Professional Documents

Culture Documents

Psvflare

Uploaded by

prembindOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Psvflare

Uploaded by

prembindCopyright:

Available Formats

JITENDRA SURVE

PIPING GUIDE

02/04/03

PSV AND FLARE SYSTEM

FLARE :: System which disposes off a plants waste gases. Flare Stacks :: Tall structures that route the gas to the atmosphere usually with a flare tip which ignites the gas. Flare Headers :: Pipelines that receive relief valve discharges, vents etc. and route this to a flare stack. Design Aspects 1. Sizing of relief manifold (Flare header) 2. Inlet Piping. 3. Layout. Sizing General steps of a relief manifold sizing check are: 1. Determine the major contingency that can cause the maximum flare loading. 2. Estimate the relieving load of each safety valve. 3. Develop the flare-header pressure profile, which will yield the back-pressures on the safety relief valves. 4. Check adequacy of the flare header size. Adequacy Check for Flare Header. The back pressure allowable on the safety relief valves varies based on the type selected. 1. Conventional == 10% of set pressure (non-fire contingency) 20% (fire contingency.). 2. Balanced bellow == 50% of set pressure. 3. Pilot operated == upto 75% of set pressure. From the flare header pressure profile, it has to be checked whether the back pressure on each safety valve is within the allowable value. Normally the pressure relief valve is conventional due to its low cost. However, an economics has to be worked out between selection of a balanced bellow valve and a higher sized pipeline. This is more relevant for safety valves with low set pressures. Segregation of flare headers as per safety valve set pressure can be more economical, if balanced bellow type valves are not considered. Other than back pressure, the most important aspect is the noise level. Sometimes eventhough the back pressures are within the required valvue, due to high velocities the noise level becomes unbearable. Hence to curtail noise generation in flare header, the Mach No. is usually limited to 0.7. Inlet Piping Preferred mounting in on top of the vessel with a nozzle that has a well rounded entrance. -1-

JITENDRA SURVE

PIPING GUIDE

02/04/03

Relief on the overhead vapor line shall be mounted with the flow through the run of any tee fitting. The least preferred relief valve mounting on an overhead vapor line is with the flow through the reducing branch of any tee fitting. When relief valves are mounted on overhead vapor lines, special consideration shall be given to the piping configuration to provide minimum input flow resistance to the relief valve. (Flow rate through the vapor line during an upset condition is much greater than normal process flow.) Sometimes interlocking systems for relief valves and block valves are specified. The minimum pipe size to the inlet of the relief valve must be same as the inlet diameter of the safety valve. The pressure drop in the inlet pipe should be less than 3%. High inlet pipe pressure drop can cause chattering. Normally block valves at the inlet of safety valve to be avoided. If provided, the valve should have full pipe-area opening and should be locked in open position. For corrosive fluids, safety valve can be protected by a rupture disk before the safety valve inlet. Setting Relief valve elevation and location. Availability of platform. Elevation that will permit free draining into the relief header. A location that will provide sufficient flexibility for stress requirements. After investigation and with the approval of process engineer, if a relief valve must be at lower elevation than the header, the tailpipe low point shall be drained. If valve is not located adjacent to line or equipment being relieved, an increase in line size to the valve is normally required with a swage connection at the relief valve inlet. Layout Must be in Upright position. Accessible from grade, floor, platform or vessel top platform. Relief valves with a center line elevation over 4 m above high point of finished surface shall be accessible from platform or permanent ladder. PSV on pulsating line should be flanged and located min from line. Screwed PSV required, use extra strong pipe nipples between valve and header. Keep this nipple short. Flare system must be self draining from safety valve outlet to the flare knock out drum. Relief valve outlets to flare headers must also be self-draining. This means relief valve shall be located higher than the flare header.

-2-

JITENDRA SURVE

PIPING GUIDE

02/04/03

When it is not possible to keep relief valve outlets self-draining to flare header, a manual drain valve at the outlet of safety outlet shall be provided.

Safety valve outlet line should always connect the flare header from top to avoid condensate backing up. Never route liquid reliefs to a flare header. There are to be routed to a nearby drain funnel or if nothing is available, run PSV discharge line to within 150 mm of Grade. PSV Vent to Atmosphere Hydrocarbon vapors are sometimes vented to atmosphere if located very high. The outlet pipe should terminate a minimum 3 M above any platform within 12 M radius. The relief valve must be accessible from a platform. A weep hole at low point of outlet to be provided to avoid accumulation of condensate. Supports and guides shall be provided for tailpipes if: 1. Required by stress to overcome thrust effect of discharging medium. 2. Attached tailpipe exceeds allowable free standing height. Allowable free standing height shall be determined as follows: [ thru 12 pipe: 0.55m X Nominal pipe size = Height (in Meters). Example: 4pipe: 0.55 m X 4 = 2.2m.], [14 and above: 0.50m X Nominal pipe size = Height in meters. Heavier wall pipe or reinforcing pads shall be used if required by stress conditions. When indicated on PID, the relief valves discharging to atmosphere shall comply with the following minimum requirements to protect personnel and equipment. 1. The discharge pipe shall be vertical. -3-

JITENDRA SURVE

PIPING GUIDE

02/04/03

2. The vent pipe at least 2 m long. 3. Terminate at least 25m above grade. 4. 3 m above the tallest accessible structure within 8m radius. 5. 30m horizontally from furnaces, boilers, air intakes etc. The End of discharge pipe shall be cut off squarely and rounded off to minimize the risk of ignition by static electricity. Pipe shall be directed away from windows, building roof overhangs, or overhead obstructions. Drain pipe if required for safety and indicated on PID otherwise a weep hole required at low point.

Use of simulator in flare header sizing. INPLANT simulator used for analyzing various pipe networks. Can be used for designing/rating total flare lines/header. Flow rates from different safety valves can be fixed and back pressures calculated. Flow rates and desired back pressures can be given to calculate pipe sizes. Safety valves sizes can be obtained. THERMAL RELIEF VALVES

As per process requirements. -4-

JITENDRA SURVE

PIPING GUIDE

02/04/03

Provided between block valves on liquid lines directly exposed to the sun as approved by process engineer. Should discharge back into the process line or a storage system. If discharged liquid cannot be accepted in either of these outlets, may discharged in open drainage system as approved process engineering. TYPES OF PSV

Conventional Relief Valve

-5-

JITENDRA SURVE

PIPING GUIDE

02/04/03

Balanced Belows PSV.

-6-

JITENDRA SURVE

PIPING GUIDE

02/04/03

Pilot Operated Valve.

-7-

JITENDRA SURVE

PIPING GUIDE

02/04/03

Typical Flare System

Relief Valves Headers Relief valve tailpipe and header configuration shall be based on the outlet temperatures of the relief valves as stated in the relief valve specification with consideration given to the actual heat loss or pickup from the atmosphere and any process consideration. Normal relief header location in the piperack is on the side where the majority of the equipment is located. If possible the header shall be located on the pipe supports with other piping. If an additional elevation is required, the header should normally be located above the pipe support columns. Pipe anchors and guides shall be provided as required to control thermal movements and forces as well as dynamic forces. If expansion loops are required, these shall be in the horizontal plane. Expansion bellows shall not be used without approval from ADNOC. Elevation of relief header is set by the required elevation of the blow down drum or road clearances whichever is greater. Headers shall be sloped as following: Unit branch headers shall be 1:200. For main headers 1:500. Direction changes necessitating elevational changes shall be so arranged so that the header drops continuously in the direction of the blow down drum (No pockets). Flat turns shall be used when practical. Header reducers shall be bottom flat.

-8-

JITENDRA SURVE

PIPING GUIDE

02/04/03

-9-

JITENDRA SURVE

PIPING GUIDE

02/04/03

Unit Branch header to main Header Connections. Connecting branches shall, if possible, connect to the top of the header or in any case, drain into the headers. The branches must be connected in such a way that there are no welds in the lower third of the circumference of the header. A 90 degree angle connection to the main header is acceptable based on the piping not exceeding 0.7 Mach.Process engineering shall define which lines meet the 0.7 MACH requirement. A 45 degree lateral connection to the main header shall be used for either two phase or liquid relief. Consideration should be given to manifolding several relief valve disharges into a common sub-header. Block Valves Valve stem of the isolating block valves should be mounted in a horizontal position, should the stem fracture. (Although the remote possibililty, the gate valve will stay open). Per the PID, where the one operating relief valve and a position for one spare is shown, the spare relief valve will be located in the warehouse. A dummy piece will be installed in place of the spare relief valve per PID. Block valves to be provided only when specified by process engineer and shown on PID. Block valves must be locked open. Bleed valve shall be installed between upstream block valve and relief valve. Downstream block valve shall be installed with the stem in the horizontal position. Should the stem fail, the gate valve will stay open. Omit valve when discharging to atmosphere.

- 10 -

JITENDRA SURVE

PIPING GUIDE

02/04/03

- 11 -

JITENDRA SURVE

PIPING GUIDE

02/04/03

- 12 -

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

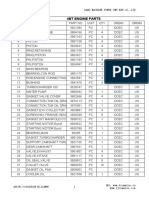

- Pf6tb & Pf6tc SeriesDocument309 pagesPf6tb & Pf6tc SeriesBudi Waskito95% (44)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CAT C-15 Operation & MaintenanceDocument125 pagesCAT C-15 Operation & Maintenancemohammad hazbehzad100% (2)

- 3512 Engine MaintenanceDocument30 pages3512 Engine Maintenancekhir khirNo ratings yet

- BZC01 PDFDocument11 pagesBZC01 PDFSegundo Francisco Jauregui Valencia0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mnaul de Servicio STX 12F (JT1200) 2005-2006Document434 pagesMnaul de Servicio STX 12F (JT1200) 2005-2006Luis Alberto TinjacaNo ratings yet

- 6277-5 WebDocument356 pages6277-5 WebTravisNo ratings yet

- Autocad Plant3d Quick Reference GuideDocument2 pagesAutocad Plant3d Quick Reference GuideHanna Obeid100% (1)

- Sae Technical Paper Series: Ernest Schwarz, Michael Reid, Walter Bryzik, and Eugene DanielsonDocument18 pagesSae Technical Paper Series: Ernest Schwarz, Michael Reid, Walter Bryzik, and Eugene Danielsonliaqat37_763886179No ratings yet

- Mike Kojima SE-RDocument33 pagesMike Kojima SE-Rpinoypride172001No ratings yet

- Deutz 2011 - Operation ManualDocument86 pagesDeutz 2011 - Operation ManualandNo ratings yet

- GEA Power Cooler Brochure 2002Document12 pagesGEA Power Cooler Brochure 2002Dory CanoNo ratings yet

- Management and Engineering of Fire Safety and Loss Prevention Onshore and OffshoreDocument295 pagesManagement and Engineering of Fire Safety and Loss Prevention Onshore and OffshoreAda Darmon100% (2)

- 4Bt Engine Parts: Cummins Kang Machine Power Imp - Exp.Co.,LtdDocument41 pages4Bt Engine Parts: Cummins Kang Machine Power Imp - Exp.Co.,Ltdjack comboNo ratings yet

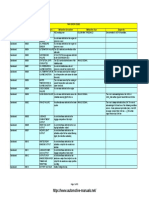

- 267 Pipe Stress Analysis ReportsDocument11 pages267 Pipe Stress Analysis ReportsRaymond MetselaarNo ratings yet

- Iveco Eg Repair ManualDocument142 pagesIveco Eg Repair ManualRobet PrasetyoNo ratings yet

- Panduan PPM D375A-5Document33 pagesPanduan PPM D375A-5aarizal100% (1)

- Medical Gas SystemsDocument81 pagesMedical Gas Systemszampacaanas100% (2)

- Tractorbaski PDFDocument44 pagesTractorbaski PDFCATNo ratings yet

- P8217 Checklist Fire Pump PDFDocument7 pagesP8217 Checklist Fire Pump PDFQuynh NguyenNo ratings yet

- JGP650P5 Jgp700e5 PDFDocument875 pagesJGP650P5 Jgp700e5 PDFAya JiboNo ratings yet

- CAU2011-PPT-TreyWalters JimWilcoxDocument34 pagesCAU2011-PPT-TreyWalters JimWilcoxprembindNo ratings yet

- GN 48-005 - HAZOP - of - Flare - and - ReliefDocument26 pagesGN 48-005 - HAZOP - of - Flare - and - ReliefMuhammad.Saim100% (7)

- PowerPoint ADocument2 pagesPowerPoint AprembindNo ratings yet

- 5 Tips for Simpler PowerPoint PresentationsDocument9 pages5 Tips for Simpler PowerPoint PresentationsBerlina YunitaNo ratings yet

- PowerPoint ADocument2 pagesPowerPoint AprembindNo ratings yet

- 5 Tips for Simpler PowerPoint PresentationsDocument9 pages5 Tips for Simpler PowerPoint PresentationsBerlina YunitaNo ratings yet

- 5 Tips for Simpler PowerPoint PresentationsDocument9 pages5 Tips for Simpler PowerPoint PresentationsBerlina YunitaNo ratings yet

- 5 Tips for Simpler PowerPoint PresentationsDocument9 pages5 Tips for Simpler PowerPoint PresentationsBerlina YunitaNo ratings yet

- 5 Tips for Simpler PowerPoint PresentationsDocument9 pages5 Tips for Simpler PowerPoint PresentationsBerlina YunitaNo ratings yet

- Photo AlbumDocument4 pagesPhoto AlbumprembindNo ratings yet

- Support DetailDocument8 pagesSupport DetailprembindNo ratings yet

- Final PPSXDocument8 pagesFinal PPSXprembindNo ratings yet

- K 6639 (1) ModelDocument1 pageK 6639 (1) ModelprembindNo ratings yet

- BR-6258nL: Quick Installation GuideDocument19 pagesBR-6258nL: Quick Installation GuideprembindNo ratings yet

- Introduction To Vessel and Vessel OrientationDocument22 pagesIntroduction To Vessel and Vessel OrientationprembindNo ratings yet

- Full exhaust install guide for CBR 600RRDocument16 pagesFull exhaust install guide for CBR 600RROmer ManaaNo ratings yet

- Ferrari f430 Error Codes DTCDocument63 pagesFerrari f430 Error Codes DTCLorenzo AlfistaNo ratings yet

- Actual Cycle Efficiency FactorsDocument29 pagesActual Cycle Efficiency Factorsمصطفى عبد القادر فايزNo ratings yet

- GEP400-4 OLY00000CB3J00766 Spare Parts CatalogueDocument889 pagesGEP400-4 OLY00000CB3J00766 Spare Parts CatalogueAugusto OliveiraNo ratings yet

- The New Mercedes-Benz 4.0 L V8 Diesel EngineDocument4 pagesThe New Mercedes-Benz 4.0 L V8 Diesel EngineEichi WatanabeNo ratings yet

- C20-32CL (Lot No 9974,8301)Document156 pagesC20-32CL (Lot No 9974,8301)Christian BedoyaNo ratings yet

- Engine IdentificationDocument54 pagesEngine IdentificationDEIDRE ANTONIETA BERNAL MORALESNo ratings yet

- d560 h2 Doosan Dp180laDocument7 pagesd560 h2 Doosan Dp180laGuvanchNo ratings yet

- Paccar MX 13Document13 pagesPaccar MX 13Marcos Vinicius BinottoNo ratings yet

- O&mDocument227 pagesO&mjennry100% (1)

- General Electric Systems Technology Manual Control Rod Drive SystemDocument38 pagesGeneral Electric Systems Technology Manual Control Rod Drive SystemEN IDNo ratings yet

- Catalog Opel InsigniaDocument1 pageCatalog Opel Insigniacaps.andrisNo ratings yet