Professional Documents

Culture Documents

Makeblock 2H Microstep Driver

Uploaded by

MakeblockOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Makeblock 2H Microstep Driver

Uploaded by

MakeblockCopyright:

Available Formats

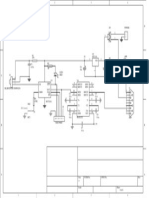

Makeblock 2H Microstep Driver

1. Introduction:

Makeblock 2H Microstep Driver is a type of two-phase hybrid stepping motor driver, the drive voltage of which is from 12VDC to 36VDC. It is designed for use with 2-phase hybrid stepper motor of all kinds with 20mm to 42mm outside diameter and less than 2.0A phase current. This circuit that it adopts is similar to the circuit of servo control which enables the motor to run smoothly almost without noise and vibration. Holding torque when the Microstep Driver rund at high speed is also significantly higher than the other two-phase drivers, whats more, the positioning accuracy is also higher. It is widely used in middle and big size numerical control devices such as curving machine, CNC machine, and computer embroider machine, packing machines and so on.

2. Features:

High performance, low price Average current control, 2-phase sinusoidal output current drive Supply voltage from 12VDC to 36VDC Opto-isolated signal I/O Overvoltage, under voltage, overcurrect, phase short circuit protection

8 channels subdivision and automatic idle-current reduction 8 channels output phase current setting Offline command input terminal Motor torque is related to speed, but not related to step/revolution High start speed High holding torque at high speed

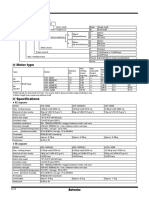

3. Electrical specification:

Input voltage Input current Output current Consumption Temperature Humidity Gas Weight 12-36VDC 2A 0.44A- 2.83A Consumption40W Working Temperature -1045 Stocking temperature -4070 Not condensation, no water droplets Prohibition of combustible gases and conductive dust 125 g

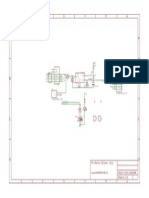

4. Pins assignments and description:

Connector Pins Configurations Table: Pin Function PUL +,PULDIR+,DIRDetails Pulse signal: PUL+ is the positive end of pulses input pin PUL- is the negative end of pulse input pin DIR signal: DIR+ is the positive end of direction input pin DIR- is the negative end of direction input pin Enable signal: ENBL+ is the positive end of direction input pin. ENBL+ This signal is used for enabling/disabling the driver. High level for enabling the driver and low level for disabling the driver. ENBLENBL- is the negative end of direction input pin. Usually left unconnected (enabled)

5. Function choice (Using DIP pins to achieve this function)

5.1 Micro step resolution setting Micro step resolution is set by SW 5,6,7,8 of the DIP switch as shown in the following Micro step resolution SW5 SW6 SW7 Pulse/rev Micro ON ON ON 200 1 OFF ON ON 400 2 ON OFF ON 800 4 OFF OFF ON 1600 8 ON ON OFF 3200 16 OFF ON OFF 6400 32 ON OFF OFF 12800 64 OFF OFF OFF 25600 128

5.2 Standstill current setting SW4 is used for this purpose. OFF meaning that the standstill current is set to be half of the selected dynamic current and ON meaning that standstill is set to be the same as the selected dynamic current. 5.3 Output current setting The first three bits (SW 1, 2, 3)of the DIP switch are used to set the dynamic current. Select a setting Closest to your motors required current SW1 ON OFF ON OFF ON OFF ON OFF SW2 ON ON OFF OFF ON ON OFF OFF SW3 ON ON ON ON OFF OFF OFF OFF PEAK 0.44 A 0.62 A 0.74 A 0.86 A 1.46 A 1.69 A 2.14 A 2.83 A RMS 0.31 A 0.44 A 0.52 A 0.61 A 1.03 A 1.20 A 1.51 A 2.0

5.4 Semi-flow function: Semi-flow function is that there is not step pulse after200 ms, the driver output current automatically reduced to 40% of rated output current, which is used to prevent motor heat.

6. Pins of motor & power:

Connect Makeblock 2H Microstep Driver with Stepper motor 42BYGHW609. Pins A+ AB+ BDC+ DCMotor wiring & Power supply Black Wire Green Wire Red Wire Blue Wire Power supply DC12-36VDC. The peak input current cannot be up to 2A

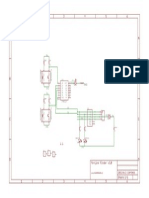

7. Adjustment of troubleshooting

7.1 The status on lights indication PWR: green, normal work light. ALM: red, failure light, the motor with phase short-circuit, overvoltage and under-voltage protection. 7.2 Troubles Alarm indicator LED off turn Reasons Measures Check wiring of power Enlarge voltage of power Correct its wiring Make RESET ineffective Adjust PMW & signal level Wrong connection for power Low voltages for power Wrong connection of stepper Motor doesnt run, motor without holding torque RESET signal is effective when offline Motor doesnt run, but maintains holding Without input pulse signal torque Motor runs direction wrong Wrong wires connection

Change connection for any of 2 wires Wrong input direction signal Change direction setting Too small relative to current Correct rated current setting setting Acceleration is too fast Reduce the acceleration Motors holding torque Rule out mechanical is too small Motor stalls failure Driver does not match with Change a suitable driver the motor

You might also like

- (SIRI Assessor Training) AM Guide Book - v2Document19 pages(SIRI Assessor Training) AM Guide Book - v2hadeelNo ratings yet

- HM CNC ROUTER MANUAL For Carving Mashine PDFDocument112 pagesHM CNC ROUTER MANUAL For Carving Mashine PDFRadovan KnezevicNo ratings yet

- CSEC IT Fundamentals of Hardware and SoftwareDocument2 pagesCSEC IT Fundamentals of Hardware and SoftwareR.D. Khan100% (1)

- Aci 207.1Document38 pagesAci 207.1safak kahraman100% (7)

- 4 Äæ Æ÷ÍêÕû Çâ Ô ÀíÍ ßÇåÎúDocument9 pages4 Äæ Æ÷ÍêÕû Çâ Ô ÀíÍ ßÇåÎúSaeid ShahnavazNo ratings yet

- Ds NV Quadro k1200 Feb15 NV Us HRDocument1 pageDs NV Quadro k1200 Feb15 NV Us HRJose PazNo ratings yet

- Analog Circuit Design Volume Three: Design Note CollectionFrom EverandAnalog Circuit Design Volume Three: Design Note CollectionRating: 3 out of 5 stars3/5 (2)

- The SAGE Handbook of Digital JournalismDocument497 pagesThe SAGE Handbook of Digital JournalismK JNo ratings yet

- Configuring GRBL v0.9 GRBL - GRBL Wiki GitHubDocument17 pagesConfiguring GRBL v0.9 GRBL - GRBL Wiki GitHubBams HaryNo ratings yet

- 4Q Labor Case DigestsDocument53 pages4Q Labor Case DigestsKaren Pascal100% (2)

- Leg Wri FInal ExamDocument15 pagesLeg Wri FInal ExamGillian CalpitoNo ratings yet

- Spindle Encodercatalog PDFDocument60 pagesSpindle Encodercatalog PDFchidambaram kasiNo ratings yet

- 04 Dasmarinas Vs Reyes GR No 108229Document2 pages04 Dasmarinas Vs Reyes GR No 108229Victoria Melissa Cortejos PulidoNo ratings yet

- Driver Rack DBX 480 - Power BoardDocument4 pagesDriver Rack DBX 480 - Power BoardWalter CruzNo ratings yet

- MD2278 Microstepping Driver SpecsDocument3 pagesMD2278 Microstepping Driver Specshoangmanh1989No ratings yet

- Dq420ma English PDFDocument6 pagesDq420ma English PDFAnderson RovaniNo ratings yet

- Analog Section: 1 MG15FX/MG30FXDocument2 pagesAnalog Section: 1 MG15FX/MG30FXgabriel_lazarescu2005No ratings yet

- Single Wall Fuel Tank: FP 2.7 A-C Fire Pump SystemsDocument1 pageSingle Wall Fuel Tank: FP 2.7 A-C Fire Pump Systemsricardo cardosoNo ratings yet

- Trinath Chigurupati, A095 576 649 (BIA Oct. 26, 2011)Document13 pagesTrinath Chigurupati, A095 576 649 (BIA Oct. 26, 2011)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Me-Base Shield v2.0Document1 pageMe-Base Shield v2.0MakeblockNo ratings yet

- Makeblock Triangular TankDocument10 pagesMakeblock Triangular TankMakeblockNo ratings yet

- Makeblock 2WD RobotDocument8 pagesMakeblock 2WD RobotMakeblockNo ratings yet

- Makeblock ForkliftDocument21 pagesMakeblock ForkliftMakeblock100% (1)

- Md0332 Wifi Shield Esp13 KeysDocument10 pagesMd0332 Wifi Shield Esp13 KeysbluesbankyNo ratings yet

- Photogrammetric Scale Noncoded Markers PlusDocument1 pagePhotogrammetric Scale Noncoded Markers PlusJosip Kovilić100% (1)

- Construct Your Dreams: Arduino BoxDocument8 pagesConstruct Your Dreams: Arduino BoxMakeblockNo ratings yet

- Makeblock Beer Robot InstructionDocument13 pagesMakeblock Beer Robot InstructionMakeblockNo ratings yet

- Construct Your Dreams: Suitable For UseDocument15 pagesConstruct Your Dreams: Suitable For UseMakeblockNo ratings yet

- Makeblock Strong Robot GripperDocument11 pagesMakeblock Strong Robot GripperMakeblock100% (1)

- Arduino 2wd Smart Robot Car Kit enDocument8 pagesArduino 2wd Smart Robot Car Kit enJeyson GuanoluisaNo ratings yet

- Discrete Flat No-Leads DFN Package PosterDocument1 pageDiscrete Flat No-Leads DFN Package Posterbbxload319No ratings yet

- Korg tr61 PDFDocument18 pagesKorg tr61 PDFramaianoNo ratings yet

- Monitor Sony Cpd-101vsDocument28 pagesMonitor Sony Cpd-101vspepitito22No ratings yet

- CS8656 E S 2015 03 A Non IsoDocument10 pagesCS8656 E S 2015 03 A Non IsoAnonymous cQAi2l7No ratings yet

- E10 User ManualDocument30 pagesE10 User ManualRodrygo BortottiNo ratings yet

- 480 Communication BoardDocument4 pages480 Communication BoardTadas PNo ratings yet

- Parts List: Original Instructions P-GN14-E (2012.05)Document88 pagesParts List: Original Instructions P-GN14-E (2012.05)Shahrooz RahmaniNo ratings yet

- 8200 MotecDocument3 pages8200 Motecyera1No ratings yet

- Latitude 3480 3488 3580 16852-1 2-7 Taos - Kbl-U - A00 - 1223 - 1Document105 pagesLatitude 3480 3488 3580 16852-1 2-7 Taos - Kbl-U - A00 - 1223 - 1cuncho lennonNo ratings yet

- SAP 4.6 Installation Guide For 2003 ServerDocument5 pagesSAP 4.6 Installation Guide For 2003 Serverpattnaikdinesh100% (1)

- LG PLDE-P008A - GL-PSL40-2 - Chassis Q552.2LLA PSU & LED Driver Schematic-1 PDFDocument3 pagesLG PLDE-P008A - GL-PSL40-2 - Chassis Q552.2LLA PSU & LED Driver Schematic-1 PDFanjan chatterjeeNo ratings yet

- LCD-24K40 Service ManualDocument55 pagesLCD-24K40 Service ManualDedi MulyadiNo ratings yet

- Kit Audio 500w MivaDocument1 pageKit Audio 500w MivaGeorge MucutaNo ratings yet

- Gelco Product Literature 23.01.2014 PDFDocument19 pagesGelco Product Literature 23.01.2014 PDFanilNo ratings yet

- Boschert: CNC Busbar Cutting - Punching - Bending SolutionDocument42 pagesBoschert: CNC Busbar Cutting - Punching - Bending SolutiondemdiinNo ratings yet

- Gaggia Brera Brew Unit Parts DiagramDocument1 pageGaggia Brera Brew Unit Parts DiagramChris VerveridisNo ratings yet

- Heidenhain EncoderDocument2 pagesHeidenhain EncoderCristian AlonsoNo ratings yet

- Ono-Sokki General Product GuideDocument43 pagesOno-Sokki General Product Guide王宗超No ratings yet

- 16×2 LCD Module Pin Out DiagramDocument11 pages16×2 LCD Module Pin Out Diagramvijay bNo ratings yet

- Nordic Semiconductor ASA nRF52840 Bluetooth Low Energy/ANT/802.15.4/2.4GHz RF Development Board (PCA10056Document13 pagesNordic Semiconductor ASA nRF52840 Bluetooth Low Energy/ANT/802.15.4/2.4GHz RF Development Board (PCA10056Thanga rajNo ratings yet

- WC67K NC Hydraulic Plate Press Brake With E21 ControllerDocument6 pagesWC67K NC Hydraulic Plate Press Brake With E21 ControllerryneleeNo ratings yet

- Sprintcut PDFDocument5 pagesSprintcut PDFpruthiviraj13100% (1)

- UArm Assembly Instructions v1Document21 pagesUArm Assembly Instructions v1dio39saiNo ratings yet

- L&T MN RelaysDocument6 pagesL&T MN RelaysArun KumarNo ratings yet

- Service Manual: Fm/Am Compact Disc PlayerDocument10 pagesService Manual: Fm/Am Compact Disc PlayerelekossNo ratings yet

- Service Manual: Fm/Am Compact Disc PlayerDocument12 pagesService Manual: Fm/Am Compact Disc PlayerguelphnowNo ratings yet

- 721-06LT Operating Instructions/ManualDocument48 pages721-06LT Operating Instructions/ManualWhitaker Brothers100% (2)

- Power Supply 17IPS19-4 VESTELDocument1 pagePower Supply 17IPS19-4 VESTELCod4009No ratings yet

- 965 Mohdhafizbinadenan2014Document96 pages965 Mohdhafizbinadenan2014pawanceeri1965No ratings yet

- Hinumerik 3100mDocument3 pagesHinumerik 3100mPham LongNo ratings yet

- 2 Channel in 4 Channel Out ADAU1701 Sigma DSP Pre-Amplifier With Bluetooth Plug-In ModuleDocument12 pages2 Channel in 4 Channel Out ADAU1701 Sigma DSP Pre-Amplifier With Bluetooth Plug-In ModuleNicolae Nechifor100% (1)

- Manuals and SchemesDocument8 pagesManuals and SchemesRishi jain0% (1)

- AK-2 Series 2-Phase Stepper Motors and DriversDocument3 pagesAK-2 Series 2-Phase Stepper Motors and DriversEdson DinizNo ratings yet

- LM339 PDFDocument12 pagesLM339 PDFelhandasya MedicalNo ratings yet

- Intro To MiRModbusTCPDocument9 pagesIntro To MiRModbusTCPOliver Ochoa GarciaNo ratings yet

- Service Manual: Induction Plate HD4918Document2 pagesService Manual: Induction Plate HD4918Arumugam Rajendran100% (2)

- Datasheet - M542H Stepper Motor DriverDocument10 pagesDatasheet - M542H Stepper Motor DriversthollanderNo ratings yet

- M542 Stepper Motor DriveDocument8 pagesM542 Stepper Motor DriveElvio JungesNo ratings yet

- DQ860MA Stepper Motor Driver GuideDocument7 pagesDQ860MA Stepper Motor Driver GuideTrentoNo ratings yet

- Construct Your Dreams: Suitable For UseDocument15 pagesConstruct Your Dreams: Suitable For UseMakeblockNo ratings yet

- Makeblock 4-Legged CrawlerDocument17 pagesMakeblock 4-Legged CrawlerMakeblockNo ratings yet

- Makeblock Small TankDocument15 pagesMakeblock Small TankMakeblockNo ratings yet

- Construct Your Dreams: Arduino BoxDocument8 pagesConstruct Your Dreams: Arduino BoxMakeblockNo ratings yet

- Makeblock SliderDocument12 pagesMakeblock SliderMakeblock100% (1)

- DC Motor Driver ICDocument11 pagesDC Motor Driver ICKoray KaraNo ratings yet

- Makeblock Strong Robot GripperDocument11 pagesMakeblock Strong Robot GripperMakeblock100% (1)

- Makeblock TurntableDocument11 pagesMakeblock TurntableMakeblockNo ratings yet

- Makeblock Tank With Robot ArmDocument17 pagesMakeblock Tank With Robot ArmMakeblock0% (1)

- Me-Servo Driver v2.1Document1 pageMe-Servo Driver v2.1MakeblockNo ratings yet

- Makeblock Big TankDocument9 pagesMakeblock Big TankMakeblockNo ratings yet

- Makeblock Beer RobotDocument19 pagesMakeblock Beer RobotMakeblockNo ratings yet

- Me-Infrared Reciver Decode v2.0Document1 pageMe-Infrared Reciver Decode v2.0MakeblockNo ratings yet

- Me-Motor Driver v2.0Document1 pageMe-Motor Driver v2.0MakeblockNo ratings yet

- Me-Line Finder v2.0Document1 pageMe-Line Finder v2.0MakeblockNo ratings yet

- Me-Lego Motor BridgeDocument1 pageMe-Lego Motor BridgeMakeblockNo ratings yet

- Makeblock 1DOF RobotDocument13 pagesMakeblock 1DOF RobotacpcalinNo ratings yet

- Me-RJ11 Adapter v2.0Document1 pageMe-RJ11 Adapter v2.0MakeblockNo ratings yet

- Bc7210a Demo Board SchematicDocument1 pageBc7210a Demo Board SchematicMakeblockNo ratings yet

- Makeblock Beer Robot InstructionDocument13 pagesMakeblock Beer Robot InstructionMakeblockNo ratings yet

- Makeblock Big Tank InstructionDocument9 pagesMakeblock Big Tank InstructionMakeblockNo ratings yet

- Makeblock Small TankDocument7 pagesMakeblock Small TankMakeblockNo ratings yet

- Makeblock 2WD CarDocument8 pagesMakeblock 2WD CarMakeblockNo ratings yet

- Discretionary Lending Power Updated Sep 2012Document28 pagesDiscretionary Lending Power Updated Sep 2012akranjan888No ratings yet

- Diagnostic Information For Database Replay IssuesDocument10 pagesDiagnostic Information For Database Replay IssuesjjuniorlopesNo ratings yet

- Lec - Ray Theory TransmissionDocument27 pagesLec - Ray Theory TransmissionmathewNo ratings yet

- C 7000Document109 pagesC 7000Alex Argel Roqueme75% (4)

- Aptio ™ Text Setup Environment (TSE) User ManualDocument42 pagesAptio ™ Text Setup Environment (TSE) User Manualdhirender karkiNo ratings yet

- Model S-20 High Performance Pressure Transmitter For General Industrial ApplicationsDocument15 pagesModel S-20 High Performance Pressure Transmitter For General Industrial ApplicationsIndra PutraNo ratings yet

- Econ Old Test 2Document7 pagesEcon Old Test 2Homer ViningNo ratings yet

- A320 Normal ProceduresDocument40 pagesA320 Normal ProceduresRajesh KumarNo ratings yet

- Benchmarking Guide OracleDocument53 pagesBenchmarking Guide OracleTsion YehualaNo ratings yet

- Abb Drives: User'S Manual Flashdrop Mfdt-01Document62 pagesAbb Drives: User'S Manual Flashdrop Mfdt-01Сергей СалтыковNo ratings yet

- iec-60896-112002-8582Document3 pagesiec-60896-112002-8582tamjid.kabir89No ratings yet

- Difference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDocument2 pagesDifference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDharma Teja TanetiNo ratings yet

- MCDO of Diesel Shed, AndalDocument12 pagesMCDO of Diesel Shed, AndalUpendra ChoudharyNo ratings yet

- AnkitDocument24 pagesAnkitAnkit MalhotraNo ratings yet

- 9IMJan 4477 1Document9 pages9IMJan 4477 1Upasana PadhiNo ratings yet

- DHPL Equipment Updated List Jan-22Document16 pagesDHPL Equipment Updated List Jan-22jairamvhpNo ratings yet

- HI - 93703 Manual TurbidimetroDocument13 pagesHI - 93703 Manual Turbidimetrojesica31No ratings yet

- Jurisdiction On Criminal Cases and PrinciplesDocument6 pagesJurisdiction On Criminal Cases and PrinciplesJeffrey Garcia IlaganNo ratings yet

- An Overview of National Ai Strategies and Policies © Oecd 2021Document26 pagesAn Overview of National Ai Strategies and Policies © Oecd 2021wanyama DenisNo ratings yet

- Code Description DSMCDocument35 pagesCode Description DSMCAnkit BansalNo ratings yet

- Piping ForemanDocument3 pagesPiping ForemanManoj MissileNo ratings yet