Professional Documents

Culture Documents

Morgardshammar Grinding Mills

Uploaded by

Tsakalakis G. KonstantinosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Morgardshammar Grinding Mills

Uploaded by

Tsakalakis G. KonstantinosCopyright:

Available Formats

..

/

...--

_,-

..

A hydrostatic shoe bearing on a primary autogenous mill. Support ring bore 2500 mm.

Front page:

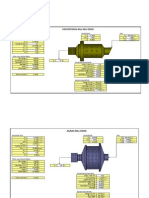

A Morgardshammar primary auto-

genous mil/6.5 x8.0 m, 3200 kW.

2

. -

A big spherical roller bearing (bore

1800 mm) being erected in its housing.

l.

I

The object of the grinding pro-

cess is a mechanical reduction in size

of crushable material. Grinding can be

undertaken in many ways. The most

common way for high capacity indus-

trial purposes is to use a tumbling

charge of grinding media in a rotating

cylinder or drum. The fragmentation of

the material in that charge occurs

through pressure, impact, and

abrasion.

Grinding is converting energy.

When the grinding charge is forced to

tumble the motor energy is converted

into new particle surface and heat.

An important point for the economy is

that the size of the grinding media

suits the material to be ground.

Introduction

The choice of mill design

depends on the particle size distri-

bution in the feed and in the product

wanted. Often the grinding is more

economic when executed in a primary

step, followed by a secondary step,

giving a fine size product.

Morgardshammar -as experts

in crushing and grinding - can offer a

full range of grinding mill types and

sizes. Our main series are CRRK,

PRRK and CHRK.

C=central trunnion discharge

P=peripherical discharge

R=spherical roller trunnion

bearing, feed end

H=hydrostatic shoe bearing,

feed end

R=spherical roller trunnion

bearing, discharge end

K=ring gear and pinion drive

CRRK is the common type in wet

grinding. The PRRK-series is often

used for dry grinding in rod mills, and

in certain ball mill applications.

Type CHRK is designed for

primary autogenous grinding, where

the large feed opening requires a

hydrostatic trunnion shoe bearing.

Small and batch grinding mills, with a

diameter of 700 mm and more, are

available. These mills are of a special

design and described on special

request.

. ~

3

...

The different types of grinding

mil ls are based on the different types

of tumbling media that can be used:

steel rods (rod mills), steel balls (ball

mills), and rock material (autogenous

mills, pebble mills).

ROD MILLS

The grinding charge in a rod mill

consists of straight steel rods with an

initial diameter of 50-100 mm. The

length of the rods is equal to the shell

length inside the head linings minus

about 150 mm. The rods are fed

through the discharge trunnion

opening. On bigger mills, which

need heavy rods, the rod charging

is made with a pneumatic or manual

operated rod charging device. The mill

must be stopped every day or every

second day for a few minutes in order

to add new rods and at the same time

pick out broken rod pieces.

As the heavy rod charge trans-

mits a considerable force to each rod,

a rod mill can not be built too big. A

shell length above 6100 mm can not

be recommended. As the length to

diameter ratio of the mill should be in

the range of 1 ,2-1 ,5, the biggest rod

mill will convert maximum 1500 kW.

Rod mills are used for primary

grinding of materials with a top size of

20-30 mm (somewhat higher for soft

materials). The production of fines is

low and consequently a rod mill is the

right machine when a steep particle

size distribution curve is desired. A

product with 80% minus 500 microns

can be obtained in an economical

manner.

The CRRK series of wet grinding

rod mills are tabulated on page 12.

4

Mill types

---

Overflow

End peripheral discharge

BALL MILLS

The grinding charge in a ball mill

consist of cast or forged steel balls.

These balls are fed together with the

feed and consequently ball mills can

be in operation for months without

stopping. The ball size is often in

the diameter range of 20-75 mm.

The biggest size is chosen when the

mill is used as a primary grinding mill.

For fine grinding of e.g. sands, balls

can be replaced by cylpebs, which

are heat treated steel cylinders with

a diameter of 12-40 mm and with the

same length as the diameter.

Ball mills are often used as

secondary grinding mills and for

regrinding of middlings in concen-

trators.

Ball mills can be of the overflow

or of the grate discharge type. Over-

flow discharge mills are used when a

product with high specific surface is

wanted, without any respect to the

particle size distribution curve. Over-

flow discharge mills give a final pro-

duct in an open circuit. Grate dis-

charge mills are used when the

PEBBLE MILLS

No steel grinding media is used

in a fully autogenous mill. When

choosing primary autogenous grind-

ing, run of mine ore up to 200-300

mm in size is fed to the mill. When

using a crushing step before the grind-

ing, the crusher setting should be

150-200 mm. The feed trunnion

opening must be large enough to

avoid plugging. The biggest pieces in

mill are important for the size

reduction of middle size pieces, which

in their turn are important for the finer

grinding. Thus the tendency of the

material to be reduced in size by

pressure, impact, and abrasion is a

very important question when primary

autogenous grinding is proposed.

When autogenous grinding is

used in the second grinding step, the

grinding media is size-controlled and

often in the range of 30-70 mm. This

size is called pebbles and screened

out in the crushing station and fed to

the mill in controlled proportion to the

mill power. The pebble weight is 5-25%

of the total feed to the plant, depending

on the strength of the pebbles. Some-

Overflow

grinding energy shall be concentrated

to the coarse particles without

production of slimes. In order to get a

steep particle size distribution curve,

the mill is used in closed circuit with

some kind of classifier and the coarse

particles- known as classifier under-

flow- are recycled. Furthermore, it

should be observed that a grate

discharge ball mill converts about

20% more energy than an overflow

discharge mill with the same shell

dimensions.

Ball mill shells are often furnish-

ed with two manholes.

Ball mills - with small balls or

cylpebs - can produce the finest

product of all tumbling mills. 80%

minus 74 microns is a normal require-

ment from the concentrators.

The CRRK series of wet grinding

ball mills are tabulated on page 12.

Grate discharge

times waste rock of high strength is

used as pebbles.

Pebble mills should always be of

the grate discharge type. The energy

that can be converted in a mill depends

on the total weight of the grinding

charge. Consequently, pebble mills

convert less power per mill volume

unit than rod and ball mills.

High quality steel rods and balls

are a considerable part of the

operating costs. Autogenous grinding

should, therefore, be considered and

tested when a new plant shall be

designed. As a grinding mill is built to

last for decades, it is more important

to watch the operation costs than the

price of the mill installation.

The CRRK series of wet grind-

ing pebble mills are tabulated on

page 13.

5

Grinding wet or dry

Wet grinding is definitely the

most usual method of grinding miner-

als as it incorporates many advan-

tages compared to dry grinding. A

requirement is, however, that water is

available and that waste water, that

can not be recirculated, can be remov-

ed from the plant without any envi-

ronmental problems. Generally, the

choice depends on whether the

following processing is wet or dry.

When grinding to a certain

specific surface area, wet grinding has

a lower power demand than dry

grinding. On the other hand, the wear

of mill lining and grinding media is

lower in dry grinding. Thus dry

grinding can be less costly.

A closed circuit dry grinding

system is very space consuming be-

cause of the classifier, the transport

devices, the dedusting filter, etc.

The feed to a dry grinding

system must be dried if the moisture

content is high. A ball mill is more

sensitive to clogging than a rod mill.

An air stream through the mill can

reduce the moisture content and

thus make a dry grinding possible in

certain applications.

A rod mill has a reduced capa-

city when used for dry grinding. The

material is hindered by the rods when

passing from the feed end to the

discharge area. Peripheral discharge

is recommended.

Due to the hindering effect that

the ball charge gives to the material

flow in dry grinding, the ball charge is

not more than 28-35% of the mill

volume. This should be compared

with 40-45% in wet grinding. The

expression used for this phenome-

non is that the charge in a dry grind-

ing mill is swollen.

Big dry grinding ball mills are

often two-compartment mills, with

big balls in the first compartment and

small balls or cylpebs in the second

ohe. An extra grate wall is used to

separate the two charges.

The temperature can increase

considerably in dry grinding mills, and

rubber lining should not be considered.

The efficiency of wet grinding is

affected by the percentage of solids.

If the pulp is too thick, the grinding

media becomes covered by too thick

a layer of material, which hinders grind-

ing. The opposite effect may be

obtained if the dilution is too high, and

this may also reduce the grinding

efficiency. A high degree of dilution

may sometimes be desirable in order

to suppress excessive slime forma-

tion.

Data given for tabulated mill

sizes on pages 12-13 are in respect

of wet grinding. Corresponding data

for dry grinding are given upon

request.

The need of grinding power

The specific power required for

a certain grinding operation, usually

expressed in kWh/ ton, is a function of

both the increase in the specific sur-

face of the material (expressed in

cm

2

/ cm

3

or cm

2

/ g) and of the grinding

resistance of the material. This can be

expressed by the formula

E = c (S-So)

where c is a material constant repre-

senting the grinding resistance, and

So and S are the specific surfaces of the

material before and after the grinding

operation respectively. The formula is

an expression of Rittinger' s Law which

is shown by tests to be reasonably

accurate up to a specific surface of

10,000 em / cm

3

.

When the grinding resistance c

has been determined by trial grinding

to laboratory scale, the net power E

required for each grinding stage desired

may be determined by the formula,

at least as long as Rittinger' s Law

is valid. If grinding is to be carried out

not to a certain specific surfaceS but

to a certain particle size k, the corre-

lation between Sand k must be deter-

mined. The particle size is often

6

expressed in terms of "particle size at

e.g. 95, 90 or 80% quantity passing"

and is denoted kgs, kgo or kso.

When the screen analyses for

the raw material and the product

respectively are known, the gross mill

power required may be calculated by

the following formula proposed by

J. Bond:

E = Eo (1 {10o - 1 (106 )

v ~ p v ~

where E = the specific power con-

sumption expressed in

kWh/short ton.

Eo = a proportionality and work

factor called "work index"

ksop = particle size of the product

at 80% passage (micron)

ksor = the corresponding value

for the raw material

(micron)

The value of Eo is a function of

the physical properties of the raw

material, the screen analyses of the

product and raw material respectively,

and the size of the mill. The value for

easily-ground materials is around 7,

while for materials that have a high

grinding resistance the value is

around 17.

Eo is correlated to a certain

reduction ratio, mill diameter etc.

Corrections must be made for each

case.

The simplest method of calculat-

ing the specific power consumption

is test grinding in a laboratory mill,

and comparison of the results with a

known reference material. The sample

is ground in batches for 3, 6, 12 ...

minutes, a screen analysis is carried

out after each period, after which the

specific surface is determined. A good

estimate of the grinding characte-

ristics of the sample can be obtained

by comparison of the specific surfaces

with corresponding values for the

reference material.

When the net power required

has been determined, an allowance is

made for mechanical losses. The

gross power requirement thus arrived

at , should with a satisfactory margin

be utilised by the mill selected.

Mill speed and grinding charge volume

The critical speed of a rotating

mill is the RPM at which a grinding

medium will begin to "centrifuge,

namely will start rotating with the mill

and therefore cease to carry out

useful work. This will occur at an RPM

of ncr, which may be determined by

the formula

42.3

n cr = RPM

y-o-

where Dis the inside diameter in

meters of the mill.

When calculating the weight of

the grinding medium charge weight,

the voids ratio for rods may be taken

to be 30% and for balls 42%.

The weight per volume will thus be

for steel rods approx. 5.5 t/m

3

for steel balls approx. 4.6 t/m

3

For coarse grinding in rod mills, the

rods used have a diameter of 50-1 00

mm and their lengths are approx. 150

mm below the effective inside shell

length. Rods will break when they have

been worn down to about 20 mm and

broken rods must from time to time

be taken out of the mill since otherwise

they will reduce the mill capacity and

may cause blockage through piling up.

The first rod charge should also

contain a number of rods of smaller

diameter.

It may be necessary to charge

the mill with rods of smaller diameter

when fine grinding is to be carried out

in a rod mill. Experience shows that

the size of the grinding media should

bear a definite relationship to the size

of both the raw material and the fini-

shed product in order that optimum

grinding may be achieved. The largest

grinding media must be able to crush

and grind the largest pieces of rock,

while on the other hand the grinding

media should be as small as possible

since the total active surface increas-

es in inverse proportion to the

diameter.

Mills are driven in practice at a

speed.corresponding to 60-80% of

the critical speed, the choice of speed

being influenced by economical

considerations. Within that range the

power is nearly proportional to the

speed.

The charge volume in the case

of rod and ball mills is a measure of

the proportion of the mill body that is

filled by rods or balls. When the mill is

stationary, raw material and liquid

should fill the voids between the

Grinding media

Olewski states that the suitable

largest ball diameter in mm can be

calculated from the formula

D = 6 Yd log d k

where d is the size of the largest

particle in mm in the feed and dk is the

size of the largest particle in microns

in the product.

The initial charge should how-

ever include balls of several smaller

sizes than the maximum. A usual rule

is that the weights of the different ball

diameters should be in proportion to

these diameters.

Example:

A crushed mineral whose largest

particles pass a screen with 25 x 25

mm apertures shall be ground to

approx. 95% passing 0.1 mm in a

2.9x3.2 m ball mill of 35 ton charge

weight. In accordance with

formula

D = 6 h5 log 1 00 = 60

that is, the. largest balls in the first

charge should be 60 mm diameter.

If we assume that the mill will in addi-

tion be charged with 50, 40 and 30 mm

balls, the distribution will be

Ball diameter Diameter Percentages Weight

(mm) ratio (tons)

60 6 33.3 11 .7

50 5 27.8 9.7

40 4 22.2 7.8

30 3 16.7 5.8

Totals 18 100.0 35.5

grinding media, in order that these

should be fully utilized.

Maximum mill efficiency is

reached at a charge volume of

approximately 55%, but for a number

of reasons 45-50% is seldom exceed-

ed. The efficiency curve is in any

case quite flat about the maximum.

In overflow mills the charge volume is

usually 40%, while there is a greater

choice in the case of grate discharge

mills.

Once the grinding operation has

reached a steady condition, only the

largest ball size - as given above - will

normally be charged.

Grinding media wear away

because of the attrition they are sub-

jected to in the course of the grinding

operation, and in addition a continuous

reduction in weight takes place owing

to corrosion. The rate of wear will in

the first place depend on the abrasive

properties of the mineral being ground

and naturally also on the hardness of

the grinding media themselves.

The wear of rods and balls is

usually quoted in grammes per ton of

material processed (dry weight) and

normal values may lie between 100

and 1500 g/ ton. Considerably higher

wear figures may however be experi -

enced in fine wet grinding of e.g. very

hard siliceous sand.

A somewhat more accurate way

of expressing wear is to state the

amount of gross kWh of grinding

power required to consume 1 kg of

grinding media. A normal value in wet

grinding is 15 kWh/ kg.

The wear figures in dry grinding

are only 1 0- 30 %of the above.

7

As may be seen on the figure

opposite, the power required to drive

the mill is, in the equilibrium condition,

N = c W Rg n KW

where c is a constant which, inter alia,

takes into consideration the mean

slope a of the charge,

W is the weight in kp of the charge

n is the RPM

Rg is the distance in metres of the

centre of gravity from the mill

centre

If N is taken to be the gross mill

power, values of the factor c in wet

grinding mills will be

rod mills 1/ 1800

ball mills, grate discharge 1 / 1200

ball mills, overflow type 1/ 1470

pebble mills 1/ 1200

W for rod and ball mills shall be

taken as the weight of the rod or ball

The diagram gives the values of

the quantity Rg/ d as a function of the

charge volume, the assumption being

that the charge has a plane surface

and is homogeneous. d is the inside

diameter of the mill in metres. The

variation of the quantity a/ d, where a

is the distance between the surface

of the charge and the mill centre, is

also shown in the same figure.

8

Mill power

charge, i. e. the weight of the pulp is to

be ignored. For pebble mills therefore

W is to be calculated on the basis of

the bulk weight of the pebbles.

a

d

0,50

0,40

0,30

0,20

0,10

~

I"

"'

"'

"'

~

~

"

Values of power consumption

stated in the tables pages 12-13 have

been calculated using the above

formula.

It should be pointed out that

factor "c" in the formula is a function of

both the shape of the inner lining

(lifter height etc.) and the RPM. The

formula is however valid with sufficient

accuracy for normal speeds and

types of lining.

f

~ _ /

..._...,

Tp

d

'""

""' ..........

~

~

~ d

.........

"

"

""

"'

I'(

10 20 30 40 50 %

Morgardshammar mill design

Morgardshammar started to

design and deliver grinding mills in the

beginning of the century. Today the

mills are computer designed and

manufactured in big plants with

modern machinery.

In order to keep manufacturing

costs at a minimum level, Morgards-

hammar has a series of standard mill

diameters up to and including 6.5 m.

Shell length, however, can be varied

and tailor made for each appl ication.

The sizes selected are shown on the

tables on page 12-13 and cover the

power range of 200-5000 kW.

SHELL

Shells with a diameter of up to

about 4 m are made in one piece.

Above this dimension, the shell is

divided into a number of identical

pieces, bolted together at site, in

order to facilitate the transport. The

shell is rolled and welded from steel

plate and is fitted with welded flanges

of the same material. The flanges are

machined in order to provide them

with locating surfaces fitting into the

respective heads. The shells of ball

and pebble mills are provided with

2 manholes with closely fitting covers.

The shells have drilled holes for

different types of linings.

HEADS AND TRUNNIONS

Heads with a diameter of up to

about 4 m are integral cast with the

trunnion in one piece. Above this

diameter the trunnion is made as a

separate part bolted to the head. The

head can then be divided in 2 or 4

pieces for easy transport and the pieces

are bolted together at site. The mate-

rial is cast steel or nodular iron. The

heads and the trunnions have drilled

holes for the lining.

TRUNNION BEARINGS

Spherical roller (antifriction)

bearings are normally used. They

offer the most modern and reliable

technology and have been used for

many years. They are delivered with

housings in a new design with ample

labyrinth seals.

For very large trunnions or

heavy mills, i.e. for primary auto-

genous grinding mills, Morgardsham-

mar uses hydrostatic shoe bearings.

They have many of the same advan-

tages as roller bearings. They work

with circulating oil under pressure.

SHORT TRUNNION

The spherical roller bearing and

the hydrostatic shoe bearing take a

very limited axial space compared to

a conventional sleeve bearing. This

means that the lever of the bearing

load is short. Furthermore, the

bending moment on the head is small

and as a result of this, the stress and

deformation of the head are reduced.

Ask Morgardshammar for

special literature on trunnion bearings.

RING GEAR

Ring gears are often supplied

with spur gears. They are always split

in 2 or 4 pieces in order to facilitate

the assembly. Furthermore, they are

symmetrical and can be turned round

in order to make use of both tooth

flanks. The material is cast steel or

nodular iron. They are designed in

accordance with AGMA.

The ring gear may be mounted

on either the feed or the discharge

head. It is fitted with a welded plate

guard.

PINION

The pinion and the counter

shaft are integral forged and heat

treated of high quality steel. For mill

power exceeding about 2500 kW two

pinions are used, one on each side of

the mill (double-drive) . The pinion is

supported on two spherical roller

bearings.

LUBRICATION SYSTEMS

The trunnion bearings are lubri -

cated by means of a small motor-

driven grease lubricator. The gear ring

is lubricated through a spray lubri-

cating system, connected to the elec-

tric and pneumatic lines. The spray

nozzles are mounted on a panel on

the gear ring guard.

MILL liNING

In order to protect the parts of

the mill that come into contact with

the material being ground, a replace-

able lining of wear-resistant material is

fitted. This may take the form of

unalloyed or alloyed rolled or cast

steel , heat treated if required, or rub-

ber of the appropriate wear resistant

quality. White cast iron, unalloyed or

alloyed with nickel (Ni-hard) , may also

be used.

The shape of the mill lining is

often of Lorain-type, consisting of

plates held in place between lifter bars

(or key bars) of suitable height bolted

on to the shell. This system is used i.a.

of all well-known manufacturers of

rubber linings. Ball mills and auto-

genous mills with metal lining also can

be provided with single or double

waved plates without lifter bars.

In grate discharge mills the grate

and the discharge lifters are a part of

the lining. The grate plates with

tapered slots or holes are of metal or

rubber design. The discharge lifters

are fabricated steel with thick rubber

coating. Rubber layer for metal linings

and heavy corner pieces of rubber

are included in a Morgardshammar

delivery as well as attaching bolts,

washers, seal rings, and self-locking

nuts. A Morgardshammar overflow mill

can be converted into a grate discharge

mill only by changing some liner parts

and without any change of the mill.

Trunnion liners are rubber

coated fabricated steel or cast steel.

In grate discharge mills the center

cone and the trunnion liner form one

piece.

FEED AND DISCHARGE

ARRANGEMENTS

Spout feeders of Ni-hard have

grown popular during the last decade.

Feed boxes of fabricated steel with

spout feeders can be carried on

flanged wheels on rails, thus making

disconnecting very easy.

Drum feeders are often used

when the flow into the mill is limited.

This type of feeder has an inside

coating of wear rubber.

Scoop feeders in combination

with drum feeders are used when

retaining oversize from a spiral or

rake classifier. As hydrocyclons are

used in most closed grinding circuits

the spout feeders are used most

frequently.

Vibrating feeders or screw

feeders are used when charging feed

to dry grinding mills.

Trommel screens are used to

protect slurry pumps and other

transport equipment from tramp iron.

Screens can have perforated rubber

sheets or wire mesh. The trommel

screens are bolted to the discharge

trunnion lining.

9

A pebble mill for silica grinding.

. .

10

A primary autogenous mil/5.9x8.5 min an iron ore concen-

trator.

A primary autogenous mil/6.5x8.0 min a zinc ore concen-

trator .

'

.,

I

r

Erection of grinding mills in an African iron ore concentrator.

A rubber lining in an autogenous mill.

11

Data

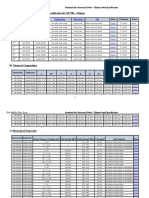

ROD MILLS TYPE CRRK FOR WET GRINDING

Size Diameter Shell length 1. Critical Mill speed 2. Mill

CRRK inside shell over flanges ~ p e e d volume

mm mm

2436 2400 3600

2736 2700 3600

2940 2900 4000

3243 3250 4300

3549 3500 4900

3849 3800 4900

4254 4150 5400

4260 4150 6000

4560 4500 6000

1. According to formula

42.3

....a- , where d is equal to internal shell

diameter within new liners.

In this case the thickness used was 60

mm for small mill sizes up to and in-

cluding 2940 and 80 mm for larger mills.

2. Volume of the cylindrical mill

proper within new liners.

%of

RPM critical RPM

mJ

28 64.5 18 14.2

26.3 64.5 17 18.2

25.4 61 15.5 23.5

24.5 60.5 14.8 29

23.1 60.5 14 41 .5

22.2 60 13.3 49.3

21 .2 60 12.7 65

21.2 60 12.7 73

20.3 60 12.2 85

3. Rod length as shown in last

column and a bulk weight of

5.5 kg/ dm

3

.

4. According to the empirical

formula P = WRgn (kW), where

1800

n is mill speed, Rg the radius of the

centre of gravity and W the charge

BALL MILLS TYPE CRRK FOR WET GRINDING

3. Charge 4. Power cal- 5. Rod

weight culated for length

at45 % 45 % charge

ton kW mm

33 180 3300

43 250 3300

55 310 3700

70 400 4000

98 605 4600

118 750 4600

154 1030 5000

174 1160 5600

205 1420 5600

weight (kg) according to the table.

Rg=0.235d at 45 per cent charge

volume.

5. Rod length 150 mm shorter

than available space between head

liners.

Ask Morgardshammar for dry

grinding rod mills and mills for special

applications.

Size Diameter Shell length 1. Critical 2.Mill 3. Mill 4. Mill 5.Charge 5. Charge 6. Power 7. Power

CRRK inside over flanges speed

shell

mm mm RPM

2436 2400 3600 28

2736 2700 3600 26.3

2940 2900 4000 25.4

3243 3250 4300 24.4

3549 3500 4900 23.1

3853 3800 5300 22.1

4260 4150 6000 21 .1

4565 4500 6500 20.3

4960 4900 6000 19.4

5360 5300 6000 18.6

5375 5300 7500 18.6

1. According to formula n =

4

~ ,

where d is equal to internal shell dia-

meter within new liners.

In this case the thickness used was 60

mm for small mill sizes up to and in-

. eluding size 2939 and 75 mm for larger

mills.

2. Approximately 75 per cent of

critical speed.

3. Volume of the cylindrical mill

proper within new liners.

12

speed volume volume grate weight

overflow discharge overflow

RPM

mJ mJ

ton

21 14.2 13.5 26

19.7 18.2 17.2 33.5

19 23.5 22.4 43.2

18.3 29.3 27.5 53.9

17.3 41 .8 39.6 76.9

16.6 53.9 51 .2 99

15.8 73.5 70.3 135.2

15.2 94.3 90.6 173.5

14.5 103.6 99.2 190.6

13.9 121.8 116.6 224.1

13.9 153 147.8 281 .5

4. Same as 3 but with a length

deduction of 300 mm (up to and in-

cluding size 2939) or 400 mm (from

size 3236 and up) for the discharge

chamber.

5. At a bulk weight for balls of

4.6 kg/ dm

3

and a charge volume of 40

per cent for overflow and 45 per cent

for discharge mills.

6. According to the empirical

formula P = WRgn (kW) , where n is

1470

weight grate calculated calculated

discharge overflow grate discharge

ton kW kW

27.6 215 260

35.6 295 355

46 395 475

57 515 615

82 775 930

107 1040 1270

145.5 1480 1800

187.5 1990 2430

205.3 2280 2770

241 .3 2780 3380

305.9 3500 4300

mill speed, Rg the radius of the centre

of gravity and W the charge weight (kg)

according to the table. Rg = 0.255d at

40 per cent charge volume.

7. According to the empirical

formula P = WRgn (kW). where

1200

Rg = 0.235 d at 45 per cent charge

volume. See further note 6.

Ask Morgardshammar for dry

grinding ball mills and mills for special

applications.

PEBBLE MILLS TYPE CRRK (CHRK) FOR WET GRINDING

Size Diameter Shell length 1. Critical 2. Mill 3. Mill Charge

CRRK inside shell over flanges speed speed volume volume

mm mm

3236 3150 3600

3538 3500 3800

3841 3800 4100

4245 4150 4500

4548 4500 4800

4952 4900 5200

5356 5300 5600

5370 5300 7000

5962 5900 6200

5980 5900 8000

6575 6500 7500

6590 6500 9000

1. According to formula n =

4

~ ,

where d is equal to internal shell dia-

meter (m) within new liners. 75 mm was

used as liner thickness.

2. Approximately 75 per cent of

critical speed.

RIGHT-HAND MILL

at45 %

RPM RPM

m3 m3

24.4 18.3 22.6 10.2

23.1 17.3 30 13.5

22.1 16.6 38.7 17.4

21 .1 15.8 51 .5 23.2

20.3 15.2 65.4 29.4

19.4 14.5 85 38.2

18.6 13.9 108 48.6

18.6 13.9 137.4 61 .8

17.6 13.2 150.5 67.7

17.6 13.2 197.2 88.7

16.8 12.6 224.7 101

16.8 12.6 272.2 122.5

3. Volume of the cylindrical mill

proper within new liners with half-worn

liners according to note 1.

4. At a bulk weight of 2.5 kg/ dm

3

for the grinding pebbles.

The sketch shows the meaning of the

terms "/eft-hand mill" and "right-hand

mill".

4. Charge 5. Power

weight calculated

at 45 %

ton kW

25.5 275

33.8 385

43.5 515

58 720

73.5 950

95.5 1290

121.5 1700

154.5 2170

169.2 2520

221 .7 3300

252.5 3960

306.2 4800

5. According to the empirical

formula p = WRgn (kW) , where

1200

n is mill speed, Rg the radius of the

centre of gravity (m) and W the charge

weight (kg) . At 45 per cent charge

volume Rg is equal to 0.235 d, where d

is the internal diameter (m) .

LEFT-HAND MILL

13

Accessories

Morgardshammar has designed

a series of single stage speed

reducers, which makes it possible to

drive the mills by motors with a

synchronous speed of 750-1000 RPM.

Inching units for slow rotation of

the mills are also furnished.

Rods to the rod mills are charg-

ed by means of manual or automatic

rod charges.

Erection cradles on hydraulic

jacks are used when erecting medium

or big size mills at site.

Ask Morgardshammar for

special bulletins on these accessories.

Grease mist lubricator for the gear ring (left) and grease

lubricator for the trunnion bearings (right).

14

L

...

)

Sieve scales

ISO and

Tyler

DIN 4188

mm

mesh inch mm

22,4 - 0,883 22,4

16 - 0,624 15,8

11 ,2 - 0,441 11 ,2

8 2,5 0,312 7,9

5,6 3,5 0,221 5,6

4 5 0,156 3,96

2,8 7 O,Q10 2,54

2 9 0,078 1,98

1,4 12 0,055 1,39

1 16 0,039 0,990

0,710 24 0,0276 0,701

0,500 32 0,0195 0,495

0,355 42 O,Q138 0,350

0,250 60 0,0097 0,246

0,180 80 0,0069 0,175

- 100 0,0058 0,147

0,125 115 0,0049 0,124

- 150 0,0041 0,104

0,90 170 0,0035 0,088

- 200 0,0029 0,073

0,63 250 0,0024 0,060

0,45 325 0,0017 0,043

- 400 0,0015 0,038

Measures

Direct Convert

factor

Length

0.30480 Feet to meters (m)

25.4001 Inches to millimeters (mm)

Mass

0.9072 Short tons to metric tons (t)

0.4536 Pounds to kilograms (kg)

Volume

3.7854 US Gallons to liters (I)

4.5461 Imp. Gallons to liters

0.02832 Cu. feet to cu. meter (m

3

)

Power

0.746 Amer HP to kilowatt (kW)

0.735 Eur. HP to kilowatt

Inertia

Reverse Metric (SI) system

factor

3.2808 1m= 10 dm = 100 em

0.03937 1 em = 10 mm = 10000 micron

1 .1 023 1 t = 1 000 kg

2.2046 1 kg = 1 000 g

0.2642 1 m

3

= 1 000 I

0.2200 1 I = 1 dm

3

= 1 000 cm

3

35.317

1.34

1.36

1 MW = 1000 kW

1 kW = 1000W

0.04214 LbsFt

2

(WR

2

) to kgm

2

(J) 23.73

. GD

2

J = -

4

Spec. Gravity, Bulk Density

0.01604 Lbs/Cu. ft to g/cm

3

62.355

Pressure

0.06892 Psi to bar 14.51

Temperature

F -32 _ C

180 - 100

1 bar = 1.02 kp/cm

2

= 100 kPa

15

Manufacturing programme

Machinery for Comminution

Jaw Crushers

Gyratory Crushers

Cone Crushers

Grinding Mills

Hammer Mills

Vibrating Screens

Feeders .

Material Handling Pumps

Laboratory Equipment

4

\.

Morgardshammar offices in

Smedjebacken, Sweden (head office) .

Krefeld, BRO ..

Rockford, USA.

Representatives throughout the world.

A Beijerinvest company

Morgardshammar AB, Fack, S-777 01 Smedjebacken, Sweden.

-

,..

Telephone: 46-240 711 00. Telegrams: morgardshammar, ludvika. Telex: 73243 morverk s.

B 89 E 78

You might also like

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Nordberg Grinding Mills Ball Rod and PebbleDocument24 pagesNordberg Grinding Mills Ball Rod and PebbleTsakalakis G. Konstantinos100% (4)

- Grinding Mills SALA Leaflet 603 E, Sweden 1973Document8 pagesGrinding Mills SALA Leaflet 603 E, Sweden 1973Tsakalakis G. Konstantinos100% (1)

- Grinding Mills Ball Mill Rod Mill Design PartsDocument53 pagesGrinding Mills Ball Mill Rod Mill Design PartsRodrigo GarcíaNo ratings yet

- 47 NCPMillsDocument5 pages47 NCPMillsraosp66No ratings yet

- Ball Mill Design & PowerDocument4 pagesBall Mill Design & PowerAlbert Eckersley100% (2)

- Grinding FundamentalsDocument49 pagesGrinding Fundamentalsalfonsopescador100% (7)

- MARCY Grinding MillsDocument48 pagesMARCY Grinding MillsTsakalakis G. Konstantinos100% (11)

- Ball, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Document131 pagesBall, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Tsakalakis G. Konstantinos100% (7)

- Ball Mill Manual PDFDocument54 pagesBall Mill Manual PDFAndrews Osei100% (1)

- MML45Semi Mobile Primary Gyratory Crushing Plant GADwgs Technical InformationDocument19 pagesMML45Semi Mobile Primary Gyratory Crushing Plant GADwgs Technical Informationgytoman0% (1)

- Modelling and Simulation of Dynamic Behaviour in Crushing PlantDocument66 pagesModelling and Simulation of Dynamic Behaviour in Crushing Plantmas26amin3465No ratings yet

- Mq45271 Ball Mill CalculationDocument130 pagesMq45271 Ball Mill CalculationAntonio Carlos de Angelis100% (1)

- Capacities and performance characteristics of jaw crushersDocument7 pagesCapacities and performance characteristics of jaw crushersvaper123No ratings yet

- Mechanical Flotation Equipment Selection GuideDocument13 pagesMechanical Flotation Equipment Selection Guidelouza8No ratings yet

- Ball Milling - Final FinalDocument12 pagesBall Milling - Final FinalKrishna TejaNo ratings yet

- C Jaw - Operating Guidelines 2004Document31 pagesC Jaw - Operating Guidelines 20042205bonilla100% (6)

- Denver Equipment Company Handbook guides engineersDocument0 pagesDenver Equipment Company Handbook guides engineersalvarezri100% (1)

- Maintenance of POLYCOM Roll Bodies With Studs: Machine Manual en-PM - RUN.003.BDocument51 pagesMaintenance of POLYCOM Roll Bodies With Studs: Machine Manual en-PM - RUN.003.BYinder Vega OsorioNo ratings yet

- OUTOKUMPUDocument12 pagesOUTOKUMPURommel Heredia Tejada100% (1)

- Codelco Chile/ El Teniente New Mine Level Project - ChileDocument26 pagesCodelco Chile/ El Teniente New Mine Level Project - ChileignacioNo ratings yet

- HPGR Faq PDFDocument9 pagesHPGR Faq PDFfran01334No ratings yet

- SAG & Ball Mill DimensioningDocument2 pagesSAG & Ball Mill DimensioningAngel Cuya100% (2)

- 5 Ways to Improve Your Health and WellnessDocument112 pages5 Ways to Improve Your Health and WellnessSegundo Colorado Villar89% (9)

- NT Features PDFDocument15 pagesNT Features PDFJoel Miguel Angel PachecoNo ratings yet

- Cost Analysis Model for Mineral ProcessingDocument63 pagesCost Analysis Model for Mineral ProcessingCristhian Portocarrero CastroNo ratings yet

- TELSMITH Rotary Drum Scrubber NewDocument7 pagesTELSMITH Rotary Drum Scrubber NewTsakalakis G. Konstantinos100% (2)

- Modelling The Specific Grinding Energy and Ball Mill Scale-UpDocument7 pagesModelling The Specific Grinding Energy and Ball Mill Scale-UpTsakalakis G. KonstantinosNo ratings yet

- Deep Cone Paste ThicknerDocument38 pagesDeep Cone Paste ThicknerzementheadNo ratings yet

- Crushing & Screening of Hard MaterialsDocument44 pagesCrushing & Screening of Hard Materialssen_subhasis_58100% (2)

- FLSMIDTH - Tablas de Referencia PDFDocument63 pagesFLSMIDTH - Tablas de Referencia PDFAntonio Sánchez100% (2)

- The Art of Rock CrushingDocument48 pagesThe Art of Rock CrushingJesusFloresRodriguez100% (1)

- HPGR Versus Sag Mill Selection For The Los BroncesDocument7 pagesHPGR Versus Sag Mill Selection For The Los BroncesRuben AltamiranoNo ratings yet

- Crusher TerminologyDocument44 pagesCrusher TerminologyJuan Francisco König100% (8)

- Enduron Screens CatalogueDocument12 pagesEnduron Screens Catalogueekrem0867No ratings yet

- Extract From The Book Belt FeederDocument93 pagesExtract From The Book Belt FeederPushp Dutt100% (1)

- Double Roll CrusherDocument6 pagesDouble Roll Crusherjaswanth60% (5)

- The Principle of Gyratory CrusherDocument14 pagesThe Principle of Gyratory CrusherNazah D'pyramidNo ratings yet

- Vibrating Screen DesignDocument12 pagesVibrating Screen DesignAinur Rohman100% (2)

- Grinding FundamentalsDocument49 pagesGrinding FundamentalsanruloNo ratings yet

- Ball MillDocument9 pagesBall MillTaufik AchmadNo ratings yet

- Vibrating FeederDocument7 pagesVibrating FeederRk Upadhyay100% (1)

- Bond F.C., 1961. Crushing and Grinding CalculationsDocument17 pagesBond F.C., 1961. Crushing and Grinding Calculationsitapui86% (7)

- 8 Crusher Rod MillDocument4 pages8 Crusher Rod MillvvananthNo ratings yet

- Ball Mills & SeparatorsDocument91 pagesBall Mills & Separatorsvijay kumar100% (2)

- Rod MillDocument9 pagesRod MillupiekupittNo ratings yet

- Ball MillDocument58 pagesBall MillFelipe CidNo ratings yet

- Cement Grinding - Cement Plant OptimizationDocument4 pagesCement Grinding - Cement Plant OptimizationHasan KamalNo ratings yet

- Mineral Processing MillingDocument6 pagesMineral Processing MillingMohsin KhanNo ratings yet

- Enhance The Performance of Tube Grinding Mills: Let Us Employ Grinding RollersDocument5 pagesEnhance The Performance of Tube Grinding Mills: Let Us Employ Grinding RollersD S VenkateshNo ratings yet

- Particle Technology: Size Reduction EquipmentsDocument7 pagesParticle Technology: Size Reduction EquipmentsMubarak AhmadNo ratings yet

- Advances in Fine Grinding & Mill System Application in The FGD IndustryDocument6 pagesAdvances in Fine Grinding & Mill System Application in The FGD IndustrychantivsNo ratings yet

- Tube Mill NoteDocument6 pagesTube Mill Notevvijaybhan100% (1)

- Cement Mill Calculation DesaignDocument1 pageCement Mill Calculation DesaignHilmy MuhammadNo ratings yet

- BwiDocument8 pagesBwiHiresomannavar MahanteshNo ratings yet

- Brochure Planetary Ball Mills enDocument12 pagesBrochure Planetary Ball Mills endrantistNo ratings yet

- Ball MillDocument11 pagesBall MillAkhil Bhadouria0% (1)

- RI 7472 Graphical Method OutlierDocument15 pagesRI 7472 Graphical Method OutlierTsakalakis G. KonstantinosNo ratings yet

- Resins in Mine Roof Support - ΙΙ by D. C. Mclean and S. Α. McKayDocument11 pagesResins in Mine Roof Support - ΙΙ by D. C. Mclean and S. Α. McKayTsakalakis G. KonstantinosNo ratings yet

- Model Building Techniques For Mineral Treatment Processes, Whiten W. J.Document16 pagesModel Building Techniques For Mineral Treatment Processes, Whiten W. J.Tsakalakis G. KonstantinosNo ratings yet

- Single Fracture of Brittle Spheres by N. Arbiter, C. C. Harris and G. A. StamboltzisDocument16 pagesSingle Fracture of Brittle Spheres by N. Arbiter, C. C. Harris and G. A. StamboltzisTsakalakis G. KonstantinosNo ratings yet

- Mining Activities in Ancient Greece From The 7th To The 1st Centuries BC John EconomopoulosDocument6 pagesMining Activities in Ancient Greece From The 7th To The 1st Centuries BC John EconomopoulosTsakalakis G. KonstantinosNo ratings yet

- Theory, Applications, and Practical Operation of HydrocyclonesDocument15 pagesTheory, Applications, and Practical Operation of HydrocyclonesTsakalakis G. Konstantinos100% (2)

- Heavy Media or Dense Media - PropertiesDocument2 pagesHeavy Media or Dense Media - PropertiesTsakalakis G. KonstantinosNo ratings yet

- Resins in Mine Roof Support - IDocument7 pagesResins in Mine Roof Support - ITsakalakis G. KonstantinosNo ratings yet

- Relationship Between Particle Size Distributions by Number and Weight Harris - StamboltzisDocument3 pagesRelationship Between Particle Size Distributions by Number and Weight Harris - StamboltzisTsakalakis G. KonstantinosNo ratings yet

- Calcination Rates of LimestoneDocument2 pagesCalcination Rates of LimestoneTsakalakis G. KonstantinosNo ratings yet

- Screen Motion AnalysisDocument3 pagesScreen Motion AnalysisTsakalakis G. KonstantinosNo ratings yet

- Filling of Underground Cavities With FlyashDocument4 pagesFilling of Underground Cavities With FlyashTsakalakis G. KonstantinosNo ratings yet

- Horsepower To Drive Rotary Kilns, Cooler or Dryer by Allis ChalmersDocument4 pagesHorsepower To Drive Rotary Kilns, Cooler or Dryer by Allis ChalmersTsakalakis G. Konstantinos100% (2)

- Chemistry of Hydration of Portland CementDocument44 pagesChemistry of Hydration of Portland CementTsakalakis G. KonstantinosNo ratings yet

- Energy and Mineral Exploitation TechniquesDocument16 pagesEnergy and Mineral Exploitation TechniquesTsakalakis G. Konstantinos100% (1)

- Bentonite C. W. Davis and H. C. VacherDocument54 pagesBentonite C. W. Davis and H. C. VacherTsakalakis G. KonstantinosNo ratings yet

- DENVER Mineral CharacteristicsDocument8 pagesDENVER Mineral CharacteristicsTsakalakis G. Konstantinos100% (1)

- Air Classifier ArticleDocument16 pagesAir Classifier ArticleTsakalakis G. Konstantinos100% (2)

- Coal Cleaning by Dense Medium Processes H.J. Ruff InprominDocument12 pagesCoal Cleaning by Dense Medium Processes H.J. Ruff InprominTsakalakis G. KonstantinosNo ratings yet

- Derivation of A Basic Efficiency Formula For Concentrating OperationsDocument17 pagesDerivation of A Basic Efficiency Formula For Concentrating OperationsTsakalakis G. KonstantinosNo ratings yet

- The Simulation of Mineral Processing Machinery, W.J. WhitenDocument3 pagesThe Simulation of Mineral Processing Machinery, W.J. WhitenTsakalakis G. KonstantinosNo ratings yet

- Crushing and Grinding Calculations NewDocument20 pagesCrushing and Grinding Calculations NewTsakalakis G. Konstantinos100% (25)

- Scale-Up and Dynamics of Large Grinding Mills - A Case StudyDocument19 pagesScale-Up and Dynamics of Large Grinding Mills - A Case StudyTsakalakis G. KonstantinosNo ratings yet

- Ball, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Document131 pagesBall, Tube and Rod Mills, Rose and Sullivan, Publication Year 1958Tsakalakis G. Konstantinos100% (7)

- Modelling The Specific Grinding Energy and Ball Mill Scale-UpDocument7 pagesModelling The Specific Grinding Energy and Ball Mill Scale-UpTsakalakis G. KonstantinosNo ratings yet

- Grinding Mill Scale-Up Problems by CC Harris N ArbiterDocument4 pagesGrinding Mill Scale-Up Problems by CC Harris N ArbiterTsakalakis G. Konstantinos100% (3)

- Recycled Aggregates Case Study (Production From Construction and Demolition Debris)Document8 pagesRecycled Aggregates Case Study (Production From Construction and Demolition Debris)Tsakalakis G. KonstantinosNo ratings yet

- Modern Solutions To Screen NG Problems: Mogensen SizerDocument8 pagesModern Solutions To Screen NG Problems: Mogensen SizerTsakalakis G. KonstantinosNo ratings yet

- RAC Viva QuestionsDocument5 pagesRAC Viva QuestionsDevesh KumarNo ratings yet

- SY35U PART FILTER PERIODICAL SERVICEDocument2 pagesSY35U PART FILTER PERIODICAL SERVICEIman SantosaNo ratings yet

- (Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodDocument33 pages(Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodAna Quintana100% (1)

- Cable Impedance Calculations - Open ElectricalDocument4 pagesCable Impedance Calculations - Open Electricaludayakumart100% (1)

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)Document3 pagesHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)crplzNo ratings yet

- 15 151905 Machine Design IDocument3 pages15 151905 Machine Design IPeeka Prabhakara RaoNo ratings yet

- Canopy Glass Thickness PDFDocument1 pageCanopy Glass Thickness PDFRufus ChengNo ratings yet

- Utilization of Waste Plastic in Manufacturing of Paver BlocksDocument4 pagesUtilization of Waste Plastic in Manufacturing of Paver BlocksAragorn RingsNo ratings yet

- Pakistan Steel Marketing DepartmentDocument5 pagesPakistan Steel Marketing DepartmentHamid NaveedNo ratings yet

- Amberjet 1200 H LDocument2 pagesAmberjet 1200 H LIraida MorosNo ratings yet

- Imsbc CodeDocument2 pagesImsbc CodeBBluningningNo ratings yet

- TDS MasterRheobuilld-623Document2 pagesTDS MasterRheobuilld-623Taposh PaulNo ratings yet

- Conversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessDocument21 pagesConversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessJaqueline SilvaNo ratings yet

- Beggs & Brill MethodDocument9 pagesBeggs & Brill Methodmatrix69No ratings yet

- Asco CC T LL Coalescer Cartridges 035A CCT 22 UK 7Document2 pagesAsco CC T LL Coalescer Cartridges 035A CCT 22 UK 7Masoud AmirzadehfardNo ratings yet

- JKR Mech DRWG PDFDocument117 pagesJKR Mech DRWG PDFFelix Semion100% (1)

- Civil Engineering Materials UOL Lahore: ConcreteDocument119 pagesCivil Engineering Materials UOL Lahore: ConcreteNawab Zada ManekaNo ratings yet

- Coutnry Wise All Commodities 2023 by IndiaDocument9 pagesCoutnry Wise All Commodities 2023 by IndiaindienkhanNo ratings yet

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument1 pageManufacturer'S Test Certificate: National Builtech Trading and Contracting CoNBTC Tubes & PipesNo ratings yet

- Carbide ToolingDocument90 pagesCarbide ToolingHuron Industrial SupplyNo ratings yet

- Iron Cast Iron Wrought IronDocument18 pagesIron Cast Iron Wrought IronvelavansuNo ratings yet

- Vicks Humidifier V745a ManualDocument5 pagesVicks Humidifier V745a ManualOrly Genoune HenkinNo ratings yet

- ACI Building Code Requirements for Thin Shells and Folded PlatesDocument84 pagesACI Building Code Requirements for Thin Shells and Folded PlateskrishnanunniNo ratings yet

- First Part Lab ManualDocument6 pagesFirst Part Lab ManualInfo EsocketNo ratings yet

- Standard Specification For GB 700Document12 pagesStandard Specification For GB 700Ma'arif Nuzul AddibNo ratings yet

- Multi Zone Completion OptionsDocument6 pagesMulti Zone Completion OptionsTong ChaipanyakulNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- Kobe Works eDocument13 pagesKobe Works eJagdish ShresthaNo ratings yet

- Almex Light Weight BrochureDocument16 pagesAlmex Light Weight BrochureGijoNo ratings yet