Professional Documents

Culture Documents

Designing Building To Close The Materials Resource Loop Sassi

Uploaded by

mymalvernOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing Building To Close The Materials Resource Loop Sassi

Uploaded by

mymalvernCopyright:

Available Formats

Proceedings of the Institution of Civil Engineers Engineering Sustainability 157 September 2004 Issue ES3 Pages 163^171 Paper

13736 Received 04/03/2004 Accepted 18/07/2004 Keywords: environment/reclamation & renovation/recycling of materials Paola Sassi Lecturer in Architecture, Welsh School of Architecture, Cardiff, UK

Designing buildings to close the material resource loop

P. Sassi MSc, RIBA

Making use of recycled and reused building materials and products in the building industry is well understood as an effective way of reducing the environmental impacts associated with materials. To facilitate the recycling of materials, buildings should be designed as recyclable buildingsbuildings that enable the dismantling and the reuse or recycling of building elements and materials. However, currently buildings are seldom designed in this way. Environmental benefits have proved insufficient to encourage the production of recyclable buildings, and other benefits, in particular economic and social benefits, appear to be key in increasing the production of such buildings. This paper reports on a study of the social and economic benefits of recyclable buildings. The study investigates current building materials and components and their ability to be dismantled and reused or recycled. A questionnaire and interviews with building designers were used to investigate the potential and the barriers to the use of recyclable materials and components as well as identifying methods to overcome the barriers and promote the technology. The paper considers how legislation and the provision of information can act as drivers for change and also suggests that to maximise the environmental benefits, buildings should in fact be designed to create a closed-loop material cycle. It concludes by pointing to a few new examples of buildings designed for reuse and recycling, which may suggest a move towards recyclable building in the construction industry.

reconciling aspirations for social progress, economic development, protection of the environment and conservation of natural resources, and the integration of these into decision-making, so that progress in one does not adversely affect another.

Only by adopting a comprehensive approach to development and ensuring a high quality of life today as well as in the future can sustainability be achieved. Social and economic issues are fundamental needs, as described in the Brundtland Report, and are as important as the need for environmental health in respect of achieving sustainable development. The construction industry has a signicant role in contributing towards sustainable development. The Department of Trade and Industrys Sustainable Construction Brief suggests the following themes for action for the construction industry3 (a) (b) (c) (d ) (e) (f) ( g) (h) design for minimum waste lean construction and minimise waste minimise energy in construction and use do not pollute preserve and enhance biodiversity conserve water resources respect people and local environment monitor and report.

1. CONTEXT 1.1. Responding to sustainable development The concept of sustainable development is a far-reaching concept addressing issues of equity and quality of life. The most well-known denition of sustainable development, Development that meets the needs of the present without compromising the ability of future generations to meet their own needs, was put forward in the Brundtland Report, Our Common Future, published in 1987.1 This denition suggests that equity should apply globally and through time, linking activities today with outcomes affecting those living in the future. It also links the concept of needs to resource and environmental issues. Todays understanding of sustainable development reects years of slow progress which have highlighted the need for2

Most of these are directly or indirectly related to construction materials. In line with the aims of sustainable construction it is therefore essential to consider construction materials and the environmental impacts associated with their manufacture, use and disposal. Recycling and reuse are recognised as effective approaches contributing towards sustainable construction. Recycling and reuse help reduce waste and the environmental impacts of incineration and landlling.4 Using recycled and reclaimed materials helps minimise the use of virgin materials, reducing the pressure on primary resources and the impact of resourcing activities on natural environments and the plant and animal species contained within them.5 1.2. Encouraging recycling and reuse Specic approaches to construction, such as reducing waste through recycling and reuse, can be enforced through legislation, encouraged through legislation and nancial incentives, and supported through education. Sassi 163

Engineering Sustainability 157 Issue ES3 Designing buildings to accommodate recycling

In the past decade research into the eld of environmental material selection has been made available to construction practitioners in the form of material selection guides.68 These have contributed to raising environmental awareness among practitioners; however, the implementation of good environmental design practice has remained voluntary. In the UK, nancial incentives and legislation are in place to encourage recycling and waste minimisation. The UK Waste Strategy 2000 for England and Wales9 sets out a waste hierarchy which puts waste avoidance as the top priority for minimising waste, followed by reuse of waste, then recycling, downcycling (refer to denition in section 1.3), incineration to produce energy and nally landlling. The Landll Tax introduced in 1996 aims to reduce the amount of waste from all sectors and the use of landll as a disposal solution. In respect of the construction industry it helps encourage waste segregation and recycling and aims to reduce the 70 million tonnes of construction and demolition waste produced each year, of which 13 millions tonnes are delivered to site and discarded unused. Recycling is also supported by the UK Government initiative Waste and Resources Action Programme (WRAP), which promotes the development of products made with recycled materials. Despite the incentives and increasing awareness of the environmental benets of recycling, recycling rates are low. Some 75% of construction and demolition waste is recovered, but of that 41% is being disposed of in exempt sites and used for landll engineering and only 35% is being recycled into new uses.10 Research by Shefeld University concluded that the practical restrictions common to many demolition projects relating to time and money were the main cause for low recovery rates. Demolition work is usually undertaken in conjunction with new building work and is often forced to take place in a very limited period of time, making deconstruction impractical. Labour costs are higher than the cost of using new materials, even taking into account the additional taxes of landlling waste. Increased emphasis on health and safety has changed demolition practice, increasing the precautions required and consequently the cost of certain material recovery processes.11 The fact that most buildings today are not designed to facilitate dismantling and reusing or recycling means that the time required for dismantling is excessive. To increase the recovery rate, buildings have to be designed to facilitate their deconstruction and the reuse or recycling of the building components and materials. This would increase the percentage of material from a building which could be recycled; it would decrease the cost of deconstruction by increasing the speed of deconstruction; it could reduce the risks associated with health and safety; it would reduce disposal costs and could increase material resale revenue. However, designing buildings for dismantling and recycling requires taking account of the buildings demolition at the design stage, when other issues take priority.5 Environmental benets alone are not sufcient incentive for designers and clients and therefore to encourage the adoption of design approaches that enable the dismantling and recycling of buildings, it would seem necessary to identify benets other than environmental ones. 164 Engineering Sustainability 157 Issue ES3

1.3. Definitions For the purposes of this research the following denitions have been adopted. (a) Reuse involves putting to new use a previously used building component taken from a building or other source. The building component can be made of a single material (e.g. brick, slate tile, timber joist, precast concrete oors) or more than one material (e.g. door with ironmongery, composite wall panels, precast concrete foundations). It can require no processing (e.g. roof tile) or signicant processing (e.g. paint stripping and nishing doors). (b) Recycling involves reprocessing a material or component to form the same material or component (e.g. metal roong recycled to make new metal roong, rubber ooring recycled into rubber ooring or concrete recycled into aggregate for concrete). (c) Downcycling involves reprocessing a material into a lowergrade use material (e.g. concrete or brick into hardcore, timber into chipboard). (d ) Reusable describes a building component that can be reused (see above), but does not necessarily mean the component can be recycled (e.g. a steel beam can be reused and recycled, while a brick can be reused, but only downcycled). (e) Recyclable describes a building component that can be recycled (see above), but does not necessarily mean the component can be reused (e.g. plasterboard can be recycled, but not generally reused; metal ashings can be recycled, but when removed are too deformed to reuse). 2. RESEARCH OBJECTIVES AND METHODOLOGY 2.1. Research aims The aim of the research project outlined in this paper and funded by the RIBA Research Trust Award is to identify benets of using recyclable building materials and components, and in particular social and economic benets that would encourage the production of recyclable buildings. To achieve this aim, the research investigated the following (a) existing building materials and components and their ability to be dismantled and recycled or reused (b) the motivation and benets of using these (c) the barriers to the use of existing and potential recyclable materials and components and ways to overcome these barriers. The focus was put on identifying economic and social benets as these were seen as providing effective incentives to using recyclable materials and components. Economic benets would help offset the additional costs associated with the increased time requirements of dismantling buildings compared to demolishing them, and social benets may help employers, clients or landlords meet their corporate responsibilities towards their employees or tenants. The economic benets could be directed towards the development client, builder or user. They could include reduced building or installation time, reduced man-power requirements, reduced need for health and safety precautions, quicker mainSassi

Designing buildings to accommodate recycling

tenance, exibility, the ability to reuse elements and resell building elements and materials. Social benets were identied as direct and indirect benets to individuals as outlined in the UK Government strategy document A better quality of life, a strategy for sustainable development in the UK.12 The strategy identies social issues affecting basic human rights (e.g. housing, education, employment and tackling poverty), human health (affected by environmental and psychological issues) and the general standard of living (e.g. greater job opportunities, strengthening communities). Social benets might affect construction workers, building users and indirectly the general public. 2.2. Research methods The research adopted three main means of investigation (a) desk-top review of building products (b) a questionnaire to building designers (c) interviews with building designers. 2.2.1. The desk-top review. The desk-top review of building products aimed to establish whether the current building market offers the industry materials and building products that would enable buildings to be built so that they could be recycled at a later date. The review was undertaken through a systematic analysis of manufacturers product literature based on the National Building Specication structure. The products specications, and in particular their installation recommendations and material characteristics, were considered. The products were assessed using the criteria developed for a previous study which classied 60 construction materials and products according to their ability to be reused, recycled or downcycled.13 2.2.2. The questionnaire. The questionnaire issued to designers investigated the use of existing recyclable technologies and the issues affecting the specication of building products. The questionnaire was issued by email and, although relatively untested, was considered an appropriate method for collecting basic data and identifying subjects for the subsequent interviews. A pilot questionnaire, sent to 200 architects registered with the Association of Environmentally Conscious Building, received a response of 7%, while the main questionnaire sent to 2000 architects registered with the Royal Institute of British Architects was completed by only just over 2% of practices. The difference in response rates seems to suggest that the topic was viewed in purely environmental terms and this conclusion was supported by the fact that a number of questionnaires were returned uncompleted, noting the inability of the respondent to complete the questionnaire due to lack of environmental design experience. None the less, keeping in mind that most responses came from architects with an interest in environmental issues, the 51 completed questionnaires gave a good impression of a broad range of work undertaken by large and small practices. 2.2.3. Interviews. The questionnaire was used to identify a number of architectural practices undertaking a range of different work. Six in-depth interviews were undertaken, and

acknowledging the writers own experience of the healthcare sector, the following categories of building were considered in the study (a) (b) (c) (d ) (e) (f) private residential and social housing community and leisure buildings ofces retail healthcare buildings transport.

The interviews investigated the barriers to adopting recyclable technologies as well as the opportunities for using them. Ways to overcome the barriers were also considered. The interviews also provided information on general architectural and building practice issues as well as illustrating different perceptions of environmental design and the principle of designing for recycling. 3. FINDINGS AND ANAL YSIS 3.1. Are recyclable building technologies currently available? The review of building elements investigated the basic systems of construction as specied in the National Building Specication. The following sections were included in the study. Section Section Section Section Section Section Section Section Section Section Section Section Section DGroundworks EIn situ concrete FMasonry GStructural carcassing HCladding/covering JWaterproong KLining, sheathing, dry partitioning LWindow, doors, stairs NFurniture equipment MSurface nishes PBuilding fabric sundries R/SPiped supply and disposal systems QPaving, fencing, site furniture.

Each section includes different construction systems, for example Section J, Waterproong, includes (a) (b) (c) (d ) (e) (f) mastic asphalt tanking/dampproof membranes mastic asphalt roong/nishes liquid applied tanking/dampproof membranes exible sheet tanking/dampproof membranes built-up felt roof coverings single-layer polymeric roof covering.

Examples of each system were considered in terms of their ability for the materials and products to be reused and recycled. Systems that could be reused or recycled were noted. The review identied three different categories of building elements and materials; these are now discussed in turn. 3.1.1. Recyclable and reusable materials and components. The rst category includes a substantial number of building elements and materials that can be reused or recycled and are currently available to the construction industry. Recyclable Sassi 165

Engineering Sustainability 157 Issue ES3 Designing buildings to accommodate recycling

materials include metals, concrete recycled into aggregate and certain types of plastics. Reusable components range from bricks and cladding panels to precast foundations and timber structural elements. Materials have to be reasonably free of contamination to be recycled and building components have to remain intact to be reused and the appropriate building specication is crucial to achieve this. A framed building structure, be it concrete, steel or timber, can be detailed to enable its recycling or reuse: a timber structure can be reused; a steel structure can be reused or recycled; a concrete structure can be recycled or downcycled to hardcore. These are commonly used building systems which can be designed for reuse or recycling without changing the typical specication. Other such building elements include: masonry walls set in lime mortar, beam and block oors, suspended precast foundations, rainscreen cladding systems, roong tiles and sheeting systems. In certain cases it may be necessary to adopt a particular installation specication to ensure the system can be easily dismantled and recycled in future. An example of such as system is a single ply roong membrane that can be mechanically xed, allowing for its dismantling in future; or xed with adhesive, which precludes its dismantling. Other examples include precast concrete oors topped with a screed that would preclude their reuse unless separated from the screed with a separating layer, or bricks set in cement mortar rather than lime mortar. Despite the ability of these products to be recycled, only a few are recycled or reused in practice. 3.1.2. Materials and components with recycling and reuse potential. A second category of building elements and materials was highlighted as having potential for being made easy to dismantle and recycle through changes to the standard specication. An example of such a building element is acoustic ooring, the tongue and grooved edges of which are normally joined with adhesives, but which could be made easy

to dismantle by replacing the adhesive with a limited number of mechanically joined straps. This option is more timeconsuming to install, but the end-product performs as the original specication, as was tested on one of the writers built projects. Another example is rubber ooring which is generally xed with adhesive, but could be loose laid in domestic situations, allowing for its dismantling and recycling at a later date. 3.1.3. Materials and components with minimal or no reuse and recycling potential. The third category includes building elements and materials which are impossible to reuse or recycle. To this category belong such building elements as applied nishes, both internal and external, including: renders, plasters, tiling and applied roong nishes. Certain composite constructions, such as concrete walls cast in situ using insulation as sacricial shuttering, are also impossible to reuse and recycle owing to the contamination of the materials. A complete change of product design is required to make these building elements recyclable. 3.1.4. Reusable components falling short of expectation. The questionnaire issued to architects highlighted a further issue. Building designers were asked about the feasibility of reusing specic building systems that were designed for reuse. Some of these products appeared to fall short of expectations. Suspended ceilings, for example, were considered to be difcult, even impossible, to reuse owing to the likelihood of being damaged in the process of dismantling and reinstalling (Fig. 1). 3.1.5. Potential for reuse and recycling: conclusion. In conclusion, recyclable technologies are available for many construction products, but there is a need for: increasing awareness among designers of the appropriate recyclable specication;

Fig. 1. Building products and their ability to be reused effectivelyquestionnaire results

166

Engineering Sustainability 157 Issue ES3

Designing buildings to accommodate recycling

Sassi

and technical product design improvements for reusable products that are impractical to reuse and non-reusable or recyclable products.

including: loose-laid rubber ooring tiles, suspended ceilings and other demountable construction systems. The results suggest that design approaches such as designing to facilitate maintenance and to a slightly lesser degree designing for exibility were being adopted very often; however, the motivation for adopting these approaches came from the client, not the building designers. Where the designers showed more initiative was in respect of pushing for designing buildings for future dismantling and for element reuse. However, these approaches were seldom adopted (Figs 2 and 3). Comments from those designers who did design for recycling indicated that environmental and sustainability issues, such as reducing embodied energy, conserving resources and reducing

3.2. Motivations for using recyclable materials and components How could building speciers be motivated to use such recyclable materials and components? Through the questionnaire, building designers were asked how often they adopted specic design approaches, including designing for ease of maintenance and other approaches which would easily be achieved by designing buildings for dismantling. They were also questioned in respect of their experience and inuences in specifying a selection of recyclable materials and components

Fig. 2. Frequency of adoption of specific approaches to building designquestionnaire results

Fig. 3. Influences on the adoption of specific approaches to building designquestionnaire results

Engineering Sustainability 157 Issue ES3 Designing buildings to accommodate recycling

Sassi

167

40 35 30 Respondents: % 25 20 15 10 5 0 Cost Construction sequence Client requirement Performance Aesthetics

of recyclable materials and components: cost, awareness and technology. 3.4.1. Cost. The biggest barrier according to all interviewees was cost. Building construction is driven by cost, and recyclable materials and components do not provide sufcient cost benets. Disassembly is seen as an expensive luxury. Many clients also tend to shy away from new building methods which are perceived to be associated with a higher risk than traditional ones. 3.4.2. Awareness. The cost issues are aggravated by a lack of awareness among designers and clients of the nature and availability of recyclable materials and components, including those associated with no additional cost. Furthermore, the benets of recyclable materials and components are not generally recognised. 3.4.3. Technology. While many commonly used materials and products can be reused or recycled, for others this remains impossible. Some components designed for reuse, in practice perform less than satisfactorily. Building materials and components that present particular technological challenges include building nishes as well as the increasing number of composite materials. 4. DISCUSSION

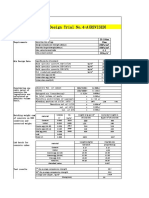

Fig. 4. Influences on the selection of building products questionnaire results

waste were the main drivers for adopting this approach. Recyclable designs were also seen to address the need to access building elements with different life expectancy at different times, the high cost of initial manufacture and exibility. While using recyclable materials and components still appears to be primarily seen as an environmental solution, some of the other advantages are now being recognised. In selecting and specifying building products, designers appeared less inuenced by clients and more by the product performance (Fig. 4). This would suggest that subject to recyclable materials and components performing adequately, designers should not present a barrier to their use. 3.3. Benefits of recyclable technologies Potential benets of using recyclable materials and components identied in the interviews and through the questionnaires are shown in Table 1. The benets have been classied into four sectors covering the life of a building from construction to demolition. Economic benets have been subdivided into issues concerning time, cost, marketing and public relations. Social benets have been subdivided into issues of health and safety, healthy environment and community. The design approaches have been taken from a selection of design-for-recycling guidance notes developed over the past ve years11,1416 and expanded to include issues highlighted in the interviews. 3.4. Barriers to the use of recyclable materials and components The research identied three main barriers to expanding the use 168 Engineering Sustainability 157 Issue ES3

4.1. Overcoming barriers To overcome the barriers to the use of recyclable materials and components, the research points to four main approaches. 4.1.1. Improving awareness among designers and clients. Perhaps the rst step required is to raise awareness among designers and clients of the environmental as well as the social and economic benets of the technology. Clients appeared to be key in setting design performance aims and would also be the ones to benet economically from buildings that are economic to run and maintain. With the aim of providing information on recyclable technologies, the research is setting up a website with case studies of buildings that have made use of recyclable technologies, as well as general information on the subject. To increase awareness among building designers a dissemination of the principles and benets of recyclable buildings through industry journals would alert the industry to the importance and possibilities of this topic. The construction industry institutes have regular publications, which reach all their members, that could be used for this rst step. The initial awareness-raising has to then be supported by a publication providing design and specication guidance. While containing similar information to the website, the formal act of publishing such guidance would raise the status of the issue. Funding for such a publication may be gained from Government-funded organisations involved in waste minimisation such as WRAP or the Landll Tax Credit Scheme. Clients, as mentioned earlier, have perhaps more impact on the fundamental aims of a building project and raising their awareness is crucial. Apart from making information available through umbrella organisations such as the British Council for Ofces or the Housing Corporation, there is a need to promote Sassi

Designing buildings to accommodate recycling

Design approach to enable dismantling and recycling Simplify fixing systems and enable removal by means of small hand tools and handheld electrical tools, avoiding specialist plant Provide realistic tolerances for assembly and disassembly Mechanical fixings in lieu of chemical or welded fixings

Construction phase Health and safety improved working conditions

Building use Time and cost faster, easier access for maintenance and upgrading

Building value

Building life end Time and cost demolition facilitated Community provision of employment for manual workers Time and costsoft strip facilitated

Health and safety improved working conditions

Healthless likelihood of offgassing during occupation Time and cost faster, easier access for maintenance and upgrading Costfewer building elements facilitates replacement Costdurable highquality products Time and costas above Time and costas above Healthy environment improvements in technology are easier to adopt, thus improving indoor environment Time and cost faster, easier access for maintenance and upgrading Community adaptable housing enables people to occupy the same building for longer, strengthening the community Costeasy reconfiguration of fitout

Marketingpotential for marketing as healthy building

Minimise number of parts fixings and types of fixings Design joints and components to withstand dismantling process Fully accessible service voids

Time and cost demolition facilitated

Public relations (PR)durable highquality products

Time and cost commissioning facilitated Time and cost prefabrication options reduce installation time

Time and cost demolition facilitated Community compliance with Waste Electrical and Electronic Equipment regulations

Dismantleable services

Marketingcontinual option for being at the forefront of technology

Independent building layers/allow for parallel disassembly

Time and cost construction of different elements could take place concurrently Time and cost commissioning facilitated

PRupgradable exterior and interior finishes for high profile Marketingflexible building to respond to market requirements

Time and cost dismantling of different elements could take place concurrently

Adaptable interior layouts and flexible fitouts

Avoid toxic materials

Health and safety improved working condition Health and safety improved working condition

Health and safety improved working condition Health and safety improved working condition PRresale facilitated

Make components sized and of a weight to suit the means of handling and provide means of handling and locating Provide as-built drawings and maintenance log including identification of points of disassembly, component and materials Solid (non-composite) materials and materials that require minimal reworking, and avoid non-recyclable materials such as composite materials and treatments and secondary finishes to materials that complicate reprocessing

Time and cost easier maintenance

Costrepair possible

PRoften highquality materials

Costresale value

Table 1. Benefits of recyclable technologies identified through the research questionnaire and interviews

Engineering Sustainability 157 Issue ES3 Designing buildings to accommodate recycling

Sassi

169

designing for recycling and reuse to be included in the construction industry benchmarking systems or legislation. 4.1.2. Quantifying economic benets. Knowing what are the economic benets over the lifetime of building could be crucial in terms of providing clients with incentives for adopting the technologies. The economic benets can be divided into three stages: the construction stage, the building-in-use stage and the building disposal stage. To monitor the economic advantages during the construction stage a monitoring system would have to be devised, which could be modelled on the Building Research Establishments SMARTWASTE system. The SMARTWASTE system, which can be licensed for a fee, provides a monitoring framework to measure the amount of waste produced on site. Clients using this system regularly can compare their costs associated with waste on different projects and set themselves targets for improvement. A similar system could be devised for monitoring time and cost of building activities, in particular commissioning. The same monitoring system could be linked to the health and safety records to monitor improvements in workers wellbeing relating to working conditions. Assessing the economic benets of the building in use would be feasible where facilities managers are employed and maintenance records are available. A comparison of maintenance costs of loose-t buildings and xed buildings would provide a basic economic comparison, whereby different building types, refurbishment patterns and other issues affecting maintenance would clearly have to be considered. The economic advantages at the disposal stage could be estimated by analysing a building specication and design. The assessment could use a system similar to the Demolition Recovery Index system used by EnviroCentre as part of their Demolition Protocol, which assesses the potential for material recovery from demolition.17 Having assessed the amount of material, current market prices would have to be applied to assess the economic impact of using recyclable materials. 4.1.3. Improving the practical aspects of recyclable designs. Using truly recyclable materials and components can contribute to reducing the cost of dismantling which at present is the biggest barrier to recycling buildings. There are two groups of materials and components that could be improved in terms of dismantling with relative ease. Section 3.1.2 identied materials and components with reuse and recycling potential: these are components that could be dismantled subject to changes to their typical installation. An example highlighted was that of rubber ooring typically glued, but that could be loose laid. Such components would need to be installed in a way that enables their dismantling, and then their performance monitored. This has been done informally for some components by the writer, but a structured analysis in conjunction with the material or component manufacturer would be required. The second group of components are those that are theoretically designed for dismantling and reuse, but seldom are, as identied in section 3.1.4. Further investigation would be 170 Engineering Sustainability 157 Issue ES3

necessary to establish where the failure in the system lies, before redesigning the component in conjunction with the manufacturer. 4.1.4. Legislation. Considering the progress made in respect of other environmental concerns such as global warming and ozone depletion, there seems to be a tendency within the building industry to only address issues when forced to do so by legislation. In the Netherlands, recycling rates of 90% of construction and demolition waste were achieved through the introduction of The Demolition and Construction Wastes Landll Ban in 1997 which prohibits the landlling of reusable or burnable construction and demolition waste.18 In the UK the Landll Tax is the main legislative tool used to support an increase in recycling and indirectly the principle of designing for recycling. Current levels of tax are thought unlikely to substantially reduce the construction and demolition waste; however, higher levels of taxation may have more impact. Further research could be benecial in establishing what degree of impact the Landll Tax and the Aggregate Tax could have in promoting recyclable designs. In addition to waste minimisation related legislation, there might be scope for linking designing for recycling to the Construction (Design and Management) Regulations, which address health and safety issues. Equally, the Green Paper on corporate social responsibility issued by the European Commission in July 200119 may help to promote the social benets of improved working conditions provided by certain forms of recyclable designs. 4.2. Setting appropriate aims Throughout the research, mention was made of the possibility of reuse or recycling. The UK Waste Strategy 2000 for England and Wales9 supports a waste hierarchy that puts reuse at the top of the waste minimisation action plan, followed by recycling. The main aim of the strategy is to reduce waste going to landll and being incinerated, and both reuse and recycling contribute towards this aim. However, while materials and products that can be recycled can potentially be kept out of the waste stream indenitely, being able to reuse a material or product may only prolong its life before entering the waste stream. Examples of products that can be reused, but not recycled, and which will therefore eventually enter the waste stream, include veneered or melamine-faced particleboards, metal composite panels with extruded insulation, composite acoustic matting, PVC-nished windows and structural insulated timber roof panels. With such building components, the environmental advantages of reuse will depend on the life of the component. For structural elements, reuse may lengthen the life of the components, keeping them away from the waste stream for centuries. For nishing elements with a life expectation of as low as ve years for internal nishes and 25 years for external nishes,7 reuse may only provide a nominal environmental advantage. Materials and products that can be recycled again and again enter a closed-loop cycle, which by denition continues indenitely. Materials that biodegrade can also be considered to be part of a closed-loop cycle, being created in nature and degrading into natural material. For the purpose of minimising waste going to landll or being incinerated, the ideal is to use Sassi

Designing buildings to accommodate recycling

materials and components that can be reused and recycled rather than just one or the other. 5. CONCLUSIONS Current environmental thinking considers waste production a more serious issue than resource depletion.20 The environment is more likely to suffer from its inability to absorb the waste produced by society rather than a lack of resources. Therefore emphasis has to be placed on creating closed-loop material cycles which would reduce waste in the long term as well as in the short term. At the moment, closed-loop material buildings are virtually non-existent. A building that nearly achieves the closed-loop status is the Glencoe National Trust Visitor Centre in Scotland by Gaia Architects. The building has a concrete foundation, timber structure entirely screwed, and most nishes, including an innovative timber oor, are removable and either natural or recyclable. For aesthetic reasons some external and internal areas are rendered and plastered respectively, reducing the recyclability of these areas. Two other schemes, currently being designed by PCKO and AHMM architects, are for prefabricated and relocatable housing. The houses are designed to be taken apart and re-erected on new sites after some years on one site. Similarly to the Glencoe National Trust Visitor Centre, some areas will probably not be recyclable and therefore miss the target of achieving a closed-loop material cycle, but nevertheless present a signicant step towards closed-loop buildings. The existence of one or two examples, however, reects a new interest in the construction industry for designing for recycling and closed-loop material cycles. The current environment of increased concern for sustainable issues, including environmental and social issues, should help support the use of recyclable materials and components. Subject to technological improvements, and promoted through the economic and social benets identied, designing closed-loop buildings could become accepted as a realistic approach to design. REFERENCES 1. TOMLINSON C. The Brundtland Report: Our Common Future. Oxford University Press, Oxford, 1987. 2. DEPARTMENT FOR THE ENVIRONMENT, FOOD AND RURAL AFFAIRS. Sustainable Indicators in Your Pocket. DEFRA, London, 2004. 3. SUSTAINABLE CONSTRUCTION TEAM. Sustainable Construction Brief. Department for Trade and Industry, London, 2004. 4. Available at: http://www.greenpeace.org/international_en/ campaigns/intro?campaign_id=3989; Accessed 26 April 2004. 5. COVENTRY S., WOOLVERIDGE C. and HILLIER S. The Reclaimed and Recycled Construction Materials Handbook. CIRIA, London, 1999, CIRIA C513. 6. ANINK D., BOONSTRA C. and MAK J. Handbook of Sustainable 7. 8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

Building: an Environmental Preference Method for Selection of Materials for Use in Construction and Refurbishment. James and James, London, 1996. ANDERSON J., SHIERS D. and SINCLAIR M. The Green Guide to Specication. Blackwell Science, Oxford, 2002. WOOLLEY T., KIMMINS S. and HARRISON R. Green Building Handbook: a Guide to Building Products and their Impact on the Environment. E&FN Spon, London, 1997. DEPARTMENT OF THE ENVIRONMENT, TRANSPORT AND THE REGIONS. Waste Strategy 2000 for England and Wales Part 1 and 2. HMSO, London, 2000. HOBBS G. and HURLEY J. Deconstruction and reuse of construction materials. Deconstruction and materials reuse: technology. Economics and policy CIB 266. Proceedings of the CIB Task Group 39Deconstruction Meeting, New Zealand, April 2001. FLETCHER S., POPOVIC O. and PLANK R. Designing for future reuse and recycling. Proceedings of a BRE Conference, DeconstructionClosing the Loop, Watford, May 2000. SUSTAINABLE DEVELOPMENT UNIT. A Better Quality of Life, a Strategy for Sustainable Development in the UK. DEFRA, London, 1999. SASSI P. Study of current building methods that enable the dismantling of building structures and their classications according to their ability to be reused, recycled or downcycled. Proceedings of the Sustainable Building 2002 Conference, Oslo, 2002. CROWTHER P. Developing guidelines for designing for deconstruction. Proceedings of DeconstructionClosing the Loop, Building Research Establishment, Watford, May 2000. THORMARK C. Recycling Potential and Design for Disassembly in Buildings. Lund Institute of Technology, 2001. SASSI P. and THOMPSON M. Summary of a study on the potential of recycling in the building industry and the development of an indexing system to assess the suitability of materials for recycling and the benets from recycling. Proceedings of Building a New Century, 5th Conference on Solar Architecture and Design, Bonn, 1998. MANZIES B. Sustainable design and construction: the demolition protocol, Proceedings of Recycling by Design and Waste Minimisation by Specication, Green Register Seminar, London, 2004. KOWALCZYK T., VAN BILK K., REACTANCE P. and TO DORSTHORST B. State of the art deconstruction in the Netherlands. In Overview of Deconstruction in Selected Countries, CIB Report 252, Florida, 2000. EUROPEAN COMMISSION. Green PaperPromoting a European Framework for Corporate Responsibility. EC, Brussels, July 2001. EDWARDS B. and DUPLESSIS C. Snakes in Utopia, a brief history of sustainability. Architectural Design, 2001, 71, No. 4, July.

Please email, fax or post your discussion contributions to the secretary by 1 March 2005: email: kathleen.hollow@ice.org.uk; fax: +44 (0)20 7665 2294; or post to Kathleen Hollow, Journals Department, Institution of Civil Engineers, 1^7 Great George Street, London SW1P 3AA.

Engineering Sustainability 157 Issue ES3 Designing buildings to accommodate recycling

Sassi

171

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- MS For Chamber ConstructionDocument17 pagesMS For Chamber ConstructionWilliam C. Pasamonte100% (1)

- Ielts Liz - Writing Task 1 PDFDocument48 pagesIelts Liz - Writing Task 1 PDFchung hieu100% (1)

- 19.building Movement Control During Construction - Rev.01-17august 2009Document49 pages19.building Movement Control During Construction - Rev.01-17august 2009Syerifaizal Hj. Mustapha100% (1)

- Kautzky: ReinholdDocument1 pageKautzky: ReinholdmymalvernNo ratings yet

- R.C. Foundation Design for Oil Storage TankDocument17 pagesR.C. Foundation Design for Oil Storage Tanknerioalfonso100% (2)

- BS 1722-2 2006 - Specification For Strained Wire and Wire Mesh Netting FencesDocument54 pagesBS 1722-2 2006 - Specification For Strained Wire and Wire Mesh Netting FencesAnoyNo ratings yet

- Project Report RsDocument38 pagesProject Report RsVaishnavi PandeyNo ratings yet

- CONSTRUCTION TECHNOLOGY IV DEMOLITIONDocument25 pagesCONSTRUCTION TECHNOLOGY IV DEMOLITIONusler4u100% (1)

- 01-8 QCS 2014Document12 pages01-8 QCS 2014Raja Ahmed Hassan100% (1)

- Fyfe Co Brochure 5-5-09Document20 pagesFyfe Co Brochure 5-5-09PE Eng100% (1)

- Basic Notes and Interview QuestionsDocument50 pagesBasic Notes and Interview QuestionsRaheel AliNo ratings yet

- Peter Smithson Conversations With StudentsDocument102 pagesPeter Smithson Conversations With Studentsmymalvern100% (2)

- Quality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFDocument74 pagesQuality & Composition of Cement Clinker - INFINITY FOR CEMENT EQUIPMENT PDFSiddharth Singh100% (1)

- Specifications For Waterproofing WorksDocument16 pagesSpecifications For Waterproofing WorkssplashierprinceNo ratings yet

- Eduardo Souto Moura - Estadio Do BragaDocument4 pagesEduardo Souto Moura - Estadio Do BragaarkitektusNo ratings yet

- (Architecture Ebook) Modern Bamboo ArchitectureDocument13 pages(Architecture Ebook) Modern Bamboo ArchitectureIna TothNo ratings yet

- Wood ConnectionsDocument289 pagesWood ConnectionsmymalvernNo ratings yet

- Alt 2 LayoutDocument3 pagesAlt 2 LayoutmymalvernNo ratings yet

- Kim Carleton Graves, Masha Zager - Dining Table (2002, Taunton Press) PDFDocument17 pagesKim Carleton Graves, Masha Zager - Dining Table (2002, Taunton Press) PDFmymalvernNo ratings yet

- OASE 90 - 44 WanderingDocument5 pagesOASE 90 - 44 WanderingmymalvernNo ratings yet

- About The Authors: Christopher Schwarz Is The Pub-Steve Shanesy Was One of The FoundDocument1 pageAbout The Authors: Christopher Schwarz Is The Pub-Steve Shanesy Was One of The FoundmymalvernNo ratings yet

- Pages From Pwwcaf14 PDFDocument1 pagePages From Pwwcaf14 PDFmymalvernNo ratings yet

- Le Corbusier House 03Document1 pageLe Corbusier House 03mymalvernNo ratings yet

- Le Corbusier House 01Document1 pageLe Corbusier House 01mymalvernNo ratings yet

- Read This Important Safety Notice: Metric Conversion ChartDocument1 pageRead This Important Safety Notice: Metric Conversion ChartmymalvernNo ratings yet

- Read This Important Safety Notice: Metric Conversion ChartDocument1 pageRead This Important Safety Notice: Metric Conversion ChartmymalvernNo ratings yet

- WSF 750 OriginalDocument10 pagesWSF 750 OriginalUbaid NazirNo ratings yet

- About The Authors: Christopher Schwarz Is The Pub-Steve Shanesy Was One of The FoundDocument1 pageAbout The Authors: Christopher Schwarz Is The Pub-Steve Shanesy Was One of The FoundmymalvernNo ratings yet

- Ria . +MMVDocument1 pageRia . +MMVmymalvernNo ratings yet

- Pages From Pwwcaf14Document1 pagePages From Pwwcaf14mymalvernNo ratings yet

- Colorado: THE RockiesDocument1 pageColorado: THE RockiesmymalvernNo ratings yet

- OASE 90 - 10 An Architecture Close To Its Inhabitants PDFDocument5 pagesOASE 90 - 10 An Architecture Close To Its Inhabitants PDFmymalvernNo ratings yet

- OASE 90 - 16 Half An Hour of Silence PDFDocument4 pagesOASE 90 - 16 Half An Hour of Silence PDFmymalvernNo ratings yet

- OASE 90 - 14 Intentions Inventions PDFDocument3 pagesOASE 90 - 14 Intentions Inventions PDFmymalvernNo ratings yet

- Navy Wood ProtectionDocument226 pagesNavy Wood ProtectionPlainNormalGuy2No ratings yet

- Architectural Programming and Predesign ManagerDocument1 pageArchitectural Programming and Predesign ManagerDoodo SukmanataNo ratings yet

- OASE 90 - 19 Social Space and Structuralism PDFDocument5 pagesOASE 90 - 19 Social Space and Structuralism PDFmymalvernNo ratings yet

- The essence of architectureDocument5 pagesThe essence of architecturemymalvernNo ratings yet

- OASE 90 - 23 Speaking Through The Silence of Perceptual PhenomenaDocument4 pagesOASE 90 - 23 Speaking Through The Silence of Perceptual PhenomenamymalvernNo ratings yet

- OASE 90 - 28 Friendly ArchitectureDocument4 pagesOASE 90 - 28 Friendly ArchitecturemymalvernNo ratings yet

- OASE 90 - 38 Richards S Alternative PDFDocument5 pagesOASE 90 - 38 Richards S Alternative PDFmymalvernNo ratings yet

- OASE 90 - 31 Huh Wow Wow Huh PDFDocument6 pagesOASE 90 - 31 Huh Wow Wow Huh PDFmymalvernNo ratings yet

- OASE 90 - 35 Does Good Architecture Deal With The TruthDocument6 pagesOASE 90 - 35 Does Good Architecture Deal With The TruthmymalvernNo ratings yet

- Effect of Rice Husk Ash and Sugarcane Bagasse Ash On Mechanical Properties and Sorptivity of ConcreteDocument38 pagesEffect of Rice Husk Ash and Sugarcane Bagasse Ash On Mechanical Properties and Sorptivity of ConcreteHidayat UllahNo ratings yet

- CVX7640 28Document18 pagesCVX7640 28malingauomNo ratings yet

- Proposed Construction Warehouse at Wadgaon Sheri, PuneDocument16 pagesProposed Construction Warehouse at Wadgaon Sheri, Punesri projectssNo ratings yet

- Iscussion Orum: Thermal Analysis of Draft Tube and Spiral Case Mass ConcreteDocument1 pageIscussion Orum: Thermal Analysis of Draft Tube and Spiral Case Mass ConcreteSiamakSabaNo ratings yet

- 1 s2.0 S0141029620342395 MainDocument14 pages1 s2.0 S0141029620342395 MainKim HyeonJinNo ratings yet

- FoC Anchor Toolkit Global 20201105 00FullVersionDocument166 pagesFoC Anchor Toolkit Global 20201105 00FullVersiontuancapecc3No ratings yet

- How To Calculate Quantities of Cement, Sand and Aggregate For Nominal Concrete Mix (1 - 2 - 4) - HapphoDocument20 pagesHow To Calculate Quantities of Cement, Sand and Aggregate For Nominal Concrete Mix (1 - 2 - 4) - HapphoJamohl Supremo AlexanderNo ratings yet

- MPR Format Jan 2022Document88 pagesMPR Format Jan 2022meerut nazibabad projectNo ratings yet

- Eco-friendly construction materials for green buildingsDocument8 pagesEco-friendly construction materials for green buildingsVeeranagouda N KudariNo ratings yet

- 2019-Value Engineering Using Load-Cell Test Data of Barrette Foundations - A Case StudyDocument30 pages2019-Value Engineering Using Load-Cell Test Data of Barrette Foundations - A Case StudyDavid Aponte RojasNo ratings yet

- TM - MasterSuna - SBS - 8000 ENDocument3 pagesTM - MasterSuna - SBS - 8000 ENVyankat ChateNo ratings yet

- Nuvoco Vistas IPO AnalysisDocument5 pagesNuvoco Vistas IPO AnalysisDaksh MaruNo ratings yet

- Hoover Dam (USA) : Problem Technology/ EquipmentDocument8 pagesHoover Dam (USA) : Problem Technology/ EquipmentEdence PuahNo ratings yet

- Lab Concrete Mix Design C15-C40Document19 pagesLab Concrete Mix Design C15-C40Soundar Pachiappan100% (1)

- Design of Android Application For Curing and Irrigation PPT FinalDocument19 pagesDesign of Android Application For Curing and Irrigation PPT FinalBhimavarapu HarikaNo ratings yet

- NDT - RHDocument2 pagesNDT - RHRajesh KumarNo ratings yet

- Analysis and Design of One-Way SlabsDocument6 pagesAnalysis and Design of One-Way SlabsricardoNo ratings yet