Professional Documents

Culture Documents

Liquefaction of Gases (Akshay)

Uploaded by

Rupesh PillaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquefaction of Gases (Akshay)

Uploaded by

Rupesh PillaiCopyright:

Available Formats

LIQUEFACTION OF GASES

Gases such as nitrogen, oxygen and methane require the use of very low temperatures to liquefy and store them at relatively low pressures. To achieve this, a whole range of cryogenic technologies has been developed to ensure the economical liquefaction of gases. The reason why such technology has become important is that storage of these gases is more economic and versatile in their liquid form. There are several ways in which refrigeration can be supplied to a process to cool and/or condense a gas or mixture of gases. These can be grouped into the three fundamental principles used in commercial applications: 1. The Joule-Thomson effect 2. Compression/condensation and expansion of a pure component 3. Expansion turbines or engines. Most processes in cryogenic technology use one or more of the above principles. Alternatively, they may use a mixed refrigerant as working fluid. The refrigeration requirements for each cryogenic process are made up of the following elements: heat ingress from the atmosphere irreversible thermodynamic losses through heat exchange the requirement to produce liquid from what is normally a gas. Heat ingress is usually kept to a minimum by good insulation practices and is a small proportion of the refrigeration requirement in industrial liquefaction processes. Heat exchanger warm-end losses and other irreversible losses are minimized through the use of compact, high-efficiency heat exchangers. Such exchangers are plate-fin aluminum or stainless steel units, as well as wound coil or etched exchangers made in stainless steel or sometimes aluminum. They have economical temperature difference approaches of 23C in contrast with normal shell and tube exchangers, which are economical at much higher temperature differences. The importance of good heat transfer in cryogenic processes cannot be overemphasized because of the significant cost of liquefaction of fluids, such as N2, O2 and CH4. The references attached to this section give a more detailed analysis of the benefits of compact heat exchange. The three basic methods of Refrigeration, used singly or in combination with each other. Figure 25 schematically diagrams the mechanical components and flow of gas through the Linde - Hampson air liquefier. As the air is compressed it rejects heat to its surroundings. Additional cooling of the pressurized air occurs in the counter-flow heat exchanger from the colder return-gas. Exiting the heat exchanger, the pressurized air is expanded. Figure 25. Linde-Hampson air liquefier: (a) compressor; (b) counterflow heat exchanger; (c) expansion valve; (d) liquid air outlet; and (e) make-up air inlet. Through a valve resulting in a drop in pressure and temperature, to the extent that some of the air exits the valve in liquid form. The remaining cold gas returns up through the counterflow heat exchanger. Being warmed by the incoming pressurized air, it returns to the suction side of the compressor near room temperature. Adding the same mass in gaseous form at the inlet of the compressor then compensates for the amount of liquid that is extracted from the machine.

Advantages of Liquefaction 1. Liquefaction of gases produces cryogenic temperatures required for fundamental research. 2. Liquefaction helps in storing large volume of gases in small storages. Applications of Cryogenics a. Industrial applications: Shrink fitting of metals Liquid oxygen is used in welding, in the manufacture of steel Liquid oxygen in artificial breathing in hospitals & aircrafts. For the preservation of blood, dead bodies and medicines. For freezing the food for preservation - By spray of liquid nitrogen. Quick healing of wounds. Cooling the body parts by anesthesia. b. Agriculture: Preservation of bull insemination for better creed. For the manufacture of cryogenic magnets Super conductive transformers and Super conduction motors Used in separation of gases i.e. air, Coke oven gas, Helium 3 from Helium 4 Economic transport of ice cream. Superconductivity makes computers compact Liquid hydrogen is used as a fuel in rockets.

You might also like

- XXXX Inj MOld Cost EstimationDocument23 pagesXXXX Inj MOld Cost EstimationAmitava DattaNo ratings yet

- Routsis Injection Molding ReferenceDocument176 pagesRoutsis Injection Molding ReferenceRupesh PillaiNo ratings yet

- Eastman Polymers - Processing and Mold Design GuidelinesDocument44 pagesEastman Polymers - Processing and Mold Design GuidelinesnimonhNo ratings yet

- Injection MoldingDocument8 pagesInjection MoldingDebasmiti MishraNo ratings yet

- 2007 ANTEC Mold DesignDocument6 pages2007 ANTEC Mold DesignRupesh PillaiNo ratings yet

- Chuck Hedley ThesisDocument111 pagesChuck Hedley ThesisMohd Hairie Yusuf100% (1)

- DFM BaseDocument18 pagesDFM BaseRupesh PillaiNo ratings yet

- DFM BaseDocument18 pagesDFM BaseRupesh PillaiNo ratings yet

- Your Order Number Is: 2516769 Windchimes#@! JabongDocument1 pageYour Order Number Is: 2516769 Windchimes#@! JabongRupesh PillaiNo ratings yet

- Ip AddressDocument1 pageIp AddressRupesh PillaiNo ratings yet

- Reliance DTH Add On PackDocument2 pagesReliance DTH Add On PackRupesh PillaiNo ratings yet

- ANSYS FLUENT 12.1 in Workbench Users GuideDocument78 pagesANSYS FLUENT 12.1 in Workbench Users GuideRupesh PillaiNo ratings yet

- Ansys Training Book.Document15 pagesAnsys Training Book.Sarath Babu SNo ratings yet

- LicenseDocument13 pagesLicenseRupesh PillaiNo ratings yet

- Mollier ChartDocument1 pageMollier ChartrkkumarcpriNo ratings yet

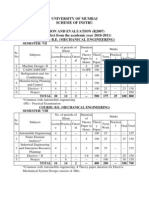

- University of Mumbai Scheme of Instruction and Evaluation for B.E. Mechanical EngineeringDocument82 pagesUniversity of Mumbai Scheme of Instruction and Evaluation for B.E. Mechanical EngineeringJayesh NavareNo ratings yet

- ReadmeDocument1 pageReadmeRupesh PillaiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Inorganic Irritants (Phosphorus & Iodine) : - S.Sinduja Roll No: 30Document20 pagesInorganic Irritants (Phosphorus & Iodine) : - S.Sinduja Roll No: 30sindujasaravananNo ratings yet

- Reference 3 - StabilityDocument3 pagesReference 3 - Stabilitytan_hoe_1No ratings yet

- BTK AGUSTUS MutasiObatDocument48 pagesBTK AGUSTUS MutasiObatwulanwidya06No ratings yet

- Unit Operations For Waste Water Treatment: Course ContentDocument10 pagesUnit Operations For Waste Water Treatment: Course ContentGruzei CatbaganNo ratings yet

- OK Tubrod 15.14Document1 pageOK Tubrod 15.14Tiberiu MunteanuNo ratings yet

- McGraw-Edison Resilite Series Brochure 1985Document6 pagesMcGraw-Edison Resilite Series Brochure 1985Alan MastersNo ratings yet

- NIOSH 7907 - Ácidos VolátilesDocument6 pagesNIOSH 7907 - Ácidos VolátilesjosepthfrancisNo ratings yet

- Meristematic TissuesDocument4 pagesMeristematic TissuesNur Syiffa RosmanNo ratings yet

- 40 QUESTIONS IN 40 MINUTES FOR CHEMISTRYDocument21 pages40 QUESTIONS IN 40 MINUTES FOR CHEMISTRYAliyat OlatundeNo ratings yet

- Medc Product Overview Web PDFDocument92 pagesMedc Product Overview Web PDFThinh TranNo ratings yet

- DNA and PROTEIN SYNTHESIS MODULE OVERVIEW 2012Document29 pagesDNA and PROTEIN SYNTHESIS MODULE OVERVIEW 2012Desiree CastilloNo ratings yet

- Fire Protection Fundamentals GuideDocument41 pagesFire Protection Fundamentals GuideyoussryNo ratings yet

- Review of Related Literature and StudiesDocument10 pagesReview of Related Literature and StudiesAngelica JanoyNo ratings yet

- Estimating Fracture Toughness of Thermally Aged Cast Stainless SteelsDocument193 pagesEstimating Fracture Toughness of Thermally Aged Cast Stainless SteelsraelgfsNo ratings yet

- Lopa SilDocument10 pagesLopa Silkhali54No ratings yet

- Ashurst, J. Technology and Use Hydraulic Lime. 1997Document4 pagesAshurst, J. Technology and Use Hydraulic Lime. 1997Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- MSDS Tri Sodium PhosphateDocument1 pageMSDS Tri Sodium PhosphateTalha Jamil MalikNo ratings yet

- Chem 121 Organic Chemistry I Acids and Bases LectureDocument2 pagesChem 121 Organic Chemistry I Acids and Bases LectureJayson FranciscoNo ratings yet

- Solid Dispersion PolymorphismDocument37 pagesSolid Dispersion PolymorphismAmey KamtheNo ratings yet

- Master Program in Pharmacy Macedonia Skopje 2009Document92 pagesMaster Program in Pharmacy Macedonia Skopje 2009abdurahman27100% (1)

- Bezaprint Black BDC - TdsDocument2 pagesBezaprint Black BDC - TdsMahdiNo ratings yet

- Phy Assignment03E PDFDocument25 pagesPhy Assignment03E PDFBhawna SharmaNo ratings yet

- Articulo de QuimicaDocument9 pagesArticulo de QuimicaIvan DiazNo ratings yet

- Repacking Licence For Web March2020 3Document11 pagesRepacking Licence For Web March2020 3aiktiplarNo ratings yet

- ASTM E1-14 Standard Specification For ASTM Liquid-In-Glass Thermometers1Document51 pagesASTM E1-14 Standard Specification For ASTM Liquid-In-Glass Thermometers1Edwin Duran100% (2)

- Oxidative Stress in ImmunotoxicityDocument6 pagesOxidative Stress in ImmunotoxicityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Combined Impact and Attrition MethodDocument7 pagesCombined Impact and Attrition MethodBernadette Beltran0% (2)

- AmylaseDocument13 pagesAmylaseDr. Kalavati PrajapatiNo ratings yet

- What Is Anaerobic DigestionDocument3 pagesWhat Is Anaerobic DigestionRalf Jade Vince GundranNo ratings yet

- Husky 515 Graco PDFDocument36 pagesHusky 515 Graco PDFrobby damanikNo ratings yet