Professional Documents

Culture Documents

Prospekt

Uploaded by

antonio2008Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prospekt

Uploaded by

antonio2008Copyright:

Available Formats

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.

de Web : www.tube-scarfing.com

PRODUCT RANGE

1. CUTTING RINGS FOR TUBE INSIDE WELD BEAD SCARFING 2. MECHANICAL TUBE INSIDE WELD BEAD SCARFING TOOLS TSE-MC 3. HYDRAULIC TUBE INSIDE WELD BEAD SCARFING TOOLS TSE-HD 4. MECHANICAL + HYDRAULIC TUBE INSIDE WELD BEAD SCARFING SYSTEMS 5. TUBE OUTSIDE WELD BEAD SCARFING INSERTS SNMG 6. TUBE OUTSIDE WELD BEAD SCARFING INSERTS SNMX POSITIVE 7. TUBE OUTSIDE WELD BEAD SCARFING INSERTS SNMX NEGATIVE 8. TUBE OUTSIDE WELD BEAD SCARFING INSERTS SDUN (SDUX) 9. TUBE OUTSIDE WELD BEAD SCARFING INSERTS ROMX 10. TUBE OUTSIDE WELD BEAD SCARFING INSERTS SDUW 11. TUBE OUTSIDE WELD BEAD SCARFING BLADES LDGN 12. FERRITE CORES (IMPEDER CORES) ZR, ZRF, ZRH, ZRS, ZRSH, ZRHU, ZRSHU 13. FERRITE CORES (IMPEDER CORES) ZR, ZRF, ZRH, ZRS, ZRSH, ZRHU, ZRSHU 14. FERRITE CORES (IMPEDER CORES) ZR, ZRF, ZRH, ZRS, ZRSH, ZRHU, ZRSHU 15. EPOXY FIBREGLASS TUBES (IMPEDER CASINGS) 16. SILICONE FIBREGLASS TUBES (IMPEDER CASINGS) 17. MUSCOVITE MICA SILICON TUBES 18. PHLOGOPHITE MICA SILICON TUBES 19. FLEXIBLE PTFE TUBES 20. TURNING / MILLING / DRILLING INSERTS 21. HSS CIRCULAR SAW BLADES 22. HSS-E CIRCULAR SAW BLADES 23. TCT CIRCULAR SAW BLADES 24. CHROME VANADIUM FRICTION SAW BLADES 25. FILTER FABRICS 26. MAGNETIC SEPARATORS WITH DISKS (MSWD SERIES) 27. GRAVITY FLAT BED FILTERS WITH FILTERING FABRIC (GFBF SERIES) 28. HYDROSTATIC FILTRATION SYSTEMS WITH FILTERING FABRIC (HSFS SERIES) 29. ROTATING DRUM FILTRATION SYSTEMS WITH FILTERING FABRIC (RDFS SERIES)

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

CUTTING RINGS FOR TUBE INSIDE WELD BEAD SCARFING

DESCRIPTION SR0-AR3,5 SR0-AR4 SR0-AR4,5 SR0-AR5,5 SR0-AR6 SR0-AR6,5 SR0-AR7 SR1-AR7 SR1AR7 ALU SR1-AR8 SR1-AR8 ALU SR1-AR9 SR1-AR9 ALU SR1-AR10 SR1-AR10 ALU SR2-AR10 SR2-AR10 ALU SR2-AR11 SR2-AR11 ALU SR2-AR12 SR2-AR12 ALU SR3-AR14 SR3-AR14 ALU SR3-AR17 SR3-AR17 ALU SR4-AR23 SR5-AR25 SR5-AR28 SR6-AR34 SR7-AR39 SR8-AR46 UN COATED x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x GOLD COATED x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x BLACK COATED x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x GREY COATED x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

x = AVAILABLE (OTHER CUTTING RING SIZES ARE AVAILABLE ON REQUEST)

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

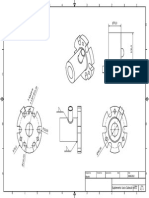

MECHANICAL TUBE INSIDE WELD BEAD SCARFING TOOLS

(TO REMOVE THE WELD BEAD FROM LONGITUDINAL WELDED TUBES) MECHANICAL TOOL ID TUBE CUTTING RING HOLDER CUTTING RING SR0-AR4,5 TSE-MC 14/17 14 17 mm SH014-SR4,5 TSE-MC 17/21 TSE-MC 21/26 17 21 mm SH017-SR4,5

SH017-SR6,5 SR0-AR5,5 SR0-AR4,5 SR0-AR5,5 SR0-AR6,5 SR0-AR6 SR0-AR6,5 SR0-AR7 SR1-AR7 SR1-AR8 SR1-AR9 SR1-AR10 SR1-AR7 SR1-AR8 SR1-AR9 SR1-AR10 SR2-AR10 SR2-AR11 SR2-AR12 SR1-AR7 SR1-AR8 SR1-AR9 SR2-AR10 SR2-AR11 SR2-AR12 SR3-AR14 SR3-AR17 SR2-AR10 SR2-AR11 SR2-AR12 SR3-AR14 SR3-AR17 SR4-AR23 SR3-AR14 SR3-AR17 SR4-AR23 SR5-AR25 SR5-AR28 SR4-AR23 SR5-AR25 SR5-AR28 SR6-AR34

21 26 mm SH1-SR6,5

SH1-SR1

TSE-MC 26/34

26 34 mm SH2-SR1

SH2-SR2

TSE-MC 32/50

32 50 mm SH3-SR1

SH3-SR2

SH3-SR3

TSE-MC 48/72

48 72 mm SH4-SR2

SH4-SR3 SH4-SR4

TSE-MC 70/100

70 100 mm SH5-SR3

SH5-SR4 SH5-SR5

TSE-MC 98/130 TSE-MC 98/160

98 130 mm SH6-SR4 98 160 mm SH6-SR5

SH6-SR6

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

HYDRAULIC TUBE INSIDE WELD BEAD SCARFING TOOLS

(TO REMOVE THE WELD BEAD FROM LONGITUDINAL WELDED TUBES) HYDRAULIC TOOL ID TUBE CUTTING RING HOLDER CUTTING RING SR1-AR7 TSE-HD 26/34 26 34 mm SH2-SR1

SH2-SR2 SR1-AR8 SR1-AR9 SR2-AR10 SR2-AR11 SR2-AR12 SR1-AR7 SR1-AR8 SR1-AR9 SR2-AR10 SR2-AR11 SR2-AR12 SR3-AR14 SR3-AR17 SR2-AR10 SR2-AR11 SR2-AR12 SR3-AR14 SR3-AR17 SR4-AR23 SR3-AR14 SR3-AR17 SR4-AR23 SR5-AR25 SR5-AR28 SR4-AR23 SR5-AR25 SR5-AR28 SR6-AR34 SR4-AR23 SR5-AR25 SR5-AR28 SR6-AR34 SR4-AR23 SR5-AR25 SR5-AR28 SR6-AR34 SR5-AR25 SR5-AR28 SR6-AR34 SR7-AR39 SR6-AR34 SR7-AR39 SR8-AR46

TSE-HD 32/50

32 50 mm SH3-SR1

SH3-SR2

SH3-SR3

TSE-HD 48/72

48 72 mm SH4-SR2

SH4-SR3 SH4-SR4

TSE-HD 70/100

70 100 mm SH5-SR3

SH5-SR4 SH5-SR5

TSE-HD 98/140

98 140 mm SH6-SR4

SH6-SR5 SH6-SR6

TSE-HD 135/180

135 180 mm SH6-SR4

SH6-SR5 SH6-SR6 SH6-SR4 SH6-SR5 SH6-SR6 SH6-SR5 SH6-SR6 SH6-SR7 SH6-SR6 SH6-SR7 SH6-SR8

TSE-HD 180/280

180 280 mm

TSE-HD 230/400

230 400 mm

TSE-HD 400/600

400 600 mm

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

MECHANICAL + HYDRAULIC TUBE INSIDE WELD BEAD SCARFING SYSTEMS FOR LONGITUDINAL WELDED TUBES

We offer customized high quality solutions for complete turnkey mechanical + hydraulic tube inside weld bead scarfing systems. We can offer systems for tube id 10,5 mm up to 600 mm. Please do not hesitate to contact us directly.

Neue-Welt-Strae 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TUBE OUTSIDE SCARFING INSERTS SNMG

DESCRIPTION

SNMG 15

RADIUS

R7 R9 R 11 R 13 R 15 R 18 R 20 R 22 R 25 R 27 R 30 R 35 R 40 R 45 R 50 R 55 R 60 R 70 R 80 R 90 R 10 R 12 R 15 R 20 R 25 R 30 R 35 R 40 R 45 R 50 R 55 R 60 R 70 R 80 R 90 R100 R110 R00 R50 R60 R70 R80 R90 R100 R110 R120 R130 R140 R150 R160 R180 R200

GOLD COATED

x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

BLACK COATED

x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

SNMG 19

SNMG 25

x = AVAILABLE (OTHER RADIUSES ARE AVAILABLE ON REQUEST) HOLDERS ARE AVAILABLE ON REQUEST

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TUBE OUTSIDE SCARFING INSERTS SNMX POSITIVE

DESCRIPTION

SNMX 15-22 (SNMX 150708)

RADIUS

R7 R9 R 11 R 13 R 15 R 18 R 20 R 22 R 25 R 27 R 30 R 35 R 40 R 45 R 50 R 55 R 60 R 70 R 80 R 90 R 10 R 12 R 15 R 20 R 25 R 30 R 35 R 40 R 45 R 50 R 55 R 60 R 70 R 80 R 90 R100 R110 R00 R50 R60 R70 R80 R90 R100 R110 R120 R130 R140 R150 R160 R180 R200

GOLD COATED

x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

BLACK COATED

x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

SNMX 19-22 (SNMX 190912)

SNMX 25-22 (SNMX 251224)

x = AVAILABLE (OTHER RADIUSES ARE AVAILABLE ON REQUEST) HOLDERS ARE AVAILABLE ON REQUEST

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TUBE OUTSIDE SCARFING INSERTS SNMX NEGATIVE

DESCRIPTION

SNMX 15-21 (SNMX 150608)

RADIUS

R7 R9 R 11 R 13 R 15 R 18 R 20 R 22 R 25 R 27 R 30 R 35 R 40 R 45 R 50 R 55 R 60 R 70 R 80 R 90 R 10 R 12 R 15 R 20 R 25 R 30 R 35 R 40 R 45 R 50 R 55 R 60 R 70 R 80 R 90 R100 R110 R00 R50 R60 R70 R80 R90 R100 R110 R120 R130 R140 R150 R160 R180 R200

GOLD COATED

x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

BLACK COATED

x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

SNMX 19-21 (SNMX 190612)

SNMX 25-21 (SNMX 250924)

x = AVAILABLE (OTHER RADIUSES ARE AVAILABLE ON REQUEST) HOLDERS ARE AVAILABLE ON REQUEST

Neue-Welt-Strae 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TUBE OUTSIDE SCARFING INSERTS SDUN (SDUX)

DESCRIPTION SDUN 190416 (SDUX 190416) RADIUS R9 R 11 R 13 R 15 R 18 R 20 R 22 R 25 R 27 R 30 R 35 R 40 R 42 R 45 R 50 R 60 R 70 R 75 R 90 R 100 GOLD COATED x x x x x x x x x x x x x x x x x x x x BLACK COATED x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x

R 00 x R 60 x R 80 x R 95 x R 105 x R 130 x R 145 x R 300 x R 400 x R 550 x x = AVAILABLE (OTHER RADIUSES ARE AVAILABLE ON REQUEST) HOLDERS ARE AVAILABLE ON REQUEST

SDUN 250616 (SDUX 250616)

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TUBE OUTSIDE SCARFING INSERTS ROMX

DESCRIPTION ROMX 2404 RADIUS BLACK COATED R 10 x R 13 x R 16 x R 21 x R 27 x R 38 x R 47 x R 60 x R 73 x R 85 x R 98 x x = AVAILABLE (OTHER RADIUSES ARE AVAILABLE ON REQUEST) HOLDERS ARE AVAILABLE ON REQUEST

Neue-Welt-Strae 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TUBE OUTSIDE SCARFING INSERTS SDUW

(FOR BIG TUBES WITH SLOW PRODUCTION SPEED) DESCRIPTION RADIUS UN GOLD COATED COATED SDUW 250920 R 00 x x R 25 x x R 35 x x R 45 x x R 50 x x R 55 x x R 65 x x R 85 x x R 120 x x R 160 x x R 200 x x R 250 x x x = AVAILABLE (OTHER RADIUSES ARE AVAILABLE ON REQUEST) HOLDERS ARE AVAILABLE ON REQUEST

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TUBE OUTSIDE SCARFING INSERTS (BLADES) LDGN

DESCRIPTION LDGN 130560 (FOR STAINLESS STEEL) RADIUS UN COATED GOLD COATED x x x x x x x x x x x x x x

R9 x R 10 x R 12 x R 15 x R 18 x R 20 x R 25 x R 30 x R 35 x R 40 x R 45 x R 50 x R 60 x R 70 x x = AVAILABLE (OTHER RADIUSES ARE AVAILABLE ON REQUEST) HOLDERS ARE AVAILABLE ON REQUEST

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

FERRITE CORES (IMPEDER CORES)

TYPE ZR 3x200 4x200 5x200 6x200 7x200 8x200 9x200 10x200 11x200 12x200 TYPE ZRF 3x200 4x200 5x200 6x200 7x200 8x200 9x200 10x200 11x200 12x200 TYPE ZRH TYPE ZRS 4x200 5x200 6x200 7x200 8x200 9x200 10x200 11x200 12x200 TYPE ZRSH TYPE ZRHU TYPE ZRSHU

6x3x200 7x3x200 8x3x200 8x4x200 9x4x200 10x4x200 10x5x200 11x5x200 12x5x200 12x6x200 12x7x200 13x6x200 13x7x200 13x8x200 14x7x200

6x3x200 7x3x200 8x3x200 9x3x200 10x3x200 10x5x200 11x3x200 11x5x200 12x3x200 12x4x200 13x5x200 13x7x200 14x4x200 14x5x200 14x7x200 15x4x200 15x5x200 15x6x200 15x7x200 16x5x200 16x6x200 16x7x200 16x8x200 17x5x200 17x6x200 17x7x200

6x3x200 7x3x200 8x3x200 8x4x200 9x4x200 10x4x200 10x5x200 11x5x200 12x5x200 12x6x200 12x7x200 13x6x200 13x7x200 13x8x200 14x7x200

7x3x200 8x3x200 9x3x200 10x3x200 10x5x200 11x3x200 11x5x200 12x3x200 12x4x200 13x5x200 13x7x200 14x4x200 14x5x200 14x7x200 15x4x200 15x5x200 15x6x200 15x7x200 16x5x200 16x6x200 16x7x200 16x8x200 17x5x200 17x6x200 17x7x200

13x200

13x200

13x200

14x200

14x200

14x200

15x200

15x200

15x7x200

15x200

15x7x200

16x200

16x200

16x8x200

16x200

16x8x200

17x200

17x200

17x8x200

17x200

17x8x200

OTHER SIZES AND LENGTH ARE AVAILABLE ON REQUEST, PLEASE DO NOT HESITATE TO ASK FOR

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

FERRITE CORES (IMPEDER CORES)

TYPE ZR 18x200 TYPE ZRF 18x200 TYPE ZRH 18x9x200 TYPE ZRS 18x200 TYPE ZRSH 18x5x200 18x6x200 18x8x200 18x9x200 19x6x200 19x8x200 20x6x200 20x10x200 21x6x200 21x10x200 22x6x200 22x10x200 22x11x200 23x6x200 23x11x200 23x13x200 24x6x200 24x12x200 25x6x200 25x10x200 25x12x200 26x10x200 26x13x200 27x8x200 27x13x200 28x13x200 28x14x200 29x10x200 30x15x200 32x13x200 32x16x200 33x10x200 33x15x200 TYPE ZRHU 18x9x200 TYPE ZRSHU 18x5x200 18x6x200 18x8x200 18x9x200 19x6x200 19x8x200 20x6x200 20x10x200 21x6x200 21x10x200 22x6x200 22x10x200 22x11x200 23x6x200 23x11x200 23x13x200 24x6x200 24x12x200 25x6x200 25x10x200 25x12x200 26x10x200 26x13x200 27x8x200 27x13x200 28x13x200 28x14x200 29x10x200 30x15x200 32x13x200 32x16x200 33x10x200 33x15x200

19x200 20x200 21x200 22x200

19x200

19x9x200

19x200 20x200 21x200 22x200

19x9x200 20x8x200 20x10x200 21x10x200 22x11x200

20x200 20x10x200 21x200 21x10x200 22x200 22x11x200

23x200

23x200

23x200

24x200 25x200

24x200 25x200 25x12x200

24x200 25x200

25x12x200

26x200 27x200 28x200 29x200 30x200 32x200 33x200

26x200 26x13x200 27x200 28x200 28x14x200 29x200 30x200 30x15x200 32x200 33x200

26x200 27x200 28x200 29x200 30x200 32x200 33x200

26x13x200

28x14x200

30x15x200

OTHER SIZES AND LENGTH ARE AVAILABLE ON REQUEST, PLEASE DO NOT HESITATE TO ASK FOR

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

FERRITE CORES (IMPEDER CORES)

TYPE ZR 34x200 36x200 TYPE ZRF 34x200 36x200 TYPE ZRH TYPE TYPE ZRS ZRSH 34x200 34x17x200 36x200 36x18x200 38x19x200 40x20x200 42x21x200 44x20x200 45x20x200 46x23x200 48x20x200 48x24x200 50x20x200 54x20x200 55x20x200 55x27x200 60x30x200 65x32x200 70x35x200 73x36x200 80x40x200 85x42x200 90x45x200 95x48x200

100x50x200 102x51x200

TYPE ZRHU

TYPE ZRSHU 34x17x200 36x18x200 38x19x200 40x20x200 42x20x200 44x20x200 45x20x200 46x23x200 48x20x200 48x24x200 50x20x200 54x20x200 55x20x200 55x27x200 60x30x200 65x32x200 70x35x200 73x36x200 80x40x200 85x42x200 90x45x200 95x48x200

100x50x200 102x51x200

OTHER SIZES AND LENGTH ARE AVAILABLE ON REQUEST, PLEASE DO NOT HESITATE TO ASK FOR

Neue-Welt-Str. 5 66740 Saarlouis Germany Tel.: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

EPOXY FIBREGLASS TUBES

OUTSIDE DIAMETER OD IN MM 3 mm TEMPERATURE RESISTANCE 160C INSIDE WALL READY CUT DIAMETER THICKNESS LENGTH ID IN MM IN MM IN MM 2 mm 0,5 mm 30 mm STANDARD LENGTH IN MM

1050 mm

650 mm

610 mm

20 mm

1050 mm

BLACK COATED EPOXY FIBREGLASS TUBE

TEMPERATURE RESISTANCE 280C

WHITE COATED EPOXY FIBREGLASS TUBE

TEMPERATURE RESISTANCE 900C

Neue-Welt-Str. 5 66740 Saarlouis Germany Tel.: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

SILICONE FIBREGLASS TUBES

OUTSIDE DIAMETER OD IN MM 3 mm TEMPERATURE RESISTANCE 180C READY CUT INSIDE WALL LENGTH DIAMETER THICKNESS IN MM ID IN MM IN MM 2 mm 0,5 mm 30 mm STANDARD LENGTH IN MM

1150 mm

650 mm

610 mm

20 mm

1150 mm

Neue-Welt-Str. 5 66740 Saarlouis Germany Tel.: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

MUSCOVITE MICA SILICONE TUBES

OUTSIDE DIAMETER OD IN MM 8 mm TEMPERATURE RESISTANCE 550C INSIDE WALL READY CUT DIAMETER THICKNESS LENGTH ID IN MM IN MM IN MM 4 mm 0,5 mm 30 mm STANDARD LENGTH IN MM

1000 mm

58 mm

50 mm

4 mm

1000 mm

Neue-Welt-Str. 5 66740 Saarlouis Germany Tel.: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

PHLOGOPITE MICA SILICONE TUBES

OUTSIDE DIAMETER OD IN MM 8 mm TEMPERATURE RESISTANCE 700C INSIDE WALL READY CUT DIAMETER THICKNESS LENGTH ID IN MM IN MM IN MM 4 mm 0,5 mm 30 mm STANDARD LENGTH IN MM

1000 mm

58 mm

50 mm

4 mm

1000 mm

Neue-Welt-Str. 5 66740 Saarlouis Germany Tel.: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

FLEXIBLE PTFE TUBES

OUTSIDE DIAMETER OD IN MM 2 mm INSIDE DIAMETER ID IN MM 1 mm WALL THICKNESS IN MM 0,5 mm STANDARD LENGTH IN METER 10 meter

50 mm

48 mm

5 mm

100 meter

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TURNING / MILLING / DRILLING INSERTS

We offer a wide range of different ISO carbide inserts for turning / milling / drilling processes, but certainly we are also able to supply customized solutions. Our inserts are available in different carbide grades and PVD/CVD coatings.

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

HSS CIRCULAR SAW BLADES

Our new high performance HSS DMo5 circular saw blade. Owing to the new special PVD multilayer coating (TiN, TiCN, AlTiCN) we reach multiple higher lifetime compared with standard coated HSS circular saw blades. Your advantages: Better cutting quality Longer lifetime Less machine stops Reduced saw blade costs Lower re-sharpening costs

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

HSS-E CIRCULAR SAW BLADES

Our new high performance HSS-E circular saw blade. Owing to the new special PVD multilayer coating (AlTiN-Si) we reach multiple higher lifetime compared with standard coated HSS-E circular saw blades. Your advantages: Better cutting quality Longer lifetime Less machine stops Reduced saw blade costs Lower re-sharpening costs

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

TCT CIRCULAR SAW BLADES

Our new high performance TCT circular saw blade. The teeth are equipped with high quality tungsten carbide. Owing to the new special PVD multilayer coating (AlTiN or AlTiN-Si) we reach multiple higher lifetime compared with standard coated TCT circular saw blades. Your advantages: Better cutting quality Longer lifetime Less machine stops Reduced saw blade costs

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

CHROME VANADIUM FRICTION SAW BLADES

Our new high performance friction saw blade. The friction saw blades are made of special Chrome Vanadium steel and carefully tempered according to their purpose. They have hollow ground sides and the teeth are sharpened.

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

FILTER FABRICS

We offer different high quality filter fabrics made by: viscose, polyester, polypropylene, bi-component fibres

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

MAGNETIC SEPARATORS (MSWD SERIES) WITH DISKS

MSWD magnetic separators with disk are used to remove ferrous metallic particles produced by different industrial processes and found suspended in liquid lubrocoolants. The filtration occurs by means of a rotating magnetic drum of variable size according to the flow rate of the liquid lubrocoolant to treat. Based on the flow rate, the standard production of our series of magnetic filters is divided in: Light series MSWD/1 Heavy series MSWD/2 For flow rates from 50 to 500 L/min. For flow rates from 600 to 2.000 L/min.

Advantages: Low energy consumption Low maintenance costs Simple and automatic operation Easy to install Without consumption of filtering means Self-cleaning

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

GRAVITY FLAT BED FILTERS (GFBF SERIES) WITH FILTERING FABRIC

In our GFBF type flat bed gravity strainers filtration occurs by gravity and the used filtering means is the non woven fabric capable to retain contaminating particles of any kind, both metallic and non-metallic particles produced by different industrial processes and found suspended in liquid lubrocoolants. The average degree of filtration that can be obtained varies according to the type of filtering fabric used and to the caking on the fabric itself due to the layer of accumulated sludge. The flow rate of lubrocoolant to filtrate determines the size of the gravity strainer and the extension of the filtering surface necessary for the purpose. Based on the flow rate of the liquid to be treated, standard production of our series of gravity strainers is divided in: Normal series Type GFBF for flow rates from 50 to 500 L/min. Wide series Type GFBF/L for flow rates from 250 to 1.500 L/min. Overlapped series Type GFBF/S for flow rates from 500 to 4.500 L/min. While our normal GFBF series strainers and the large GFBF/L series consist of a single filtering unit, the overlapped GFBF/S series consists of 2 or 3 GFBF/S type strainers installed one above the other. This allows to obtain a total filtering surface suited to the considerable filtration capacities remarkably reducing the total filter dimension. The total capacity of liquid to be treated is divided and distributed to the individual filtration units via pipes and valves that divide the flow. The overlapped series is particularly recommended for centralised systems designed to supply filtered liquid to several manufacturing machines. All our gravity strainers can be equipped (upon request) with a magnetic filter so that the liquid to treat is subject to a prefiltration treatment. The GFBF/M series strainers, combined with magnetic filter, are used when there is a high content of ferrous particles suspended in the liquid to treat. Pre-filtrating the lubrocoolant considerably limits the consumption of filtering fabric allowing a large part of the pollutant magnetic particles to be eliminated before these reach the filtering bag in the gravity strainer. Advantages: Low energy consumption Low maintenance costs Simple and automatic operation Easy to install Flexibility in the choice of filtering fabric and degree of filtration The flat bed gravity strainer and conveyor belt can both be made of stainless steel

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

HYDROSTATIC FILTRATION SYSTEMS (HSFS SERIES) WITH FILTERING FABRIC

Our gravity strainers with high hydrostatic head type HSFS are used to remove ferrous metallic of any kind, both metallic and non-metallic, produced by different industrial processes and found suspended in liquid lubrocoolants (emulsions or whole oils). Filtration occurs by gravity and the filtration means used is non woven fabric. The average degree of filtration that can be obtained varies according to the type of filtering fabric used and the thickness of sludge accumulated on it during the filtration cycle. Thanks to the high level of liquid the filtering bag can hold and the high pressure exerted by the liquid, the efficiency of the filtering fabric is considerable increased. Indeed, compared with traditional gravity strainers with flat bed it has the same flow rate of liquid to be filtered, the size of the filter is considerably smaller and therefore obtains high degrees of filtration reducing consumption of the filtering fabric. The filtering surface is calculated based on the flow rate of lubrocoolant to be treated. The standard production of HSFS hydrostatic strainers is available for flow rates up to 3.000L/min. All our hydrostatic strainers can be equipped (upon request) with a magnetic filter so the liquid to treat is subject to a prefiltration treatment. The HSFS-M series hydrostatic strainers, combined with magnetic filter, are used when there is a high content of ferrous particles suspended in the liquid to be treated. The magnetic separator can eliminate a large part of the pollutant magnetic particles before they reach the filtering bag of the hydrostatic filter, which considerable reduces the caking cycles and feed of the fabric. Pre-filtrating lubrocoolants using a magnetic separator is strongly recommended to limit the consumption of filtering fabric. Our hydrostatic strainers, type HSFS can be built entirely of stainless steel.

Neue-Welt-Str. 5 66740 Saarlouis Germany Phone: +49 6831 7647674 Fax: +49 6831 7647675 Email: info@tube-scarfing.de Web : www.tube-scarfing.com

ROTATING DRUM FILTRATION SYSTEMS (RDFS SERIES) WITH FILTERING FABRIC

Our RDFS series are used in mechanical machining for the filtration of coolants and liquids containing all types of contaminating particles. The type of filtering fabric used determines the degree of filtration. The circumference and width of the system provides a large filtering surface and allows significant capacities in reduced spaces. These type of filtration systems are suitable for the filtration of coolants (emulsions or whole oils) used on machine tools with chip removal, with tool for abrasion, in grinding machines, on transfer machines, work centres, drawing, lapping and honing machines, etc. They are also suitable for the filtration of washing and machining waters in industrial production processes such as washing machines, quenching waters, painting waters, etc. The filtration system RDFS series can be fitted individually, assuring an excellent efficiency, but can also combined with any type of filtration systems to obtain the grade of filtration desired, for example magnetic separators with disks. RDFS series is suitable for capacities of 20 to 3.000 l/min. Can be fitted to single machines or centralised systems.

You might also like

- Suplemento Vacio Cabezal Rev01Document1 pageSuplemento Vacio Cabezal Rev01antonio2008No ratings yet

- Usuario 17/05/2012: Designed by Checked by Approved by Date DateDocument1 pageUsuario 17/05/2012: Designed by Checked by Approved by Date Dateantonio2008No ratings yet

- Usuario 17/05/2012: Designed by Checked by Approved by Date DateDocument1 pageUsuario 17/05/2012: Designed by Checked by Approved by Date Dateantonio2008No ratings yet

- Croquis LogisticaDocument1 pageCroquis Logisticaantonio2008No ratings yet

- DWG TrueView DWG Convert Conversion ReportDocument1 pageDWG TrueView DWG Convert Conversion ReportCosmin CinciNo ratings yet

- SEO-optimized title for extruder female die design drawingDocument1 pageSEO-optimized title for extruder female die design drawingantonio2008No ratings yet

- 7 Slides Cell DesignDocument30 pages7 Slides Cell DesignpsunmoorthyNo ratings yet

- TL - 082-nDocument23 pagesTL - 082-nKenedi LopezNo ratings yet

- PCB FinalDocument1 pagePCB Finalantonio2008No ratings yet

- Diodes npn pnp - Semiconductor devicesDocument1 pageDiodes npn pnp - Semiconductor devicesantonio2008No ratings yet

- SEO-optimized title for extruder female die design drawingDocument1 pageSEO-optimized title for extruder female die design drawingantonio2008No ratings yet

- BC548 Hoja de Datos PDFDocument5 pagesBC548 Hoja de Datos PDFJuan FiNo ratings yet

- Linear & Switching Voltage Regulator HandbookDocument118 pagesLinear & Switching Voltage Regulator Handbookzack9mm2003No ratings yet

- PSH PLLDocument1 pagePSH PLLantonio2008No ratings yet

- Primer Nivel Torre de Enfriamiento Rev0Document1 pagePrimer Nivel Torre de Enfriamiento Rev0antonio2008No ratings yet

- Pneumatic Conveying SystemsDocument57 pagesPneumatic Conveying SystemsSakthi Vel100% (1)

- Conveying Bends Article Paul SoltDocument8 pagesConveying Bends Article Paul SoltJoel Olson100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PCT 304414 PDFDocument36 pagesPCT 304414 PDFNugrawan SatriaNo ratings yet

- DLP Science 6 - q1 WK 4 Day 5Document9 pagesDLP Science 6 - q1 WK 4 Day 5Sonny MatiasNo ratings yet

- Global Milling Annual 2013Document60 pagesGlobal Milling Annual 2013Global MillingNo ratings yet

- NCERT Solutions For Class 6 April 3 Science Chapter 5 Separation of SubstancesDocument3 pagesNCERT Solutions For Class 6 April 3 Science Chapter 5 Separation of SubstancesPravin PatilNo ratings yet

- MPAP - MU16069 - en Sifter PDFDocument8 pagesMPAP - MU16069 - en Sifter PDFAdlan Albi SiregarNo ratings yet

- Essential cocktail tools and glassesDocument7 pagesEssential cocktail tools and glassesKarl Andrei PimentelNo ratings yet

- Science Q1 W7Document74 pagesScience Q1 W7John Giles Jr.No ratings yet

- D409M - 11ae1 PDFDocument14 pagesD409M - 11ae1 PDFPOSSDNo ratings yet

- Dullente - COT 2 Lesson PlanDocument3 pagesDullente - COT 2 Lesson PlanJENMARIE DULLENTENo ratings yet

- Summative Test in Science 6 No.4Document2 pagesSummative Test in Science 6 No.4Yram Ecarg OudiserNo ratings yet

- q1 Science 6 Separating Mixtures DetailedDocument7 pagesq1 Science 6 Separating Mixtures DetailedSHARON OCAYNo ratings yet

- 4 - Competency Based Learning MaterialDocument25 pages4 - Competency Based Learning MaterialRobert Jan SusaloNo ratings yet

- Strainer Screen & Mesh Selection GuideDocument4 pagesStrainer Screen & Mesh Selection Guidelenasko0% (1)

- BPP G11 - Q2.2Document7 pagesBPP G11 - Q2.2Rio Krystal MolateNo ratings yet

- Separating Mixtures TechniquesDocument11 pagesSeparating Mixtures Techniqueschona redillasNo ratings yet

- Project Study 2Document41 pagesProject Study 2James AlcariaNo ratings yet

- Hi SifterDocument3 pagesHi SifterAndy HermanNo ratings yet

- Science6 - q1 - Mod2les1 - Separating Mixtures Through Filtering and Sieving - FINAL08032020Document17 pagesScience6 - q1 - Mod2les1 - Separating Mixtures Through Filtering and Sieving - FINAL08032020jerlie concepcion100% (3)

- Jenis AyakDocument5 pagesJenis AyakFauzi AlifkaNo ratings yet

- 01 LC Vibratory Sifter 01Document2 pages01 LC Vibratory Sifter 01Ravi YadavNo ratings yet

- Bechtel - Use of Startup StrainerDocument17 pagesBechtel - Use of Startup Strainerreach_arindomNo ratings yet

- Tapasya Product Catalogue PDFDocument104 pagesTapasya Product Catalogue PDFMahesh Patil KahatulNo ratings yet

- SUMMATIVE TEST (Separating Mixtures) 6Document1 pageSUMMATIVE TEST (Separating Mixtures) 6Ledie Lou Cetoy Superales100% (3)

- Process Validation ProtocolDocument31 pagesProcess Validation ProtocolMangesh Parulekar92% (13)

- Sieve Bend ScreenDocument5 pagesSieve Bend Screenwedge wire screensNo ratings yet

- (Science 6 WK 5 L9) - Separating Mixtures Through SievingDocument22 pages(Science 6 WK 5 L9) - Separating Mixtures Through SievingRhea OciteNo ratings yet

- Harga Perkiraan Sendiri (HPS)Document2 pagesHarga Perkiraan Sendiri (HPS)Ady Surya Lesmana100% (1)

- Eaton Basket and Screen Design DetailsDocument12 pagesEaton Basket and Screen Design DetailsArun GuptaNo ratings yet

- Fabrication of Multi-Purpose Sieving MachineDocument36 pagesFabrication of Multi-Purpose Sieving MachineBoopathi KalaiNo ratings yet

- Sorghum Flour Codex StandardDocument3 pagesSorghum Flour Codex StandardhymasarathiNo ratings yet