Professional Documents

Culture Documents

Built-Up Steel Beam

Uploaded by

animesh91Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Built-Up Steel Beam

Uploaded by

animesh91Copyright:

Available Formats

Design wind load 0.

16 kN/m^2

[As per IS 800- 2007]

Analysis:

DL = 0.05 kN/m

2

WL

thr

= 0.16

kN/m

2

-Thrust pressure (downwards)

1.2 m

4 m

Loading on main beam:

0.2 kN/m

0.64 kN/m

Load Combinations for design: (As per IS 800-2007)

1.40601 kN/m -Acting downwards

WL

thr

=0.16 x 4 = -UDL on main beam due to Thrust pressure

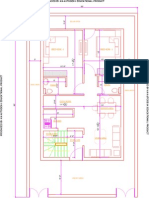

1 DESIGN OF MAIN BEAM

Purlin spacing =

Main beam spacing=

DL =0.05 x 4 = -UDL on main beam due to DL

*Considering the loads acting on main beam as UDL instead of point loads that are transferred from purlin to

main beam.

1.5 (DL+WL

thr

) =

1

1.2 m

8 m

R

e

R

f

1.2 m

7

-From the symmetry of the loading, the reaction force from beam support are;

R

e

=R

f

= 5.62404 kN -For the load case 1.5 (DL+WL

thr

), downwards

Bending Moment:

M

max

= 11.248 kN-m -For the load case 1.5 (DL+WL

thr

), downwards

(Maxm. BM at section of the beam)

thr

UDL

Loading on the main beam and support condition

Spacing of purlins =

No. of purlins =

1

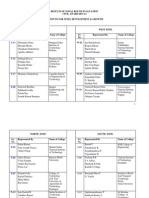

Trial Section: b

f

=80

t

f

=4

BUILT UP SECTION (refer fig.)

Grade: E 350

f

u

= 490 MPa

f

y

= 350 MPa d

w

=150 t

w

=4

d

w

- clear depth of the web

b

f

- width of the flange

*All dimensions are in mm

Sectional properties:

A = 1240 mm

2

m = 9.73 kg/m

H = 158

r

z

= 63.0 mm r

y

= 16.6 mm

Z = 62.3

x10

3

mm

3

Z = 8.6

x10

3

mm

3

t

f

, t

w

- thickness of flange & web

respectively

2

Z

ze

= 62.3

x10

3

mm

3

Z

ye

= 8.6

x10

3

mm

3

I

z

= 4.92 x10

6

mm

4

I

y

= 0.3421

x10

6

mm

4

Z

zp

= 71.780

x10

3

mm

3

Z

yp

= 13.40

x10

3

mm

3

Y_ver= 57.887 mm X_hori= 10.8065 mm

m- mass per unit length of the section

Classification of section

= 0.8452

For I-sections:

Plastic Compact

9.4 10.5

7.944 8.874

b/t

f

= 9.500

Z

zp

,Z

yp

- Plastic section modulus @ major & minor axes respectively

Z

ze

,Z

ye

- Elastic section modulus @ major & minor axes respectively

I

z

,I

y

- Second moment of area @ major & minor axes respectively

r

z

,r

y

- Radius of gyration @ major & minor axes respectively

D,t- Depth & thickness of the section respectively

Semi-compact

[ As per Table 2 of IS 800- 2007]

15.7

13.269

b- outstand element of compression flange

t

f

- thickness of the flange

.'. Section is Semi-compact

e=(250/_y )

2

b

= 0.868

Moment carrying capacity of the section

= 72.243

h= 154.0 mm

t

f

= 4 mm

h/t

f

= 38.50

h/t

LLT/r 35 38.5 40

70 485.5 478.85 476

72.243 455.4736

80 381.2 374.62 371.8

.'. f = 455.4736004

M

d

- moment carrying capacity of the section

z

p

- plastic section modulus for the given c/s

f

bd

- design bending compressive stress

Calculation of f

bd

:

h- c/c distace betwn. the flanges

f

cr,b

interpolation

-Table 14 of IS 800- 2007

H_J=[_b z_p _bJ

I_II/r

_min

3

.'. f

cr,b

= 455.4736004

LT

=0.49

fy

.'. f

cr,b

340 350 360

500 200.9 203.55 206.2

455.4736 195.0455

450 191.6 194 196.4

.'. f

bd

= 195.045 MPa

.'. M

d

= 12.148 kN-m

M

d

> M

max.

SAFE Stress Ratio= 0.926

where, M

max.

is maxm. bending moment in the main beam for the all possible load cases.

Shear capacity of the section:

V

u,max

= 5.62404 kN -For the load case 1.5 (DL+WL

thr

), downwards

-Maxm. SF at section of the beam

f

yw

- yield strength of web of the section

-Table 14 of IS 800- 2007

-For Builtup steel sections

f

bd

interpolation

-Table 13 (b) of IS 800- 2007

-Moment carrying capacity of the section

V

d

- shear capacity of the section

mo

- partial safety factor=1.1

I_J=(A_:_yw

)/(_mo3)

3

A

v

= 600

mm

2

f

yw

= 350 MPa

.'. V

d

= 110.221 kN

0.6 V

d

= 66.13 kN

.'. 0.6 V

d

> V

u,max

[As per Cl. 8.2.1.2 of IS 800- 2007]

Deflection:

Load Combinations for serviceability:

0.937 kN/m -Acting downwards

50.800 mm (occuring at the mid-point of the beam)

span/150 = 53.33 mm Hence OK

-Maxm. deflection at any point in the beam for

any possible load case

A

v

-Shear area of the section i.e web area for I-sectn.

-So, no reduction in moment carrying capacity is to be

made

Hence SAFE

1.0 (DL+WL

thr

) =

_mox

=

_o=

_mox=(5w_cq l

^4)/384EI

44

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Inception ReportDocument36 pagesInception Reportanimesh9159% (17)

- DP1100Document3 pagesDP1100tunradotNo ratings yet

- C32 Electronic Unit Injector - Adjust PDFDocument4 pagesC32 Electronic Unit Injector - Adjust PDFmanu luvunga100% (2)

- Residential BuildingDocument1 pageResidential Buildinganimesh91No ratings yet

- INSDAG Award BriefDocument2 pagesINSDAG Award Briefanimesh91No ratings yet

- Deflection of BeamsDocument41 pagesDeflection of BeamsMubaaracq Meerasahib100% (3)

- Environment Report of FlyoverDocument53 pagesEnvironment Report of Flyoveranimesh91100% (1)

- Second Order Analysis With ProgramDocument8 pagesSecond Order Analysis With Programanimesh91No ratings yet

- A Brief Overview of 2 Order (Or P-Delta) Analysis: ObjectiveDocument8 pagesA Brief Overview of 2 Order (Or P-Delta) Analysis: Objectiveanimesh91No ratings yet

- Connection - Beam-Column in SteelDocument9 pagesConnection - Beam-Column in Steelanimesh91No ratings yet

- Built-Up Steel ColumnDocument13 pagesBuilt-Up Steel Columnanimesh91No ratings yet

- Second Order Analysis of StructuresDocument10 pagesSecond Order Analysis of Structuresanimesh91No ratings yet

- P 5.0.1 Loading Condition For Columns: 5.0 Analysis of ColumnDocument6 pagesP 5.0.1 Loading Condition For Columns: 5.0 Analysis of Columnanimesh91No ratings yet

- 1.introduction (Tan K H, NUS)Document30 pages1.introduction (Tan K H, NUS)nsureshbabuNo ratings yet

- Starboard Strategies Issue 13-MinDocument28 pagesStarboard Strategies Issue 13-MinkrishnamrutamNo ratings yet

- DNF Stand PipeDocument3 pagesDNF Stand PipeChristopher BrownNo ratings yet

- MyNotes ConcreteDocument18 pagesMyNotes ConcreteKarl Si AkoNo ratings yet

- Kathrein 739506Document2 pagesKathrein 739506Carlos CostaNo ratings yet

- Flight DynamicsDocument57 pagesFlight DynamicsDexto100% (2)

- Bends - Route SelectionDocument6 pagesBends - Route SelectionanishsrNo ratings yet

- DUNAN Fan Coil UnitDocument14 pagesDUNAN Fan Coil UnitDjordjeNo ratings yet

- Uponor Dop Klett CPR 20 Ic 251 V 001Document3 pagesUponor Dop Klett CPR 20 Ic 251 V 001jamppajoo2No ratings yet

- VocationalDocument2 pagesVocationalMegha RoyNo ratings yet

- Master Antenna Television System and Satellite SystemDocument6 pagesMaster Antenna Television System and Satellite SystemMHEP_DANIELNo ratings yet

- MC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIDocument8 pagesMC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIblueword66No ratings yet

- Insulin, Recombinant HumanDocument2 pagesInsulin, Recombinant HumanMuhammad AkramNo ratings yet

- L19 External DiffusionDocument30 pagesL19 External DiffusionEga NabellaNo ratings yet

- Parts Catalog: F Y 8 - 3 1 F X - 0 0 0Document86 pagesParts Catalog: F Y 8 - 3 1 F X - 0 0 0julian gonzalezNo ratings yet

- Know It BrochureDocument8 pagesKnow It BrochureSonali SinhaNo ratings yet

- AKSML 230 - 33 KV - Sheet1Document2 pagesAKSML 230 - 33 KV - Sheet1Arif HossenNo ratings yet

- Piping Handbook Hydrocarbon Processing 1968 PDFDocument140 pagesPiping Handbook Hydrocarbon Processing 1968 PDFbogdan_chivulescuNo ratings yet

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeDocument4 pagesTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaNo ratings yet

- Stelzer Catalog PDFDocument12 pagesStelzer Catalog PDFlhphong021191No ratings yet

- IA SeriesDocument20 pagesIA Seriessina20795No ratings yet

- No35-Inclined Roof SystemDocument24 pagesNo35-Inclined Roof SystemKitanovic NenadNo ratings yet

- AE Yanmar 6GL UTDocument151 pagesAE Yanmar 6GL UTMehdi Es-SafiNo ratings yet

- CP R70 Smart View Monitor Admin GuideDocument106 pagesCP R70 Smart View Monitor Admin Guideoorhan41No ratings yet

- 80010360Document2 pages80010360mdisicNo ratings yet

- Email TMK88065 PDFDocument3 pagesEmail TMK88065 PDFlily_ng3642No ratings yet

- Debug 1214Document2 pagesDebug 1214Faizah Ayulia NawitaNo ratings yet

- People Soft Bundle Release Note 9 Bundle9Document29 pagesPeople Soft Bundle Release Note 9 Bundle9rajiv_xguysNo ratings yet

- Result Summary: Beam To Girder Shear Tab Shear Connection Code AISC 360-10 LRFDDocument14 pagesResult Summary: Beam To Girder Shear Tab Shear Connection Code AISC 360-10 LRFDLexNo ratings yet