Professional Documents

Culture Documents

H-652 Ecc Specification For Piping Design-Rev3

Uploaded by

vermaakash22Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H-652 Ecc Specification For Piping Design-Rev3

Uploaded by

vermaakash22Copyright:

Available Formats

ABB Lummus Global B.V.

SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

THIS DOCUMENT/DRAWING IS THE PROPERTY OF ABB LUMMUS GLOBAL B.V. INCLUDING ALL PATENTED AND PATENTABLE FEATURES AND/OR CONFIDENTIAL INFORMATION AND ITS USE IS CONDITIONED UPON THE USER S AGREEMENT NOT TO REPRODUCE THE DOCUMENT/DRAWING, IN WHOLE OR IN PART, NOR THE MATERIAL DESCRIBED THEREON, NOR TO USE THE DOCUMENT/DRAWING FOR ANY PURPOSE OTHER THAN AS SPECIFICALLY PERMITTED IN WRITING BY ABB LUMMUS GLOBAL B.V.

Specification For:

PIPING DESIGN

IDOCS 13.3.2

2.00 1.00 3.00

REV.

2006-10-18 2006-08-11 2007-01-15

DATE

Revised A.F.D. UPDATED A.F.D. REVISED A.F.D.

DESCRIPTION

JJVA JBRO JJVA

PREPARED

JBRO JBRO JBRO

CHECKED

ADB ADB ADB

APPROVED

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 1 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

INDEX SECTION PAGE

1. 1.1 1.2 1.3 1.4 2. 2.1 2.2 2.3 3. 3.1 3.2 3.3 3.4 3.5 3.6 4. 4.1 4.2 4.3 4.4 4.5

GENERAL INTRODUCTION RELATED SPECIFICATIONS PLOTPLAN REQUIREMENTS UNITS PIPING SYSTEMS LAYOUT GENERAL UTILITY SERVICES INSTRUMENT RELATED PIPING PIPING COMPONENTS JOINTING FLANGES SPECTACLE BLINDS AND SPADES DRAINS AND VENTS VALVES INSULATION PIPING AND LAYOUT CRITERIA EQUIPMENT GENERAL PUMPS COMPRESSORS STEAM TURBINES HEAT EXCHANGERS

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

5 5 5 5 5 5 5 6 6 7 7 7 8 8 8 9 9 9 9 10 10 10

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

Page 2 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

INDEX (Contd) SECTION 4.6 4.7 4.8 5. 5.1 5.2 5.3 5.4 6. 6.1 6.2 6.3 6.4 7. 7.1 7.2 7.3 8. 8.1 8.2 8.3 8.4 AIR-COOLERS FURNACES AND HOT OIL PIPING PRESSURE VESSELS AND COLUMNS CLEARANCES ESCAPE WAYS VERTICAL CLEARANCES HORIZONTAL CLEARANCES OTHER CLEARANCES ACCESSIBILITY FROM GRADE OR PLATFORM: BY A PERMANENT LADDER: BY PORTABLE DEVICES OR SCAFFOLDING NOTES PIPING DRAWINGS SCOPE OF PIPING DESIGN DRAWINGS ISOMETRICS PIPING PLAN DRAWINGS ERGONOMIC ASPECTS OF VALVES GENERAL CATEGORY 1: CRITICAL VALVES CATEGORY 2: NON-CRITICAL VALVES CATEGORY 3: NON-OPERATIONAL VALVES PAGE 11 11 11 12 12 12 12 13 13 13 13 14 14 15 15 15 15 16 16 16 16 16

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 3 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

INDEX (Contd) SECTION ATTACHMENTS I ERGONOMIC VALVE POSITIONING 17 PAGE

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 4 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

1. 1.1

GENERAL INTRODUCTION This specification describes the minimum requirements for design and layout of all onshore process and utility systems for Lummus Based Projects. Where this specification is in contradiction with details on a PEFS, the PEFS shall prevail.

1.2

RELATED SPECIFICATIONS Shop and Field Fabrication of Piping Piping Materials Piping Standard Drawings, H-653 Protective Steam Heating of Piping System E-00000-PI-7737-0008 E-00000-PI-7706-0002 E-00000-PI-7737-0014 E-00000-PI-7737-0009

1.3

PLOTPLAN REQUIREMENTS Plotplan requirements and equipment spacing will be conform the Refinery Safety Code, supplemented with the GE GAP guidelines, and the API and NFPA codes. The latest editions of these documents shall be used, unless otherwise indicated.

1.4

UNITS Unless otherwise specified, metric, Celsius and kilogram units shall be applied, but nominal size of piping shall be in accordance with inch system (NPS).

2. 2.1

PIPING SYSTEMS LAYOUT GENERAL Piping shall be routed such that the optimum piping layout is achieved in terms of process requirements, flexibility to allow for thermal expansion and contraction, economics, ergonomics, operation, inspection, and maintenance. Having considered these factors, the number of flanges, fittings, valves and welds shall be minimized. All lines within battery limits should be run side by side on elevated pipe racks. Crossing main pipe racks shall be at different levels to facilitate changing direction and crossing pipelines. All piping entering and leaving a plot area or processing unit shall be grouped together as far as practicable. All piping shall be anchored at the plot limit and shall be agreed with client or partner contractors. Piping expansion loops in pipe racks and tracks shall be raised in elevation to stay clear of adjacent piping, with the exception of flare headers and no pocket lines. Normal pipe size in pipe tracks and main pipe bridges shall not be less than 1, based on a supporting steel span of 4 meter.

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 5 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

Where block valves are used in branch lines at top of headers, they shall preferably be located in the horizontal run so that the lines will drain both ways. For the following services, the branch lines shall be taken from the top of the header: flare, steam, plant air, instrument air, fuel gas, nitrogen, water lines 1 and smaller; Also vapor lines with possible liquid entrainment shall be taken from top of the main header. Small bore connections (1 and smaller) on piping subject to vibration, either induced by Process or at rotating equipment, shall be reinforced with gussets. Flare Main headers shall run sloping 1:500 to the flare knockout drums, and Sub headers shall be 1:200, unless otherwise noted on the flow diagrams. Slope requirements for other lines shall be noted on the PEFS and be1:500, unless otherwise indicated. Flushing connections shall be as close as possible to the block valves in process lines. The flushing outlet in horizontal lines shall be at the bottom. Sample connections should preferably be taken from a vertical line; Where this is not possible they should be taken from the side of a horizontal line. Piping through walls or floors shall run through a sleeve or hole of sufficient size to facilitate installation of prefabricated piping and allow for insulation (if applicable). Sealing shall be applied as appropriate. 2.2 UTILITY SERVICES Where required for maintenance or cleaning purpose, utility stations shall be provided at grade and at working levels for elevated equipment. The utility stations at grade shall be located advantageously in the units so that the required areas can be covered with a 15 m radius. All steam lines (except superheated steam), shall be designed to avoid formation of condensate and shall be provided with adequate drip legs and steam traps at the lowest points. Steam lines from different systems shall not collect in the same steam trap, but each system shall have its own trap. Steam traps shall be accessible for maintenance. 2.3 INSTRUMENT RELATED PIPING When a safety valve discharge is to atmosphere, the exhaust pipe shall terminate at least 2.5 m above any service platform located within a radius of 7.5 m. A 10 mm weep hole will be provided for drainage at the low point of the tail pipe. The end of the vent pipe shall be cut off straight and provided with a bird screen. Safety valves discharging to the flare header shall be located at a higher elevation than the flare header. The lead and tail pipes shall be self-draining or sloping 1:500. At the inlet and outlet of safety valves, the valve stem will always oriented horizontally.

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 6 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

Lines smaller than 3 in which thermowell connections are required, shall be increased locally to 3. The minimum straight length of the increased pipe diameter shall be 300 mm. Level gauges shall be placed in such a position that the instrument is readable from ground level, platform or permanent ladder. When the visible level range in a glass is continued in a second (staggered) level glass, both instruments shall be readable from the same location. In control valve installation, sufficient clearance for actuator accessibility and/or removal shall be provided.

3. 3.1

PIPING COMPONENTS JOINTING The minimum distance between weld-edges shall be 50 mm for details, see par 11.3 of H-652 The distance between fillet and pressure retaining butt joints may be reduced to 6 mm. This is applicable for saddles, dummy legs, shoes, brackets and the like interfering pressure retaining but joints. Longitudinal welds seams shall be welded preferably within the range of 30 and 110 respectively from the 12:00 position to avoid interference with the pipe supports and nozzles. For carbon steel and austenitic stainless steel butt welds and reinforcements shall be separated from full penetration welds 30 mm or one and a half (1.5) times the joint thickness, whichever is greater. This requirement is intended specifically for nozzles and longitudinal or circumferential welds. In general, joints in lined piping systems shall be flanged. Exceptions are made for lines which can be lined partly or completely after erection, and cement-lined piping. Pipe spools for hot-dip galvanizing shall be with flanged ends, and have maximum dimensions of 12m x 3m x 1m. These dimensions are to be confirmed by sub-contracting.

3.2

FLANGES The use of flanges shall be kept to a minimum and shall only be installed for: Pipe specification requirements. All connections to equipment (except stated otherwise). Pipe components like control valves and valves as specified in the particular piping classes. To facilitate assembling and dismantling of lines (for maintenance purposes at equipment). Where extra specified on PEFSs. If raised face flanges are to be connected to flat-face flanges (cast iron, GRE or special flanges on equipment), a special flat-face flange shall be specified and indicated on the isometric.

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 7 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

Flanges connected to equipment shall have the same rating as the equipment flange. Bolt holes of all flanges shall straddle the vertical centerlines for horizontal piping and shall straddle the plant north-south line for vertical piping. Exceptions may occur when connecting pipe flanges to equipment nozzles. In this case, a detail of bolt holes straddling a certain centerline of that flange shall be stated on the piping detail drawing or isometric. 3.3 SPECTACLE BLINDS AND SPADES Spectacle blinds and spades up to a weight of 25 kg can be installed in horizontal and vertical lines. Spectacle blinds and spades with a weight over 25 kg shall only be installed in horizontal lines and shall be accessible by mobile crane or be provided with a hoisting device. 3.4 DRAINS AND VENTS Hydrostatic test vents and drains shall be provided, at all high and low points in piping. Vents and drains for operation and maintenance are needed for taking systems out of operation within the limits of the Shell SHE policy and the local governmental permits. At these moment in time these rules dictates that people should not be contacted with products and there should not be any environmental foreign materials wasted to the air or the sewer. The filing or emptying of systems should be as much as possible be done through closed systems via hoses etc. . This means that on lines containing liquids with environmental foreign materials there should be a valved low point drain (blinded), which can be hooked up with a hose to a sewer system, and a valved high point vent installed. Lines containing gasses, without condensibles, and lines smaller than 3 can be purged with nitrogen and do not need valved low point drains but do need a valved purge connection at the block valves. Waterlines, airlines, nitrogenlines etc. do not need valved low point drains because these are not environmental foreign materials. When plugs or screwed caps are provided, these shall be seal welded after testing. No test vents or drains are required in air and nitrogen lines. When available, valved vents or drains provided for operational purpose, or pressure instrument connections (as indicated on the PEFS), may be used for hydrostatic test purpose. For list see E-00000-PI-7880-0063. ( 13.3.2 ) 3.5 VALVES Valves above roads and in overhead pipe tracks shall be avoided. The valve stem, handwheel or actuator shall not obstruct walkways or platforms. Valves shall not be located within a vessel skirt. Gate valves installed around safety relief valves and in flare lines shall be positioned with the stem horizontal (preferred) or downward. See attachment I for ergonomic valve positions. Valves in cryogenic liquid service with an extended bonnet shall be installed with the stem oriented upwards (preferred), or with a maximum inclination of 30 deg. to the vertical. Drain valves in cryogenic liquid service shall be installed likewise. The drain connections shall be provided with support/bracing, preferably to the header. Valves in cryogenic service with no-flow connections (such as vents and pressure gauges) and valves in methanol service, where the trapped gas bubble protects the valve packing from too low temperatures, may be installed at an angle up to 90 from vertical (i.e. they may be installed in vertical pipes).

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 8 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

If a check valve is installed in such a way that when it closes liquid accumulates in the pipes, a drain is required upstream from the valve. 3.6 INSULATION Personnel protection shall be applied to non-insulated piping or equipment with an operating temperature of 70 C and higher, and extended to 2.0 m above and/or 0.8 m beyond any access or operating area. If personnel protection is required for surface temperatures 250 C. physical barriers such as protective metal sheeting/screens shall be used instead of insulation. For surface temperatures > 250 C, insulation shall be used for personnel protection; 4. 4.1 PIPING AND LAYOUT CRITERIA EQUIPMENT GENERAL Piping adjacent to equipment shall be arranged such that ample access is provided for maintenance, e.g. by cranes, forklift trucks, etc., and that removal and replacement of equipment, or parts of equipment, can be performed requiring minimal removal of the piping. Gussets, as per relevant piping standard, shall be installed to all connections 1 and smaller on piping to equipment subject to vibration. Piping systems in cryogenic service shall be kept as short as possible. 4.2 PUMPS Piping at pumps shall be sufficiently flexible and adequately supported to ensure that under no circumstances the nozzles of this equipment will be subject to stress that could disturb the alignment of the pump. Pump suction lines shall be as direct as possible and shall be free draining to the pump suction nozzle. Pockets in suction lines are not permitted, so as to avoid collection of vapor or gas. To avoid cavitation in horizontal centrifugal pumps of the double-suction type, sufficient straight length shall be provided immediately upstream the suction nozzle of the pump, so that equal flow distribution to both impeller sides is guaranteed. In addition, the first elbow in the suction line will have preferable a 90 angle to the pump shaft centerline. Eccentric reducers in pump suction lines shall be installed with the topside flat if suction header is located below the suction nozzle, or when suction header is located above the suction nozzle and a horizontal piece of suction line is installed between reducer and first elbow. Where necessary, provision shall be made to facilitate removal of internal elements, housing sections and strainers. For maintenance reasons, provision shall be made for draining the discharge and suction lines of pumps:

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 9 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

Suction lines may be drained through pump casing. However, when eccentric reducers with topside flat are used in suction lines, such arrangement may require an additional drain. Vertical discharge lines shall be drained by a valved drain, connected to the check valve, or installed between the check valve and the first block valve. Special draining and flushing hook-ups are required for pumps handling toxic, volatile or otherwise hazardous fluids. These will be indicated on the PEFSs. 4.3 COMPRESSORS Suction lines between knockout drums and compressors shall preferably be as short as practicable, without pockets and sloping downward towards the knockout drum. Where this is impossible, the low points shall be provided with a drain/trap to remove any possible accumulation of liquid. Pulsation dampeners or equipment with same effect, e.g. knockout drums, installed in suction and discharge lines of reciprocating compressors shall be located as close as possible to the compressors. Pulsation dampeners and piping between pulsation dampeners and compressors are normally part of compressor vendors scope. In compressor suction lines, temporary/permanent strainers shall be installed before start-up. Size shall be suction line size and they shall be installed in such a way that each one can be removed easily. Around each unit, enough spacing shall be provided for maintenance, dismantling, piston removal, crane access, etc. Break flanges shall be added when appropriate. The suction and discharge piping layout shall be checked by the compressor vendor if necessary. Piping to and from compressors shall be designed to keep vibration to a minimum. Avoid overhanging weight of pipe. Gussets are to be provided as per relevant piping standard to all connections 1 and smaller where required. 4.4 STEAM TURBINES Piping to and from turbines shall be designed in such a way that expansion forces and moments on the turbine flanges will be kept to a minimum, and vibration in the piping system shall be prevented. Ample spacing for crane access shall be provided for dismantling the turbine casing and lifting of the rotor. Liquid (condensate) in lines to the turbine shall be avoided by providing drip pockets and steam traps. Distance between the last drip pocket and turbine shall be minimum. 4.5 HEAT EXCHANGERS

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 10 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

A spool piece or flanged elbow shall be provided in the piping to the channel nozzles, to allow removal of heads and to pull the bundle if applicable. Do not connect a valve directly to the channel side of the exchangers. Enough space in front of the channel side of the exchanger shall be allowed for pulling the tube bundles or cleaning fixed tube bundles with cleaning rods. For heat exchangers installed at ground level (single or stacked), or installed on the top floor of a structure, no fixed maintenance equipment shall be provided. Heat exchangers with a removable tube bundle and installed between two floors of a structure, which can not be reached by a bundle puller will be provided with a monorail. 4.6 AIR-COOLERS To assure sufficient supply of air flow to fin fan coolers, a minimum clearance of 2.5 m or fan diameter shall be used between bottom of air inlet and the deck or floor on which the air cooler is installed. The effect of flooring (closed or open grating) shall be taken into account. Accessibility shall be provided for maintenance to the drivers and the in and outlet nozzles of the air coolers. No other equipment and pressure relief valves shall be installed underneath the total surface of air coolers. Keep flange connections below air coolers to a minimum. 4.7 FURNACES AND HOT OIL PIPING All piping around a furnace shall be arranged such that access to the burners, peepholes, observation windows, access doors, header box covers, etc. is maintained. Piping at the burner front shall be arranged in such a way that it does not obstruct insertion/removal of lighting torches and/or burner guns. Pipelines for liquid fuel, fuel gas, pilot gas, general service steam (steaming out and atomizing steam) and purge air around furnaces shall be by subheaders with block valves at the main header. In general, symmetrical piping should be designed for branches to burners. Smothering steam block valves and manifold must be located at a safe distance from the furnace, minimum 15 m. Downstream the block valve a weep hole of 6 mm diameter shall be provided at the lowest point. 4.8 PRESSURE VESSELS AND COLUMNS Design of piping shall be coordinated with process requirements of equipment to achieve an optimum nozzle position. Inlet nozzles shall be arranged such, to avoid the inlet stream impinging on the vessel wall, or against level and gauge glass connections. Interconnecting piping between vessels/columns without valves, may be considered as a part of the equipment and, therefore, may be subject to limitations and/or design requirements given by

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 11 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

the applicable code and other regulations. This piping shall be marked on the PEFS in a manner, which distinguishes it from other piping. For stripping steam to towers the check valve, vent and block valve shall be located close to the tower in horizontal position to prevent condensate from entering the tower. Piping at columns should drop immediately when leaving the nozzle and run parallel and as close as practicable to the column itself. Columns and vessels that are grouped together shall, if practicable, be elevated in such a way that their level gauges can be read from one (1) common level. Level glass nozzle locations shall prevent impingement by process streams. In general manholes are to be oriented towards the access side. Dropping areas and maintenance areas are to be designated where applicable.

5. 5.1

CLEARANCES ESCAPE WAYS Escape routes will lead from all stairways, congested plant areas or buildings to open areas. Escape passages should have clear corridor widths of 0.9 meter and a clear headroom of 2.1 meters above grade. Escape passages should preferably run straight avoiding abrupt changes of direction.

5.2

VERTICAL CLEARANCES 6.0 m over main roads. 6.0 m over railways. 4.0 m for truck/ crane access and plant roads. 2.7 m for normal overhead in the units and forklift truck access. 2.1 m for normal headroom over walkways and platforms.

5.3

HORIZONTAL CLEARANCES 0.75 m for access ways and walkways and 0.9m for thoroughfares / escapes. 1.0 m for maintenance areas. 2.8 m for forklift truck access. 1.2 m between pump foundations

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 12 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

5.4

OTHER CLEARANCES The minimum spacing between pipe shall be: 75 mm pipe to pipe, pipe to insulation and insulation to insulation. 30 mm flange to pipe and flange to insulation or the insulation of a pipe in trenches and piperacks. The distance between the insulation of a low-temperature pipe and any other object shall be at least 100 mm The minimum clearance underneath lines supported on sleepers shall be 400 mm from bottom of line to grade. The minimum distance between handwheels and any obstruction shall be 100mm. The minimum clearance below process drains shall be 150 mm.

6.

ACCESSIBILITY The following are the minimum accessibility requirements for principal operating components:

6.1

FROM GRADE OR PLATFORM: Control valves, on-off valves. Pressure Relief valves (except thermal relief valves). Battery limit valves. Operating valves 4 and over. Operating spectacle blinds. Manholes higher than 4000 mm above grade. Flow meters (except orifice type). Sample collection points.

6.2

BY A PERMANENT LADDER: Operating valves 3 (150#) and smaller. Level instruments on towers and vessels. Pressure indicators. Temperature indicators.

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 13 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

Handholes. Sample take-off points. 6.3 BY PORTABLE DEVICES OR SCAFFOLDING (maximum 4500 mm above grade): Orifice type flow meters. Restriction orifices. Check valves. Pressure connections (except indicators). Temperature connections (except indicators). Manholes on vessels with an elevation of 4000 mm and below. 6.4 NOTES In addition to above accessibility requirements, considerations are to be made regarding maintenance requirements such as extra space for catalyst handling, lay-down areas, overhaul requirements, etc. Maximum use of available mobile equipment is to be implemented, otherwise permanent facilities such as hinge points, monorails, etc. are to be provided. Platforms in front of manholes shall have a minimum clear width of 900 mm and shall be located at an elevation in the range of 600-1200 mm below the centerline of the manhole. Recommended is 750 mm. The orientation of manholes on towers and vessels shall preferably be to the direction of the road, or away from pipe racks. All nozzles on equipment, with or without spades,spacers or spectacle blinds, situated below 6.00m above grade or supporting platform, and should be only accessible during turn-arounds, do not need permanent acces facilities. The maximum centerline-elevation of a valve handwheel above grade or platform shall be in accordance with attachment - I. When an (operating) valve is unavoidably to be located at a higher elevation, suitable provisions shall be made to make the valve accessible for operation. On platforms, control valves and safety valves shall be installed inside the handrailings.

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 14 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

7. 7.1

PIPING DRAWINGS SCOPE OF PIPING DESIGN DRAWINGS Scope of Piping Design Drawings Site Plan. Overall ISBL Plot Plan Detailed ISBL Plot Plans Section Plot Plans Piping Area Key Plan Piping Plan Drawings Piping Isometrics Piping Bill of Materials (on isometrics) All drawings shall be produced as per JOB standards. Extracted from 3D Model N N Y Y N Y Y Y

7.2

ISOMETRICS Isometrics shall be A3 size and include a bill of material. Isometrics shall be made for: Carbon steel lines all sizes. Stainless steel and alloy steel lines all sizes. Non Metal for underground lines all sizes

7.3

PIPING PLAN DRAWINGS Piping plan drawings shall be A0 size and produced on scale 1 : 33 1/3

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 15 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

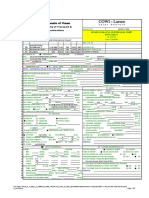

8. 8.1

ERGONOMIC ASPECTS OF VALVES GENERAL The minimum distance between handwheels and any other obstruction shall be100mm Valves are classified into categories 1, 2 or 3, and this categories are specified on the PEFS .

8.2

CATEGORY 1: CRITICAL VALVES (see Optimum area of attachment I) Frequently used valves, more than once every six (6) months Quick action is required The chance of a failure is possible with serious consequences Valves shall be operable from grade or permanent platform accessed by stairs

8.3

CATEGORY 2: NON-CRITICAL VALVES (see Optimum or Acceptable area of attachment I) (Cat. 2B) Operating frequently is less than every six (6) months (Cat. 2B) Quick action is not required (Cat. 2A) The chance of a failure is small and may not lead to serious consequences (Cat. 2A) Permanent access is aimed for extra cost should be justifiable. In case of permanent access is not being provided, auxiliary equipment (e.g. mobile platforms, skywalkers and/or scaffolding) should be identified to gain access.

8.4

CATEGORY 3: NON-OPERATIONAL VALVES Operational use is very rare and not in emergency. Valves which do not need to be accessible by a permanent ladder or platform Valves can be accessible by scaffolding, portable ladder, mobile platform, etc. when it is convenient to do.

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 16 of 17

ABB Lummus Global B.V. SPECIFICATION

Client Plant Location Shell Eastern Petroleum (Pte) Ltd. Shell ECC Project Singapore Pular Ular, Singapore 120.421 Dept./Sect. Doc. No. Always refer to this number 04217 Project H-652 Specification Rev. 3.00

E-00000-PI-7737-0013

ATTACHMENT - I ERGONOMIC VALVE POSITIONING

Note: The height of access are revised from DEP 30.00.60.13-Gen to suit the people who having average height of 170cm.

LGN SSPE xx-xxxx-xx.xxx (2002-04-10) H-652 ECC Specification for Piping Design.dot

H-652 ECC SPECIFICATION FOR PIPING DESIGN-rev3.DOC

Page 17 of 17

You might also like

- Gauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFDocument2 pagesGauge - Pole - Cover - For - Floating - Roof - Tanks LR PDFArlen NurlanNo ratings yet

- Nitrogen Generator Functional TestDocument10 pagesNitrogen Generator Functional TestBudi UtomoNo ratings yet

- Welding Procedure Specification for ASME Section IXDocument4 pagesWelding Procedure Specification for ASME Section IXRahul MoottolikandyNo ratings yet

- Check Valve List for Power PlantDocument4 pagesCheck Valve List for Power Plantbandithaguru6338No ratings yet

- PU P ROA02164227803 DE ME DTA 001 01 B - Tank - 200m3 - R5 PDFDocument8 pagesPU P ROA02164227803 DE ME DTA 001 01 B - Tank - 200m3 - R5 PDFDDA7No ratings yet

- Inspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Document6 pagesInspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Shubham ShuklaNo ratings yet

- Fuel Oil Road Tanker Unloading Pump DatasheetDocument4 pagesFuel Oil Road Tanker Unloading Pump DatasheetGop MangukiyaNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- BOA Bid Evaluation CriteriaDocument10 pagesBOA Bid Evaluation CriteriaOmogbai InijezeNo ratings yet

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayNo ratings yet

- RPA Rim Seal Foam Pourer GuideDocument3 pagesRPA Rim Seal Foam Pourer Guideadilmomin45No ratings yet

- Vortex BreakerDocument2 pagesVortex Breakernaruto256No ratings yet

- Reconstruction Airport Expansion JointsDocument5 pagesReconstruction Airport Expansion JointsaltipatlarNo ratings yet

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocument10 pagesEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNo ratings yet

- DWS 2510 Valve SpecificationDocument7 pagesDWS 2510 Valve SpecificationsudjonoNo ratings yet

- QCS-2010 Section 21 Part 33 ActuatorsDocument5 pagesQCS-2010 Section 21 Part 33 Actuatorsbryanpastor106No ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CAgus MarpaungNo ratings yet

- AE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksDocument6 pagesAE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksQualityNo ratings yet

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- ControTrace Installation Checklist PipeDocument1 pageControTrace Installation Checklist PipeEnoch TwumasiNo ratings yet

- Attachment #4 - Inspection Test Plan ITP - Line Pipes CoatingDocument7 pagesAttachment #4 - Inspection Test Plan ITP - Line Pipes CoatingLarry UbuNo ratings yet

- Supplier'S Document Cover Page (For A4/A3 Documents Only)Document5 pagesSupplier'S Document Cover Page (For A4/A3 Documents Only)Tanveer Ahmed QuadriNo ratings yet

- Cooler Drawin API-23 Seal PlanDocument5 pagesCooler Drawin API-23 Seal PlankishorsinghNo ratings yet

- Align Pumps and Drivers To Maximise Energy-PumpAlignmentDocument5 pagesAlign Pumps and Drivers To Maximise Energy-PumpAlignmentDelfinshNo ratings yet

- Sonatrach: Project SpecificationDocument13 pagesSonatrach: Project SpecificationAliZenatiNo ratings yet

- G I Drawing For Droplet SeperatorDocument4 pagesG I Drawing For Droplet SeperatorPerumal KumarNo ratings yet

- Bonney Forge WFI Recommended Flexolet, Pipet, and Weldolet Weld ProfilesDocument17 pagesBonney Forge WFI Recommended Flexolet, Pipet, and Weldolet Weld ProfilesozkanhasanNo ratings yet

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- VP 3209 e 031a 02 0013 Rev.dDocument254 pagesVP 3209 e 031a 02 0013 Rev.dSuryaprakashNo ratings yet

- BTP2B-EPCIC-BTJTB-M-TDS-0003 Rev.X PDFDocument7 pagesBTP2B-EPCIC-BTJTB-M-TDS-0003 Rev.X PDFandrianoNo ratings yet

- Software Cost Estimation Models and Techniques A Survey IJERTV3IS20384Document6 pagesSoftware Cost Estimation Models and Techniques A Survey IJERTV3IS20384balj balhNo ratings yet

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- Material and Equipment Standard For Large Welded Low Pressure Storage Tanks M-Me-110Document17 pagesMaterial and Equipment Standard For Large Welded Low Pressure Storage Tanks M-Me-110Javeed A. KhanNo ratings yet

- Po SR No-112 (170159) 6X150 2150 MM ExtDocument1 pagePo SR No-112 (170159) 6X150 2150 MM ExtDebasis Pattnaik DebaNo ratings yet

- 6.1 Data Sheet For Pipeline Ball ValveDocument3 pages6.1 Data Sheet For Pipeline Ball ValveDeepak PalNo ratings yet

- Indra: Detail Pre-Commissioning Procedure For Service Test of Nitrogen For Unit 040/041/042/043Document109 pagesIndra: Detail Pre-Commissioning Procedure For Service Test of Nitrogen For Unit 040/041/042/043AnhTuấnPhanNo ratings yet

- Water Network Development: Standard DrawingsDocument40 pagesWater Network Development: Standard Drawingsabdul jackil100% (1)

- C C CCCCCCCCCCCC C CDocument62 pagesC C CCCCCCCCCCCC C CGaurav VashishtNo ratings yet

- Tanky 53 KL Rev.1Document187 pagesTanky 53 KL Rev.1Priyo Jati WahyonoNo ratings yet

- M-42 Plate Coolers PDFDocument52 pagesM-42 Plate Coolers PDFGeorgi GalevNo ratings yet

- Mucog 1910502 Mec DS 055Document12 pagesMucog 1910502 Mec DS 055vinodNo ratings yet

- Characteristic curves for Blackmer pumpsDocument12 pagesCharacteristic curves for Blackmer pumpsJulianNo ratings yet

- Engineering Design Guide For Storage TanksDocument107 pagesEngineering Design Guide For Storage Tankssonng.engNo ratings yet

- Class 1 Div 2 scrubber vessel P&IDDocument1 pageClass 1 Div 2 scrubber vessel P&IDomarNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Specification For Atmospheric Storage TanksDocument18 pagesSpecification For Atmospheric Storage TanksHamid MansouriNo ratings yet

- Boiler Steam Dump SilencerDocument7 pagesBoiler Steam Dump SilencerRaju Gopinathan Nair100% (1)

- JMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006Document9 pagesJMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006AshutoshNo ratings yet

- Abs VmoaDocument7 pagesAbs VmoaTxavitoNo ratings yet

- Curves MLX-MLN 106-021Document2 pagesCurves MLX-MLN 106-021Andres SanchezNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- Job Specification For Supply: 8474L 000 JSS 1691 001 0Document12 pagesJob Specification For Supply: 8474L 000 JSS 1691 001 0Kumar sssssNo ratings yet

- 31 1 Static Equipment Vertical ErectionDocument2 pages31 1 Static Equipment Vertical Erectionpunitg_2No ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- Paint Specification Package CDocument32 pagesPaint Specification Package CMohammedNo ratings yet

- SA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02Document5 pagesSA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02altipatlarNo ratings yet

- Piping Class PDFDocument4 pagesPiping Class PDFanil pkNo ratings yet

- H-652 Ecc Specification For Piping Design - 01Document17 pagesH-652 Ecc Specification For Piping Design - 01vermaakash22100% (1)

- H-005 Ecc Piping Design InstructionsDocument39 pagesH-005 Ecc Piping Design Instructionsvermaakash22No ratings yet

- H-005 Ecc Piping Design Instructions-Rev3Document39 pagesH-005 Ecc Piping Design Instructions-Rev3vermaakash22100% (1)

- Caesar - Flexibility Details For FittingsDocument9 pagesCaesar - Flexibility Details For Fittingsvermaakash22No ratings yet

- AlstomDocument148 pagesAlstomstupid143100% (5)

- Steam TurbineDocument56 pagesSteam Turbinegirish_nonie77% (26)

- SUB: Application For The Post of "Piping Design Engineer"Document4 pagesSUB: Application For The Post of "Piping Design Engineer"vermaakash22No ratings yet

- 1.12372715 - 07 Sep 2012Document4 pages1.12372715 - 07 Sep 2012vermaakash22No ratings yet

- E ReceiptDocument1 pageE Receiptvermaakash22No ratings yet

- Steam & Water Flow Circuit Diagram for 5x660MW Power PlantDocument2 pagesSteam & Water Flow Circuit Diagram for 5x660MW Power Plantvermaakash22No ratings yet

- PidDocument85 pagesPidvermaakash22No ratings yet

- Pipe Stress Analysis Concepts Explained in 40 CharactersDocument41 pagesPipe Stress Analysis Concepts Explained in 40 Charactersvermaakash22No ratings yet

- Surface Finish For FlangesDocument2 pagesSurface Finish For Flangesvermaakash22No ratings yet

- ASME Classes 150 –300 Gate and Globe Valves 1/2 – 24” (15 – 600 mmDocument10 pagesASME Classes 150 –300 Gate and Globe Valves 1/2 – 24” (15 – 600 mmvermaakash22No ratings yet

- Piping Design Engineer Resume - Sarang P. GatfaneDocument3 pagesPiping Design Engineer Resume - Sarang P. GatfaneEr Rupesh Vilas SawantNo ratings yet

- Distillation TechDocument16 pagesDistillation Techvermaakash22No ratings yet

- 1.12372715 - 07 Nov 2012Document5 pages1.12372715 - 07 Nov 2012vermaakash22No ratings yet

- Nehal PatelDocument3 pagesNehal Patelvermaakash22No ratings yet

- PandID Sheets of A Process PlantDocument36 pagesPandID Sheets of A Process Plantvermaakash22No ratings yet

- (Ddau Am (E (Ê$.) : (NN BM H$M'M WJVMZ Es Oñq - Q G DV© - MZ Ewëh$ HW$B Xo' Am (E WJVMZ Xo' (V (WDocument4 pages(Ddau Am (E (Ê$.) : (NN BM H$M'M WJVMZ Es Oñq - Q G DV© - MZ Ewëh$ HW$B Xo' Am (E WJVMZ Xo' (V (Wvermaakash22No ratings yet

- Presentation Projet QgiiDocument40 pagesPresentation Projet Qgiivermaakash22No ratings yet

- H-653 Ecc Standard Dwgs Index Rev4Document27 pagesH-653 Ecc Standard Dwgs Index Rev4vermaakash22No ratings yet

- Iso Check Proce.Document6 pagesIso Check Proce.vermaakash22No ratings yet

- H-005 Ecc Piping Design Instructions-Rev3Document39 pagesH-005 Ecc Piping Design Instructions-Rev3vermaakash22100% (1)

- Reliance Jamnagar Refinery PhotosDocument23 pagesReliance Jamnagar Refinery Photosvermaakash22No ratings yet

- H-652 Ecc Specification For Piping Design-Rev3Document17 pagesH-652 Ecc Specification For Piping Design-Rev3vermaakash22No ratings yet

- H-653 Ecc Standard Dwgs Index-Rev3Document3 pagesH-653 Ecc Standard Dwgs Index-Rev3vermaakash22No ratings yet

- H-652 Ecc Spec For Pipingdesign-Rev.4 PDFDocument17 pagesH-652 Ecc Spec For Pipingdesign-Rev.4 PDFvermaakash22No ratings yet

- H-653 Ecc Standard Dwgs Index-Rev3Document3 pagesH-653 Ecc Standard Dwgs Index-Rev3vermaakash22No ratings yet

- H-653 Ecc Standard Dwgs IndexDocument3 pagesH-653 Ecc Standard Dwgs Indexvermaakash22No ratings yet

- Pump Suction CharacteristicsDocument10 pagesPump Suction Characteristicsvermaakash22No ratings yet

- SUB: Application For The Post of "Piping Design Engineer"Document1 pageSUB: Application For The Post of "Piping Design Engineer"vermaakash22No ratings yet

- Gen 253 Dep 31.38.01.11-Gen., Section 3.5Document5 pagesGen 253 Dep 31.38.01.11-Gen., Section 3.5vermaakash220% (1)