Professional Documents

Culture Documents

TFP1305 07 2005

Uploaded by

mohammadazraiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TFP1305 07 2005

Uploaded by

mohammadazraiCopyright:

Available Formats

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

Model DV-5 Deluge Valve, Diaphragm Style, 1-1/2 thru 8 Inch (DN40 thru DN200), 250 psi (17,2 bar) Vertical or Horizontal Installation General Description

The 1-1/2 thru 8 inch (DN40 thru DN200), Model DV-5 Deluge Valves are diaphragm type valves designed for vertical or horizontal installation and for fire protection system service. They are used as automatic water control valves in deluge, preaction, and special types of fire protection systems such as foam-water and double interlock systems. When properly trimmed, the DV-5 Valves are also able to provide actuation of fire alarms upon system operation. The diaphragm style design of the DV-5 Valve allows external resetting providing for easy resetting of a deluge or preaction system without having to open a valve handhole cover to manually reposition a clapper and/or latch mechanism. Simply repressurizing the diaphragm chamber resets the valve. The one-piece, diaphragm style design of the DV-5 also allows internal and external coating of the valve to provide corrosion resistance. The internal corrosion resistance offered by the Rilsan coating makes the DV-5 suitable for most seawater and brackish water supplies when utilized in deluge systems. The external corrosion resistance of the Rilsan coating permits the use of the DV-5 in corrosive atmospheres associated with many types of industrial processing plants and outdoor installations.

End Connections Available and Weights

End Connection Inlet Thread Groove Flange Flange Outlet Thread Groove * Groove * Flange 1-1/2 Inch (DN40) 9 lbs. (4,1 Kg) 8 lbs. (3,6 Kg) N/A N/A 2 Inch (DN50) 12 lbs. (5,4 Kg) 10 lbs. (4,5 Kg) N/A N/A Nominal Valve Size 3 Inch (DN80) N/A 31 lbs. (14,1 Kg) 39 lbs. (17,7 Kg) 47 lbs. (21,3 Kg) 4 Inch (DN100) N/A 61 lbs. (27,7 Kg) 74 lbs. (33,6 Kg) 80 lbs. (36,3 Kg) 6 Inch (DN150) N/A 99 lbs. (44,9 Kg) 107 lbs. (48,5 Kg) 115 lbs. (52,3 Kg) 8 Inch (DN200) N/A 150 lbs. (68,1 Kg) 170 lbs. (77,8 Kg) 190 lbs. (87,5 Kg)

WARNING The Model DV-5 Deluge Valves described herein must be installed and maintained in compliance with this document, as well as with the applicable standards of the National Fire Protection Association, in addition to the standards of any other authorities having jurisdiction. Failure to do so may impair the performance of these devices.

* The Grooved Outlet is recommended for use in Preaction Systems to accommodate the

use of a Groove x Groove Riser Check Valve. Refer to Technical Data Sheet TFP1410, TFP1415, TFP1420, TFP1460, or TFP1465 as applicable.

The owner is responsible for maintaining their fire protection system and devices in proper operating condition.

The installing contractor or manufacturer should be contacted with any questions.

Page 1 of 8

JULY, 2005

TFP1305

Page 2 of 8

TFP1305

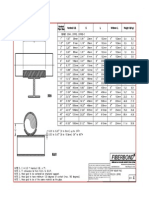

VALVE PARTS NO. DESCRIPTION 1 2 3 4 QTY. Refer to Kit NR (b) (a) (a) (a) (a) (a) (b) (a) (a) (a) (a) (a) (a) (a)

REPLACEMENT PARTS NO. DESCRIPTION (a) P/N

Valve Body . . . . . . . . . . . 1 Diaphragm . . . . . . . . . . . 1 Handhole Cover . . . . . . . 1 Flat Washer, 1-1/2 Inch Valve, M12 . . . 4 2 & 3 Inch Valves, M16 . . 4 4 & 6 Inch Valves, M16 . . 8 8 Inch Valves, M20 . . . . . 8 Hex Bolt, 1-1/2 Inch Valve, M12 x 30 . . . . . . . . . . . . . 4 2 & 3 Inch Valves, M16 x 50 . . . . . . . . . . . . . 4 4 Inch Valve, M16 x 50 . . 6 6 Inch Valve, M16 x 55 . . 6 8 Inch Valve, M20 x 70 . . 6 Hex Nut, 4 & 6 Inch Valves, M16 . . 2 8 Inch Valves, M20 . . . . . 2

Handhole Cover Parts Kit, Includes Items 3-5 1-1/2 Inch Valve . . . . . . . . . . . 92-477-1-106 2 Inch Valve . . . . . . . . . . . . . . 92-477-1-108 3 Inch Valve . . . . . . . . . . . . . . 92-477-1-110 Includes Items 3-6 4 Inch Valve . . . . . . . . . . . . . . 92-477-1-102 6 Inch Valve . . . . . . . . . . . . . . 92-477-1-104 8 Inch Valve . . . . . . . . . . . . . . 92-477-1-112 Diaphragm Kit, Includes Item 2 1-1/2 Inch Valve . . . . . . . . . . . 92-477-1-105 2 Inch Valve . . . . . . . . . . . . . . 92-477-1-107 3 Inch Valve . . . . . . . . . . . . . . 92-477-1-109 4 Inch Valve . . . . . . . . . . . . . . 92-477-1-101 6 Inch Valve . . . . . . . . . . . . . . 92-477-1-103 8 Inch Valve . . . . . . . . . . . . . . 92-477-1-111

DIAPHRAGM TAB ORIENTED PERPENDICULAR TO VALVE BODY

1 STUDS, SEE NOTE 2

NOTES: 1. NR - Not Replaceable. 2. 4, 6, & 8 Inch Valve Bodies are equipped with studs as shown, allowing Diaphragm and Handhole Cover to be "hung" in place to ease assembly. Bodies of 1-1/2, 2, and 3 Inch Valves are not equipped with studs.

6 (4, 6, & 8 INCH VALVES ONLY)

4 5 3

DIAPHRAGM ORIENTATION TAB

FIGURE 1 1-1/2 thru 8 INCH (DN40 thru DN200) MODEL DV-5 DELUGE VALVE ASSEMBLY

Nominal Valve Size 1

3 Inch (DN80) 4 Inch (DN100) 6 Inch (DN150) 8 Inch (DN200)

1 2 3 4

ANSI B16.1 (Class 125) 2 Dim. Dim. A B 6.00 0.75 (152,4) (19,0) 7.50 0.75 (190,5) (19,0) 9.50 0.88 (241,3) (22,2) 11.75 0.88 (298,5) (22,2)

Flange Drilling Specification Nominal Dimensions in Inches and (mm) ISO 7005-2 JIS B 2210 ISO 7005-2 (PN10) 3 (10K) (PN16) 4 Qty. Dim. Dim. Qty. Dim. Dim. Qty. Dim. Dim. A B N A B N A B N 0.75 6.30 8 4 N/A (19,0) (160,0) USE 7.09 0.75 6.89 0.60 8 8 ISO 2084 (180,0) (19,0) (175,0) (15,0) (PN16) 0.91 0.75 9.45 9.45 8 8 (23,0) (19,0) (240,0) (240,0) 0.91 11.61 0.91 11.61 12 N/A 8 8 (23,0) (295,0) (23,0) (295,0)

Qty. N

AS 2129 (Table E) Dim. Dim. A B N/A

Qty. N

8 8

7.00 (178,0) 9.25 (235,0) 11.50 (292,0)

0.71 (18,0) 0.87 (22,0) 0.87 (22,0)

8 8 8

Flange end 1-1/2 & 2 Inch (DN40 & DN50) DV-5 Valves are not offered. Same drilling as for B16.5 (Class 150) and B16.42 (Class 250). Same drilling as for BS 4504 Section 3.2 (PN10) and DIN 2532 (PN10). Same drilling as for BS 4504 Section 3.2 (PN16) and DIN 2532 (PN16).

Dim. A Bolt Circle Diameter Dim. B Bolt Hole Diameter Qty. N Number of Bolt Holes

TABLE A DIMENSIONAL SPECIFICATIONS FOR SELECTION OF FLANGE DRILLING

TFP1305

Page 3 of 8

Port Description Diaphragm Chamber Supply Water Supply Pressure & Alarm Test Alarm Actuation & System Drain Main Drain Diaphragm Chamber Supply Automatic Shut-Off Valve Actuation * Valves are available with ports threaded per ISO 7/1. SYSTEM OPEN TO ATMOSPHERE

Port 1-1/2 Inch (DN40) 1/2" P1 1/2" P2 3/4" P3 3/4" P4 1/2" P5

Port Sizes in NPT per ANSI B1.20.1 * 2 Inch 3 Inch 4 Inch 6 Inch (DN50) (DN80) (DN100) (DN150) 1/2" 1/2" 1/2" 1/2" 1/2" 1/2" 1/2" 1/2" 3/4" 3/4" 1" 1" 3/4" 1-1/4" 2" 2" 1/2" 1/2" 1/2" 1/2"

8 Inch (DN200) 1/2" 1/2" 1" 2" 1/2"

WATERFLOW TO SYSTEM DIAPHRAGM CHAMBER

P3

ALARM PORT OPEN TO ATMOSPHERE

P5

WATERFLOW TO AUTOMATIC SHUT-OFF VALVE

ALARM PORT WATERFLOW TO ALARM

VALVE WATERWAY DIAPHRAGM SEAT

VALVE WATERWAY

DIAPHRAGM CHAMBER OPEN TO ATMOSPHERE

P1 P2

WATER SUPPLY PRESSURE & ALARM TEST PORT DIAPHRAGM CHAMBER SUPPLY PORT 250 PSI MAX. WATER SUPPLY WATERFLOW FROM WATER SUPPLY

DIAPHRAGM RETRACTS OPENING VALVE WATERWAY

FIGURE 2A

SET POSITION DRAIN FROM SYSTEM

FIGURE 2B

OPERATED POSITION RESIDUAL DRAIN FROM SYSTEM

P3

SYSTEM DRAIN PORT SYSTEM DRAIN DIAPHRAGM CHAMBER OPEN TO ATMOSPHERE

DIAPHRAGM AUTOMATICALLY FLEXES TO ITS SEATED POSTION

VALVE WATERWAY

P4

MAIN DRAIN PORT WATER SUPPLY SHUT OFF WATER SUPPLY SHUT OFF

FIGURE 2C

SYSTEM DRAIN POSITION

FIGURE 2D

RESIDUAL DRAIN POSITION

FIGURE 2 1-1/2 thru 8 INCH (DN40 thru DN200) MODEL DV-5 DELUGE VALVE SET AND OPEN POSITIONS

Page 4 of 8

TFP1305

8" (204,0 mm)

Technical Data

Approvals: UL Listed, C-UL Listed, and FM Approved, when trimmed per the following Technical Data Sheets: Deluge Systems: TFP1310 - Wet Pilot Actuation TFP1315 - Dry Pilot Actuation TFP1320 - Electric Actuation Single Interlock Preaction Systems: TFP1410 - Wet Pilot Actuation* TFP1415 - Dry Pilot Actuation* TFP1420 - Electric Actuation *UL and C-UL only. Double Interlock Preaction Systems: TFP1460 - Electric/Pneumatic TFP1465 - Electric/Electric Deluge Valve: Components for the 1-1/2 thru 8 inch (DN40 thru DN200), Model DV-5 Deluge Valves are shown in Figure 1. The DV-5 Valves are for vertical or horizontal installations, and they are rated for use at a maximum service pressure of 250 psi (17,2 bar). The take-out dimensions are shown in Figure 3, and the flanged connections are available drilled per ANSI, ISO, AS, and JIS specifications (Ref. Table A). Threaded port connections of the DV-5 Valves are available NPT threaded or threaded per ISO 7/1 as detailed in the Ordering Procedure section. Valves with NPT threaded ports will readily accept the trim arrangements detailed in Technical Data Sheets referenced under Approvals. Patents: U.S.A. : 6,095,484

Materials Of Construction

NOTES The Rilsan coating for the DV-5 Valve provides corrosion resistance and is intended to extend the life of the DV-5 Valve when exposed to internal and external corrosive conditions. Although the Rilsan coating is intended to resist corrosion, it is recommended that the end user or other technical expert familiar with conditions at the proposed installation be consulted with respect to the suitability of this coating for a given corrosive condition. Deluge systems using a seawater or brackish water supply require special considerations in order to extend the life of the valve and trim. This type of system ideally should be configured with a primary source of clean fresh water (e.g., a pressurized water tank) and only upon system operation is the secondary water supply (seawater or brackish water) allowed to enter the system. After the system operation, the system should then be thoroughly flushed with clean fresh water. Following this recommendation will increase the service life of the DV-5 Valve and Valve Trim.

Body. Rilsan* coated ductile iron per ASTM A536-77, Grade 65-45-12. Handhole Cover. Rilsan* coated ductile iron per ASTM A536-77, Grade 65-45-12. Diaphragm. Nylon fabric reinforced, natural rubber per ASTM D2000. V-Ring. Natural rubber per ASTM D2000. Diaphragm Cover Fasteners. Galvanized carbon steel. *Rilsan is a registered trademark of ATOFINA Chemicals, Inc. (The Rilsan coating is a polyamide (Nylon 11) coating.)

1-1/2 Inch (DN40)

Groove x Groove & Thread x Thread

8-5/8" (220,0 mm)

2 Inch (DN50)

Groove x Groove & Thread x Thread

12-3/4" (324,0 mm)

3 Inch (DN80)

Groove x Groove, Flange x Flange, & Flange x Groove

15-3/4" (400,0 mm)

4 Inch (DN100)

Groove x Groove, Flange x Flange, & Flange x Groove

18-1/8" (460,0 mm)

6 Inch (DN150)

Groove x Groove, Flange x Flange, & Flange x Groove

22-1/2" (570,0 mm)

8 Inch (DN200)

Groove x Groove, Flange x Flange, & Flange x Groove

FIGURE 3 MODEL DV-5 DELUGE VALVE TAKE-OUT DIMENSIONS (Applies to all available end configurations)

TFP1305

Page 5 of 8

FLOW RATE IN LITRES PER MINUTE (LPM) (1 GPM = 3,785 LPM) 200 9.0 8.0 7.0 400 600 1000 2000 3000 5000 7000 10000 15000 0,600 0,500 0,400

NOMINAL PRESSURE DROP IN POUNDS PER SQUARE INCH (PSI)

6.0

DN

5.0 4.0 3.0

40)

H(

/2 I

(DN

NC

50)

0,300

2 IN

0,200

3 IN

2.0

6 IN

CH

(DN

0,100 0,090 0,080 0,070 0,060 0,050 0,040 0,030

1.0 0.9 0.8 0.7 0.6 0.5 0.4 0.3 50 100 200 400 600

0,022 1000 2000 3000 4000

FLOW RATE IN GALLONS PER MINUTE (GPM)

The approximate friction loss, based on the Hazen and Williams formula and expressed in equivalent length of pipe with C=120, is as follows: 9 feet of 1-1/2 Sch. 40 pipe for the 1-1/2 inch DV-5 Valve calculated on a typical flow rate of 100 GPM. 16 feet of 2 inch Sch. 40 pipe for the 2 inch DV-5 Valve calculated on a typical flow rate of 175 GPM. 20 feet of 3 inch Sch. 40 pipe for the 3 inch DV-5 Valve calculated on a typical flow rate of 350 GPM. 29 feet of 4 inch Sch. 40 pipe for the 4 inch DV-5 Valve calculated on a typical flow rate of 600 GPM. 46 feet of 6 inch Sch. 40 pipe for the 6 inch DV-5 Valve calculated on a typical flow rate of 1500 GPM. 72 feet of 8 inch Sch. 30 pipe for the 6 inch DV-5 Valve calculated on a typical flow rate of 2500 GPM.

GRAPH A 1-1/2 thru 8 INCH (DN40 thru DN200) MODEL DV-5 DELUGE VALVE NOMINAL PRESSURE LOSS VERSUS FLOW

Operating Principles

The Model DV-5 Deluge Valve is a diaphragm style valve that depends upon water pressure in the Diaphragm Chamber (Ref. Figure 2A) to hold the Diaphragm closed against the water supply pressure. When the DV-5 Valve is set for service, the Diaphragm Chamber is pressurized through the trim connections from the inlet side of the systems main control valve. Open-

ing an actuation device, for example the solenoid valve in the Electric Actuation Trim (Ref. Technical Data Sheet TFP1320), releases water from the Diaphragm Chamber faster than it can be replenished through an 1/8 inch (3,2 mm) restriction provided by the diaphragm chamber supply connection provided in the applicable trim arrangements. This results in a rapid pressure drop in the Diaphragm Chamber and the force differential applied through the Diaphragm to hold the Diaphragm in the set position is

reduced below the valve trip point. The water supply pressure then forces the Diaphragm open permitting water to flow into the system piping, as well as through the Alarm Port to actuate the system alarms (Ref. Figure 2B).

NOMINAL PRESSURE DROP IN BAR (1 PSI = 0,06895 BAR)

1- 1

CH

(DN

80)

CH

CH

(DN

100

4 IN

(DN

150

CH

8 IN

200

Page 6 of 8

TFP1305

Installation

NOTES Proper operation of the Model DV-5 Deluge Valves depends upon their trim being installed in accordance with the instructions given in their respective Technical Data Sheet. Failure to follow the appropriate trim diagram may prevent the DV-5 Valve from functioning properly, as well as void listings, approvals, and the manufacturers warranties. The DV-5 Valve must be installed in a readily visible and accessible location. The DV-5 Valve, associated trim, and wet pilot lines must be maintained at a minimum temperature of 40F/4C. Heat tracing of the DV-5 Valve or its associated trim is not permitted. Heat tracing can result in the formation of hardened mineral deposits that are capable of preventing proper operation. Before a system hydrostatic test is performed refer to the Installation section of Technical Data Sheet TFP1310, TFP1315, TFP1320, TFP1410, TFP1415, TFP1420, TFP1460, or TFP1465.

Before closing a fire protection system main control valve for maintenance work on the fire protection system that it controls, permission to shut down the affected fire protection systems must first be obtained from the proper authorities and all personnel who may be affected by this action must be notified.

Drop In Water Supply Pressure Below Normal Range

during a fire condition) must be verified at least once a year as follows:

NOTE Operation tests for DV-5 Valves used in double interlock preaction systems must be performed as outlined in TFP1460 or TFP1465, as applicable.

Step 1. If water must be prevented from flowing beyond the riser, perform the following steps. Close the Main Control Valve. Open the Main Drain Valve. Open the Main Control Valve one turn beyond the position at which water just begins to flow from the Main Drain Valve. Close the Main Drain Valve. Step 2. Determine the type of actuation/detection system, and operate the DV-5 Valve accordingly.

NOTE If the water supply pressure is significantly reduced below the normally expected static pressure range (as could occur in the case of a water main break or repair), and there is a subsequent drop in the diaphragm chamber water pressure below its normal range (due, for example, to a leak in a piping connection to or from the diaphragm chamber or, a leak in the diaphragm chamber check valve caused by dirt or debris in the check valve seal area), a deluge valve such as the Model DV-5 could inadvertently trip, if its water supply pressure is quickly restored.

A drop in the water supply pressure to below its normal range (as in the case of an interrupted water supply condition) constitutes an emergency impairment as defined by NFPA 25. Should this condition occur, immediately close the main control valve and utilize the following procedure to reset the system: Step 1. Prior to the water supply pressure being restored to the closed main control valve, note the pressure indicated by the diaphragm chamber pressure gauge and determine if the pressure is within the normally expected range. Step 2. If the diaphragm chamber pressure is below the normal range, check for and correct any source of leakage from the diaphragm chamber prior to resetting the system. Step 3. After the water supply pressure is restored to the main control valve, reset the Model DV-5 Deluge Valve in accordance with the Valve Setting Procedure section.

NOTE Be prepared to quickly perform Steps 3, 4, and 5, if water must be prevented from flowing beyond the riser.

Wet Pilot Actuation Open the Inspectors Test Connection. Dry Pilot Actuation Open the Inspectors Test Connection. Electric Actuation Test the deluge releasing panel (automatic control unit) in accordance with the manufacturers instructions to energize the solenoid valve. Step 3. Verify that the DV-5 Valve has tripped, as indicated by the flow of water into the system. Step 4. Close the systems Main Control Valve. Step 5. Close the Diaphragm Chamber Supply Control Valve. Step 6. Reset the DV-5 Deluge Valve in accordance with the Valve Setting Procedure provided in TFP1310, TFP1315, TFP1320, TFP1410, TFP1415, or TFP1420, as applicable. Internal Valve Inspection Once every five years during the annual operational test procedure and prior to the DV-5 Valve being reset, the interior of the DV-5 Valve must be cleaned and inspected for wear and damage. Damaged or worn parts must be replaced. (Replacement of the Diaphragm every ten years is recommended.) When reinstalling the Diaphragm Cover, the Diaphragm Cover Fasten-

Care and Maintenance

The following procedures and inspections must be performed as indicated, in addition to any specific requirements of the NFPA, and any impairment must be immediately corrected. The owner is responsible for the inspection, testing, and maintenance of their fire protection system and devices in compliance with this document, as well as with the applicable standards of the National Fire Protection Association (e.g., NFPA 25), in addition to the standards of any authority having jurisdiction. The installing contractor or product manufacturer should be contacted relative to any questions. It is recommended that automatic sprinkler systems be inspected, tested, and maintained by a qualified Inspection Service in accordance with local requirements and/or national codes.

NOTES When the system is using either a seawater or brackish water supply, internal and external inspection of the DV-5 Valve and Trim is essential. Parts showing any signs of corrosion must be replaced to ensure the integrity of the system.

NOTE For fire protection systems subject to an emergency impairment caused by an interrupted water supply condition, it is recommended that consideration be given to installing a low water supply pressure switch with the appropriate alarm/indications to monitor the water supply pressure.

Annual Operation Test Procedure Proper operation of the DV-5 Valve (i.e., opening of the DV-5 Valve as

TFP1305

Page 7 of 8

ers must be uniformly and securely tightened using a cross-draw sequence. After tightening, doublecheck to make certain that all of the Diaphragm Cover Fasteners are securely tightened.

Tyco Fire & Building Products shall not be responsible for sprinkler system design errors or inaccurate or incomplete information supplied by Buyer or Buyers representatives. IN NO EVENT SHALL TYCO FIRE & BUILDING PRODUCTS BE LIABLE, IN CONTRACT, TORT, STRICT LIABILITY OR UNDER ANY OTHER LEGAL THEORY, FOR INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LABOR CHARGES, REGARDLESS OF WHETHER TYCO FIRE & BUILDING PRODUCTS WAS INFORMED ABOUT THE POSSIBILITY OF SUCH DAMAGES, AND IN NO EVENT SHALL TYCO FIRE & BUILDING PRODUCTS LIABILITY EXCEED AN AMOUNT EQUAL TO THE SALES PRICE.

3 Inch F x F ANSI Flange x ANSI Flange . . . . . . . . . 3 Inch F x G ANSI Flange x 3.50 inch (88,9 mm) Groove O.D. . . . . . . . . . 4 Inch G x G 4.50 inch (114,3 mm) Groove O.D. x 4.50 inch (114,3 mm) Groove O.D. . . . . . . . . . 4 Inch F x F ANSI Flange x ANSI Flange . . . . . . . . . 4 Inch F x G ANSI Flange x 4.50 inch (114,3 mm) Groove O.D. . . . . . . . . . 6 Inch G x G 6.62 inch (168,3 mm) Groove O.D. x 6.62 inch (168,3 mm) Groove O.D. . . . . . . . . . 6 Inch F x F ANSI Flange x ANSI Flange . . . . . . . . . 6 Inch F x G ANSI Flange x 6.62 inch (168,3 mm) Groove O.D. . . . . . . . . . 8 Inch G x G 8.62 inch (219,1 mm) Groove O.D. x 8.62 inch (219,1 mm) Groove O.D. . . . . . . . . . 8 Inch F x F ANSI Flange x ANSI Flange . . . . . . . . . 6 Inch F x G ANSI Flange x 8.62 inch (219,1 mm) Groove O.D. . . . . . . . . .

P/N 52-477-1-012

P/N 52-477-1-412

NOTES If the water supply contains chemicals which tend to attack a Nylon fabric reinforced, natural rubber or the five year inspection indicates a build-up of debris within the valve that could affect its proper operation, then the frequency of the internal valve inspection procedure must be appropriately increased. If the system has a seawater or brackish water supply, then the frequency of the internal valve inspection procedure must be appropriately increased. (An annual internal valve inspection for a system having a seawater or brackish water supply is recommended.) With reference to Figure 1, make certain that the Diaphragm is correctly oriented; otherwise, the DV-5 cannot be properly set. Under-tightening the Diaphragm Cover Bolts can result in leakage past the valve seat as indicated by leakage from the Automatic Drain Valve.

P/N 52-477-1-913 P/N 52-477-1-013

P/N 52-477-4-613

P/N 52-477-1-915 P/N 52-477-1-015

THE FOREGOING WARRANTY IS MADE IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

P/N 52-477-4-615

Ordering Procedure

NOTES Refer to Table A for Flange Drilling Specifications. Part Numbers for factory pre-trimmed Model DV-5 Valves are provided in the Price Book.

Standard DV-5 Deluge Valve (American Standard Flange Drilling, Threaded Ports, and Groove Outside Diameter, as applicable): Specify: (specify size inch) Model DV5 Deluge Valve with (specify end connections), P/N (specify).

1-1/2 Inch G x G 1.90 inch (48,3 mm) Groove O.D. x 1.90 inch (48,3 mm) Groove O.D. . . . . . . . . . 1-1/2 Inch T x T NPT x NPT . . . . . . . . . . 2 Inch G x G 2.37 inch (60,3 mm) Groove O.D. x 2.37 inch (60,3 mm) Groove O.D. . . . . . . . . . 2 Inch T x T NPT x NPT . . . . . . . . . . 3 Inch G x G 3.50 inch (88,9 mm) Groove O.D. x 3.50 inch (88,9 mm) Groove O.D. . . . . . . . . .

P/N 52-477-1-916 P/N 52-477-1-016

Limited Warranty

Products manufactured by Tyco Fire & Building Products are warranted solely to the original Buyer for ten (10) years against defects in material and workmanship when paid for and properly installed and maintained under normal use and service. This warranty will expire ten (10) years from date of shipment by Tyco Fire & Building Products. No warranty is given for products or components manufactured by companies not affiliated by ownership with Tyco Fire & Building Products or for products and components which have been subject to misuse, improper installation, corrosion, or which have not been installed, maintained, modified or repaired in accordance with applicable Standards of the National Fire Protection Association, and/or the standards of any other Authorities Having Jurisdiction. Materials found by Tyco Fire & Building Products to be defective shall be either repaired or replaced, at Tyco Fire & Building Products sole option. Tyco Fire & Building Products neither assumes, nor authorizes any person to assume for it, any other obligation in connection with the sale of products or parts of products.

P/N 52-477-1-416

Replacement Valve Parts: Specify: (description) for use with (specify) size Model DV-5 Deluge Valve, P/N (see Figure 1). Other DV-5 Deluge Valves:

NOTES Other DV-5 Deluge Valves are valves ordered with any combination of flange, threaded port, or groove outside diameter not offered under Standard DV-5 Deluge Valve offerings. Valves with NPT threaded ports are intended for use with the Standard DV-5 Valve Trim offered and detailed in Technical Data Sheets TFP1310, TFP1315, TFP1320, TFP1410, TFP1415, TFP1420, TFP1460, and TFP1465. Valves with ISO threaded ports are intended for use with special order trim that is provided by local distributors to meet the specific needs of certain localities. Please contact your local distributor regarding valves and valve trim for specific localities.

Specify: (specify size) Model DV-5 Deluge Valve with (specify) connections with (specify NPT or ISO) threaded ports, P/N (See Page 8).

P/N 52-477-1-919 P/N 52-477-1-069

P/N 52-477-1-910 P/N 52-477-1-060

P/N 52-477-1-912

Page 8 of 8

TFP1305

Part Numbers For Other Model DV-5 Deluge Valves:

Other 1-1/2 Inch Valves with ISO Ports

ISO Thread x ISO Thread . . . . . . . . . . P/N 52-477-1-169

Part Numbers For Other Model DV-5 Deluge Valves:

Other 4 Inch Valves with NPT Ports

ISO Flange x 4.50 inch (114,3 mm) Groove O.D . . . . . ISO Flange x ISO Flange . . . . . . . . . . AS Flange x AS Flange. . . . . . . . . . . AS Flange x 4.50 inch (114,3 mm) Groove O.D . . . . . JIS Flange x JIS Flange . . . . . . . . . . JIS Flange x 4.50 inch (114,3 mm) Groove O.D . . . . . P/N 52-477-5-213 P/N 52-477-5-113 P/N 52-477-4-313 P/N 52-477-4-413 P/N 52-477-4-713 P/N 52-477-4-813

Part Numbers For Other Model DV-5 Deluge Valves:

Other 8 Inch Valves with NPT Ports

ISO (PN10) Flange x 8.62 inch (219,1 mm) Groove O.D . . . . . . ISO (PN16) Flange x 8.62 inch (219,1 mm) Groove O.D . . . . . . ISO (PN10) Flange x ISO (PN10) Flange . . . . ISO (PN16) Flange x ISO (PN16) Flange . . . . AS Flange x AS Flange . . . . . . . . . . . AS Flange x 8.62 inch (219,1 mm) Groove O.D . . . . . . JIS Flange x JIS Flange . . . . . . . . . . . JS Flange x 8.62 inch (219,1 mm) Groove O.D . . . . . . P/N 52-477-1-256 P/N 52-477-1-216 P/N 52-477-1-136 P/N 52-477-1-146 P/N 52-477-1-516 P/N 52-477-1-616 P/N 52-477-1-716 P/N 52-477-1-816

Other 2 Inch Valves with ISO Ports

ISO Thread x ISO Thread . . . . . . . . . . P/N 52-477-1-160

Other 3 Inch Valves with NPT Ports

ISO Flange x 3.50 inch (88,9 mm) Groove O.D . . . . . . . . . . ISO Flange x ISO Flange . . . . . . . . . . AS Flange x AS Flange . . . . . . . . . . . AS Flange x 3.50 inch (88,9 mm) Groove O.D . . . . . . . . . . JIS Flange x JIS Flange . . . . . . . . . . . JIS Flange x 3.50 inch (88,9 mm) Groove O.D . . . . . . . . . . P/N 52-477-1-252 P/N 52-477-1-132 P/N 52-477-1-512 P/N 52-477-1-612 P/N 52-477-1-712 P/N52-477-1-812

Other 4 Inch Valves with ISO Ports

ISO Flange x ISO Flange . . . . . . . . . . ISO Flange x 4.50 inch (114,3 mm) Groove O.D . . . . . 4.50 inch (114,3 mm) Groove O.D x 4.50 inch (114,3 mm) Groove O.D . . . . . P/N 52-477-4-113 P/N 52-477-4-213

Other 8 Inch Valves with ISO Ports

P/N 52-477-1-923 ISO (PN10) Flange x ISO (PN10) Flange . . . . ISO (PN16) Flange x ISO (PN16) Flange . . . . ISO (PN10) Flange x 8.62 inch (219,1 mm) Groove O.D. . . . . . ISO (PN16) Flange x 8.62 inch (219,1 mm) Groove O.D. . . . . . 8.62 inch (219,1 mm) Groove O.D. x 8.62 inch (219,1 mm) Groove O.D. . . . . . P/N 52-477-1-116 P/N 52-477-1-126 P/N 52-477-1-216 P/N 52-477-1-226

Other 3 Inch Valves with ISO Ports

ISO Flange x ISO Flange . . . . . . . . . . P/N 52-477-1-112 ISO Flange x 3.50 inch (88,9 mm) Groove O.D . . . . . . . . . . P/N 52-477-1-212 3.50 inch (88,9 mm) Groove O.D x 3.50 inch (88,9 mm) Groove O.D . . . . . . . . . . P/N 52-477-1-922

Other 6 Inch Valves with NPT Ports

ANSI Flange x 6.50 inch (165,1 mm) Groove O.D . . . . . ISO Flange x 6.62 inch (168,3 mm) Groove O.D . . . . . ISO Flange x 6.50 inch (165,1 mm) Groove O.D . . . . . ISO Flange x ISO Flange . . . . . . . . . . 6.50 inch (165,1 mm) Groove O.D x 6.50 inch (165,1 mm) Groove O.D . . . . . AS Flange x AS Flange. . . . . . . . . . . AS Flange x 6.62 inch (168,3 mm) Groove O.D . . . . . AS Flange x 6.50 inch (165,1 mm) Groove O.D . . . . . JIS Flange x JIS Flange . . . . . . . . . . JS Flange x 6.62 inch (168,3 mm) Groove O.D . . . . . JS Flange x 6.50 inch (165,1 mm) Groove O.D . . . . . P/N 52-477-4-225 P/N 52-477-5-625 P/N 52-477-5-215 P/N 52-477-5-115

P/N 52-477-1-926

P/N 52-477-1-935 P/N 52-477-4-315 P/N 52-477-4-415 P/N 52-477-5-415 P/N 52-477-4-715 P/N 52-477-4-815 P/N 52-477-5-815

Other 6 Inch Valves with ISO Ports

ISO Flange x ISO Flange . . . . . . . . . . ISO Flange x 6.62 inch (168,3 mm) Groove O.D . . . . . ISO Flange x 6.50 inch (165,1 mm) Groove O.D . . . . . 6.62 inch (168,3 mm) Groove O.D x 6.62 inch (168,3 mm) Groove O.D . . . . . 6.50 inch (165,1 mm) Groove O.D x 6.50 inch (165,1 mm) Groove O.D . . . . . P/N 52-477-4-115 P/N 52-477-4-625 P/N 52-477-4-215

P/N 52-477-1-925

P/N 52-477-1-945

TYCO FIRE & BUILDING PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

You might also like

- Water Control Valve DV-5Document8 pagesWater Control Valve DV-5Christian FherNo ratings yet

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- Tyco - Mokri Sprinkler VentilDocument20 pagesTyco - Mokri Sprinkler VentilMuhidin KozicaNo ratings yet

- TFP910 03 2020Document20 pagesTFP910 03 2020alfian.ichsan25No ratings yet

- TFP1305 08 2018 ObsoleteDocument8 pagesTFP1305 08 2018 Obsoletefassart.jNo ratings yet

- TFP910 09 2014Document20 pagesTFP910 09 2014goskleNo ratings yet

- TFP910 03 2021Document20 pagesTFP910 03 2021muralyyNo ratings yet

- Valvula de Diluvio de 2 PulgadasDocument8 pagesValvula de Diluvio de 2 PulgadasRobertoNo ratings yet

- Válvula de Alarma Tyco AV 1 300Document20 pagesVálvula de Alarma Tyco AV 1 300Isaac JimenezNo ratings yet

- Valvula Check AlarmDocument20 pagesValvula Check AlarmCarlos Amaya CuevaNo ratings yet

- Unit 1 - FPSDocument3 pagesUnit 1 - FPSGreen MichaelsNo ratings yet

- TFP910 03 2006Document22 pagesTFP910 03 2006Jerome LazaroNo ratings yet

- Warning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoDocument6 pagesWarning: L1200 Superseded by LS200. For L1100 & DVU, See New InfoRiky AyalaNo ratings yet

- 09 Válvula de AlarmaDocument22 pages09 Válvula de AlarmaRuben Saucedo JacomeNo ratings yet

- Valvula Alarma de 4 PulgadasDocument22 pagesValvula Alarma de 4 PulgadasRobertoNo ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- Valvula Diafragma AquamaticDocument59 pagesValvula Diafragma AquamaticderbisNo ratings yet

- GE AquaMatic Products Catalog Rev ZDocument176 pagesGE AquaMatic Products Catalog Rev ZMehdi AcilNo ratings yet

- HansenDocument4 pagesHansenBruna MacedoNo ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- Direct Acting Excess Pressure ValvesDocument8 pagesDirect Acting Excess Pressure ValvescartarNo ratings yet

- Valves Grese NDocument92 pagesValves Grese NRandall KirchbergNo ratings yet

- Valves Grese NDocument92 pagesValves Grese NYair Alexis Muñoz Rojas100% (1)

- TFP950 10 2010Document6 pagesTFP950 10 2010elpelaracingNo ratings yet

- Digital Control ValveDocument8 pagesDigital Control Valvecnrk777100% (1)

- File - 116 - 116 - 20-Butterfly ValveDocument4 pagesFile - 116 - 116 - 20-Butterfly Valvephuong daoNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Tyco DPV 1 Tfp1090Document30 pagesTyco DPV 1 Tfp1090Nadolu MarianNo ratings yet

- SRC Alpha Version1 PDFDocument26 pagesSRC Alpha Version1 PDFRajat JainNo ratings yet

- 3 WayDocument18 pages3 WayLeonardNo ratings yet

- Manual Zetkama Fig.215 - 216Document8 pagesManual Zetkama Fig.215 - 216George_Wabag_2014No ratings yet

- 518 Model DDX Deluge Valve, 2 To 8 InchesDocument12 pages518 Model DDX Deluge Valve, 2 To 8 InchesmuhamedzNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- Series 767FR Specification SheetDocument4 pagesSeries 767FR Specification SheetFEBCONo ratings yet

- CATALOG GE Osmonics AquaMaticDocument316 pagesCATALOG GE Osmonics AquaMaticCyrilDepalomaNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- A075 Valve Operation Guide PDFDocument130 pagesA075 Valve Operation Guide PDFedhy_03No ratings yet

- Vad 213Document11 pagesVad 213Sen Van0% (1)

- Cat SeriesDocument5 pagesCat SeriesEliasNo ratings yet

- Es F 856STDocument4 pagesEs F 856STFEBCONo ratings yet

- HPTDocument48 pagesHPTyg89No ratings yet

- 2, 5 Inch Side Door Stripper PDFDocument16 pages2, 5 Inch Side Door Stripper PDFOvRrj AhmedNo ratings yet

- Goyen Dust Collector Valves & Cleaning System ComponentsDocument20 pagesGoyen Dust Collector Valves & Cleaning System ComponentsIndustry Air Sales Ltd.No ratings yet

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- Gufmc 0138 UsDocument8 pagesGufmc 0138 Usmusaismail8863No ratings yet

- Methven Nefa Pressure Reducing Valves ReferenceDocument36 pagesMethven Nefa Pressure Reducing Valves ReferenceLen Salisbury100% (1)

- Series: Control ValvesDocument20 pagesSeries: Control ValvesHugo SA de CVNo ratings yet

- Febco DCD and DC 850 856 870 and 876Document12 pagesFebco DCD and DC 850 856 870 and 876Brandon TrocNo ratings yet

- INBAL GeralDocument10 pagesINBAL GeralAlisson Gustavo KalilNo ratings yet

- 10 ValvesDocument23 pages10 ValvesPower PlantNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- MS-02-445 Instrument Manifold SystemsDocument32 pagesMS-02-445 Instrument Manifold SystemsmkrzoNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- Choke E Series MasterFloDocument14 pagesChoke E Series MasterFloianherzogNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationFrom EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationRating: 4.5 out of 5 stars4.5/5 (21)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Factors, Multiples, Primes, Prime Factors, LCM and HCFDocument2 pagesFactors, Multiples, Primes, Prime Factors, LCM and HCFKatrice LiNo ratings yet

- TUV Nord TrainingDocument39 pagesTUV Nord TrainingmohammadazraiNo ratings yet

- Outreach P2 Math PDFDocument131 pagesOutreach P2 Math PDFmohammadazraiNo ratings yet

- DS68 9-597 PDFDocument9 pagesDS68 9-597 PDFRamon FragaNo ratings yet

- Expansion Loop Guideline ExtractDocument8 pagesExpansion Loop Guideline ExtractmohammadazraiNo ratings yet

- Flare Tip FailureDocument4 pagesFlare Tip FailuremohammadazraiNo ratings yet

- Eng Lang A Exemplars P1 Writing and P2Document83 pagesEng Lang A Exemplars P1 Writing and P2mohammadazraiNo ratings yet

- Outreach P2 Math PDFDocument131 pagesOutreach P2 Math PDFmohammadazraiNo ratings yet

- Painting & Coating SpecDocument19 pagesPainting & Coating SpecmohammadazraiNo ratings yet

- Nitrogen Generation by PSADocument12 pagesNitrogen Generation by PSALakshmi Pathi Bojja100% (1)

- Pipe SupportsDocument234 pagesPipe SupportsSam Weber100% (1)

- Supports 20FREDocument6 pagesSupports 20FREmohammadazraiNo ratings yet

- Ptsme 2015 Abu Dhabi - TrainingDocument6 pagesPtsme 2015 Abu Dhabi - TrainingmohammadazraiNo ratings yet

- Pbe 20050301 31Document3 pagesPbe 20050301 31mohammadazraiNo ratings yet

- Jiangyinshi BeihaiDocument1 pageJiangyinshi BeihaiNazhani Rohaidin100% (1)

- Momentum 2 2012.ashxDocument52 pagesMomentum 2 2012.ashxmohammadazraiNo ratings yet

- Calcium CarbonateDocument2 pagesCalcium CarbonatemohammadazraiNo ratings yet

- Momentum 2 2012.ashxDocument52 pagesMomentum 2 2012.ashxmohammadazraiNo ratings yet

- 3D & 5D Pipe Bend For PipelineDocument6 pages3D & 5D Pipe Bend For PipelinemohammadazraiNo ratings yet

- Soda AshDocument2 pagesSoda AshmohammadazraiNo ratings yet

- LIQUITOTE IBC Tanks PDFDocument2 pagesLIQUITOTE IBC Tanks PDFpramodtryNo ratings yet

- Class Notations TableDocument247 pagesClass Notations TableRobert DelafosseNo ratings yet

- DNV Publication ListDocument14 pagesDNV Publication ListmohammadazraiNo ratings yet

- Dupre - Travis Crane Operation and MaintenanceDocument23 pagesDupre - Travis Crane Operation and MaintenancemohammadazraiNo ratings yet

- CPD 002 RevisedDocument7 pagesCPD 002 Revisedanlekgen99No ratings yet

- Notaries Public KL & SelangorDocument3 pagesNotaries Public KL & SelangormohammadazraiNo ratings yet

- CPD 002 RevisedDocument7 pagesCPD 002 Revisedanlekgen99No ratings yet

- ASSAI Booklet Ver2Document2 pagesASSAI Booklet Ver2mohammadazraiNo ratings yet

- 3D & 5D Pipe Bend For PipelineDocument6 pages3D & 5D Pipe Bend For PipelinemohammadazraiNo ratings yet

- ASSAI Booklet Ver2Document2 pagesASSAI Booklet Ver2mohammadazraiNo ratings yet

- Cai Mep Project Pile SpecDocument33 pagesCai Mep Project Pile Speckim y hNo ratings yet

- Documents List (EGCS)Document8 pagesDocuments List (EGCS)Ivan HoNo ratings yet

- Oil Gas CatalogueDocument184 pagesOil Gas CatalogueMbamali ChukwunenyeNo ratings yet

- Catalogo Gates Acoples y Mangueras PDFDocument626 pagesCatalogo Gates Acoples y Mangueras PDFJose Antonio Gutierrez Lopez100% (1)

- Make List CPWDDocument8 pagesMake List CPWDamandeep0% (1)

- Super EgoDocument40 pagesSuper Egolong_kongoNo ratings yet

- User Manual: ATEQ D520Document134 pagesUser Manual: ATEQ D520Suranyi BotondNo ratings yet

- Painting SpecificationDocument19 pagesPainting Specificationamirthraj74No ratings yet

- Electromechanical Boq ForensicDocument31 pagesElectromechanical Boq ForensicDesigner ForeverNo ratings yet

- Technical Specifications With SaddlesDocument6 pagesTechnical Specifications With Saddlesmihaidanpan791No ratings yet

- Practical Guide To PolypropyleneDocument114 pagesPractical Guide To PolypropyleneMousom Som83% (6)

- Ut For WeldDocument82 pagesUt For WeldphanthanhhungNo ratings yet

- LS20-100 Sullair Manual PDFDocument114 pagesLS20-100 Sullair Manual PDFJames Hanks50% (2)

- MK1-2100AB001 - R0 - MTO Installation Material Area 2100Document12 pagesMK1-2100AB001 - R0 - MTO Installation Material Area 2100Farshad MahmoudiNo ratings yet

- 23 PDFDocument26 pages23 PDFCuesta AndresNo ratings yet

- Major 2 - Brosura TehnicaDocument14 pagesMajor 2 - Brosura TehnicaIgor Matijević100% (2)

- Wellhead - Saquib ErbilDocument109 pagesWellhead - Saquib ErbilYasir AhmedNo ratings yet

- Cost Estimates Piping R.A DicksonDocument18 pagesCost Estimates Piping R.A Dicksoncateerpillar100% (3)

- Jacking Pipes Humes PDFDocument24 pagesJacking Pipes Humes PDFrizanindya100% (1)

- Product Data: Convertible Air Handlers 1-1/2 - 5 TonDocument28 pagesProduct Data: Convertible Air Handlers 1-1/2 - 5 TonJonathan CapraNo ratings yet

- Bill of Quantities-Civil (0514) - 2930 Cast Hse RevDocument24 pagesBill of Quantities-Civil (0514) - 2930 Cast Hse RevVenkata RaoNo ratings yet

- Flow CellDocument22 pagesFlow CellheikelNo ratings yet

- BPV 13 01 PDFDocument19 pagesBPV 13 01 PDFJason BakerNo ratings yet

- API 12F Steel Tank Data Sheet: Form No. API12FDS1Document2 pagesAPI 12F Steel Tank Data Sheet: Form No. API12FDS1Magin Idelfonso TorreblancaNo ratings yet

- Testing StandardDocument7 pagesTesting StandardDiego Fernando Pedroza UribeNo ratings yet

- KP Sharma EstimateDocument31 pagesKP Sharma EstimateSudip GhimireNo ratings yet

- Design Considerations-Vacuum Sewer SystemsDocument7 pagesDesign Considerations-Vacuum Sewer SystemsGustavo TonelliNo ratings yet

- The Fiberbond® Engineering Guide: Engineered Composite Piping SystemsDocument41 pagesThe Fiberbond® Engineering Guide: Engineered Composite Piping Systemssammar_10No ratings yet

- General Notes: Abbrevations: Symbols: Fire Protection:: Schedule of Equipments Vicinity MapDocument12 pagesGeneral Notes: Abbrevations: Symbols: Fire Protection:: Schedule of Equipments Vicinity MapHelios100% (1)