Professional Documents

Culture Documents

Study On Biochemical Methane Potential and Engineering Application of Sludge Dehydrated Water Through Hydrothermal Drying Treatment

Uploaded by

SEP-PublisherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study On Biochemical Methane Potential and Engineering Application of Sludge Dehydrated Water Through Hydrothermal Drying Treatment

Uploaded by

SEP-PublisherCopyright:

Available Formats

www.ijesci.

org InternationalJournalofEnergyScience(IJES)Volume3Issue3,June2013

188

StudyonBiochemicalMethanePotentialand

EngineeringApplicationofSludge

DehydratedWaterthroughHydrothermal

DryingTreatment

MengDawei

1

,JiangZili

2

,MuHongyan

*3

andKunioYoshikawa

4

FirstFourDepartmentofEnvironmentalScienceandTechnology,TokyoInstituteofTechnology,Yokoha

ma2268502,Japan

ThirdDepartmentofEnvironmentalEngineering,BMEICO.,LTD,Beijing100027,China

1

mengdawei@bmei.net.cn;

2

jiangzili@bmei.net.cn;

*3

third.muhongyan@bmei.net.cn;

4

Four.yoshikawa.k.aa@m.titech.ac.jp

Abstract

The Hohhot sewage sludge dehydrated water

(SDW)throughhydrothermaldryingtreatmentwasstudiedin

this paper, which was evaluated by Biochemical Methane

Potential(BMP)testaswellastheguidanceforanbiochemical

methane potentialproject. The results showed that under 35

degree, after continuous 21 days fermentation, the sludge

dehydrated water performed the maximum cumulative gas

production (9450mL) with the concentration of 20gCOD/L.

Withtheincreaseofconcentrationofsludgedehydratedwa

ter, both unit biogas production and methane conversion

raterose at first and then fell, and it achieved

499.8mL/Gcodwhich was the maximum of 10gCOD/L slur

ry.According to the optimal results of commercial project in

Hohhot, the efficiency of 20gCOD/L sample, 83.42 tons of

sludge dehydrated water if all the loading of COD was de

graded were calculated to produce 342m

3

methane, corres

pondingtotheheatfrom239.5kgstandardcoal,whichcould

beusedforrecycling.

Keywords

Hydrothermal Drying; Sludge Dehydrated Water; Biochemical

MethanePotential;Methane

I nt r oduc t i on

As a new applied technology in the sludge treatment

area, hydrothermal drying technology for sludge has

attracted much attention both at home and abroad in

recent years, with advantages such asdecrement of

sludge volume, enhancement of anaerobic digestion

potential,nontoxic,green,andrecycling,etc.However,

therearealargemassofrawsludgeproducedwithout

stable processing each year, and it was seriously dis

rupted in betweensludge treatment and wastewater

treatment. Sludge contains cytoplasm, colloid, and

macromolecularorganism,etc.soithastobethekeyto

the cell disruption technology to improve sludge de

wateringperformance.

Hydrothermaldryingtechnologyholdsthecapabilities,

for instance, it can break up microbiological flocks,

rupturecells,anddissolvesolidorganicsorresolvable

macromolecular organism to molecule organism,

change the characteristics of sludge moisture funda

mentally, improve the anaerobic digestion perfor

mance of sludge, and enhance the efficiency of anae

robic digestion as well asmethaneproduction. As the

residual product, sludge dehydratedwateris also get

ting much attention for its high concentration of or

ganics and nutrition, which has a high resources po

tential. Smallscale and largescale sludge experiment

havebeenperformedbymeansofhydrothermaldrying

technology, and the result showedthat the optimum

reaction temperature was 190 and the optimum

reaction time was 30 minutes . With these optimum

operatingconditions,themoisturecontentofthesolid

residue was reduced to less than 40% by the hydro

thermal treatment followed by the mechanical dehy

dration, and the moisture content of the solid residue

could be reduced to 20% and 10% by 24 hours and 48

hours of natural drying, respectively. Meanwhile it

would be a huge resourcerecycling potential through

componentanalysisofsludgedehydratedwater.

The sewage sludge dehydrated water was studied as

theobjectofthisexperiment,whichwasresearchedon

its feasibility of methane production, and to get the

InternationalJournalofEnergyScience(IJES)Volume3Issue3,June2013 www.ijesci.org

189

betterreactionconditions.Atthesametime,itwases

sentialtoinvestigatetechnicalfeasibilityandeconomic

andrationalresearchforthistechnicalroute,inorderto

improve the hydrothermal drying technical chain of

sludge,toachieveclosedcycle treatment of both waste

water and sludge through hydrothermal drying me

thod, and to achieve the maximum of the recycle of

resource,in combination with some engineering

projectsofbiochemicalmethanepotentialfromsludge

dehydratedwater.

Ex per i ment

Materials

1)SludgeDehydratedWater

In this study, the sludge dehydrated water(SDW)

was derived from the sludge ofHohhot sewage

treatment plant (20% of total solid), which was the

residual fluid after hydrothermal drying treatment

(Table1).ItcouldbeseenthatthisSDWhadabet

ter biodegradabilityto be used as the substrate (or

zymotic fluid) of methane production, which had

theratioofBOD5/CODcr0.38.

TABLE1CHARACTERISTICSOFTHESDW

pH

SS

/mgL

1

TP

/mgL

1

NH3N

/mgL

1

CODcr

/mgL

1

BOD5

/mgL

1

6.75 1.384 0.101 1.8 41.82 15.73

2)Inoculatedsludge(IS)

Inoculatedsludgewascollectedfromtheanaerobic

digester of Beijing sewage treatment plant, which

wasaddedtoglucosewith5000mg/Ldosageforone

weekdomestication.

Facilities

In this experiment, the anaerobic methaneproducing

systemwithsimpleglassbottleswasadoptedtosimu

late anaerobic fermentation process, in order to pro

vide data support for future engineering application.

TheapparatuswasinstalledasFig.1shownbelow,and

thenitsleakproofnesswasinspected.

2.5LCSTR(continuousstirredtankreactor)tankswere

used as anaerobic reactors. Certain volume of SDW

wasaddedintoeachbottle,dilutedwithdistilledwater

to 1.5L, then inoculated with flocculent anaerobic

sludge respectivelyaccording to theinoculationquan

tityofCODSDS:VSSIS=4:1,andintheendfillednitrogen

gasfor3minutestoeliminateoxygeninside.Thebiogas

producedbyanaerobicfermentationwasmeasuredby

gasflowmeter.

FIG.1EXPERIMENTALDEVICEOFBIOCHEMICALMETHANEPOTENTIAL

Methods

1)BiochemicalMethanePotentialtest

Table 1 showed that the concentration of COD and

ammonia nitrogen is relatively high for methano

gens normal growth, and it was essential for the

SDWwithgradientdilution.Anaerobicbottleswere

numberedconsecutivelyfromNo.1toNo.6,among

whichNo.1~No.4werethezymoticfluidswith1,2,4,

8 times dilution of the raw SDW, similarly,

No.5~No.6 were the comparisonsample (CP., con

taining375mLrawfluidand1125mLdistilledwater)

andtheblankone(BK.,containing1500mLdistilled

waterand125mLinoculatedsludge).

TABLE2CHARACTERISTICSOFTHESDW

No. COD/gL

1

1 41.82

2 20.91

3 10.45

4 5.23

The alkalescency of the zymotic fluid was adjusted

topHof7.5~8.0bymeansof3mol/LNaOHsolution,

andreactorsinstalledasshowninFig.1,wereplaced

in constant temperature incubator with

35degreesCelsius[15].Littlewaterwasaddedinto6

graduated cylinders in order to make the liquid

level coincide with zero graduation, and two

records of methane yield at 8:00 and 16:00 every

daywerekeptwithslowlyvibratinganaerobicbot

tlesforabout30minonetime,inordertoavoidthe

emergency of partial acidification. After the com

pletion of methane production, pH values were

testedforallofzymoticfluids.

2)SludgeHydrothermalDryingpretreatment

Thisprojectcouldreducethewatercontent(WC)of

www.ijesci.org InternationalJournalofEnergyScience(IJES)Volume3Issue3,June2013

190

sludge from 80% to 20% through hydrothermal

dryingmethod.Atfirst,wetsludgewasaddedinto

steam reaction kettle, where heat was exchanged

with saturated steam at 190 for 30min. Then, the

sludge after hydrothermal drying with 85% water

content,hadsuchliquidityastogravitationallyflow

into pressofiner for mechanical dehydration, in ad

dition,theSDWwasthetestsample.

AnalysismethodandInstrument

Cumulative biogas yield and daily biogas yield of

SDWwerecalculatedbythevolumeofalkalineeffluent.

CODcrwastestedbythepotassiumdichromatemethod,

usingHACHDR/890waterqualityanalyzer.Ammonia

nitrogen was measured by the sodiums reagent spec

trophotometry method, using HACH IL500 au

toanalyzer.The value of pH was tested by Laser

PHS3C, and suspended solid (SS) and BOD5 were

testedbymeansofstandardmethods.

Resul t s and Di sc ussi on

Biochemical Methane Potential of Sludge Dehydrated

Water

1)CumulativeBiogasYieldandDailyBiogasYield

The main propose was to investigatebiochemical

methane potential of the SDW, by keeping records

of alkali liquor volume regularly, calculating cu

mulativeanddailybiogasyield.

0 2 4 6 8 10 12 14 16 18 20 22

0

2000

4000

6000

8000

10000

C

u

m

u

l

a

t

i

v

e

b

i

o

g

a

s

y

i

e

l

d

/

m

L

Time/d

40gCOD/L (No.1)

20gCOD/L (No.2)

10gCOD/L (No.3)

5gCOD/L (No.4)

CP. (No.5)

BK. (No.6)

FIG.2CUMULATIVEMETHANEPRODUCTIONWITHDIFFERENTCODOF

SLUDGEDEHYDRATEDWATER

Cumulative biogas yield with different COD load

ings of SDW was shown in Fig.2. At the beginning

of 6 days, all except compared and blank samples

hadhigher biogas yield, the order of which was

No.2>No.1>No.3>No.4. The rate of biogas produc

tion began to slow down for the first time after 6

daysfermentation.However, the yield of No.2 sam

ple rapidly increased again after 10 days, reaching

the maximum of790mL, 39.8% larger than the

second one (NO.3). The ultimate order ofcumula

tivebiogasyieldwasNo.2>No.3>No.1>No.4.

Intheinitiatingstageoffermentation,No.1sample

had the top speed of biogas production but with

normal cumulative biogas production. The reason

might be with too high concentration of ammonia

nitrogen(1800mg/L)andthenearlyneutralzymotic

fluid in the end, inhibition effect occurred after 6

days fermentation to methanogens rather than aci

dification generated by acetic acid bacteria, which

ledtothelowbiogasproductionefficiency(6750mL

cumulative biogas yield). No.2 sample had a rapid

speed at the beginning, but stagnated during

6th~10thdays,andthencameuptosignificantbio

gas efficiency again. It might because the mixed

anaerobic fermentation bacteria could better adapt

to this zymotic fluid with the organic loading con

ditions, which could breed in abundance and coo

peratewithmethanogenstoconvertorganismfrom

thezymoticfluid.Themethaneproducingcurveof

No.3samplewassimilartoNo.1,bothofwhichap

peared dead time from 6th to 10th, then produced

biogasagain,andultimatelyreached5825mLinthe

17thday.

Therefore, No.2 sample havingthe top speed of

biogas production in the initiating stage as well as

the largest biogas yield, achieved biogas summit

again after merely 3 days, and was significantly

better than No.3 and No.1 samples account of bio

gas production efficiency and cumulative biogas

production, which presentedimportant references

forreasonableadjustmenttotheorganicloadingof

zymoticfluidinengineeringapplication.

0 2 4 6 8 10 12 14 16 18 20 22

0

100

200

300

400

500

600

700

800

900

D

a

i

l

y

b

i

o

g

a

s

y

i

e

l

d

/

m

L

d

-

1

Time/d

40gCOD/L (No.1) 20gCOD/L (No.2)

10gCOD/L (No.3) 5gCOD/L (No.4)

CP. (No.5) BK. (No.6)

FIG.3DAILYMETHANEPRODUCTIONWITHDIFFERENTCODOFSLUDGE

DEHYDRATEDWATER(SDW)

InternationalJournalofEnergyScience(IJES)Volume3Issue3,June2013 www.ijesci.org

191

As it was seen in Fig.3thatthe daily biogas produc

tion of No.1 sample had the maximum production

during initial 6 days (gas peak period: I), and then

quicklydroppedtoanendinthe11thday.No.2and

No.3samplesquicklyachievedeachbiogassummit

initially, gradually stopped to produce after 6 days

(lag period: II), then achieved their second biogas

producing peaks during III period, and gradually

reduced after the 14th day (ending period: IV).

BiogassummitsoccurredinNo.4sampleinthefirst

6daysaswell,inwhichbiogaswasyieldedsteadily

during period of II, then eliminated after the 10th

day.

Li considered that microbial community mainly

consumedEPS(extracellularpolymericsubstances)

for their own growth at the initial anaerobic diges

tionperiod,andthentheoutputofcumulativebio

gas and daily biogas dropped gradually with the

decrease of EPS. In addition,hydrolytic enzyme

produced from anaerobic bacterium could dissolve

intracellular macromolecules out of microbial cell

wall tosupply new substrates for methanogens. So

thermal hydrolysis method could obviously acce

lerate this hydrolytic process and raise biogas pro

ductionfinally.

2)UnitbiogasProduction

After anaerobic biogas productioncame into stable,

unit biogas production and the percentage of me

thane conversion were shown in Fig.4. Unit biogas

production represented the volume of produced

methane when per COD of zymotic fluid was de

gradedafterfermentation.Underthecircumstances

of 35 degree Celsius and 101.3kPa, there would be

395mL pure methane produced when 1gCOD was

degraded, somethane conversionratemeantthe per

centage of the value of COD converted to methane

againstthetotalvalueofCOD.

Theunitbiogaswascalculatedasfollows:

u =

0

0

1uuu

(C

0

-C

1

) v

0

G(mL/g)unitbiogas;

G0(mL)cumulativemethaneproduction;

C0(mg/L)CODvalueofSDWbeforefermentation;

C1(mg/L)CODvalueofSDWafterfermentation;

V0(L)volumeofSDW(0.3L).

The results showed that with the increase of zy

motic fluid concentration, both unit biogas yield

and methane conversion rate presented first in

creased and then decreased trend, and the maxi

mumobtainedfromNo.3samplehasoccurred(unit

biogas yield: 449.8mL/gCOD and methane conver

sion rate: 95.7%). The order of zymotic fluids ac

cording to unit biogas yield was:

No.3>No.2>No.4>No.1, which might because the

concentration of450mg/L ammonia nitrogen had

beenfarbelowthelimitsofsignificantinhibitionof

anaerobic microorganism (1500~3000mg/L).The

methanogens withthe highest activities could con

vert the low molecular organic matter (e.g. acetic

acid, ethanol) to methane, which had been pro

duced by hydrolytic bacterium. When the concen

trationofzymoticfluidexceededNo.3orevenNo.4,

with the increased concentration of ammonia ni

trogen, the activities of both acidforming bacte

rium and methanogens were inhibited. However,

No.4 sample might be its lower concentration, or

ganic matters from zymotic fluid had been con

sumedbymostanaerobicmicrobesfortheirgrowth

and metabolism, and the shortchain fatty acids

producingmethane might be in short supply.

Meanwhile, with the rapid increase of concentra

tionoforganicmattersinzymoticfluid,unitbiogas

yield appeared plummet trend, which indicated

that methanogens activities had beeninhibitedob

viouslybyammonianitrogen.

0

100

200

300

400

500

40 20 10

Unit gas prod.

conv. rate

Concentration/gCODL

-1

U

n

i

t

b

i

o

g

a

s

y

i

e

l

d

/

m

L

g

C

O

D

-

1

5

0

10

20

30

40

50

60

70

80

M

e

t

h

a

n

e

c

o

n

v

e

r

s

i

o

n

r

a

t

e

/

%

FIG.4UNITBIOGASPRODUCTIONANDMETHANECONVERSIONOFSLUDGE

DEHYDRATEDWATER(SDW)

3) Comparative Analysis for Biochemical Methane

Potential

Several biogas yield results of anaerobic tests were

listed in Table 3 with similar points of anaerobic

materials, reaction temperature for methanogens,

biogas producing time, and pH range. Because of

the different pretreatment methods as well as spe

cific operating conditionsduring the experiment,it

turnedoutdifferentbiogasyieldandmethanecon

www.ijesci.org InternationalJournalofEnergyScience(IJES)Volume3Issue3,June2013

192

versionraterespectively.

Hu statedthat methane yield (average methane

content 69%) was 50mL/g VS for the mixture of

bluealgaeandanaerobicgranularsludge(ratio6:1).

Wang did research on sewage sludge anaerobic di

gestibility by means of thermal hydrolysis pre

treatment (170 and 30 minutes) and achieved

biogas production rate of 250mL/g COD. Rao

adopted three adding rate (5%, 7%, and 10%) in

turn during biogas production for 75 days, and

achieved the methane yield of 0.12~0.14m

3

CH4/kg

CODaftersteadyanaerobicoperation.Aboveall,it

hadanobviousadvantageofthesewagesludgefor

methane production after thermal hydrolysis pre

treatmentcomparedtoothermeans.

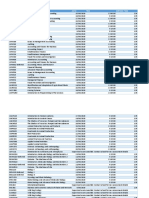

TABLE3CONTRASTOFBIOCHEMICALMETHANEPOTENTIALWITHSIMI

LARANAEROBICTESTS

Name Type

Time

/d

BiogasYield

/mLg

1

COD

Conv.

Rate/%

Hu batch 103.4 20.4

Wang batch 20 250 44.6

No.3

1)

batch 20 449.8 74.01

Rao semicont. 75 >260

2)

1)No.3:thesamplewiththeconcentrationof10COD/Linthispaper;

2)Biogasyieldwasthemeanvalueaftersteadyanaerobicoperation.

4)CODandpHofinletandoutlet

TheSDWchangesofCODandpHbeforeandafter

fermentation were shown inTable 4. With the in

crease of zymotic fluids concentration, COD de

gradation rate reduced gradually, and the pH after

fermentationbasedsteadilyinweakacidconditions.

It might because too high COD concentration had

significantly restrained the acidforming bacterium

activities, however, the neutral conditions were

suitable for methanogens growth. Thus, when syn

trophicacetogens converted volatile fatty acids

(VFAs, propionic acid, butyricacid,and pentatonic

acid)andethanoltoaceticacid,methanogenscould

convert them to methane. Moreover, due tothe pH

value after fermentation was higher than its origi

nal value, it indicated again the limitation of

theSDWfermentation, and more research would be

madeonhowtoimproveadaptabilityandactivities

ofacidformingbacteriumforhighconcentrationof

CODzymoticfluid.

TABLE4CONTRASTOFCODANDPHBEFOREANDAFTERMETHANEPRO

DUCTION

No

COD/gL

1

pH

Original Final Original Final

1 41.82 25.09 8.82 7.2

2 20.91 4.41 8.87 6.9

3 10.45 1.82 8.86 6.86

4 5.23 0.78 8.9 6.64

In view of unit biogas yield and methane conver

sion rate, No.3 sample had the optimal results for

449.8mL/gCOD. In consideration of cumulative

biogas production and daily biogas production,

No.2 sample had the optimal results for 9450mL

and the most times of peak values.It would be 1.5

timeswaterconsumptionadditionalfortheoriginal

zymotic fluid dilutedto No.3 than that to No.2.

However,inviewofwaterconsumption,operation

costs, and maximal methane production in engi

neeringprojects,theorganicloadingofNo.2sample

wasoptimumvalue.

FIG.5PROCESSFLOWDIAGRAMOFMETHANEPRODUCTIONFROMSLUDGE

InternationalJournalofEnergyScience(IJES)Volume3Issue3,June2013 www.ijesci.org

193

EngineeringofDesignandApplication

1)TechnologicalProcess

By the implementation of the laboratory experi

mentonmethaneproductionpotentialfromsludge

hydrothermaldryingabove,theoptimalconditions

were determined, and a technical route applied to

engineering project was developed. The technolo

gicalprocessofmethaneproductionfromSDWwas

shown in Fig.5, and aerobic processing unit was

connected subsequently todischarge after reaching

thestandards.

Hydrolytic acidification & EGSB treatment tech

nology wereadopted for the anaerobic process of

this project. SDW firstly passed through grid drain

in order to remove sundries, then entered into col

lector well. The effluent from collector well as well

as partial reflux sewage from aerobic pondflowed

into the preacidification tank (or regulation tank)

to make stable water quality and quantity, where

preacidification reaction occurred.The outlet flow

fromregulationtankwaspumpedintodistribution

reservoir, and heat was exchanged with hot steam,

the temperature of which then could rise to

35degree Celsius. The effluent from distribution

reservoirwaspumpedintoEGSBreactor,wherethe

organicmattersofSDWwereconvertedtomethane

with anaerobic microorganism (e.g. methanogens).

Then, the effluent passed through threephase se

parator, in which granular sludge was retained in

distribution reservoir and mingled with inflow to

pass through the EGSB reactor again. After anae

robicdigestion,outletgotintotheaerobictreatment

system subsequently. As well,the methane pro

duced from EGSB reactor could be applied to heat

recyclingafterrefining.

The Material and Energy Balance of Sludge Hydro

thermalDryingTreatmentSystem

In consideration of the unit of methane production

fromSDWasthepartialofthismodificationproject,it

was necessary to investigate the material and energy

balance inthe whole process, in order to reflect the

technical feasibility and advantages of Hydrothermal

Drying&RotaryKiln Incineration sludge treatment

method.Accordingtotheoptimalresults,theefficiency

of 10gCOD/L and 20gCOD/L sampleboth with 83.42

tons of SDW, if all the loading of COD was degraded,

were calculated to produce 210m

3

and 342m

3

methane,

respectively;separatelycorresponding to the heat from

110kgand239.5kgstandardcoal,whichcouldbeused

forrecycling

Concl usi ons

With the increase of zymotic fluid concentration, both

unit biogas yield and methane conversion rate pre

sentedatfirstincreasedandthendecreasedtrend,and

the maximum obtained from No.3 sample has oc

curred(unitbiogasyield:449.8mL/gCODandmethane

conversion rate: 74.1%).After biogas production,No.3

sample had the maximum of unit biogas yield

(449.8mL/gCOD)andmethaneconversionrate(74.1%),

both exceeding to those of No.2 sample

(381.8mL/gCODand62.84%).

It would be 1.5 times water consumption additionalto

theoriginalzymoticfluiddilutingtoNo.3thanthatto

No.2, however, in view of water consumption, opera

tion costs, and maximal methane production in engi

neering projects, the organic loading of No.2 sample

wasoptimumvalue.

Bycarryingoutthelaboratoryexperimentonmethane

productionpotentialfromsludgehydrothermaldrying,

methane production unit from SDWinengineering

processwasdesigned.Accordingtotheoptimalresults,

the efficiency of 10gCOD/L and 20gCOD/L sample

both with83.42 tons of SDW, if all the loading of COD

was degraded, were calculated to produce 210m

3

and

342m

3

methane, respectively;separatelycorresponding

to the heat from 110kg and 239.5kg standard coal,,

whichcouldbeusedforrecycling.

r ef er enc es

BrooksRB.Heattreatmentofsewagesludge[J].WaterPollu

tionControl,1970,69:9299.

DohanyosM,Zabranska J, Jenicek P, et al. The intensification

of sludge digestion by the disintegration of activated

sludgeandthethermalconditioningofdigestedsludge[J].

WaterScienceandTechnology,2000,42(9):5764.

Gong M L, Ren N Q, Xing D F, Startup of hydrogen

bioproduction reactor and ethanoltype fermentation[J].

ActaEnergiaeSolarisSinica,2005(02):244247.

HuP,YanQ,SongR,etal.Biogasproductionthroughanae

robic digestion from the mixture of blue algae and

sludge[J].ChineseJournalofEnvironmentalEngineering,

2009(3):559563.

HeSJ,WangJL,ZhaoX,Effectofammoniumconcentration

on the methanogenic activity of anaerobic granular

www.ijesci.org InternationalJournalofEnergyScience(IJES)Volume3Issue3,June2013

194

sludge[J]. Journal of Tsinghua University(Science and

Technology),2005(9):12941296.

JiangZL,MengDW,MuHY,etal.ExperimentalStudyon

Hydrothermal Drying for Sewage Sludge in LargeScale

Commercial Plan[J]. Journal of Environmental Science

andEngineering,2011,12(7):900910.

Jiang Z L, Meng D W, Mu H Y, et al. Study on the hydro

thermal drying technology of sewage sludge[J]. Science

ChinaTechnologicalSciences,2010,53(1):160163.

JomaaS,Shanableh A, Khali W, et al. Hydrothermal decom

position and oxidation of the organic component of mu

nicipalandindustrialwasteproducts[J].AdvancesinEn

vironmentalResearch,2003,7(3):647653.

Laurent J, Casellas M, Carrere H, et al. Effects of thermal

hydrolysis on activated sludge solubilization, surface

properties and heavy metals biosorption[J]. Chemical

EngineeringJournal,2011,166(3):841849.

Liu X Y, Xi D L, Sun Y S. Environmental Monitoring[M]. 3.

Beijing:HigherEducationPress,1987.

LiuXL,LiSZ,LiuJS,etal.Evaluationofhighsolidsanae

robic digestion process for converting excess sludge to

biogas[J]. Acta Scientiae Circumstantiae, 2011, (5):

955963.

MengDW,JiangZL,MuHY,etal.TheeffectofOperating

Parameters on the Hydrothermal Drying Treatment[J].

RenewableEnergy,2012,42:9094.

Neyens E, BaeyensJ. A review of thermal sludge

pretreatment processes to improve dewaterability[J].

JournalofHazardousMaterials,2003,98(13):5167.

PickworthB, Adams J, Panter K, et al. Maximising biogas in

anaerobic digestion by using engine waste heat for ther

mal hydrolysis pretreatment of sludge[J]. Water Science

andTechnology,2006,54(5):101108.

Rao B M.Effect ofAnaerobicDigestion on SludegDewatera

bility and Sludge Pretreatment Technologies[D]. Harbin

InstituteofTechnology,2008.

Ren N Q, Wang A J. Theory and application of anaerobic

biotechnology[M].Beijing:ChemicalIndustryPress,2004.

Vanvelsen A F M. Adaptation of methanogenic sludge to

high ammonianitrogen concentrations[J]. Water Re

search,1979,13(10):995999.

Wang Z J, Wang W, Xia Z, et al. Experimental study on

thermal hydrolysis and anaerobic digestion of sewage

sludge[J].ChinaWater&Wastewater,2003(09):14.

Wen Z,Shen S Z. Introducing a new technology for sludge

treatment[J].Environment,2007(12):7071.

WangZJ,WangW,ZhangXH,etal.Digestionofthermally

hydrolyzed sewage sludge by anaerobic sequencing

batch reactor[J]. Journal of Hazardous Materials,

2009,162(23):799803.

Wang Z J, Wang W. Enhancement of Sewage Sludge Anae

robic Digestibility by Thermal Hydrolysis

Pretreatment[J].EnvironmentalScience,2005(01):6871.

Yu F F, Wu J D. Toxicity Study of Ammonium on Methano

genic Bacteria in Anaerobic Granular Sludge[J]. Chemi

stry&Bioengineering,2008(4):7578.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Nervous System Assessment GuideDocument11 pagesNervous System Assessment Guideaderonke bello100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SCIENCE 10 3rd Quarterly Assessment QuestionnaireDocument5 pagesSCIENCE 10 3rd Quarterly Assessment QuestionnaireShanrey Mirones100% (1)

- Mill's Critique of Bentham's UtilitarianismDocument9 pagesMill's Critique of Bentham's UtilitarianismSEP-PublisherNo ratings yet

- Keller & Schoenfeld (1950) - Principles of PsychologyDocument456 pagesKeller & Schoenfeld (1950) - Principles of PsychologyPablo StuartNo ratings yet

- Gender and Human Evolution PDFDocument49 pagesGender and Human Evolution PDFSimio PensanteNo ratings yet

- Microb Monitor 2 Instructions UseDocument5 pagesMicrob Monitor 2 Instructions UseArluky NovandyNo ratings yet

- Contact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentDocument7 pagesContact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentSEP-PublisherNo ratings yet

- Improving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesDocument5 pagesImproving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesSEP-PublisherNo ratings yet

- Influence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearDocument13 pagesInfluence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearSEP-PublisherNo ratings yet

- Experimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesDocument8 pagesExperimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesSEP-PublisherNo ratings yet

- Device For Checking The Surface Finish of Substrates by Tribometry MethodDocument5 pagesDevice For Checking The Surface Finish of Substrates by Tribometry MethodSEP-PublisherNo ratings yet

- FWR008Document5 pagesFWR008sreejith2786No ratings yet

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocument5 pagesMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNo ratings yet

- Enhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentDocument6 pagesEnhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentSEP-PublisherNo ratings yet

- Effect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesDocument11 pagesEffect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesSEP-PublisherNo ratings yet

- Reaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesDocument9 pagesReaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesSEP-PublisherNo ratings yet

- Microstructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesDocument7 pagesMicrostructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesSEP-PublisherNo ratings yet

- Mindfulness and Happiness: The Empirical FoundationDocument7 pagesMindfulness and Happiness: The Empirical FoundationSEP-PublisherNo ratings yet

- Delightful: The Saturation Spirit Energy DistributionDocument4 pagesDelightful: The Saturation Spirit Energy DistributionSEP-PublisherNo ratings yet

- Enhanced Causation For DesignDocument14 pagesEnhanced Causation For DesignSEP-PublisherNo ratings yet

- Ontology-Based Testing System For Evaluation of Student's KnowledgeDocument8 pagesOntology-Based Testing System For Evaluation of Student's KnowledgeSEP-PublisherNo ratings yet

- Quantum Meditation: The Self-Spirit ProjectionDocument8 pagesQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNo ratings yet

- Isage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophyDocument8 pagesIsage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophySEP-PublisherNo ratings yet

- Cold Mind: The Released Suffering StabilityDocument3 pagesCold Mind: The Released Suffering StabilitySEP-PublisherNo ratings yet

- A Tentative Study On The View of Marxist Philosophy of Human NatureDocument4 pagesA Tentative Study On The View of Marxist Philosophy of Human NatureSEP-PublisherNo ratings yet

- Legal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialDocument4 pagesLegal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialSEP-PublisherNo ratings yet

- Social Conflicts in Virtual Reality of Computer GamesDocument5 pagesSocial Conflicts in Virtual Reality of Computer GamesSEP-PublisherNo ratings yet

- Technological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsDocument9 pagesTechnological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsSEP-PublisherNo ratings yet

- Architectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldDocument5 pagesArchitectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldSEP-PublisherNo ratings yet

- Metaphysics of AdvertisingDocument10 pagesMetaphysics of AdvertisingSEP-PublisherNo ratings yet

- Computational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpDocument6 pagesComputational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpSEP-PublisherNo ratings yet

- Damage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationDocument10 pagesDamage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationSEP-PublisherNo ratings yet

- The Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateDocument8 pagesThe Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateSEP-PublisherNo ratings yet

- Mutah UniversityDocument13 pagesMutah UniversityeyassadailehNo ratings yet

- Chemistry 3Document105 pagesChemistry 3patricia pomarNo ratings yet

- Dunhan R.A. Aquaculture and Fisheries BiotechnologyDocument385 pagesDunhan R.A. Aquaculture and Fisheries BiotechnologyAleksey DubinNo ratings yet

- Shellfish Morphology GuideDocument9 pagesShellfish Morphology GuideParimita SharmaNo ratings yet

- Concept Strengthening Sheet (CSS-01) Based On AIATS-01 RMDocument19 pagesConcept Strengthening Sheet (CSS-01) Based On AIATS-01 RMB54 Saanvi SinghNo ratings yet

- Lama 2 Gene Reviews Bookshelf - nbk97333Document25 pagesLama 2 Gene Reviews Bookshelf - nbk97333Didm S A MontNo ratings yet

- Pforams@Mikrotax - Globigerinoides ConglobatusDocument2 pagesPforams@Mikrotax - Globigerinoides ConglobatusAhmad Lumban GaolNo ratings yet

- Subtotal and Total Thyroidectomy: AuthorDocument10 pagesSubtotal and Total Thyroidectomy: AuthorAgustina TambingNo ratings yet

- Child Psychology Term Paper TopicsDocument8 pagesChild Psychology Term Paper Topicsetmqwvqif100% (1)

- Principles of Anatomy and Physiology: 14th EditionDocument47 pagesPrinciples of Anatomy and Physiology: 14th EditionDayledaniel SorvetoNo ratings yet

- Thermal Processing Food-Related Toxicants: A Review: Critical Reviews in Food Science and NutritionDocument19 pagesThermal Processing Food-Related Toxicants: A Review: Critical Reviews in Food Science and NutritionRIFQI FAYYADH ANSARNo ratings yet

- Test Bank For Friedland Relyea Environmental Science For APDocument13 pagesTest Bank For Friedland Relyea Environmental Science For APFrances WhiteNo ratings yet

- Manchester Ship Canal - Strategic Review of Fish PopulationsDocument139 pagesManchester Ship Canal - Strategic Review of Fish PopulationsSamyuktha PillaiNo ratings yet

- SMA GAMA YOGYAKARTA English PAT FormDocument12 pagesSMA GAMA YOGYAKARTA English PAT FormVivit Pramita100% (1)

- My Home To School RoadmapDocument22 pagesMy Home To School RoadmapDarlene Joyce ApolinarioNo ratings yet

- Blood Bank Data Collection FormDocument3 pagesBlood Bank Data Collection Formpbta punjab100% (1)

- Happ Chapter 8 TransesDocument13 pagesHapp Chapter 8 TransesFrencess Kaye SimonNo ratings yet

- Physical Agents Used in The Management of Chronic Pain by Physical TherapistsDocument31 pagesPhysical Agents Used in The Management of Chronic Pain by Physical TherapistsMárcia MatosNo ratings yet

- Trimester 1 2020 Exam TimetableDocument11 pagesTrimester 1 2020 Exam TimetableBagus ArdiansyahNo ratings yet

- Cbjescpl 02Document10 pagesCbjescpl 02Riya SharmaNo ratings yet

- Biology Lab Report 1 No NameDocument9 pagesBiology Lab Report 1 No NameEva93100% (1)

- PMS-poster 2 PDFDocument2 pagesPMS-poster 2 PDFKuNtii Devi VerdejofNo ratings yet

- Panniculitis ReviewDocument4 pagesPanniculitis ReviewLuluu CortésNo ratings yet

- Hospital Patient Data in HCU RoomDocument108 pagesHospital Patient Data in HCU RoomSri Ratna FitriadewiNo ratings yet

- Complete Blood Count and Biochemistry Panel ResultsDocument8 pagesComplete Blood Count and Biochemistry Panel Resultsgunjan pratapNo ratings yet