Professional Documents

Culture Documents

Jica m316d Rev

Uploaded by

agegnehutamiratCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jica m316d Rev

Uploaded by

agegnehutamiratCopyright:

Available Formats

COMPLIANCE TO THE TECHNICAL SPECIFICATION REQUIRMENT OF CATERPILLAR MODEL M316D WHEEL HYDRAULIC EXCAVATORS OFFERED TO JICA 1.

GENERAL REQUIRMENTS We offer two(2) Caterpillar model M316D wheel excavators which are diesel engine driven, turbocharged and equipped with fully enclosed cab, one piece boom, 2100mm stick, front blade, rear out rigger and 1.03m extreme excavation bucket. It has an operating weight of 17,750 kg. 2. WARRANTY We guarantee that all items, parts and components fitted on or furnished with the offered wheel excavators are brand new, of current model of the recent manufacture, of high quality and workmanship. They will also incorporate current Caterpillar improvements in design and materials. We also guarantee to replace free of charge components or parts that may break or fail to function under normal service conditions due to inferior or defective materials or poor workmanship within a period of 12 months from the date of delivery of the machine at final destination as per the attached standard Caterpillar warranty.

3. PRE-DELIVERY SERVICE We will provide pre-delivery service free of charge at our premises in Addis Ababa before delivery of the wheel excavators. This includes washing, greasing and lubrication to the companys satisfaction.

4. TRAINING We will provide familiarization training to your operators on the operation and use of the control panel and to your mechanics at our premises in Addis Ababa before delivery of the machines. The details of such training are attached herewith for further reference.

Page 1 of 7

5.

AFTER SALES SUPPORT Ries Engineering S.Co. (RESCO) has been the dealer in Ethiopia for Caterpillar products since its establishment in Addis Ababa in 1967 G.C. RESCO has well established facilities as well as qualified and experienced personnel that enable it provide full and dependable pre delivery and after sales support services to its esteemed customers. Its facilities for the purpose include among others: Spare parts warehouse where parts worth over Birr 60,000,000 are stocked for Caterpillar machines at any point in time and replenished regularly trough Caterpillar dealer network. Maintenance workshop with facilities essential for proper maintenance and overhaul of the offered machine Lubricant analysis (S.O.S) laboratory that enables identification of problems in the main components of machine before failure Vehicles with radio communication for field services Training center

We also have highly qualified, well trained technical personnel having long years of hands on experience on maintaining and servicing the offered machine. We provide maintenance service on site or at our central workshop as deemed necessary. Periodic preventive maintenance services can also be provided on contract basis. For further details please refer to our facilities Brochure, and supporting document enclosed herewith, which confirms same and will also assist you to compare our capabilities and facilities with those of others dealers and/or agents. You are also welcome to visit our facilities and to verify the facts on our product support capability for yourself. We would like also to bring to your attention that Ries Engineering S.Co. (RESCO) stocks different sized Cat XT hoses in bulk and has set up hose service facility and it provides hose assembly services to its customers for hoses up to 2 diameter. When customers have a hose failure problem it makes a new hose for them by re-fitting the reusable couplings from the old hose or new couplings. You are welcome to make use of this facility for any machine you have at any time. This facility is certified for supping contamination free dependable hoses.

Page 2 of 7

6.

MANUALS Two set of each of the following manuals will be supplied with the wheel excavators. Operation and maintenance manual Spare parts catalogue (electronic copy) Service manual (shop/repair manual)

7.

TOOLS We will supply Caterpillar standard took kit with the wheel excavators.

Page 3 of 7

Technical compliance for wheel excavator Manufacturer Model Technical Requirement 1. Bucket 1) Capacity : 0.8m3 (heaped) equal or over Manufacturer :Caterpillar Model :M316D Statement Compliance with Remark The offered Caterpillar model M316D Hydraulic wheel excavators are equipped with extreme excavation bucket with heaped capacity of 1.03m. The bucket is equipped with new Caterpillar K series tips with tapered type vertical retention system. Extreme service bucket is designed and manufactured from high strength and heat treated steel with electric arc welding at all seams. Horizontal bottom wear plates reinforce bucket for greater strength and rigidity. The bucket is equipped with extra duty tips. The offered Caterpillar model M316D wheeled type hydraulic excavators have an operating weight of 17,750 kg. The offered Caterpillar model M316D wheel type hydraulic excavators are powered by Cat C6.6 engine with ACERT Technology, water cooled, diesel and turbocharged. The engine Cat C6.6 with ACERT technology delivers 118kw/160HP Net fly wheel power at 1800 RPM under ISO 9249 standard conditions. Displacement 6600 cc. The standard cooling system is tropicalized, Page 4 of 7

2) Type: tapered lock type

3) Body, tooth : heavy duty

2. Operation Weight : 17,500kg equal or over

3. Engine 1) Type: water cooled diesel, turbo charged

2) Output : 100kW equal or over

3) Displacement: 5,000cc equal or over. 4) Cooling system: standard

closed, pressurized and pump forced type. The cooling system has an efficient tropicalized thermostat. 5) Electric system: standard The standard electrical system of the offered Caterpillar model M316D Hydraulic wheel excavators are 24V direct electric starting type and composed of charging alternator, batteries, lights and protection devise. The batteries are 2 X 12V Caterpillar high outputs, heavy duties, maintenance free batteries. Each battery has 710 Cold Cranking amps (CCA) and 100 AH capacity at 20 hrs rating. 4. Hydraulic Unit 1) Pump flow : 260l/min equal or over

The load-sensing hydraulic system combined with a separate dedicated swing pump provides fast cycle times, increased lift capacity and high bucket and stick forces. A dedicated variable displacement piston pump and fixed displacement piston motor power the swing mechanism. The max pump flow is as follows:Implement/travel circuit - 250 lit/min Swing mechanism 80 lit/min

5. Tire : manufacturers standard

The offered Caterpillar model M316D wheel excavators are equipped with standard dual pneumatic type tires, 10.00 x 20, MITAS tubeless at front and rear with spacer rings in between the tires.

6. Dimensions 1) Overall length : 9,500mm equal or less 2) Overall width : 2,600mm equal or less 7. Performance 1) Bucket curling (digging) force : 100Kn equal or Page 5 of 7

1) Shipping length=8,390 mm. 2) Overall width=2550 mm. 1) Bucket digging force =101 KN

over 2) Arm (stick) crowd force :75Kn equal or over

2) Stick force = 81 KN

8. Cabin : steel cabin (with air conditioner)

The offered caterpillar model M316D

wheel

excavators have a roomy, quite( sound proof), shock proof, fully enclosed steel cab with safety glasses, front wipers, windows, lockable service doors and side mounted rear mirrors. It is also equipped air conditioned cab with automatic climate control that adjusts the temperature and air flow for exceptional operator comfort.

The offered wheel excavators are equipped 9. Chassis Accessories with heavy duty and ruggedly constructed with precision robotic welding undercarriages with pin on/ bolt on design to ensure quality, increase rigidity, enhanced durability and long life. They are equipped with independently controlled 1) Dozer blade (front) : equipped 1) Blade at front to level the machine on slopes. 2) Outriggers at the rear. Hydraulic system is equipped with lines for hydraulic breaker. Equipped with Beacon, Rotating, Removable Multipurpose proper size fire extinguisher will be supplied for each machine.

2) Stabilizer (rear) : equipped 10. Hydraulic Port for breaker : 1 set

11.Flasher or revolving Light : 1 set 12. Accessories : multipurpose, proper size fire extinguisher Spare Parts To supply spare parts more than 5% of FOB price of the equipment, and to be selected by following

Itemized and priced list of spare parts as per the tender requirement is attached herewith for your reference and decision.

Page 6 of 7

conditions. Parts for periodic inspection for 4,000h working hour or 3 years of standard use. Examples a) All hydraulic ram packing seals and gaskets for (sets of lift cylinder, stick cylinder, bucket cylinder etc) b) All engine oil filter elements c) All fuel filter elements d) Air cleaner elements e) Hydraulic hoses f) All transmission filters (if it is not integrated with the hydraulic system) g) All hydraulic filter elements h) All electric lamps/bulbs and fuses i) Water separator (if it is separately fitted and serviced) j) All belts employed k) Sets of shovel teeth with necessary fittings l) Etc.

Expendable parts (shall be estimated beside spare parts separately) Backet tooth set (for 1 backet) X 2 sets/unit and backet (with tooth) X 1 set/unit should be included

Page 7 of 7

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- Cat Ad22 Dump TruckDocument24 pagesCat Ad22 Dump TruckGeorge AdamsNo ratings yet

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (5)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- Cat Marine Engine Selection GuideDocument98 pagesCat Marine Engine Selection GuideOzaveshe Joseph100% (4)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- 1.2 Service RequirementDocument15 pages1.2 Service RequirementagegnehutamiratNo ratings yet

- 1.2 Service RequirementDocument15 pages1.2 Service RequirementagegnehutamiratNo ratings yet

- s650 Parts ManualDocument582 pagess650 Parts ManualEuropea Recambios ()No ratings yet

- CAT Front Shovel 385CDocument16 pagesCAT Front Shovel 385CCraciun AndreiNo ratings yet

- C13 C15Document33 pagesC13 C15DDemin12345100% (2)

- Fs 6030Document36 pagesFs 6030Victor Raul Osnayo Mamani100% (1)

- Comparacion 797B 797FDocument20 pagesComparacion 797B 797FpsalaspaNo ratings yet

- CAT 950H Wheel LoaderDocument28 pagesCAT 950H Wheel Loaderojhawk1380% (5)

- A64 HD Pallet Handler Datasheet PDFDocument8 pagesA64 HD Pallet Handler Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- CAT - Wheel Loader 962HDocument32 pagesCAT - Wheel Loader 962HHenDrix ODeNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Brochure Slip-Ring MotorsDocument8 pagesBrochure Slip-Ring MotorsidontlikeebooksNo ratings yet

- 315D CatDocument20 pages315D CatFernando Omar Arena100% (1)

- Mag Drive PumpsDocument5 pagesMag Drive PumpsakkineniNo ratings yet

- Cat Dragline Product LineDocument8 pagesCat Dragline Product LineCorey HeffernanNo ratings yet

- D7GIIDocument16 pagesD7GIIlulu3232No ratings yet

- Atlas Copco Utilitary Vehicles - FamilyBrochure - ENGDocument12 pagesAtlas Copco Utilitary Vehicles - FamilyBrochure - ENGmasterandreis100% (2)

- BHEL - Agitator Specification PDFDocument68 pagesBHEL - Agitator Specification PDFRiyaz100% (1)

- Cat 320d LRRDocument28 pagesCat 320d LRRt1meNo ratings yet

- 950g Vs Volvo - Komatsu Wa380Document14 pages950g Vs Volvo - Komatsu Wa380Mohamed BakheetNo ratings yet

- Jica d8r RevDocument6 pagesJica d8r RevagegnehutamiratNo ratings yet

- D8R ComplianceDocument17 pagesD8R ComplianceagegnehutamiratNo ratings yet

- 1.1 ScopeDocument13 pages1.1 ScopeagegnehutamiratNo ratings yet

- Retroexcavadora Cat 385CDocument24 pagesRetroexcavadora Cat 385CMax Tapia Castillo100% (1)

- Technical Specification For The Purchase of 1 Unit of 240HP Crawler TractorDocument14 pagesTechnical Specification For The Purchase of 1 Unit of 240HP Crawler TractoragegnehutamiratNo ratings yet

- Loader SpecificationsDocument5 pagesLoader SpecificationsMacline IndiaNo ratings yet

- Gambella RRA D8R TTT Technical ComplianceDocument16 pagesGambella RRA D8R TTT Technical ComplianceagegnehutamiratNo ratings yet

- C 10033674Document16 pagesC 10033674Aquilino Torres Arancibia100% (1)

- ESP Canadian AdvancedDocument12 pagesESP Canadian Advancedcamillo010No ratings yet

- 938HDocument24 pages938HJusto César Ruidias Juárez100% (1)

- 938HDocument24 pages938HJaime Cruz Luque100% (1)

- 902, 906 & 908 Compact Wheel LoaderDocument12 pages902, 906 & 908 Compact Wheel LoaderPaul Sakry0% (1)

- XHD Skid Mounted CTUDocument31 pagesXHD Skid Mounted CTUYuri BadretdinovNo ratings yet

- Cargador Frontal 15yd3 PDFDocument24 pagesCargador Frontal 15yd3 PDFOscar TrigoNo ratings yet

- 902Document12 pages902Victor M. Mejia DiazNo ratings yet

- 311D LRR SRR EccvatiorDocument24 pages311D LRR SRR EccvatiorVinod YbNo ratings yet

- Ac Predator Brochure LoresDocument4 pagesAc Predator Brochure LoresAnonymous kjJfuvMMNo ratings yet

- Viking: Product ManualDocument26 pagesViking: Product ManualMailson Apaza KatataNo ratings yet

- Comparacion Motores CAT C13 y C15Document2 pagesComparacion Motores CAT C13 y C15Ronald ChangNo ratings yet

- Boletín 2004 de Especificaciones Serie C-Max McCormickDocument15 pagesBoletín 2004 de Especificaciones Serie C-Max McCormickJosé Inés Bazán MotaNo ratings yet

- Beml Report PDFDocument32 pagesBeml Report PDFCrazy TamizhaNo ratings yet

- Internship Report On BemlDocument29 pagesInternship Report On BemlYasewn KALAWANTNo ratings yet

- Mantis 20010Document16 pagesMantis 20010thauwui86No ratings yet

- 500 A 2500 KVA 1Document27 pages500 A 2500 KVA 107939312No ratings yet

- Track Feller Bunchers & Track Harvesters - ZTS (Zero Tail Swing)Document20 pagesTrack Feller Bunchers & Track Harvesters - ZTS (Zero Tail Swing)Akhmad SebehNo ratings yet

- Cable Reeling DrumDocument4 pagesCable Reeling DrumBanamali NaskarNo ratings yet

- 5130b PDFDocument20 pages5130b PDFAlexander Barrios OchoaNo ratings yet

- 1100 Series - M250C & M300CDocument2 pages1100 Series - M250C & M300Cprasadcshetty0% (1)

- Specifications and TenderinvitationDocument27 pagesSpecifications and TenderinvitationAbhiram ReddyNo ratings yet

- Ex2500-5Document5 pagesEx2500-5ntahNo ratings yet

- Large Wheel Loader Millyard Arrangements: Engine - 988H Engine - 990HDocument16 pagesLarge Wheel Loader Millyard Arrangements: Engine - 988H Engine - 990HLin CarlosNo ratings yet

- Why Universal Motors Turn On The Appliance IndustryDocument4 pagesWhy Universal Motors Turn On The Appliance IndustrymcelebimNo ratings yet

- Lab ReportDocument4 pagesLab ReportagegnehutamiratNo ratings yet

- Line IntegralDocument1 pageLine IntegralagegnehutamiratNo ratings yet

- Research Proposal: Table of ContentDocument2 pagesResearch Proposal: Table of ContentagegnehutamiratNo ratings yet

- Differential EquationDocument1 pageDifferential EquationagegnehutamiratNo ratings yet

- Integral Application: Representative RectanglesDocument1 pageIntegral Application: Representative RectanglesagegnehutamiratNo ratings yet

- F (T) 2 + 3t F (T) at F (T) Sin 2t Variable, For Short, Scalar Functions. Functions Such AsDocument1 pageF (T) 2 + 3t F (T) at F (T) Sin 2t Variable, For Short, Scalar Functions. Functions Such AsagegnehutamiratNo ratings yet

- Z-Axis Using The Same Scale As Used On The X-And Y-Axes, Assigning The Z-Coordinate 0Document1 pageZ-Axis Using The Same Scale As Used On The X-And Y-Axes, Assigning The Z-Coordinate 0agegnehutamiratNo ratings yet

- What Is Calculus?: y MX +B y F (X)Document1 pageWhat Is Calculus?: y MX +B y F (X)agegnehutamiratNo ratings yet

- One-To-One Functions Inverses: X 3x F (X) + (9xDocument1 pageOne-To-One Functions Inverses: X 3x F (X) + (9xagegnehutamiratNo ratings yet

- The Limit Process (An Intuitive Introduction) : Calculus Is A Limit in One Sense or Another. For ExampleDocument1 pageThe Limit Process (An Intuitive Introduction) : Calculus Is A Limit in One Sense or Another. For ExampleagegnehutamiratNo ratings yet

- Gambella RRA D8R TTT Technical ComplianceDocument16 pagesGambella RRA D8R TTT Technical ComplianceagegnehutamiratNo ratings yet

- SequenceDocument1 pageSequenceagegnehutamiratNo ratings yet

- Machine Type Model Tire Size Tire & Rim Ass0C. CodeDocument3 pagesMachine Type Model Tire Size Tire & Rim Ass0C. CodeagegnehutamiratNo ratings yet

- TH 514 FinalDocument24 pagesTH 514 FinalagegnehutamiratNo ratings yet

- Track-Type Tractors: Engine WeightsDocument20 pagesTrack-Type Tractors: Engine WeightsagegnehutamiratNo ratings yet

- MicroinverterDocument4 pagesMicroinvertersukirajNo ratings yet

- Cross-Curricular Focus: Life Science: NameDocument2 pagesCross-Curricular Focus: Life Science: NameAndreea Dragomir67% (3)

- CREW Radon 1 ReportDocument26 pagesCREW Radon 1 ReportDragos MihaiNo ratings yet

- Bruce E. Depalma: N-Machine: Extraction of Electrical Energy Directly From Space: The N-MachineDocument7 pagesBruce E. Depalma: N-Machine: Extraction of Electrical Energy Directly From Space: The N-MachinebanzailoicNo ratings yet

- MA 40 - Premium Quality Stationary Gas Engine OilDocument2 pagesMA 40 - Premium Quality Stationary Gas Engine OilRaden ArdyNo ratings yet

- PV Cell CharaDocument40 pagesPV Cell CharaBlessy JoyNo ratings yet

- World Lecture Hall: Useful Links For EngineersDocument9 pagesWorld Lecture Hall: Useful Links For Engineerssandi1111No ratings yet

- SPCSP CatalogDocument24 pagesSPCSP Catalogleojay24No ratings yet

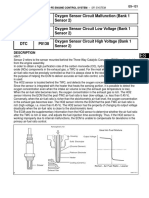

- HO2 Sensor InfoDocument24 pagesHO2 Sensor InfoÇağrı SivrikayaNo ratings yet

- TransmutationDocument7 pagesTransmutationIvan Dwi SandraNo ratings yet

- What Is A Gripper? Why Use One?: GrippersDocument4 pagesWhat Is A Gripper? Why Use One?: Gripperssagarsinghal26No ratings yet

- PM OverviewDocument25 pagesPM Overviewmohitamitabh20No ratings yet

- Aula Balancim DifusaoDocument29 pagesAula Balancim DifusaoGabrielAntoniazziNo ratings yet

- Manual Gefran 600-1Document4 pagesManual Gefran 600-1Eder AlexandreNo ratings yet

- ICE 160 230 0296 HammerDocument119 pagesICE 160 230 0296 HammerRıfat BingülNo ratings yet

- STP75NF75 ST MicroelectronicsDocument16 pagesSTP75NF75 ST MicroelectronicsAloisio RibeiroNo ratings yet

- Steam EngineDocument34 pagesSteam EnginematrixmanxflushNo ratings yet

- Manual Grindex - Bravo400.Document26 pagesManual Grindex - Bravo400.Roque LlamoccaNo ratings yet

- Cho Loss Model Radial TurbineDocument13 pagesCho Loss Model Radial TurbineNicolasNo ratings yet

- mayada5977 مهمDocument7 pagesmayada5977 مهمAmmar Al-KindyNo ratings yet

- NR-210803-Material and Energy BalanceDocument8 pagesNR-210803-Material and Energy BalanceSrinivasa Rao G100% (1)

- Introduction To Capillary PressureDocument15 pagesIntroduction To Capillary PressureMuhammad MirNo ratings yet

- SYLLABUS For CLASS-X (2018-19) English: 1.tenseDocument12 pagesSYLLABUS For CLASS-X (2018-19) English: 1.tenseShadan NawazNo ratings yet

- Company Profile - Grrsb-SmallDocument2 pagesCompany Profile - Grrsb-Smallmsis81No ratings yet

- Effects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamDocument11 pagesEffects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamPiterNo ratings yet

- 2002 Physics NQE QuestionsDocument7 pages2002 Physics NQE QuestionskarxriNo ratings yet

- TEC2647Z-2+PIR San BernardoDocument9 pagesTEC2647Z-2+PIR San BernardodinkoheNo ratings yet