Professional Documents

Culture Documents

MSDS Steel Sheet Safety Data

Uploaded by

chinck83Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSDS Steel Sheet Safety Data

Uploaded by

chinck83Copyright:

Available Formats

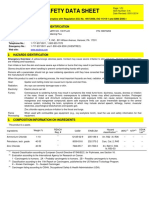

MATERIAL SAFETY DATA SHEET

MATERIAL IDENTIFICATION AND USE MATERIAL NAME:

STEEL

SUPPLIER: RUSSEL METALS INC ADDRESS: 1900 MINNESOTA COURT, SUITE 210 MISSISSAUGA ONTARIO. CANADA. L5N 3C9 TEL: 905-819-7295 FAX: 905-819-7262 INTERNET: www.russelmetals.com FORM #: MSDS-04-2009. DATE: FEBRUARY 2009

SYNONYMS: Includes all Sheet products, Plate, Strip, Bar, Slab, Ingot, Structural shapes and Tubular Products. WHMIS CLASS: D2A, D2B

1. PRODUCT INFORMATION

MATERIAL NAME: FORM #: MATERIAL USE: STEEL MSDS-01-2009 MANUFACTURE OF ARTICLES DATE: FEBRUARY 2009

2. HAZARDOUS INGREDIENTS

BASE METAL (ALL VALUES ARE EXPRESSED AS WEIGHT PERCENT AND ARE APPROXIMATES)

The exposure limit for iron-containing fumes has been established at 5 mg/m3 with ACGIH's TWA. The individual complex compounds within the fume may have lower exposure limits than the general fume. COMPONENT C.A.S. NUMBER 7439-89-6 7439-96-5 7440-47-3 TLV ACGIH (mg/m) 5 (Respirable) 0.2 (As inorganic Mn) 0.5 (Metal) LD 50 CARBON & H.S.L.A. STEELS 91-99 <2.0 <0.1 ELECTRICAL STEELS 91-99 <2.2 <1.7 LEADED & LOW ALLOY STEELS 92-96 <2.2 <1.7 RAILS & TIE PLATES 94-96 <1.7 <1.6 TUBULAR PROD. 94-96 <1.7 <0.7

IRON MANGANESE CHROMIUM

U 9000 mg/kg Oral-Rat U

0.05 (Cr +6 Soluble) 0.01 (Cr +6 Insoluble)

1.5 (Metal) 0.2 (Insoluble) 0.1 (Soluble) 1.0 (Dust) 0.2 (Fume) 0.1 10.0 (Inhalable) 3.0 (Respirable) 0.5 (Soluble) 0.05

NICKEL

7440-02-0

>9000 mg/kg Oral-Rat U U U

<1.0

<2.1

<2.1

<0.15

<0.5

COPPER PHOSPHOROUS MOLYBDENUM

7440-50-8 7723-14-0 7439-98-7

<1.0 <0.25 --

----

----

<0.1 -<0.12

<0.5 <0.1 <1.0

LEAD

7439-92-1

--

--

<0.35

--

--

NOTES: Threshold Limit Values (TLV) established by the American Conference of Governmental Industrial Hygienists (ACGIH - 2008) are 8-hour Time Weighted Average concentrations unless otherwise noted. Ingredients listed as required by the WHMIS Ingredient Disclosure List of the Hazardous Products Act (Canada). For exact composition, refer to analysis or specifications.

METALLIC AND NON-METALLIC COATINGS

GALVANIZE GALVANNEAL - Hot dipped Zinc (CAS 7440-66-6) coating. Coating weights range from 15-400 g/m per side. May be chemically passivated with a Chromium compound which leaves a residual Cr level of 11-40 mg/m per side. Petroleum based rust preventative oils are applied to oiled product. Typical oil coating weights range from 1.1-5.4 g/m per side. - Hot dipped Zinc (CAS 7440-66-6) 43% and Aluminum (CAS 7429-90-5) 55% coating. Coating weights range from 50-150 g/m per side. May also be passivated or oiled similar to Galvanize material. - Electroplated with tin (CAS 7440-31-5) coating. Coating weights range from 0.9-15 g/m per side. Treated with Chromium passivation solution which leaves a Chromium residue of 0.05-7.5 g/m per side. May be coated with an edible oil to prevent scratching. Oil coating typically 0.1 micro inches thick. C2 COATING ELECTRICAL C3 COATING ELECTRICAL C5M COATING ELECTRICAL DRY-LUBE PRE-LUBE LUBE OIL SLUSHING OIL VANISHING OIL PRECOATED - Glass film composed of Magnesium ortho-silicate formed during high temperature anneal - Oil modified polyester resin varnish film - An inorganic iron-silicate complex that is heat and oil resistant with good insulating properties. - Mixture of borate and carbonate soap lubricants for metal forming. - Petroleum based oil coating used for metal forming - Lubricating protective petroleum based oil - Mineral oil based protective coating containing small quantities of anti-oxidants - Solvent applied petroleum oil protective coating leaving a wax-like protective coating. - Cured paint/resin film applied to sheet steel. Galvanized or Galvalume coated steel sheet.

GALVALUME

TIN PLATE

CHROMIUM

RUST PROTECTION

- Electroplated with Chromium (CAS 7440-47-3) coating. Coating weights range from 0.1-0.17 g/m per side. May be coated with edible oil similar to tin plate. - Oil based rust inhibitor (Rust Ban 392) containing 60-100% light hydrotreated distillates (CAS 64742-47-8).

ZINCROMETAL

PRIMER

- Protective coating of zinc rich paint over a chromate based primer compound. Coating is applied to one side of strip. Typical coating weights range from 0.215 -0.325 g/m - Standard Shop Primer Coating for steel (#27452 Canam Grey), based on 10-20% light aliphatic naphtha solvent (CAS 64742-89-8), 5-10% petroleum distillates (CAS 6841016-2) and 5-10% Stoddard solvent (CAS 8052-41-3).

NOTES: 1. Individual coating components are present at values below the reporting requirements of the WHMIS Ingredient Disclosure List. 2. Passivation Treatment (specifically ordered) for Zinc Coated Products may contain hexavalent chromium as a portion of the chromium and chromium oxide corrosion protection coating. In these cases, the actual concentration of hexavalent present varies with steel gauge and coating weight.

3. HAZARDS IDENTIFICATION

ROUTES OF ENTRY: None in its natural solid state. High concentrations of dust may cause irritation to the eyes. Prolonged skin contact with coated steel may cause skin irritation in sensitive individuals. Inhalation of metal particulate or elemental oxide fumes generated during welding, burning, grinding or machining may pose acute or chronic health effects. Respiratory system. MANGANESE & COPPER: Inhalation overexposure to manganese or copper (or zinc coated products) may cause metal fume fever characterized by fever and chills (i.e. flu-like symptoms) which appear 4-6 hours after exposure with no long-term effects. CHROMIUM: IARC lists certain hexavalent chromium compounds under its Group 1 category - confirmed human carcinogens and metallic chromium under its Group 3 category - not classifiable as to their carcinogenicity to humans. IRON: Inhalation overexposures may cause a benign pneumoconiosis (siderosis) with few or no symptoms. LEAD: Chronic exposures may cause lead poisoning that can affect the digestive system, nervous system, reproductive systems, muscles and joints. IARC lists lead and its inorganic compounds under its Group 2B category - possibly carcinogenic to humans. MANGANESE: Existing studies are inadequate to assess its carcinogenicity. Susceptible to Parkinsons disease, metal fume fever and kidney damage. NICKEL: IARC lists metallic nickel under its Group 2B category - possibly carcinogenic to humans. Nickel may cause skin sensitivity.

TARGET ORGANS: EFFECTS OF ACUTE EXPOSURE TO MATERIAL:

EFFECTS OF CHRONIC EXPOSURE TO MATERIAL:

NOTES: International Agency for Research on Cancer (IARC) - Summaries & Evaluations (2008).

4. FIRST AID MEASURES

EYES: SKIN: INHALATION: INGESTION: FLUSH EYES WITH PLENTY OF WATER FOR AT LEAST 15 MINUTES. SEEK MEDICAL ATTENTION IF EYE IRRITATION PERSISTS. MAINTAIN GOOD PERSONAL HYGIENE. WASH AFFECTED AREA WITH MILD SOAP AND WATER. SEEK MEDICAL ATTENTION IF SKIN IRRITATION PERSISTS. REMOVE TO FRESH AIR. CHECK FOR CLEAR AIRWAY, BREATHING AND PRESENCE OF PULSE. IF NECESSARY ADMINISTER CPR. CONSULT A PHYSICIAN IMMEDIATELY. RARE IN INDUSTRY. DUST MAY IRRITATE MOUTH AND GASTROINTESTINAL TRACT. IF INGESTED, SEEK MEDICAL ATTENTION PROMPTLY.

5. FIRE FIGHTING MEASURES

FLAMMABILITY CLASSIFICATION: MEANS OF EXTINCTION: FLASH POINT (C): UPPER FLAMMABLE LIMIT % BY VOL.: SENSITIVITY TO STATIC DISCHARGE: HAZARDOUS COMBUSTION PRODUCTS: UNUSUAL FIRE HAZARDS: SPECIAL FIRE FIGHTING: Non-flammable. Will not support combustion. Not applicable for solid product. Use extinguishers appropriate for surrounding materials. N/A N/A N/A AUTO-IGNITION TEMP (C): LOWER FLAMMABLE LIMIT % BY VOL.: EXPLOSION DATA (SENSITIVITY TO IMPACT): N/A N/A No

At temperatures above the melting point, fumes containing metal oxides and other alloying elements may be liberated. None for this product. Do not use water on molten metal. None for this product.

6. ACCIDENTAL RELEASE MEASURES

LEAK AND SPILL PROCEDURES: Not applicable to steel in solid state. For spills involving fine dusts, remove by vacuuming or wet sweeping methods to prevent spreading of dust. Avoid inhalation of dusts.

7. HANDLING AND STORAGE

HANDLING: STORAGE: Operations with the potential for generating high concentrations of airborne particulates should be evaluated and controlled as necessary. Practice good housekeeping. Avoid breathing metal fumes and/or dust. Store away from acids and incompatible materials.

8. EXPOSURE CONTROLS

ENGINEERING CONTROLS: (e.g. ventilation, enclosures, specify) General or local exhaust during welding or grinding operations.

PERSONAL PROTECTIVE EQUIPMENT: GLOVES (Specify): CLOTHING (Specify): RESPIRATOR (Specify): OTHER (Specify):

Dependent upon process being performed on material each operation must be addressed for suitable equipment. Leather - faced N/A EYES (Specify): FOOTWEAR (Specify): N/A N/A

If concentrations exceed established limits use NIOSH/MSHA approved particulate respirators (dust & fume or high efficiency dust fume) when grinding or welding. N/A

9. CHEMICAL AND PHYSICAL PROPERTIES

PHYSICAL STATE: BOILING POINT: MELTING POINT: Solid Not Applicable 1530C APPEARANCE: Silver Grey Metallic (Steel) ODOUR: VAPOUR DENSITY: pH: Not Applicable Not Applicable Not Applicable

VAPOUR PRESSURE: Not Applicable DENSITY: SOLUBILITY: Not Applicable 7.86 Not Applicable

EVAPORATION RATE: Not Applicable COEFFICIENT WATER/OIL DISTRIBUTION:

10. STABILITY AND REACTIVITY

CHEMICAL STABILITY: HAZARDOUS POLYMERIZATION: INCOMPATIBILITY TO OTHER SUBSTANCES: CONDITIONS OF REACTIVITY: HAZARDOUS DECOMPOSITION PRODUCTS: Yes. Steel products are stable under normal storage and handling conditions. Hazardous polymerization cannot occur. Yes Contact with mineral acids will release flammable hydrogen gas. N/A

11. TOXICOLOGICAL INFORMATION

IRRITANCY OF MATERIAL: LD 50 (of Material): MUTAGENCITY OF MATERIAL: REPRODUCTIVE EFFECTS: TERATOGENICITY OF MATERIAL: CARCINOGENICITY OF MATERIAL: See Section 3. Not established N/A N/A N/A CHROMIUM: IARC lists certain hexavalent chromium compounds under its Group 1 category - confirmed human carcinogens and metallic chromium under its Group 3 category - not classifiable as to their carcinogenicity to humans. NICKEL: IARC lists metallic nickel under its Group 2B category - possibly carcinogenic to humans. LEAD: IARC lists lead and its inorganic compounds under its Group 2B category - possibly carcinogenic to humans. N/A Iron containing welding fume has an exposure limit of 5 mg/m (ACGIH-TLVs 2008). Welding fume may also contain contaminants from fluxes or welding consumables. Prolonged skin contact may cause reddening and drying of skin or dermatitis in sensitive individuals due to nickel and/or chromium content in steel. SENSITIZATION OF MATERIAL; N/A LC 50 (of Material): Not established

SYNERGISTIC MATERIALS: NOTE:

12. ECOLOGICAL INFORMATION

ECOTOXICITY: No data available for the material as a whole. However, individual components of the material have been found to be toxic to the environment. Metal dusts may migrate into soil and groundwater and be ingested by wildlife. No data available. No data available.

ENVIRONMENTAL FATE: ENVIRONMENTAL DEGRADATION:

13. DISPOSAL INFORMATION

WASTE DISPOSAL: GENERAL INFORMATION: Steel scrap should be recycled whenever possible. Dispose of in accordance with applicable federal, provincial/state or local regulations.

14. TRANSPORTATION INFORMATION

GENERAL SHIPPING INFORMATION: SHIPPING NAME AND DESCRIPTION: UN NUMBER: CLASS: PACKING GROUP/RISK GROUP: Material not regulated for shipping. N/A N/A N/A N/A

TRANSPORT REGULATIONS: Canadian Transportation of Dangerous Goods Regulations (TDG) Feb. 2008. US Department of Transport (DOT) Hazardous Materials shipping information (Title 49 - Transportation Mar. 2008).

15. REGULATORY INFORMATION

REGULATORY INFORMATION: ADDITIONAL CANADIAN REGULATIONS: WHMIS CLASSIFICATION: DOMESTIC SUBSTANCES LIST: OTHER CANADIAN REGULATIONS: ADDITIONAL U.S. REGULATIONS: SARA: CHEMICAL NAME Chromium Copper Lead Manganese Nickel Phosphorus Vanadium SARA THRESHOLD PLANNING QUANTITY: TSCA INVENTORY STATUS: CERCLA REPORTABLE QUANTITY (RQ): CALIFORNIA (PROPOSITION 65):

The following listing of regulations relating to a Russel Metals Inc. product may not be complete and should not be solely relied upon for all regulatory compliance responsibilities. Class D2A/D2B: Materials Causing Other Toxic Effects. The components of this material are on the federal DSL Inventory. N/A The components of this material are subject to the reporting requirements of Sections 302, 304 and 313 of Title III of the Superfund Amendments and Reauthorization Act (SARA Oct. 2006), as follows: SARA 302 (40 CFR 355, Appendix A) No No No No No Yes No SARA 304 (40 CFR Table 302.4) No No No No No Yes No SARA 313 (40 CFR 372.65) Yes Yes Yes Yes Yes Yes No CERCLA Reportable Quantities 5,000 lbs 5,000 lbs 10 lbs None listed 100 lbs 1 lb. None listed

OTHER U.S. FEDERAL REGULATIONS: ADDITIONAL EUROPEAN UNION REGULATIONS: RoHS & WEEE: Lead (Pb): Chromium VI (Cr +6):

Threshold Planning Quantities for Phosphorous is 100 lb. (45.4 kg), per 40 CFR 370.20. The components of this material are listed on the Toxic Substances Control Act Inventory. RQs for Hazardous Substances in the Comprehensive Environmental Response, Compensation, and Liability Act are: Chromium = 5000 lb. (2270 kg); Copper = 5000 lb. (2270 kg); Nickel = 100 lb. (45 kg); Phosphorous 1 lb. (0.454 kg). The Chromium (VI) component of this material is known in the State of California to cause cancer. The Lead component of this material is known in the State of California to cause cancer, and/or birth defects (or other reproductive harm). The Nickel component of this material is known in the State of California to cause cancer. Lead is regulated under 29 CFR 1910.1025. This MSDS follows the European Union Directive Restriction on the Use of Certain Hazardous Substances (RoHS) in Electrical and Electronic Equipment (2002/95/EC) and the Waste Electrical and Electronic Equipment (WEEE) Directive (2002/96/EC). The leaded low alloy steel has a lead content of <0.35%, which is above the EU Directive limit of 0.1%. Lead is not intentionally added to other steel alloys however, it may exist in trace levels. Note, the EU Directive has a lead exemption limit of up to 0.35% as an alloying element in steel. The hexavalent oxidation state of chromium does not normally exist as part of a metal or alloy.

16. OTHER INFORMATION

HAZARD LABEL RATING SYSTEMS: NFPA CODE: H=0 F=0 R=0 HMIS CODE: H=1* F=0 R=0 PPE: See Section 8 * Denotes possible chronic hazard if airborne dusts or fumes are generated. PREPARED BY: TELEPHONE: DISCLAIMER: RUSSEL METALS INC. AND ENVIROTEST INC. 905-567-8500 DATE: NOTE: FEBRUARY 2009 CONTACT SUPPLIER FOR ADDITIONAL PRODUCT INFORMATION

THE INFORMATION CONTAINED HEREIN BASED ON DATA CONSIDERED ACCURATE. HOWEVER, NO WARRANTY IS EXPRESSED OR IMPLIED REGARDING THE ACCURACY OF THESE DATA OR THE RESULTS OBTAINED FROM THE USE THEREOF.

You might also like

- Hot-Dip Galvanizing Material Safety Data SheetDocument5 pagesHot-Dip Galvanizing Material Safety Data SheetyeezeeNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Carbon Steel and HSLA Plate MSDSDocument7 pagesCarbon Steel and HSLA Plate MSDSShawn ChiassonNo ratings yet

- MSDS Blades 6-12-01Document3 pagesMSDS Blades 6-12-01Wisnu Akhmad SNo ratings yet

- Material Safety Data Sheet: Welding Alloys USA IncDocument4 pagesMaterial Safety Data Sheet: Welding Alloys USA IncShenny AldanaNo ratings yet

- I. Product Identification: Material Safety Data SheetDocument5 pagesI. Product Identification: Material Safety Data SheetSteel BridgeNo ratings yet

- MSDS NiCrDocument2 pagesMSDS NiCrBety FajriaNo ratings yet

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- Msds Cobalt PDFDocument3 pagesMsds Cobalt PDFwangchao821No ratings yet

- Safely weld alloys with MSDSDocument2 pagesSafely weld alloys with MSDSElMacheteDelHuesoNo ratings yet

- La 71 MSDSDocument2 pagesLa 71 MSDSdeepak2803No ratings yet

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Document9 pagesMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshNo ratings yet

- 4 ESAB Solid Wires Nov 06Document84 pages4 ESAB Solid Wires Nov 06ananth84No ratings yet

- Brass Alloys Material Safety Data SheetDocument3 pagesBrass Alloys Material Safety Data SheetALEJANDRA FONTALVO STUDENTNo ratings yet

- Material Safety Data Sheet Thoriated TungstensDocument5 pagesMaterial Safety Data Sheet Thoriated TungstensveraNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- MSDS METAL CORED WIREDocument2 pagesMSDS METAL CORED WIREElMacheteDelHuesoNo ratings yet

- Esab Sds Can332-C Ercuni 70-30Document5 pagesEsab Sds Can332-C Ercuni 70-30jromero_rpgNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Mild Steel Solid Mig Wire MSDSDocument2 pagesMild Steel Solid Mig Wire MSDSsalcabesNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Zincalume Galv Truecore MSDSDocument6 pagesZincalume Galv Truecore MSDScuongdcNo ratings yet

- Flux Core Welding WireDocument3 pagesFlux Core Welding Wiremuhamad bukhari abu hassanNo ratings yet

- 360, 370, 380 Brazing Rod MG MSDS 6-09Document3 pages360, 370, 380 Brazing Rod MG MSDS 6-09orcbane27No ratings yet

- Welding, Cutting & Grinding-1Document131 pagesWelding, Cutting & Grinding-1like saddamNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- 51 EX Msds 9-07Document3 pages51 EX Msds 9-07Mohamed AdelNo ratings yet

- Material Safety Data Sheet: MSDS No. GW001 Carbon Steel Gas Welding RodsDocument7 pagesMaterial Safety Data Sheet: MSDS No. GW001 Carbon Steel Gas Welding Rodssajeev27No ratings yet

- Safety Data Sheet for OXWELD 200 CUTTING & SCARFING POWDERDocument4 pagesSafety Data Sheet for OXWELD 200 CUTTING & SCARFING POWDERmohamed AdelNo ratings yet

- Nickel Base Welding Wire MSDS Provides Health and Safety InformationDocument7 pagesNickel Base Welding Wire MSDS Provides Health and Safety InformationLawrence Lancy LoboNo ratings yet

- MSDS for US Forge E 6010 Covered ElectrodeDocument3 pagesMSDS for US Forge E 6010 Covered Electrodemohamed AdelNo ratings yet

- MsdsDocument3 pagesMsdsTobi MazzoccaNo ratings yet

- MSDS AlloysDocument15 pagesMSDS AlloysMaryam EradewiNo ratings yet

- MSDS Tungsten Electrode Safety DataDocument2 pagesMSDS Tungsten Electrode Safety DataSerkan ApayNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company IdentificationMohamed AdelNo ratings yet

- Material Safety Data Sheet: Gouging Carbon ElectrodesDocument5 pagesMaterial Safety Data Sheet: Gouging Carbon Electrodesranesh rajanNo ratings yet

- SDS Thermit PortionDocument8 pagesSDS Thermit PortionMahmoud MakladNo ratings yet

- 32 EX Msds 9-07Document3 pages32 EX Msds 9-07Mohamed AdelNo ratings yet

- Coreshield 8003 - ESABDocument6 pagesCoreshield 8003 - ESABBiju_PottayilNo ratings yet

- MsdsDocument5 pagesMsdsLisa NurhasanahNo ratings yet

- Material Safety Data Sheet: Silicomanganese SlagDocument8 pagesMaterial Safety Data Sheet: Silicomanganese SlagbamboNo ratings yet

- Boc Universal GasDocument5 pagesBoc Universal GasshaggerukNo ratings yet

- Aluminum Wires and Rods 1Document2 pagesAluminum Wires and Rods 1OteranmoralesNo ratings yet

- Avesta Inox EDocument2 pagesAvesta Inox EMiguel Angel Sanchez FernandezNo ratings yet

- Controlling Hazardous Fumes and Gases During WeldingDocument2 pagesControlling Hazardous Fumes and Gases During WeldingMohd MustafhaNo ratings yet

- Material Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Document2 pagesMaterial Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Rama Krishna Reddy DonthireddyNo ratings yet

- 1 TufTrak EC SMAW Msds 2-10Document3 pages1 TufTrak EC SMAW Msds 2-10mohamed AdelNo ratings yet

- 3bortho MSDS 201710Document4 pages3bortho MSDS 201710Olteanu CatalinNo ratings yet

- Safety Precaution in Welding: Ashok Kumar Engineer Sales-Chennai D&H Secheron Electrodes PVT - LTDDocument36 pagesSafety Precaution in Welding: Ashok Kumar Engineer Sales-Chennai D&H Secheron Electrodes PVT - LTDPrakash RajNo ratings yet

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Document1 pageMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayeNo ratings yet

- Safety Data Sheet for All-State AquaSafe No. 100 FluxDocument5 pagesSafety Data Sheet for All-State AquaSafe No. 100 Fluxmohamed AdelNo ratings yet

- Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - IdentificationluisarmandomayonietoNo ratings yet

- Msds Standard Weld Metal Domestic InternationalDocument8 pagesMsds Standard Weld Metal Domestic InternationalKate HowardNo ratings yet

- Pig Iron SDS PrimetradeDocument4 pagesPig Iron SDS PrimetradePravin PatilNo ratings yet

- Safety Info Sheet Stainless SteelDocument7 pagesSafety Info Sheet Stainless SteelKSBNo ratings yet

- Nic-L-Weld 99 59Document9 pagesNic-L-Weld 99 59CezaryCezasNo ratings yet

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Rev00 - Installation Manual Capacitive Sensor PDFDocument2 pagesRev00 - Installation Manual Capacitive Sensor PDFchinck83No ratings yet

- Manual: Electrical Control Unit ECU-10 For Flow®Document39 pagesManual: Electrical Control Unit ECU-10 For Flow®chinck83No ratings yet

- Merv Rating ChartDocument1 pageMerv Rating Chartgenas7265No ratings yet

- Fan Sound Sound Ratings Fe 300Document8 pagesFan Sound Sound Ratings Fe 300chinck83No ratings yet

- Galvanizing ProcessDocument5 pagesGalvanizing Processchinck83No ratings yet

- Fan Performance Characteristics of Centrifugal Fans Fe 2400Document4 pagesFan Performance Characteristics of Centrifugal Fans Fe 2400Mohammed AbdalrhmanNo ratings yet

- 06 BEAMSPLITTER Cleaning-Advice EnglishDocument1 page06 BEAMSPLITTER Cleaning-Advice Englishchinck83No ratings yet

- BFM Connecting SleeveDocument4 pagesBFM Connecting Sleevechinck83No ratings yet

- Transfer Matrix Method For Predicting Muffler Transmission LossDocument4 pagesTransfer Matrix Method For Predicting Muffler Transmission Lossconcord1103No ratings yet

- Measuring Yarns PDFDocument1 pageMeasuring Yarns PDFchinck83No ratings yet

- Baghouses and Filters For Particulate Matter Control: Course No: C05-010 Credit: 5 PDHDocument61 pagesBaghouses and Filters For Particulate Matter Control: Course No: C05-010 Credit: 5 PDHBudy Andika100% (2)

- Objective Properties PDFDocument2 pagesObjective Properties PDFchinck83No ratings yet

- Understanding Fan Pressures and TheoryDocument52 pagesUnderstanding Fan Pressures and Theoryabhishek_bhatia2k5No ratings yet

- AN Ngineering: Fan & Fan System VibrationDocument6 pagesAN Ngineering: Fan & Fan System VibrationAmit PanditaNo ratings yet

- Engineering Design Guideline - HX Rev 3Document24 pagesEngineering Design Guideline - HX Rev 3axle_ramNo ratings yet

- Engineering Design Guideline - HX Rev 3Document24 pagesEngineering Design Guideline - HX Rev 3axle_ramNo ratings yet

- Determining Size in Microscopic ImagesDocument5 pagesDetermining Size in Microscopic Imageschinck83No ratings yet

- High-Pressure, High-Density Centrifugal Compressor TechnologyDocument2 pagesHigh-Pressure, High-Density Centrifugal Compressor Technologychinck83No ratings yet

- Manufacturing Process FertilizerDocument14 pagesManufacturing Process FertilizermoentaseerNo ratings yet

- (Man) NTN BearingHandling 9103 (Y2012)Document7 pages(Man) NTN BearingHandling 9103 (Y2012)chinck83No ratings yet

- (Art) Pressure Vessel External Pressure - Good (2011) LDocument10 pages(Art) Pressure Vessel External Pressure - Good (2011) Lchinck83No ratings yet

- (Art) Shotpeener-Blast Cleaning With Steel Shot and Grit For Surface Preparation (2001)Document2 pages(Art) Shotpeener-Blast Cleaning With Steel Shot and Grit For Surface Preparation (2001)chinck83No ratings yet

- KXGT6301 Week 8Document38 pagesKXGT6301 Week 8chinck83No ratings yet

- (Art) What Design of Abrasive Blast Cleaning Machine Is Best For You (Y2012) GGDocument7 pages(Art) What Design of Abrasive Blast Cleaning Machine Is Best For You (Y2012) GGchinck83No ratings yet

- Crushing & Grinding Flow Sheet DINUDocument1 pageCrushing & Grinding Flow Sheet DINUchinck83No ratings yet

- Fuzzy Logic Application-Specific Processor For Traffic Control in ATM NetworkDocument6 pagesFuzzy Logic Application-Specific Processor For Traffic Control in ATM Networkchinck83No ratings yet

- QuickLime MSDS (2012)Document2 pagesQuickLime MSDS (2012)chinck83No ratings yet

- Gamma Scout Datasheet May2011Document1 pageGamma Scout Datasheet May2011chinck83No ratings yet

- Solvent Assisted Extraction of Oil From Moringa Oleifera Lam. Seeds PDFDocument7 pagesSolvent Assisted Extraction of Oil From Moringa Oleifera Lam. Seeds PDFjii100% (1)

- Welcome To The Largest Oil Company in The Philippines, Petron CorporationDocument28 pagesWelcome To The Largest Oil Company in The Philippines, Petron Corporationcarlo_sinlao86% (7)

- Power Crisis in The PhilippinesDocument4 pagesPower Crisis in The PhilippinesRenz Anthony EspinoNo ratings yet

- Oil Spill: Its Impact On Environment and Indian EconomyDocument12 pagesOil Spill: Its Impact On Environment and Indian Economyaaa19No ratings yet

- Pds - Epigard TL 543 Hs Finish (f15)Document2 pagesPds - Epigard TL 543 Hs Finish (f15)Sachin SinghalNo ratings yet

- MCQ For Class-Viii - Science - ADocument21 pagesMCQ For Class-Viii - Science - AmohilNo ratings yet

- Saudi Aramco Engineering Standard - Safety Identification and Safety ColorsDocument17 pagesSaudi Aramco Engineering Standard - Safety Identification and Safety ColorsRiaz Rashid67% (3)

- HIstory Matching Using MbalDocument6 pagesHIstory Matching Using MbalRima Apriani JamilahNo ratings yet

- Tankers: Mcquilling Partners, IncDocument13 pagesTankers: Mcquilling Partners, IncSumitNo ratings yet

- Zeta WareDocument4 pagesZeta WarerizuNo ratings yet

- Exercise 8Document2 pagesExercise 8NurfauziyahNo ratings yet

- GER 3620K (1) - Heavy Duty Gas Turbine O&M Consideration - ZulfiqarDocument60 pagesGER 3620K (1) - Heavy Duty Gas Turbine O&M Consideration - Zulfiqaramer_arauf100% (2)

- Ankleshwar GGSDocument10 pagesAnkleshwar GGSjai chaudhariNo ratings yet

- Opportunity Magazine - The BakkenDocument47 pagesOpportunity Magazine - The BakkenThe Brandon SunNo ratings yet

- Oil RefineringDocument4 pagesOil RefineringmritunjayNo ratings yet

- Capital Cost EstimatesDocument52 pagesCapital Cost EstimatesKrishna JaiswalNo ratings yet

- Bapco Terminal Info - GAC BahrainDocument3 pagesBapco Terminal Info - GAC Bahrainchris chazNo ratings yet

- Technical Manuel 60 KvaDocument70 pagesTechnical Manuel 60 KvaCarlos Martinez100% (3)

- Capitulo3 2Document4 pagesCapitulo3 2FabiolaNo ratings yet

- Namira Afralita Azahra - 2B - Jurnal KAODocument7 pagesNamira Afralita Azahra - 2B - Jurnal KAOLita NamiraNo ratings yet

- Fuchs Usa-Sugar BrochureDocument4 pagesFuchs Usa-Sugar BrochureOscar CabreraNo ratings yet

- Offshore Oil and Gas Environmental ImpactsDocument4 pagesOffshore Oil and Gas Environmental ImpactsTejasNo ratings yet

- Guidelines For Fuels and Lubes PurchasingDocument24 pagesGuidelines For Fuels and Lubes PurchasingFuchsbauNo ratings yet

- Fluid Flow in Oil ReservoirsDocument29 pagesFluid Flow in Oil ReservoirsRoy EtNo ratings yet

- Aromatheraphy 7-Lessons Introductory CourseDocument21 pagesAromatheraphy 7-Lessons Introductory CourseFelicianaLentiniNo ratings yet

- Paper Chromatography PDFDocument8 pagesPaper Chromatography PDFAmit GhadeNo ratings yet

- Prosper 2222Document39 pagesProsper 2222aliNo ratings yet

- Oil Treatment (Dehydration) PDFDocument66 pagesOil Treatment (Dehydration) PDFMahathir Che Ap86% (7)

- Team 13 (Assam-Arakan Basin) - 1Document20 pagesTeam 13 (Assam-Arakan Basin) - 1jai donNo ratings yet