198 520 138,6 147 886 ** 165,3 620 165,3 251 175 * Values corresponding to the minimum anchorage length. The maximum permissible load is valid for good bond conditions as described in EN 1992-1-1. For all other conditions multiply by the value by 0,7. The volume of mortar correspond to the formula 1,2(d0-ds)lb/4 for hammer drilling

** For installation temperature 0 C. For lower temperature l bd is limited to 700 mm

02 / 2012

11

Hilti HIT-HY 200 Post-installed rebar

Example of pre-calculated values for overlap joints Rebar yield strength fyk = 500 N/mm, concrete C25/30, good bond conditions Anchorage length Design Mortar Anchorage Rebar lbd value NRd volume length lbd [mm] [mm] [kN] [ml] [mm]

Design value Mortar NRd volume [kN] [ml] 2 or 5= 0.7 1=2=3=4=5=1.0 1 = 3 = 4 = 1.0 360 73,3 152 360 104,7 152 560 114,0 236 470 136,7 198 24 760 ** 154,7 321 570 165,8 241 966 ** 196,7 676 196,6 408 285 375 79,5 124 375 113,6 141 580 123,0 218 480 145,4 181 25 790 ** 167,5 297 590 178,7 222 1000 ** 212,1 704 ** 213,3 376 265 390 86,0 124 390 122,9 202 590 130,1 305 500 157,5 259 26 800 ** 176,4 414 620 195,3 321 1000 ** 220,5 733 ** 230,9 517 379 420 99,8 124 420 142,5 175 610 144,9 254 540 183,2 224 28 810 ** 192,4 337 670 227,3 278 1000 ** 237,5 789 ** 267,7 416 328 450 114,5 124 450 163,6 199 630 160,3 278 580 210,8 256 30 820 ** 208,7 362 710 ** 258,1 314 1000 ** 254,5 845 ** 307,2 442 374 480 130,3 124 480 186,1 261 650 176,4 353 620 240,4 337 32 830 ** 225,3 451 760 ** 294,7 413 1000 ** 271,4 902 ** 349,8 543 490 * Values corresponding to the minimum anchorage length. The maximum permissible load is valid for good bond conditions as described in EN 1992-1-1. For all other conditions multiply by the value by 0,7. The volume of mortar correspond to the formula 1,2(d0-ds)lb/4 for hammer drilling.

** For installation temperature 0 C. For lower temperature l bd is limited to 700 mm

12

02 / 2012

You might also like

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- CMB Iso 6020-2Document63 pagesCMB Iso 6020-2David AlbellaNo ratings yet

- Extraction of Total Lipids From Chicken Egg Yolk, Column Chromatography and Qualitative Tests For LipidsDocument10 pagesExtraction of Total Lipids From Chicken Egg Yolk, Column Chromatography and Qualitative Tests For Lipidsmarilujane75% (8)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Royal Seal Catalogue 2014Document218 pagesRoyal Seal Catalogue 2014saurabhbit1950% (2)

- Technical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175Document85 pagesTechnical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175ing urbanNo ratings yet

- Hit Hy-150 PDFDocument16 pagesHit Hy-150 PDFEduardo Antonio Duran SepulvedaNo ratings yet

- TDS Nitomortar TC2000 Saudi ArabiaDocument3 pagesTDS Nitomortar TC2000 Saudi ArabiaHarry BawingNo ratings yet

- Jenkins Quantitative ChemistryDocument496 pagesJenkins Quantitative ChemistryMaster Of BlankNo ratings yet

- Glycine LeachDocument74 pagesGlycine LeachabrahanNo ratings yet

- 2013 Hilti Hit-Hy 200 With Hit-VDocument4 pages2013 Hilti Hit-Hy 200 With Hit-VDifa LiuNo ratings yet

- 2013 Hilti Hit-Hy 200 With His - (R) NDocument4 pages2013 Hilti Hit-Hy 200 With His - (R) NDifa LiuNo ratings yet

- 2014 Hilti Hit-Hy 200 With Hit-ZDocument5 pages2014 Hilti Hit-Hy 200 With Hit-ZDifa LiuNo ratings yet

- Hy-200 FTM 2012-09Document70 pagesHy-200 FTM 2012-09Inhinyero SibilNo ratings yet

- Anclaje Quimico HILTIDocument84 pagesAnclaje Quimico HILTIWuceirNo ratings yet

- Technical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553Document31 pagesTechnical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553ing urban100% (2)

- Hilti Hit-Hy 200 With Hit-V RodDocument20 pagesHilti Hit-Hy 200 With Hit-V RodFodor ZoltanNo ratings yet

- Hilti Hit Hy 200 With Hit VDocument18 pagesHilti Hit Hy 200 With Hit VRobinReyndersNo ratings yet

- Deep Hole Drlling On Maching Centres BOTEKDocument2 pagesDeep Hole Drlling On Maching Centres BOTEKmapalptsNo ratings yet

- 1 MMP METI Fit CatalogueDocument16 pages1 MMP METI Fit CataloguemohdnazirNo ratings yet

- Hilti HIT HY 150 MAX With RebarDocument14 pagesHilti HIT HY 150 MAX With RebarNelly BuquironNo ratings yet

- 04 TD Dichtol GBDocument2 pages04 TD Dichtol GBsusu222000No ratings yet

- Ancore Chimice CHEMOFASTDocument13 pagesAncore Chimice CHEMOFASTPopa AndreiNo ratings yet

- Hilti Hit Re 500 Cu Has Hit-V His-N 1Document36 pagesHilti Hit Re 500 Cu Has Hit-V His-N 1Sorin RaduNo ratings yet

- Anchor Fastening Technology Manual: Hilti HIT-HY 170 Mortar With Rebar (As Anchor)Document15 pagesAnchor Fastening Technology Manual: Hilti HIT-HY 170 Mortar With Rebar (As Anchor)AlexZaNo ratings yet

- Hilti HIT-RE 500 For "Underwater Fastenings"Document5 pagesHilti HIT-RE 500 For "Underwater Fastenings"nikifNo ratings yet

- Hilti HIT-HY 150 With Rebar PDFDocument16 pagesHilti HIT-HY 150 With Rebar PDFMuzammil HawaNo ratings yet

- 2011 Hit-Re 500 With His - (R) NDocument3 pages2011 Hit-Re 500 With His - (R) NDifa LiuNo ratings yet

- Hilti HIT RE 500 Post Installed Rebars PDFDocument12 pagesHilti HIT RE 500 Post Installed Rebars PDFHazim HaNo ratings yet

- HIT-RE 500 Injection Adhesive With RebarDocument1 pageHIT-RE 500 Injection Adhesive With Rebarhit2284No ratings yet

- Chemical Anchoring DataDocument8 pagesChemical Anchoring DataAnonymous QG76ewHJNo ratings yet

- Interzone 485Document4 pagesInterzone 485Sinan A AzizNo ratings yet

- Ti e Protegol 32-55 TD Jan 08Document4 pagesTi e Protegol 32-55 TD Jan 08A MahmoodNo ratings yet

- Application Instructions Application InstructionsDocument5 pagesApplication Instructions Application InstructionsmameeranNo ratings yet

- 16.10 Site Equipment (72dpi)Document24 pages16.10 Site Equipment (72dpi)Jack JeffNo ratings yet

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocument20 pagesHilti Hit Hy 150 Max Con Barra Corrugadalandsv01No ratings yet

- Hilti HIT MM Plus 1Document14 pagesHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuNo ratings yet

- PDFDocument23 pagesPDFAnas EidNo ratings yet

- Conbextra GP2 (T)Document4 pagesConbextra GP2 (T)Gautam PaulNo ratings yet

- Copon - Hycote 162 HBDocument2 pagesCopon - Hycote 162 HBSherif AbdelhameedNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-40-00Document14 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-40-00anony8103No ratings yet

- Hilti Te Md20Document6 pagesHilti Te Md20Berwil Rimachi VilaNo ratings yet

- AI Hempe's Galvosil 15780 EnglishDocument5 pagesAI Hempe's Galvosil 15780 EnglishTamerGalhoumNo ratings yet

- FTM - HY110 with+REBARDocument13 pagesFTM - HY110 with+REBARRomyMohanNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFUbaid Mazhar Abidi SyedNo ratings yet

- RE500 Fastening With Rebar (SEP 2011)Document60 pagesRE500 Fastening With Rebar (SEP 2011)Homer DongNo ratings yet

- 7270 1000 Eng TM PDFDocument1 page7270 1000 Eng TM PDFJordanNo ratings yet

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDocument21 pagesHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisNo ratings yet

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarNo ratings yet

- Nitoseal 280Document2 pagesNitoseal 280shanon33No ratings yet

- Conbextra GPIDocument4 pagesConbextra GPIVenkata Raju KalidindiNo ratings yet

- GalvosilDocument5 pagesGalvosilAditya DasNo ratings yet

- Floline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit ValueDocument3 pagesFloline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit Valuejerryruki71No ratings yet

- Auya30lblu - Aoya30lbtl - InstallDocument2 pagesAuya30lblu - Aoya30lbtl - InstallpepondeAvilesNo ratings yet

- Denso Protal 7900HTDocument2 pagesDenso Protal 7900HTalbertojanetaNo ratings yet

- Technical Data Sheets: Fluid FilmDocument5 pagesTechnical Data Sheets: Fluid FilmRAHULNo ratings yet

- Instructions For Dytex Solvent Cement Jointing of PVC-U and PVC-C Dimension d12 To d140Document3 pagesInstructions For Dytex Solvent Cement Jointing of PVC-U and PVC-C Dimension d12 To d140TUAN ANHNo ratings yet

- PA02 Spec MIT Spot & Soda Blasting (IFC)Document7 pagesPA02 Spec MIT Spot & Soda Blasting (IFC)Mohd YusriNo ratings yet

- SIKA Sikadur 42 MP Normal HCDocument5 pagesSIKA Sikadur 42 MP Normal HCKang Mas WiralodraNo ratings yet

- Nitoseal® 200Document4 pagesNitoseal® 200Venkata Raju KalidindiNo ratings yet

- Standards Pillars and Bushes2Document136 pagesStandards Pillars and Bushes2sansagithNo ratings yet

- DCMT 4Document2 pagesDCMT 4cart_thickNo ratings yet

- DCMT 2Document2 pagesDCMT 2cart_thickNo ratings yet

- 4Document1 page4cart_thickNo ratings yet

- DCMT 1Document2 pagesDCMT 1cart_thickNo ratings yet

- DCMT 5Document2 pagesDCMT 5cart_thickNo ratings yet

- DCMT 3Document2 pagesDCMT 3cart_thickNo ratings yet

- FEB 28 2018 Russia Beyond: CultureDocument3 pagesFEB 28 2018 Russia Beyond: Culturecart_thickNo ratings yet

- 5Document2 pages5cart_thickNo ratings yet

- FirspaciDocument3 pagesFirspacicart_thickNo ratings yet

- ForhmrDocument2 pagesForhmrcart_thickNo ratings yet

- 3Document1 page3cart_thickNo ratings yet

- TodnhmrDocument4 pagesTodnhmrcart_thickNo ratings yet

- TodownreapsrDocument2 pagesTodownreapsrcart_thickNo ratings yet

- For Form FunDocument3 pagesFor Form Funcart_thickNo ratings yet

- Ballio 1Document2 pagesBallio 1cart_thickNo ratings yet

- ForhmrDocument2 pagesForhmrcart_thickNo ratings yet

- Fohis 1Document2 pagesFohis 1cart_thickNo ratings yet

- ForhistDocument3 pagesForhistcart_thickNo ratings yet

- Ghali NevilleDocument1 pageGhali Nevillecart_thickNo ratings yet

- EgengborgDocument2 pagesEgengborgcart_thickNo ratings yet

- For FerguDocument3 pagesFor Fergucart_thickNo ratings yet

- DyncloDocument2 pagesDynclocart_thickNo ratings yet

- Ballio 2Document4 pagesBallio 2cart_thickNo ratings yet

- NilsDocument2 pagesNilscart_thickNo ratings yet

- For BridgDocument3 pagesFor Bridgcart_thickNo ratings yet

- 13 PSCDocument4 pages13 PSCcart_thickNo ratings yet

- KanishearDocument3 pagesKanishearcart_thickNo ratings yet

- The Game Played Is Vint, The National Card-Game of Russia and The Direct Ancestor of Auction Bridge, With Which It Is Almost Identical. (Translator's Note)Document1 pageThe Game Played Is Vint, The National Card-Game of Russia and The Direct Ancestor of Auction Bridge, With Which It Is Almost Identical. (Translator's Note)cart_thickNo ratings yet

- ChandruDocument2 pagesChandrucart_thickNo ratings yet

- EtDocument2 pagesEtcart_thickNo ratings yet

- Ukraine's Foreign TradeDocument12 pagesUkraine's Foreign TradeЮлия ИщенкоNo ratings yet

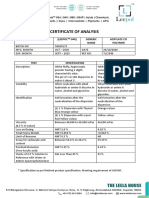

- Certificate of Analysis: Name of Product (Leepol - 940) Generic Name Acrylate Co PolymerDocument1 pageCertificate of Analysis: Name of Product (Leepol - 940) Generic Name Acrylate Co Polymerjuan felixNo ratings yet

- James 2012Document35 pagesJames 2012Ruben FelipeNo ratings yet

- ICS AppendicesDocument499 pagesICS Appendicespiyushjoshi84No ratings yet

- Code q2 Ques Ans Neet 2022Document43 pagesCode q2 Ques Ans Neet 2022Rafeeq ActsNo ratings yet

- Fluorocarbon Rubber: Preperation & PropertiesDocument8 pagesFluorocarbon Rubber: Preperation & PropertiesBenjaminLeonardNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument14 pagesSafety Data Sheet: 1. IdentificationJivendra KumarNo ratings yet

- SZS Bi Nghien Su Ceramic Zs Czs HelicoDocument2 pagesSZS Bi Nghien Su Ceramic Zs Czs HelicoAnonymous Ske1XzNo ratings yet

- cHEM 11 uNIT 5 OrgchemDocument68 pagescHEM 11 uNIT 5 OrgchemAce CardenoNo ratings yet

- Gurugram University: Inorganic ChemistryDocument12 pagesGurugram University: Inorganic ChemistryYamini SainiNo ratings yet

- 1314 Lab - Single Replacement Lab As Inquiry BasedDocument2 pages1314 Lab - Single Replacement Lab As Inquiry Basedapi-239433858No ratings yet

- Ujian PRA US 1 Kelas 9 Dengan Kunci JawabanDocument7 pagesUjian PRA US 1 Kelas 9 Dengan Kunci JawabanSinta NovaliaNo ratings yet

- CFR 21 175.300Document26 pagesCFR 21 175.300CarlosEnriqueFloresLanderoNo ratings yet

- HPLC Troubleshooting Guide: Bulletin 826BDocument20 pagesHPLC Troubleshooting Guide: Bulletin 826BYulis AdrianaNo ratings yet

- Recovery of Bitumen From Oil or Tar Sands Using Ionic LiquidsDocument5 pagesRecovery of Bitumen From Oil or Tar Sands Using Ionic LiquidsDanielMadridDíazNo ratings yet

- Phenol - Structure, Preparation, Uses and ReactionsDocument3 pagesPhenol - Structure, Preparation, Uses and ReactionsahumanbeinginearthNo ratings yet

- Experiments - LBYCH34 Experiment Manual Student SDocument24 pagesExperiments - LBYCH34 Experiment Manual Student SShean Berwin GonzalesNo ratings yet

- Soil Stabilization Using Lime and Fly AshDocument4 pagesSoil Stabilization Using Lime and Fly AshSneha KarmakarNo ratings yet

- Effect of Zinc Oxide Nanoparticle On Pro PDFDocument4 pagesEffect of Zinc Oxide Nanoparticle On Pro PDFJoseph EspinozaNo ratings yet

- Hot-Dip Galvanizing - Wikipedia, The Free EncyclopediaDocument3 pagesHot-Dip Galvanizing - Wikipedia, The Free EncyclopediadiehardjamesbondNo ratings yet

- Questions 1-13 Are True or False. Write T For True and F For False, Respectively, in The Left Margin Preceding The Question NumberDocument20 pagesQuestions 1-13 Are True or False. Write T For True and F For False, Respectively, in The Left Margin Preceding The Question Numberhshshs hshs sshdgNo ratings yet

- Sodium Formate-Is.13475.1992 0Document14 pagesSodium Formate-Is.13475.1992 0imran shaukatNo ratings yet

- Kertas 2 Pep Akhir Tahun Ting 4 Terengganu 2018 - SoalanDocument19 pagesKertas 2 Pep Akhir Tahun Ting 4 Terengganu 2018 - SoalaniswaniswanNo ratings yet

- High-Performance Fumasep Ion Exchange Membranes For Electro Membrane ProcessesDocument6 pagesHigh-Performance Fumasep Ion Exchange Membranes For Electro Membrane ProcessesshadyghanemNo ratings yet

- CH 23 StudentDocument33 pagesCH 23 StudentRabin ShresthaNo ratings yet

- All Tricks For Chemistry by Saket SirDocument6 pagesAll Tricks For Chemistry by Saket SirAnand HNo ratings yet

- Periodic Table Color CodedDocument1 pagePeriodic Table Color CodedETHAN HENG ZENG AN MoeNo ratings yet