Professional Documents

Culture Documents

A New Sorption Model With A Dynamic Correction For The Determination of

Uploaded by

leizar_death64Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A New Sorption Model With A Dynamic Correction For The Determination of

Uploaded by

leizar_death64Copyright:

Available Formats

Journal of Membrane Science 330 (2009) 5156

Contents lists available at ScienceDirect

Journal of Membrane Science

j our nal homepage: www. el sevi er . com/ l ocat e/ memsci

A new sorption model with a dynamic correction for the determination of

diffusion coefcients

Ond rej Vopi cka

, Vladimir Hynek, Miroslav Zga zar, Karel Friess, Milan

Spek

Institute of Chemical Technology, Department of Physical Chemistry, Technick 5, Prague 6, 166 28, Czech Republic

a r t i c l e i n f o

Article history:

Received 8 July 2008

Received in revised form

13 November 2008

Accepted 21 December 2008

Available online 30 December 2008

Keywords:

Diffusion coefcient

Dynamic correction

Vapor sorption

Laplace transform

Cellulose-based membranes

a b s t r a c t

This paper describes animprovement to the method used for the calculationof diffusioncoefcients from

data obtained by the measurement of vapor sorption kinetics in a at, non-porous polymeric membrane.

The advantage of our corrected model is that it can be applied to systems displaying both fast and slow

sorption kinetics, as is demonstrated using cellulose myristate hexane and cellulose acetovalerate

ethanol systems at a temperature of 298K. Experiments were conductedona speciallydevelopedsorption

apparatus equipped with McBains spiral quartz balances. Sorption kinetics are generally described by

the solution of Ficks second law, the solution of which assumes relative pressure in the form of the unit

step function. Our correction involves modifying this solution so that a more realistic relative pressure

increase is assumed in terms of the Laplace transform.

2008 Elsevier B.V. All rights reserved.

1. Introduction

The transport of a vapor in a at, non-porous polymeric

membrane has frequently been described in terms of the

solutiondiffusion model, [1]. This model posits that the trans-

port process can be divided into three sub-processes; namely, the

sorption of the penetrant into the membrane, diffusion through

the membrane, and desorption. This type of transport is typically

described in terms of permeability, solubility and diffusion coef-

cients. The gravimetric sorption method enables us to determine

the sorption and diffusion coefcients for a pure vapor in a poly-

meric membrane, and to estimate the appropriate permeability

coefcients, [1,2]. This paper focuses on determining the diffusion

coefcients of vapors when sorbate pressure changes over time.

2. Theoretical part

2.1. Objective

The gravimetric sorption method involves measuring the mass

of vapor sorbed in a polymer membrane as a function of time until

a constant value is reached at equilibrium. Prior to the start of such

experiments, absolute pressure is effectively equal to zero and the

membrane does not contain any vapor. During these experiments

Corresponding author. Tel.: +420 220444029.

E-mail address: Ondrej.Vopicka@vscht.cz (O. Vopi cka).

a constant temperature is maintained and the pressure of the pure

vapor equals that of the pressure selected for the experiment. The

relative pressure is described using the unit step function:

p()

p

=

_

0 if 0

1 if > 0

, (1)

where p() denotes the dependence of vapor pressure on time and

p

= lim

(p()) is vapor pressure at sorption equilibrium. In the

literature [3,4], the solution of Ficks second law for sorption in a

at sheet membrane assuming a constant diffusion coefcient has

been described as follows:

Q()

Q

= 1

8

2

i=N

i=0

1

(2i +1)

2

exp

_

2

D (2i +1)

2

l

2

_

, (2)

where N , Q() is the amount of vapor sorbed by the mem-

brane, Q

is the amount of vapor sorbed at sorption equilibrium,

l denotes the thickness of the membrane and D is the constant

diffusion coefcient. In reality, however, the relative pressure of

vapor during a sorption experiment does not follow Eq. (1) exactly.

Therefore, the boundary conditions assumed in Eq. (2) are also not

satised. However, this discrepancy becomes insignicant when

the kinetics of relative pressure increase (i.e. when the vapor is

released into the evacuated volume containing the membrane)

are much faster than the sorption process itself. Eq. (2) can be

corrected to obtain a more general formula for the calculation

of diffusion coefcients. Solutions to similar problems have been

described in the literature [3,57].

0376-7388/$ see front matter 2008 Elsevier B.V. All rights reserved.

doi:10.1016/j.memsci.2008.12.037

52 O. Vopi cka et al. / Journal of Membrane Science 330 (2009) 5156

2.2. Correction I

The aim of correcting the initial solution Eq. (2) is to involve a

more realistic model of relative pressure increase.

Let x

1

() be an input function and y

1

() be the output function

of the system assigned to the input function. Assume that we are

looking for a new output function y

2

() for the same (physical)

system assigned to a new input function x

2

(), which is known.

If all the above mentioned functions satisfy the assumptions of the

Laplace transform(see Appendix, A), we can dene X

1

(s) = L{x

1

()}

and Y

1

(s) = L{y

1

()}, where s is a complex variable and L denotes

the Laplace transform. Then we can state Y

1

(s) = X

1

(s) H(s), and

the system function H(s) can be expressed. The new output func-

tion takes the formy

2

() = L

1

{H(s) X

2

(s)}, where L

1

denotes the

inverse Laplace transform.

This general approach allows us to incorporate additional

dynamics into the model of the process being described. Non-

instantaneous pressure increase is incorporated in the model of

sorption kinetics.

In this paper, Eq. (2) is the output function assigned to input

functionEq. (1), andwe are lookingfor a newoutput functionlinked

to the following new input function:

p

cI

()

p

=

_

0 if 0

1 exp(a) if > 0

(3)

where p

cI

() is the vapor pressure dependence on time assumed in

Correction I, and a is a real positive parameter denoting the inverse

value of the time constant. The Laplace transform, [8,9] of Eq. (3)

can be expressed as

L{p

cI

()}

p

=

1

s

a

s +a

. (4)

The Laplace transform of Eq. (1) has the form

L{p()}

p

=

1

s

. (5)

For a nite value of nonnegative integer N and assuming > 0,

the Laplace transform of Eq. (2) can be expressed in the following

form:

L{Q()}

Q

=

1

s

8

2

i=N

i=0

1

(2i +1)

2

l

2

2

D (2i +1)

2

+s l

2

. (6)

Eq. (6) is the product of the Laplace transformof the input func-

tion Eq. (5) and the system function. When the system function is

expressedandmultipliedby the Laplace transformof the newinput

functionEq. (4), the Laplace transformof the correctedequationcan

be formulated thus:

L{Q

cI

()}

Q

=

_

1

s

8

2

i=N

i=0

1

(2i +1)

2

1

s +d (2i +1)

2

_

_

a

s +a

_

,

(7)

where

d =

2

D

l

2

. (8)

Assuming that a / = d (2i +1)

2

for any integer 0 i N, andthat

> 0, the inverse Laplace transform of Eq. (7) can be expressed in

the following form:

Q

cI

()

Q

= 1 exp(a)

8

2

i=N

i=0

_

1

(2i +1)

2

a

d (2i +1)

2

a

_

exp(a) exp((2i +1)

2

d )

_

. (9)

When < 0, this equation is identically equal to zero. Provid-

ing that the value of parameter a has already been evaluated, Eq.

(9) can then be used to calculate the diffusion coefcient from the

experimental sorption kinetic data.

As mentionedinSection2.1, theunit stepfunctiondoes not accu-

rately describe the real relative pressure increase. This discrepancy

cannot be ignored when the vapor sorption rate becomes faster,

and approaches the velocity of the relative pressure increase. The

ratio of sorption velocity to relative pressure increase is measured

using the a/d ratio. When a/d , no correction is needed. In the

literature [3], a solutionequivalent toEq. (9) has beenderivedunder

time-dependent boundary conditions similar to those described in

Eq. (3). Both solutions converge to the same function as Nincreases.

The advantages of correcting the initial solution Eq. (2) are that

there is no need to solve Ficks second law for each model of rela-

tive pressure increase, and that it becomes possible to incorporate a

model of mass sensor dynamic response (e.g. Cahn microbalances)

into the sorption kinetics model.

2.3. Correction II

In Correction I the dependence of relative pressure on time was

assumed in the formof Eq. (3). However, the dependence of relative

pressure on time during sorption experiments is more accurately

expressed as

p

cII

()

p

=

_

0 if 0

1 exp() exp() if > 0

(10)

where p

cII

() is the vapor pressure dependence on time assumed in

Correction II, and is a real positive parameter. The Laplace trans-

form of this equation takes the form

L{p

cII

()}

p

=

1

s

2

(s +)

2

. (11)

As in Section 2.2, we thus obtain the Laplace transform of the

corrected equation:

L{Q

cII

()}

Q

=

_

1

s

8

2

i=N

i=0

1

(2i +1)

2

1

s +d (2i +1)

2

_

s

_

1

s

2

(s +)

2

_

. (12)

Assuming that > 0, and that / = d (2i +1)

2

for any integer

0 i N, the corrected model can be expressed thus:

Q

cII

()

Q

= 1 exp() exp()

8

i=N

i=0

_

1

(2i +1)

2

_

A exp(d (2i+1)

2

)+(C A) exp()

_

_

,

(13)

where

A =

2

2

2d (2i +1)

2

+d

2

(2i +1)

4

(14a)

C =

2

d (2i +1)

2

(14b)

Providing that the value of parameter has already been eval-

uated, the diffusion coefcient can be calculated by tting Eq. (13)

to the experimental sorption kinetic data.

O. Vopi cka et al. / Journal of Membrane Science 330 (2009) 5156 53

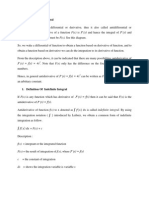

Fig. 1. Approximation of relative pressure increase obtained using Correction I pres-

sure model: cellulose myristatehexane; 298K; p =5.458kPa.

2.4. Experimental data tting

Prior to the start of each experimental run, data recording was

initiated manually. Therefore, there was some delay between the

start of data recording (zero time) and the start of the pressure

increase. To reect this Eq. (3) had to be modied thus:

p

cI

(t)

p

=

_

0 if t b 0

1 exp(a (t b)) if t b > 0

, (15)

where b is the time delay and t is the time recorded by the

apparatus. The values of the parameters a and b were determined

usingtheGaussNewtonoptimizationmethod[10]. Fig. 1shows the

approximation for the relative vapor pressure data obtained using

Eq. (3).

The GaussNewton method was used to calculate the diffusion

coefcient using Eq. (9), in which the substitution = t b was

employed. The diffusion coefcient was also calculated using Eq.

(2), in which the same substitution was made. Figs. 2 and 3 show

the approximations for the relative sorbed amount data obtained

using Eqs. (2) and (9), respectively. These models and the measured

Fig. 2. Approximation of sorption kinetic data using uncorrected sorption model:

cellulose myristatehexane; 298K; p =5.458kPa.

Fig. 3. Approximation of Correction I sorption model to sorption kinetic data: cel-

lulose myristatehexane; 298K; p =5.458kPa.

data are plotted against the square root of time in Fig. 4, the initial

nonlinearity of the corrected model being caused by the pressure

correction.

When Correction II is used, Eq. (10) must be changed as follows:

p

cII

(t)

p

=

_

0 if t 0

1exp( (t)) (t) exp( (t )) if t > 0

(16)

The GaussNewton method was used to calculate the values of

and from the measured pressure increase, the rst estimation

of the time delay being determined using a method developed

by Strejc [11], i.e. b

0.1

a

. Fig. 5 shows the approximation for

the relative pressure increase data obtained using Eq. (10). The dif-

fusion coefcient was calculated by optimizing Eq. (13)(with the

Fig. 4. Approximation of both Correction I (blue solid line) sorption model and

uncorrected model (red dashed line) to sorption kinetic data: plotted against square

root of time; cellulose myristatehexane; 298K; p =5.458kPa. (For interpretation

of the references to color in this gure legend, the reader is referred to the web

version of the article.)

54 O. Vopi cka et al. / Journal of Membrane Science 330 (2009) 5156

Fig. 5. Approximation of relative pressure increase obtained using Correction II

pressure model: cellulose myristatehexane; 298K; p =5.458kPa.

substitution = t ) to the sorption kinetic data. Fig. 6 shows the

approximation for the relative sorbed amount data obtained using

Eq. (13). Fig. 7shows the Correction I sorption model, the Correc-

tion II sorption model and the measured data plotted against the

square root of time. Integer N equals 5 in these approximations.

Correction I assumes a / = d (2i +1)

2

and Correction II assumes

/ = d (2i +1)

2

for 0 i N; assumptions which must be checked

during the GaussNewton processes.

We evaluated the 95% condence intervals for the diffusion

coefcients in two steps; (i) we used the Bonferroni method [10]

to determine the discrepancy of the model from the measured

datasuch condence intervals D D

t

serve as a measure of

quality of t; (ii) the 95% condence intervals were recalculated in

respect to the variability inthickness. The appropriate relative devi-

ations were approximately 14% for the cellulose myristatehexane

system, and 9% for the cellulose acetovalerateethanol system.

Figs. 8 and 9 plot the diffusion coefcients and 95% condence

intervals against the equilibrium vapor pressures. Tables 1 and 2

list the equilibriumvapor pressures, a/d ratios, calculated diffusion

coefcients and D

t

values.

Fig. 6. Approximation of Correction II sorption model to sorption kinetic data: cel-

lulose myristatehexane; 298K; p =5.458kPa.

Fig. 7. Approximation of Correction I (blue solid line) and Correction II (red dashed

line) sorption models to sorption kinetic data: plotted against square root of time;

cellulose myristatehexane; 298K; p=5.458kPa. (For interpretation of the refer-

ences to color in this gure legend, the reader is referred to the web version of the

article.)

Fig. 8. Dependence of diffusioncoefcients onequilibriumpressure of hexane vapor

at 298K in the cellulose myristate membrane (error bars of 14% show the 95% con-

dence interval).

Fig. 9. Dependence of diffusion coefcients on equilibrium pressure of ethanol

vapor at 298K in the cellulose acetovalerate membrane (error bars of 9% show the

95% condence interval).

O. Vopi cka et al. / Journal of Membrane Science 330 (2009) 5156 55

Table 1

Results of tting of uncorrected model and corrected models to sorption kinetic data, cellulose myristatehexane.

p (kPa) a/d 10

12

Dcor. II (m

2

s

1

) 10

12

D

t

cor. II

(m

2

s

1

) 10

12

Dcor. I (m

2

s

1

) 10

12

D

t

cor. I

(m

2

s

1

) 10

12

Dno cor. (m

2

s

1

) 10

12

D

t

no cor.

(m

2

s

1

)

1.271 4.9 29 2 30 2 18 2

2.839 3.4 34 1 35 1 20 2

4.542 3.4 36 1 37 1 19 2

5.458 5.2 38 1 39 1 24 2

8.547 3.5 41 2 42 2 26 2

10.668 5.1 45 3 46 3 29 3

11.633 5.3 48 3 48 3 32 3

Table 2

Results of tting of uncorrected model and corrected models to sorption kinetic data, cellulose acetovalerateethanol.

p (kPa) a/d 10

15

Dcor. II (m

2

s

1

) 10

15

D

t

cor. II

(m

2

s

1

) 10

15

Dcor. I (m

2

s

1

) 10

15

D

t

cor. I

(m

2

s

1

) 10

15

Dno cor. (m

2

s

1

) 10

15

D

t

no cor.

(m

2

s

1

)

0.713 62.3 343 3 344 3 334 3

1.396 100.5 308 4 309 4 300 4

1.975 80.0 417 4 417 4 403 5

2.583 85.5 413 5 414 5 403 5

3.208 64.6 544 6 545 6 523 6

3.907 46.7 594 8 595 8 561 9

4.682 98.4 584 9 585 9 572 9

5.157 80.2 651 8 652 8 634 8

5.632 65.1 611 8 612 8 589 8

3. Experimental part

3.1. Membranes and chemicals

Both membranes used were obtained from the Institute of

Macromolecular Compounds, Russian Academy of Sciences, St.

Petersburg, Russia: cellulose acetovalerate [12] with a thickness

of (35 2) m (95% condence interval of mean, normal distri-

bution) and a melting point of 170

C; cellulose myristate [13]

with a thickness of (100 7) m (95% condence interval of

mean, normal distribution) and a melting point of 130

C. Melting

points weremeasuredusingaSetaramDSC131differential scanning

calorimeter at temperature increases of 10

C per minute within

a temperature interval of 25300

C. Ethanol (ethanol absolute,

99.0100.0%, Merck) and n-hexane (min. 99.0%, Penta) were used

as obtained.

3.2. Apparatus

We used a self-constructed sorption apparatus [14,15] equipped

with McBains spiral quartz balances to measure the sorbed mass of

the compound in a polymer sample. The sorption of a vapor into a

polymer matrix results in the elongation of the quartz spiral, which

was monitored by a camera system specially developed by Neovi-

sion s.r.o., the Czech Republic. The absolute pressure of the pure

vapor was continuously measured by pressure gauges (Oerlikon

Leybold Vacuum GmbH, Germany).

A membrane was suspended on the end of the quartz balances

anddegassedat anabsolute pressure lower than1 Pa until the mass

of the sample remained constant over time. Prior to each measure-

ment, the membrane was degassed for approximately three times

longer thanthe time neededfor desorptionto the initial mass of the

degassed membrane. At the start of eachexperiment, the vapor was

introduced into the evacuated volume containing the membrane.

The valve separating the evacuated volume and the vapor container

was opened manually so that oscillation of the quartz spiral was

minimized. Therefore the parameters of the pressure increase (a

or ) were not constant and were calculated separately for each

experiment. The whole apparatus was maintained at 298 K for all

experiments.

4. Results and discussion

Fig. 8 plots the diffusion coefcients calculated for the cellu-

lose myristatehexane system against hexane equilibrium vapor

pressure. The a/d ratio for this system ranged from 3 to 5. Sig-

nicant differences between the diffusion coefcients calculated

by the corrected models and those obtained using the uncor-

rected model can be seen, thereby showing that our dynamic

correction is necessary when the a/d ratio approaches this

range.

Fig. 9 plots the diffusion coefcients calculated for the cellulose

acetovalerateethanol system against ethanol equilibrium vapor

pressure. The a/d ratio for this systemrangedfrom47to 101. No sig-

nicant differences can be seen between the diffusion coefcients

calculated by the corrected models and those obtained using the

uncorrected model. No correction is necessary when the a/d ratio

approaches this range.

Although the description of relative pressure increase in Cor-

rection I is assumed to be less accurate than that in Correction II,

Fig. 8(cellulose myristatehexane system) shows that the differ-

ences betweenthe diffusioncoefcients calculatedbythe corrected

models were negligible (compared to the differences between the

coefcients calculated by the corrected models and those obtained

using the uncorrected model).

5. Conclusions

Our correction method incorporates a more realistic pressure

increase into sorption kinetics using the Laplace transform and, at

the same time, removes the need to solve Ficks second law for

each pressure model. This was shown for two models of pressure

increase. According to Correction I, as the number of terms in the

series increases, the sorptionkinetics model converges to a solution

published by Crank [3].

Using cellulose myristatehexane and cellulose acetovalerate

ethanol systems, we have shown that the use of our correction

extends the applicability of the sorption model for the calculation

of diffusion coefcients to faster sorption processes. When sorp-

tion is slow in relation to pressure increase, both the corrected

models and the uncorrected model produced very similar diffusion

56 O. Vopi cka et al. / Journal of Membrane Science 330 (2009) 5156

coefcients, thereby alsoshowing that our models canbe usedeven

when no correction is strictly necessary.

Furthermore, this approach makes it possible to incorporate the

additional dynamics of a slowly responding mass sensor (e.g. Cahn

microbalances). Indeed, more than one additional dynamics can be

incorporated in an initial model.

Acknowledgment

This work was supported by grant research project MSM

6046137307 of the Czech Ministry of Education, Youth and Sports.

Appendix A. Laplace transform

The Laplace transform of the function f () is dened as

L{f ()} =

_

0

f () exp(s)d, (A.1)

where s is a complex variable and L denotes the Laplace transform.

The function f () is assumed to be piecewise continuous, where all

points of discontinuity are isolated and the function approaches a

nite limit fromeach side of the point of discontinuity, and f () = 0

for < 0. It is also assumed that our function f () is of exponential

order

0

so that

lim

f () exp() = 0 (A.2)

when >

0

. If we assume an exponential order function, we

can nd M and for > T

0

so that

|f ()| < Mexp(). (A.3)

Functions occurring in the solution for the time responses of

stable linear systems are of exponential order 0. The general treat-

ment shown in Section 2.2 is based on the Laplace transformof the

convolution integral.

If x() and h() are piecewise continuous functions of exponen-

tial order and x() = h() = 0 for < 0, the convolution integral is

dened as follows

y() =

_

0

x(t)h( t)dt, (A.4)

where y() is a piecewise continuous function of exponential

order and y() = 0 for < 0. The Laplace transformof the convolu-

tion integral is thus given by

L{y()} = X(s)H(s) = H(s)X(s), (A.5)

where X(s) = L{x()} and H(s) = L{h()}. All functions used in

this article meet the requirements of the Heaviside expansion the-

orem, which was used to obtain inverse Laplace transforms. For

a more general treatment of the Laplace transform the reader is

referred to the literature [8].

Nomenclature

A dened by Eq. (14a)

a real positive parameter dened in Eq. (3) [s

1

]

b the time delay dened in Eq. (15) [s]

C dened in Eq. (14b) [s

1

]

d dened in Eq. (8) [s

1

]

D diffusion coefcient m

2

[s

1

]

D

t

deviation of the diffusion coefcient (see Section

2.4) m

2

[s

1

]

time delay dened in Eq. (16) [s]

H(s) system function (see Section 2.2)

i integer

l thickness of at membrane m

L Laplace transform operator

L

1

inverse Laplace transform operator

N nonnegative integer

p() dependence of absolute pressure any pressure unit

p

= lim

(p()) the same as p()

p

cI

() assumed pressure dependence Eq. (3) the same as

p()

p

cII

() assumed pressure dependence [Eq. (10)] the same

as p()

Q() mass of sorbed vapor dependent on time any mass

unit

Q

= lim

(Q()) The same as Q()

Q

cI

() corrected sorbed mass dependence [Eq. (7)]the

same as Q()

Q

cII

() corrected sorbed mass dependence [Eq. (12)]the

same as Q()

s complex variable [s

1

]

time [s]

t time recorded by the apparatus (see Section 2.4) [s]

real positive parameter dened in Eq. (10) [s

1

]

x

1

() example input function (see Section 2.2)

X

1

(s) Laplace transform of x

1

()

x

2

() example input function (see Section 2.2)

y

1

() example output function (see Section 2.2)

Y

1

(s) Laplace transform of y

1

()

y

2

() example output function (see Section 2.2)

References

[1] M. Mulder, Basic Principles of Membrane Technology, Kluwer Academic Pub-

lisher, Dordrecht, 1998.

[2] K. Friess, M.

Spek, V. Hynek, P. Sysel, K. Bohat, P. Izk, Comparison of

permeability coefcients of organic vapor through non-porous polymer mem-

branes by two different experimental techniques, J. Membr. Sci. 53 (2004)

179185.

[3] J. Crank, The Mathematics of Diffusion, 2nd ed., Claredon Press, Oxford,

1975.

[4] J. Crank, G.S. Park, Diffusion in Polymers, 2nd ed., Academic Press, London,

1975.

[5] E. Cesari, V. Torra, J.L. Macqueron, R. Prost, J.P. Dubes, H. Tachoire, Thermo-

gense: application comparative de lanalyse harmonique et du ltrage inverse,

Thermochim. Acta 53 (1982) 1727.

[6] R.A. Siegel, A Laplace transform technique for calculating diffusion time lags, J.

Membr. Sci. 26 (1986) 251.

[7] A.E. Yaroshchuka, M.A. Glausb, L.R. Van Loonb, Diffusion through conned

media at variable concentrations in reservoirs, J. Membr. Sci. 319 (2008)

133140.

[8] W.R. LePage, Complex Variables andthe Laplace Transformfor Engineers, Dover

Publications, Inc., New York, 1961.

[9] F. Oberhettinger, L. Badii, Tables of Laplace Transforms, Springer-Verlag, Berlin,

1973.

[10] G.A.F. Seber, C.J. Wild, Nonlinear Regression, John Wiley & Sons, Inc., 2003.

[11] V. Strejc, O mo znostech vy s sho vyu zit theorie regulace v praxi, Prce, Praha,

1958.

[12] L. Feigin, V. Klechkovskaya, N. Stepina, A. Tolstikhina, A. Khripunov, Yu.

Baklagina, A. Volkov, R. Antolini, On the supramolecular organization of

LangmuirBlodgett cellulose acetovalerate lms, Colloids Surf. A 198200

(2002) 1319.

[13] P.Yu. Kuznetsov, A.K. Khripunov, E.V. Kruchinina, V.M. Kuznetsov, L.D. Turkova,

A.V. Penkova, Transport properties of cellulose ester membranes for separating

gas and liquid mixtures, Russ. J. Appl. Chem. 77 (11) (2004) 18221877.

[14] O. Vopi cka, V. Hynek, K. Friess, M.

Spek, P. Sysel, Aparatura pro stanoven sorpce

par v polymerech, Chem. Listy 103 (2009) in press.

[15] K. Friess, M.

Spek, V. Hynek, C. Panayiotou, Sorption of VOCs and water vapors

in polylactate membrane with nanocomposite llers, Desalination 200 (2006)

265266.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Gibbs Phase Rule RevisitedDocument3 pagesThe Gibbs Phase Rule Revisitedleizar_death640% (1)

- Humidity Calibration of Dynamic Vapor Sorption (DVS) InstrumentDocument5 pagesHumidity Calibration of Dynamic Vapor Sorption (DVS) Instrumentleizar_death64No ratings yet

- Kapustin Ski IDocument2 pagesKapustin Ski Ileizar_death64No ratings yet

- Brewster Angle Microscopy: Keith J. StineDocument29 pagesBrewster Angle Microscopy: Keith J. Stineleizar_death64No ratings yet

- ASAP2020 Operator's ManualDocument522 pagesASAP2020 Operator's ManualKim IKbeomNo ratings yet

- GTaC-Dover BishopDocument160 pagesGTaC-Dover Bishopleizar_death64100% (1)

- Dynamic Light Scattering in Supramolecular Materials ChemistryDocument14 pagesDynamic Light Scattering in Supramolecular Materials Chemistryleizar_death64No ratings yet

- SMC 012Document14 pagesSMC 012leizar_death64No ratings yet

- Validation of Analytical Methods Using A Regression ProcedureDocument4 pagesValidation of Analytical Methods Using A Regression Procedureleizar_death64No ratings yet

- SMC 004Document19 pagesSMC 004leizar_death64No ratings yet

- Capítulo 4 - Técnicas ExperimentalesDocument53 pagesCapítulo 4 - Técnicas Experimentalesleizar_death64No ratings yet

- Quimica de Materiales-1Document217 pagesQuimica de Materiales-1leizar_death64No ratings yet

- SMC 003Document16 pagesSMC 003leizar_death64No ratings yet

- Orgunic Biologicul Chemistry: Application of The Principle of Hard and Soft Acids and Bases To Organic ChemistryDocument1 pageOrgunic Biologicul Chemistry: Application of The Principle of Hard and Soft Acids and Bases To Organic Chemistryleizar_death64No ratings yet

- Absolute Electronegativity and Absolute Hardness Lewis Acids and BasesDocument1 pageAbsolute Electronegativity and Absolute Hardness Lewis Acids and Basesleizar_death64No ratings yet

- Titanium Alloys For Biomedical ApplicationsDocument9 pagesTitanium Alloys For Biomedical Applicationsleizar_death64No ratings yet

- Trigonometric IdentitiesDocument13 pagesTrigonometric Identitiesedgenuity dominoNo ratings yet

- PIP Question Bank 2014 15Document13 pagesPIP Question Bank 2014 15radhikasontakayNo ratings yet

- ExerciseDocument15 pagesExerciseNguyen NamNo ratings yet

- 2 1 2D Visual ServoingDocument13 pages2 1 2D Visual ServoingPedro Alfonso Patlán RosalesNo ratings yet

- Problems in Lagragian MechanicsDocument1 pageProblems in Lagragian MechanicsPaul RyanNo ratings yet

- Integrals QUIZDocument3 pagesIntegrals QUIZNorma Alejandra AbrenaNo ratings yet

- On The Robustness of Safe Reinforcement Learning Under Observational PerturbationsDocument30 pagesOn The Robustness of Safe Reinforcement Learning Under Observational Perturbations刘天岑No ratings yet

- Time Series and Spatial Data Analysis With Scilab: NfoclearinghouseDocument63 pagesTime Series and Spatial Data Analysis With Scilab: NfoclearinghouseAnonymous xpxooiNo ratings yet

- Blasius EquationDocument7 pagesBlasius EquationaathiraNo ratings yet

- Introduction To Computational Finance and Financial EconometricsDocument54 pagesIntroduction To Computational Finance and Financial EconometricsMR 2No ratings yet

- Holton ErrataDocument2 pagesHolton ErrataSenju HerkNo ratings yet

- Semi-Analytical Solution of Point Reactor Kinetic Model With Source Term, Step and Ramp ReactivitiesDocument11 pagesSemi-Analytical Solution of Point Reactor Kinetic Model With Source Term, Step and Ramp ReactivitiesUmair FarooqNo ratings yet

- COMEDK MathsDocument8 pagesCOMEDK Mathssingh.krishnaanuragNo ratings yet

- Unit 1 BasicDocument28 pagesUnit 1 BasicTaha IbrahimNo ratings yet

- Mathematics For Physicist: Adhi Harmoko SaputroDocument68 pagesMathematics For Physicist: Adhi Harmoko SaputroMila AprianiNo ratings yet

- March 13 Homework Solutions Math 151, Winter 2012 Chapter 7 Problems (Pages 373-379)Document8 pagesMarch 13 Homework Solutions Math 151, Winter 2012 Chapter 7 Problems (Pages 373-379)Pei JingNo ratings yet

- Definition of IntegralDocument7 pagesDefinition of IntegralwidhissNo ratings yet

- r5100204 Mathematical MethodsDocument4 pagesr5100204 Mathematical MethodssivabharathamurthyNo ratings yet

- Elements of Mathematics - 001Document12 pagesElements of Mathematics - 001Christian ArloNo ratings yet

- Indeterminate Equations HandoutDocument8 pagesIndeterminate Equations HandoutRitobrata NathNo ratings yet

- MMA103 Chapter 3 Linear EquationDocument33 pagesMMA103 Chapter 3 Linear EquationKORRAKOT KlinkaewnarongNo ratings yet

- 3.3 Polynomial in Factor Form SolutionsDocument8 pages3.3 Polynomial in Factor Form SolutionsVasile Nicoleta100% (1)

- Robust H Controller For Construction Elevator Drivesystem Vibrations AttenuatorDocument9 pagesRobust H Controller For Construction Elevator Drivesystem Vibrations AttenuatorDr Saba TareqNo ratings yet

- Numerical Analysis Module 2 Fundamentals of Vector SpacesDocument33 pagesNumerical Analysis Module 2 Fundamentals of Vector Spacespartha4uNo ratings yet

- Scilab ProgramsDocument47 pagesScilab ProgramsNatraj Anita Prabhurao HulsureNo ratings yet

- EM702p Second-Order Linear Ordinary Differential EquationsDocument20 pagesEM702p Second-Order Linear Ordinary Differential EquationsDHT845No ratings yet

- Cryptography PDFDocument105 pagesCryptography PDFHave No IdeaNo ratings yet

- Catenary Curve - ChainDocument8 pagesCatenary Curve - ChainwexlerNo ratings yet

- Problem 13 66Document2 pagesProblem 13 66Mar TendoNo ratings yet

- By David Roodman: How To Do Xtabond2: An Introduction To "Difference" and "System" GMM in StataDocument48 pagesBy David Roodman: How To Do Xtabond2: An Introduction To "Difference" and "System" GMM in StataRui Cardoso PedroNo ratings yet