Professional Documents

Culture Documents

1 Min 5 Secs 5 Min 15 Secs 45 Secs 11.5 Mins 30 Secs 30 Secs 15 Secs 1 Min 30 Secs

Uploaded by

Rohini RajagopalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Min 5 Secs 5 Min 15 Secs 45 Secs 11.5 Mins 30 Secs 30 Secs 15 Secs 1 Min 30 Secs

Uploaded by

Rohini RajagopalCopyright:

Available Formats

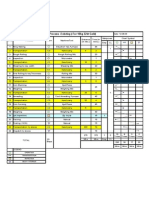

Project: Sr. No.

A 1 2 3 4 5 6 7 8 9 Activity Floor Operations Truck docks at loading bay Seal checked and broken HPT moves till truck HPT moved to Inbound Staging Area Segregating and Checking of SKUs HPT brought to pallet for put-away Pallet moved till Rack Writing Location on boxes Put-away using Reach Truck Total

Time and Motion Study (Grohe: Inbo Duration (in minutes) 1 min 5 secs 5 min 15 secs 45 secs 11.5 mins 30 secs 30 secs 15 secs 1 min 30 secs 21.3

B System Process 10 Uploading of Locations in CIEL Total

10 mins 31.3

otion Study (Grohe: Inbound Process) Duration (in secs) Manpower 65 300 15 45 690 30 30 15 90 1280 1 1 1 1 1 1 1 1 1

600 1880

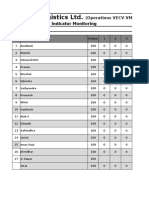

Sr. No. A 1 2 3 4 5 6 B 7 8 9 C 10 11

D 1 2 3

E 1 2 3 4 5

Activity Floor Operations Picking Pallet fixing Movement for checking Box No. Checking Box No. and moving to pallet Taping incase the box is open Moving to Picking Staging Area Writing Store Name and Order No. and pasting the sticker Checking Checking quantity and MRP label MRP Label printing & Sticking Scanning of all pieces in excel (in case damage piece or short or excess) Packing Packing Plastic wrapping & Strapping System Process System Process CIEL entry and Celio WMS entry EAN upload Checking Order Summary and other details if status reverts to 35 Floor Operations Despatch Stock Transfer Note( SAS) Packing List generation Stamp and Signature on LR Filling details by transporter and stamp on sticker Putting billing rolls in a box and taping it

Total Time (In Manpower Secs)

1 4 16 55 sec 2 4

1 1 1 1 1 1

12 1440 4

1 1 1

7 4

10 10 10

2 2 1 10

TITLE: TIME AND MOTION STUDY SR NO A 1 2 3 4 5 6 ACTIVITY FLOOR OPERATIONS PICKING Pallet fixing Movement for checking box no Checking box no & moving to pallet Taping in case the box is open Moving to picking staging area Writing store name & order no; pasting sticker

LOCATION: KUEHNE+NAGEL TIME (IN SECS) MANPOWER %

60 240 960 55 120 240 1675

1 1 1 1 1 1

0.79% 3.16% 12.64% 0.72% 1.58% 3.16%

B 7 8 9

CHECKING Checking quantity and MRP label MRP Label printing & Sticking Scanning of all pieces in excel (in case damage piece or short or excess)

720 1440 240 2400

1 1 1

9.48% 18.97% 3.16%

C PACKING 10 Packing 11 Plastic wrapping & Strapping SYSTEM PROCESS D 1 2 3 SYSTEM PROCESS CIEL entry and Celio WMS entry EAN upload Checking Order Summary and other details if status reverts to 35 FLOOR OPERATIONS DISPATCH Stock Transfer Note( SAS) Packing List generation Stamp and Signature on LR Filling details by transporter and stamp on sticker Putting billing rolls in a box and taping it Opening gate on the Bay Moving the pallet to the truck Mounting the box on truck

420 240

1 1

5.53% 3.16%

600 600 600

1 1 1

7.90% 7.90% 7.90%

E 1 2 3 4 5 6 7 8

120 120 60 600 24 53 57 20 1054 7589

1 1 1 1 1 1 1 1

1.58% 1.58% 0.79% 7.90% 0.31% 0.69% 0.75% 0.26%

TOTAL

You might also like

- Activity of Product QS - Lean ManufacturingDocument11 pagesActivity of Product QS - Lean ManufacturingFabio Velasco SossaNo ratings yet

- Rajat AroraDocument30 pagesRajat AroraBibhu Ranjan MohantyNo ratings yet

- Improvement On FIFODocument17 pagesImprovement On FIFOristian_rehi355No ratings yet

- DtsDocument6 pagesDtsDeepak ANo ratings yet

- Casting Process - Existing UpdatedDocument9 pagesCasting Process - Existing UpdatedNirmal JosephNo ratings yet

- Transportation ManagementDocument24 pagesTransportation ManagementNarasimha Prasad BhatNo ratings yet

- Motion and Time Study (Practical)Document18 pagesMotion and Time Study (Practical)Francois de VilliersNo ratings yet

- Content Expectations: Quick Response PDCA Assignment / Breakdown Factor Tree AnalysisDocument10 pagesContent Expectations: Quick Response PDCA Assignment / Breakdown Factor Tree AnalysisGobinath AnbalaganNo ratings yet

- Lifting COG Shift DDTL-IfR SouthDocument6 pagesLifting COG Shift DDTL-IfR Southvovancuong8No ratings yet

- Cause&Effect MatrixDocument7 pagesCause&Effect MatrixkotharideepNo ratings yet

- Problem SolvingDocument52 pagesProblem Solvingshanmugam86No ratings yet

- Tank Truck Receiving PetronDocument36 pagesTank Truck Receiving PetronJf LarongNo ratings yet

- Control Plan Extrusion of Tyre TreadsDocument4 pagesControl Plan Extrusion of Tyre TreadsChetan MetkarNo ratings yet

- Seven QC ToolsDocument11 pagesSeven QC ToolsChiranjit ChakravartiNo ratings yet

- Flow Process Chart: Line Feeder Material: 217 Total 505 288Document1 pageFlow Process Chart: Line Feeder Material: 217 Total 505 288Deepak PalNo ratings yet

- Appendix 1 Medical Device Adverse Event Complaint Return and Reporting ProcessDocument4 pagesAppendix 1 Medical Device Adverse Event Complaint Return and Reporting ProcessAl VlaerNo ratings yet

- Dispatch Checking Procedure SCP v5Document15 pagesDispatch Checking Procedure SCP v5Denzel Edward CariagaNo ratings yet

- Fyp SlideDocument52 pagesFyp SlideZulhilmi ZalizanNo ratings yet

- Material ManagementDocument88 pagesMaterial ManagementManojNo ratings yet

- Software Metrics in Use: Don HarveyDocument29 pagesSoftware Metrics in Use: Don HarveysendtosayakNo ratings yet

- '1 S' Seiri: Sorting / Segregation & Removal: Walking & Working Area SegregationDocument3 pages'1 S' Seiri: Sorting / Segregation & Removal: Walking & Working Area SegregationdanaonlineNo ratings yet

- Plant LayoutDocument65 pagesPlant Layoutsupriya127100% (1)

- ISO 6346 - Wikipedia, The Free EncyclopediaDocument10 pagesISO 6346 - Wikipedia, The Free EncyclopediaJogi Oscar SinagaNo ratings yet

- Complex Inbound Process With VAS Using POSC ApproachDocument39 pagesComplex Inbound Process With VAS Using POSC ApproachAnton JagtapNo ratings yet

- %Xon'Lvwulexwlrq5Htxluhphqwv3Odqqlqj %'53dvsduwri, 62Lo'RzqvwuhdpDocument9 pages%Xon'Lvwulexwlrq5Htxluhphqwv3Odqqlqj %'53dvsduwri, 62Lo'RzqvwuhdpSumit Kumar SinghNo ratings yet

- Rolled Throughput Yield (6 Sigma)Document8 pagesRolled Throughput Yield (6 Sigma)Laaiba IshaaqNo ratings yet

- SabicTahir - Leading KPI Zenica March'10Document3 pagesSabicTahir - Leading KPI Zenica March'10mac1677No ratings yet

- Quality Circle Forum of India: Problem Solving TechniquesDocument121 pagesQuality Circle Forum of India: Problem Solving TechniquesSamNo ratings yet

- Capacity VerificationDocument5 pagesCapacity VerificationHarsha MP100% (2)

- Current Fiscal ProjectsDocument10 pagesCurrent Fiscal ProjectsThuận HoàngNo ratings yet

- S.No. Customer Wi. Versiwi. Versi DepartmentDocument25 pagesS.No. Customer Wi. Versiwi. Versi DepartmentBALACHANDAR SNo ratings yet

- Standardized Work and Problem SolvingDocument34 pagesStandardized Work and Problem Solvingjayeshjpillai100% (3)

- Six Sigma (Part 2) : Manuel Rincón, M.Sc. October 15th, 2004Document79 pagesSix Sigma (Part 2) : Manuel Rincón, M.Sc. October 15th, 2004linapau7No ratings yet

- WMM Calibration of PlantDocument7 pagesWMM Calibration of PlantKaushlendra Singh80% (5)

- Run at Rate AuditDocument12 pagesRun at Rate AuditPurushothama Nanje GowdaNo ratings yet

- Facility Planning - Group 1 - Roll No 61 To 65Document29 pagesFacility Planning - Group 1 - Roll No 61 To 65nileshwankhade50% (2)

- System StatusDocument18 pagesSystem StatusMarco Antônio Claret TeixeiraNo ratings yet

- Kpi For Warehouse OperationsDocument24 pagesKpi For Warehouse OperationsAnuragPrasadNo ratings yet

- CRM Deloitte 201210Document67 pagesCRM Deloitte 201210Asia KentNo ratings yet

- Workzone - Safety - IMP 1 PDFDocument37 pagesWorkzone - Safety - IMP 1 PDFSuryavenkat RaghavanNo ratings yet

- 7-Steps Service OperationDocument66 pages7-Steps Service OperationWagih Abd El-Aziz77% (22)

- MACE Formats 1Document46 pagesMACE Formats 1Ashish VaidNo ratings yet

- SAP Integration Test Sample Template MM - QMDocument9 pagesSAP Integration Test Sample Template MM - QMsaifrahman1234100% (2)

- 13F64!01!0000KM0 A00 Robot Manual - ApprovedDocument19 pages13F64!01!0000KM0 A00 Robot Manual - ApprovedMourad TdjNo ratings yet

- Summer 2013 Internship OverviewDocument16 pagesSummer 2013 Internship Overviewapi-247239790No ratings yet

- Process Analysis IIDocument22 pagesProcess Analysis IITianzhu Sylvia LeiNo ratings yet

- SC-CF-04 - Completion of Declarations - External ManualDocument74 pagesSC-CF-04 - Completion of Declarations - External ManualiadhiaNo ratings yet

- Standard ChecklistscorrectedDocument51 pagesStandard Checklistscorrectedmohan_krishna372No ratings yet

- Stock Taking Process WMS - 2018-19Document17 pagesStock Taking Process WMS - 2018-19Ashutosh ShriwasNo ratings yet

- DCC Technicals For All MachinesDocument58 pagesDCC Technicals For All MachinesSaudia AwakeNo ratings yet

- BA - 89401868 - 000600 - INNOFILL - EN - 01 FillerDocument338 pagesBA - 89401868 - 000600 - INNOFILL - EN - 01 Fillergrivr100% (12)

- Business Process For WarehouseDocument4 pagesBusiness Process For Warehouseluxshan888No ratings yet

- SPSR GSL Late SupplyDocument1 pageSPSR GSL Late SupplyNajib NawiNo ratings yet

- Js Insight Gas Form CDocument64 pagesJs Insight Gas Form CSomayajula SuryaramNo ratings yet

- Green Belt Project Documentation 182191KSP9300CDocument45 pagesGreen Belt Project Documentation 182191KSP9300CPrakashRai100% (1)

- Property Formdd1149Jul2006Version PDFDocument2 pagesProperty Formdd1149Jul2006Version PDFdibyaranjanbhrNo ratings yet

- Bangladesh BriefDocument4 pagesBangladesh BriefRohini RajagopalNo ratings yet

- China January 2012Document29 pagesChina January 2012Yogesh KumarNo ratings yet

- Cattell 16 Factor Test ResultsDocument4 pagesCattell 16 Factor Test ResultsRohini RajagopalNo ratings yet

- China January 2012Document29 pagesChina January 2012Yogesh KumarNo ratings yet

- Bangladesh BriefDocument4 pagesBangladesh BriefRohini RajagopalNo ratings yet

- China January 2012Document29 pagesChina January 2012Yogesh KumarNo ratings yet

- Abstract For Paper PresentationDocument5 pagesAbstract For Paper PresentationRohini RajagopalNo ratings yet

- ORF Discourse: India-Bangladesh Relations: Past, Present and FutureDocument6 pagesORF Discourse: India-Bangladesh Relations: Past, Present and FutureShalini MayankaNo ratings yet

- Mamta BhushanDocument26 pagesMamta BhushanDinesh HegdeNo ratings yet

- Top Five CRM Trends You Should Know AboutDocument26 pagesTop Five CRM Trends You Should Know AboutRohini RajagopalNo ratings yet

- ORF Discourse: India-Bangladesh Relations: Past, Present and FutureDocument6 pagesORF Discourse: India-Bangladesh Relations: Past, Present and FutureShalini MayankaNo ratings yet

- Heikkeri ElenaDocument74 pagesHeikkeri ElenaRohini RajagopalNo ratings yet

- Pest Analysis of Indian It IndustryDocument2 pagesPest Analysis of Indian It IndustryangayarkannirNo ratings yet

- Modul 5Document61 pagesModul 5Rohini RajagopalNo ratings yet

- Retail AtmosphericsDocument12 pagesRetail AtmosphericsRohini RajagopalNo ratings yet

- Final Project of CRM On Hospitality SectorDocument51 pagesFinal Project of CRM On Hospitality Sectornidhi17% (6)

- The Meaning of Your ResponsesDocument4 pagesThe Meaning of Your ResponsesRohini RajagopalNo ratings yet

- SSRN Id2165134Document1 pageSSRN Id2165134Rohini RajagopalNo ratings yet

- Full Text 01Document83 pagesFull Text 01Rohini RajagopalNo ratings yet

- "One World, One Burger"-Mcdonald'SDocument77 pages"One World, One Burger"-Mcdonald'SDhiraj KumarNo ratings yet

- Top Tens of Employee Engagement1Document95 pagesTop Tens of Employee Engagement1Rohini RajagopalNo ratings yet

- d2 l2 PestleDocument21 pagesd2 l2 PestleRohini RajagopalNo ratings yet

- SSRN Id2165134Document1 pageSSRN Id2165134Rohini RajagopalNo ratings yet

- Retail AtmosphericsDocument12 pagesRetail AtmosphericsRohini RajagopalNo ratings yet

- 9 Sales TrainingDocument50 pages9 Sales TrainingRohini RajagopalNo ratings yet

- Competancy Mapping SPIDERWEBSDocument57 pagesCompetancy Mapping SPIDERWEBSRohini RajagopalNo ratings yet

- Tanishq QreDocument6 pagesTanishq QreRohini RajagopalNo ratings yet

- Leadership PresentationDocument94 pagesLeadership PresentationshashanktamgadgeNo ratings yet

- Competency Mapping QuestionnaireDocument26 pagesCompetency Mapping QuestionnaireRohini Rajagopal91% (22)

- 2Kv Hdfpc-Dlo, Rhh/Rhw-2 & Rw90: Flexible Stranded Rope-Lay Class I Tinned Copper Per ASTM B33 and B172Document3 pages2Kv Hdfpc-Dlo, Rhh/Rhw-2 & Rw90: Flexible Stranded Rope-Lay Class I Tinned Copper Per ASTM B33 and B172gerrzen64No ratings yet

- Java Lab RecordDocument29 pagesJava Lab RecordCyberDootNo ratings yet

- Catamsia 9.0 Cara InstallDocument2 pagesCatamsia 9.0 Cara InstalljohnsonNo ratings yet

- Acropolis Institute of Technology & Research, Indore: BT101 Engg ChemistryDocument6 pagesAcropolis Institute of Technology & Research, Indore: BT101 Engg ChemistryTanmay Jain100% (1)

- Dictionaries Godot GDScript Tutorial Ep 12 Godot TutorialsDocument4 pagesDictionaries Godot GDScript Tutorial Ep 12 Godot TutorialsChris LewinskyNo ratings yet

- End-Of-Sale and End-Of-Life Announcement For The Cisco Telepresence Sx20 With 12X CameraDocument3 pagesEnd-Of-Sale and End-Of-Life Announcement For The Cisco Telepresence Sx20 With 12X CameraAmrous MohamedNo ratings yet

- Students' Perceptions of Learning Mode in MathematicsDocument10 pagesStudents' Perceptions of Learning Mode in MathematicsChoy CristobalNo ratings yet

- Getting Started With PIC18F4550 and MPLABX IDE - PIC ControllersDocument11 pagesGetting Started With PIC18F4550 and MPLABX IDE - PIC ControllersKrishanu Modak100% (1)

- Teambang Unit Plan Final PlanDocument7 pagesTeambang Unit Plan Final Planapi-312120177No ratings yet

- A Study of Design and Analysis of Automobile Wheel Rim Using Different Fillet Radius and Different Y Spoke AngleDocument8 pagesA Study of Design and Analysis of Automobile Wheel Rim Using Different Fillet Radius and Different Y Spoke AngleIJRASETPublicationsNo ratings yet

- SWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDocument65 pagesSWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDanielDeFrancescoNo ratings yet

- Income Tax Calulator With Functions and Robus Validation: PFC - Assignment - Part 1Document4 pagesIncome Tax Calulator With Functions and Robus Validation: PFC - Assignment - Part 1tran nguyenNo ratings yet

- Baixar A Guide To The Project Management Body of Knowledge (PMBOK® Guide) - Seventh Edition and The Standard For Project Management (ENGLISH) PDF GrátDocument2 pagesBaixar A Guide To The Project Management Body of Knowledge (PMBOK® Guide) - Seventh Edition and The Standard For Project Management (ENGLISH) PDF Gráteduelis0% (17)

- Rotary InformationDocument14 pagesRotary InformationMohammad UsmanNo ratings yet

- Facial RecognitionDocument5 pagesFacial RecognitionPeterNo ratings yet

- Excel NotesDocument9 pagesExcel NotesAhnNo ratings yet

- Pelina PositionPaperDocument4 pagesPelina PositionPaperJohn Tristan HilaNo ratings yet

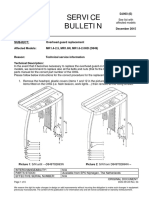

- Service Bulletin: SubjectDocument6 pagesService Bulletin: SubjectWaitylla DiasNo ratings yet

- Polytec Vibrometer Controller OFV-5000Document121 pagesPolytec Vibrometer Controller OFV-5000vnetawzNo ratings yet

- The Students Allotted With The Is Available at The End of The DocumentDocument4 pagesThe Students Allotted With The Is Available at The End of The DocumentShivaNo ratings yet

- PDF N Fcom Sek TF N Eu 20190311 DSC PLP LeduDocument600 pagesPDF N Fcom Sek TF N Eu 20190311 DSC PLP Leduhussein mohklisNo ratings yet

- Multi DIALOG MDM - MDT. MDM 10-20kVA Single - Single-Phase and Three - Single-Phase MDT 10-80kVA Three - Three-Phase NETWORK RANGEDocument8 pagesMulti DIALOG MDM - MDT. MDM 10-20kVA Single - Single-Phase and Three - Single-Phase MDT 10-80kVA Three - Three-Phase NETWORK RANGEMARCOS LARA ROMERO DE AVILANo ratings yet

- TRENDS AND CRITICAL THINKINGExamDocument4 pagesTRENDS AND CRITICAL THINKINGExamRyan TamelinNo ratings yet

- ACI Infotech Solutions SynposisDocument14 pagesACI Infotech Solutions SynposisSid KandukuriNo ratings yet

- Elisee - 150 Service ManualDocument176 pagesElisee - 150 Service ManualDawoodNo ratings yet

- Live Video Analytics at Scale With Approximation and Delay-ToleranceDocument17 pagesLive Video Analytics at Scale With Approximation and Delay-TolerancejsprchinaNo ratings yet

- T100-V Service ManualDocument22 pagesT100-V Service ManualSergey KutsNo ratings yet

- Module 11A.5.2 L1 2016-08-16Document234 pagesModule 11A.5.2 L1 2016-08-16Abdul Aziz KhanNo ratings yet

- Running IDocument3 pagesRunning IQuality Design & ConstructionNo ratings yet

- Flashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessDocument34 pagesFlashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessMarcos CostaNo ratings yet