Professional Documents

Culture Documents

Schneider 3-Way Valves

Uploaded by

darby1028Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schneider 3-Way Valves

Uploaded by

darby1028Copyright:

Available Formats

Venta

01

V311

Three-way Plug Valve, Flanged PN 16

V311 can be used in a wide range of applications, such as heating, cooling, air handling and domestic hot water systems. Soft EPDM seals provide tight shut off. The valve can handle the following types of media: Hot and chilled water. Water with antifreeze additives such as glycol. If the valve is used for media at temperatures below 0 C (32 F), it should be equipped with a stem or yoke heater in order to prevent ice formation on the valve stem.

SPECIFICATIONS

Design . . . . . . three-way plug valve stem up closed . . . . . . . . . . . . . . . . . . . . . . . . (A port / B-AB open) Pressure class . . . . . . . . . . . . . . . . . . . . . . . PN 16 Flow characteristic A - AB . . . . . . . . . . . . . . . EQM Flow characteristic B - AB . . . . . . .Complementary Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 mm Rangeability Kv/Kvmin . . . . . . . . . . . . . . . . . . . . >50 Leakage A - AB and B - AB . . . . . . . . Tight sealing Pm . . . . . . . . . . . . . . . . . . 400 kPa (58 psi), water Max. temperature of medium: . . . . . . . . . . . .120 C Min. temperature of medium: . . . . . . . . . . . .20 C Connection . . . . . . Flange according to ISO 7005-2 Materials Body . . . . . . . . . . . . . . . .Nodular iron EN-JS 1030 Stem . . . . . . . . . . . . . . . . Stainless steel SS 2346 Plug . . . . . . . . . . . . . . . . . . . . . . . . Brass CW602N Plug Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . EPDM Seat . . . . . . . . . . . . . . . . .Nodular iron EN-JS 1030 Standard packing box . . . . . . . . . . . Venta (EPDM) Pressure Equipment Directive PED 97/23/EC Cat. 0

Size DN in. Kv m3/h Part number

15 15 15 20 25 32 40 50

1 1 1 2

1.6 2.5 4.0 6.3 10 16 25 38

731-1117-000 731-1121-000 731-1125-000 731-1129-000 731-1133-000 731-1137-000 731-1141-000 731-1145-000

Key to Technical specication The rangability is the ratio of Kv and Kvmin. Kv (Cv) is the ow through the valve in m3/h at the specied valve lift and at a pressure drop of 100 kPa across the valve. Kvmin is the minimum controllable ow (m3/h) at a pressure drop of 100 kPa within the range in which the valve characteristics conform to the slope requirements of IEC 534-1.

Venta

V311

02

DESIGN AND CHARACTERISTICS

The design of the V311 gives good resistance against solid particles in the fluid. The plug is guided throughout the lift, which reduces the risk of vibrations. The V311 is designed to be used as a mixing valve. The valve closes port A with the stem up. The flow characteristics A -AB of the V311 is equal percentage modified. The flow characteristics B - AB is complement to A - AB for constant sum of flow at = 0,5.

CHARACTERISTICS

Flow AB 100 80 60 40 B 20 0 0 20 40 60 80 Relative valve lift A

DESIGN

100

Installed characteristics = 0,5

CAVITATIONS

Pressure drop chart at the beginning of cavitation (kPa) Static pressure before valve 1600 1400 1200 1000 800 600 400 200 0 0 0 100 200 300 400 500 600 kPa Pressure drop over valve

160C (320F) 140C (284F) 120C (248F) 100C (212F) 80C (176F) 20C (68F)

CAVITATIONS

Cavitation takes place in a valve when the velocity of the flow between the plug and seat increases to the extent that gas bubbles are created in the water. When, after the plug and seat, the velocity decreases, the gas bubbles collapse (implode), generating conciderable noise and causing conciderable wear on the valve. By means of the cavitation diagram shown in the figure it can be checked if risk of cavitation exists with the working conditions in the pertinent installation. Proceed as follows: Using the static pressure before the valve (e.g. 1000 kPa), plot the horizontal line to the line for the temperature of the liquide (e.g. 120 C).

Pressure drop limit where cavitation might occur is dependent of valve inlet pressure and temperature of water.

If the computed pressure drop exceeds the value read from the diagram there is risk for cavitation.

Schneider Electric Telephone Europe: Malm, Sweden +46 40 38 68 50 Telephone Asia Pacific: Singapore +65 6776 3166 www.schneider-electric.com/buildings

003-2681-3 January 2011 co

2011 Schneider Electric. All rights reserved.

From the intersection point, plot a vertical line downwards and read off the max.permissible pressure drop across the valve.

Venta

V311

03

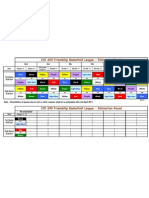

SPECIFICATION OF ACTUATOR

Use the diagram below to select actuator motor for the V311 to close required Pc. A suitable actuator is selected, using the summary data sheet F-10-6.

ACTUATOR POWER

M800 / MG900 SR

INSTALLATION

The valve should be mounted with flow direction in accordance with the valve marking. It is recommended to install the valve in the return pipe, in order to avoid exposing the actuator to high temperatures. The valve must not be installed with the actuator mounted below the valve. To ensure that suspended solids will not become jammed between the valve plug and seat, a filter should be installed upstream of the valve, and the pipe system should be flushed before the valve is installed.

Schneider Electric Telephone Europe: Malm, Sweden +46 40 38 68 50 Telephone Asia Pacific: Singapore +65 6776 3166 www.schneider-electric.com/buildings

003-2681-3 January 2011 co

2011 Schneider Electric. All rights reserved.

Venta

V311

04

INSTALLATION

AB

A B

AB

A B

AB B

A. Circuit without local circulating pump.

B. Circuit with local circulating pump.

C. Circuit with local circulating pump. The KV value of the valve to be selected so that the pressure drop across the control valve becomes equal to or greater than P.

To obtain good function the pressure drop The KV value of the valve to be selected so that the entire available pressure across the valve should be no less than drop, P, falls across the control valve. half of the available pressure drop (P). This will give a valve authority of 50%.

PRESSURE DROP CHART

Press. drop psi kPa 2000 200 1500 Capacity Kv (m /h at p=100 kPa) 0,25 0,4 0,63 1,0 1,6 2,5 4 6,3 10 16 25 40

150 1000 800 600 500 400 300 200 20 100 80 70 60 50 40 30 20

8 7 6 5

10

4 3 2

1 0,01 0,2

0,02

0,03 0,04

0,06 0,08 0,1 0,8 1,0 2

0,2 3 4

0,3 0,4 0,5 5 6 8 10

0,8 1 20

2 30

3 40 50

5 6 7 8 9 10 80 100 200

20 300

30 500

40 50 60

80 100 l/s gpm Flow

0,3 0,4 0,5

1000

Schneider Electric Telephone Europe: Malm, Sweden +46 40 38 68 50 Telephone Asia Pacific: Singapore +65 6776 3166 www.schneider-electric.com/buildings

003-2681-3 January 2011 co

2011 Schneider Electric. All rights reserved.

8 7 6 5

Venta

V311

05

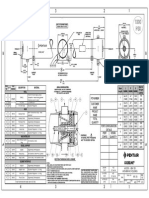

DIMENSIONS AND WEIGHT

M8 E

C F G B

Part No 731-

Conn. A DN In. mm B mm C mm

Dimensions D mm E mm F mm G mm H mm

Weight

kg

1117 1121 1125 1129 1133 1137 1141 1145

15 15 15 20 25 32 40 50

1 1 1 2

130 130 130 150 160 180 200 230

65 65 65 75 80 90 100 115

123 123 123 126 131 144.5 146 161

4x14 20 4x14 20 4x14 20 4x14 20 4x14 20 4x19 20 4x19 20 4x19 20

38 38 38 41 46 59.5 61 76

95 95 95 105 115 140 150 165

65 65 65 75 85 100 110 125

2.5 2.5 2.5 3.2 3.8 6.6 7.5 10.0

SPARE PARTS

Stufng box Standard type S . . . . . . . . . . . max 150 C (302 F) Item number . . . . . . . . . . . . . . . . . . . 1-001-0800-0

On October 1st, 2009, TAC became the Buildings Business of its parent company Schneider Electric. This document reflects the visual identity of Schneider Electric, however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to reflect appropriate corporate brand changes. All brand names, trademarks and registered trademarks are the property of their respective owners.

Schneider Electric Telephone Europe: Malm, Sweden +46 40 38 68 50 Telephone Asia Pacific: Singapore +65 6776 3166 www.schneider-electric.com/buildings

003-2681-3 January 2011 co

2011 Schneider Electric. All rights reserved.

You might also like

- Venta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)Document5 pagesVenta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)DedeKurniawanNo ratings yet

- Two-Way Pressure Balanced Plug Valve, Flanged, PN16: Field Devices EuropeDocument4 pagesTwo-Way Pressure Balanced Plug Valve, Flanged, PN16: Field Devices EuropeDedeKurniawanNo ratings yet

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Document5 pagesVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardNo ratings yet

- Series 825YD Specification SheetDocument2 pagesSeries 825YD Specification SheetFEBCONo ratings yet

- Ball Valves and Rotary Actors GuideDocument12 pagesBall Valves and Rotary Actors GuideAdvokat HadziTonicNo ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Series 826YD Specification SheetDocument2 pagesSeries 826YD Specification SheetFEBCONo ratings yet

- V SeguridadDocument8 pagesV SeguridadARJONA_JGNo ratings yet

- Electro ValvulasDocument89 pagesElectro ValvulasJuan Domingo OrlandiniNo ratings yet

- Tyco - Mokri Sprinkler VentilDocument20 pagesTyco - Mokri Sprinkler VentilMuhidin KozicaNo ratings yet

- Taconova 2012 PDF Catalogue PDFDocument374 pagesTaconova 2012 PDF Catalogue PDFSani PoulouNo ratings yet

- TAC Venta V341 F-30-50: Three-Way Plug Valve, Bronze PN16 (232 Psi) 2002-01-15Document4 pagesTAC Venta V341 F-30-50: Three-Way Plug Valve, Bronze PN16 (232 Psi) 2002-01-15denitoNo ratings yet

- Two-Way Pressure Balanced Plug Valve, Flanged, PN16: Field Devices EuropeDocument4 pagesTwo-Way Pressure Balanced Plug Valve, Flanged, PN16: Field Devices EuropeGourav SharmaNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- SsovgasvalvesDocument12 pagesSsovgasvalvesTin Aung KyiNo ratings yet

- Valve and Actuator CatalogueDocument60 pagesValve and Actuator Catalogueashfaq-matte-79930% (1)

- TA-FUSION-C EN LowDocument16 pagesTA-FUSION-C EN LowTroi LauraNo ratings yet

- Fuses1 11Document19 pagesFuses1 11Joshi DhvanitNo ratings yet

- DRIESCHER - High-voltage high breaking capacity fuses up to 36 kVDocument12 pagesDRIESCHER - High-voltage high breaking capacity fuses up to 36 kVDuron WalkerNo ratings yet

- Lift Check ValvesDocument4 pagesLift Check Valveslejyoner62No ratings yet

- VXF41Document6 pagesVXF41Dukagjin RamqajNo ratings yet

- Valves ActuatorsCAT0408Document60 pagesValves ActuatorsCAT0408Rami ReddyNo ratings yet

- Cooling Coils For Chilled Water For Connection To Circular DuctsDocument4 pagesCooling Coils For Chilled Water For Connection To Circular DuctserreagaaNo ratings yet

- IEC Contactors Bulletin 100 guideDocument78 pagesIEC Contactors Bulletin 100 guideTomás PachecoNo ratings yet

- 3-Way Valve - ThreadedDocument4 pages3-Way Valve - ThreadedAhrian BenaNo ratings yet

- VCLDocument5 pagesVCLoutlander2008No ratings yet

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991No ratings yet

- Condenser BushingDocument4 pagesCondenser BushingSanthosh RMNo ratings yet

- Pressure relief devices for power transformersDocument8 pagesPressure relief devices for power transformersnagpurwale2011No ratings yet

- Liquid Chillers and Heat Pumps 50 HZ: 30HT, HQ, HW 043-280 30HZ, HZ"P",HZ"V" 043-280Document16 pagesLiquid Chillers and Heat Pumps 50 HZ: 30HT, HQ, HW 043-280 30HZ, HZ"P",HZ"V" 043-280manchau717No ratings yet

- Automatically Balanced Combination Valves Ab-Qm: Data SheetDocument12 pagesAutomatically Balanced Combination Valves Ab-Qm: Data SheetbatazivoNo ratings yet

- k512 en MainDocument8 pagesk512 en MainSani PoulouNo ratings yet

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDocument4 pagesData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990No ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- Belimo valves and actuators guide for shut-off and butterfly valvesDocument12 pagesBelimo valves and actuators guide for shut-off and butterfly valves윤병택No ratings yet

- Walvoil Cartridge Ventielen HICDocument20 pagesWalvoil Cartridge Ventielen HICddNo ratings yet

- Rexroth A2VK Series PDFDocument12 pagesRexroth A2VK Series PDFMomo-Princess Peanut-buttercupNo ratings yet

- Water Cooled Package Service NewDocument23 pagesWater Cooled Package Service NewDiêm Công ViệtNo ratings yet

- Tour and Andersson MD60 SpecificationsDocument14 pagesTour and Andersson MD60 SpecificationsblindjaxxNo ratings yet

- SBC 782 Slam Shut Valves GuideDocument8 pagesSBC 782 Slam Shut Valves Guideluis_d_mNo ratings yet

- Ta-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsDocument16 pagesTa-Fus1On-C: Combined Control and Balancing Valves With Independent EQM CharacteristicsCatalin DinuNo ratings yet

- Delta Controls 592 ManualDocument10 pagesDelta Controls 592 Manualchris75726No ratings yet

- Pm512 en MainDocument8 pagesPm512 en MainDusan GordicNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- Tyco DPV 1 Tfp1090Document30 pagesTyco DPV 1 Tfp1090Nadolu MarianNo ratings yet

- 310-1512715 Bilge System H01Document11 pages310-1512715 Bilge System H01buturca sorinNo ratings yet

- Pump Protection Valve DatasheetDocument9 pagesPump Protection Valve DatasheetmishraenggNo ratings yet

- Hidraulica, Compones, Partes, para Uso en La Oleodinamica (118) MDocument10 pagesHidraulica, Compones, Partes, para Uso en La Oleodinamica (118) Mcarlosmedina111No ratings yet

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- VictaulicDocument6 pagesVictaulicAndreyNo ratings yet

- Pre-Setting Manual Balancing Valves CIM 788: Technical InformationDocument7 pagesPre-Setting Manual Balancing Valves CIM 788: Technical InformationblindjaxxNo ratings yet

- 1016Document46 pages1016Jorge DovaleNo ratings yet

- 791e PDFDocument12 pages791e PDFbertovalenNo ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- SDM 102 eDocument24 pagesSDM 102 eseaqu3stNo ratings yet

- Vickers Valve DG4S4Document13 pagesVickers Valve DG4S4ZMCONTROLNo ratings yet

- Canalis KTA Characteristics GuideDocument32 pagesCanalis KTA Characteristics Guideodin_auerNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Grades of Stainless Steel A2, A4 in Relation To Fasteners - Graphskill LTDDocument5 pagesGrades of Stainless Steel A2, A4 in Relation To Fasteners - Graphskill LTDdarby1028No ratings yet

- 38aks016 CarrierDocument138 pages38aks016 CarrierYolanda Borbon100% (1)

- FreonsDocument4 pagesFreonsdarby1028No ratings yet

- M 501Document24 pagesM 501darby1028100% (1)

- Motor StarterDocument67 pagesMotor Starter7402653100% (2)

- D5200 ManualDocument264 pagesD5200 ManualManas GeorgeNo ratings yet

- 4 Fire Damper Halton DNV CertificateDocument3 pages4 Fire Damper Halton DNV Certificatedarby1028No ratings yet

- Carrier psychrometric chart analysisDocument1 pageCarrier psychrometric chart analysisonspsnons100% (3)

- Air Duct CalculatorDocument1 pageAir Duct CalculatorRinaldy100% (9)

- Eurovent 2.3Document24 pagesEurovent 2.3pipipopo75100% (1)

- Indian Calendar With HolidaysDocument12 pagesIndian Calendar With HolidayssmiledepakNo ratings yet

- E2RMDocument3 pagesE2RMdarby1028No ratings yet

- Air Duct CalculatorDocument1 pageAir Duct CalculatorRinaldy100% (9)

- CCK Schedule - Rev CDocument1 pageCCK Schedule - Rev Cdarby1028No ratings yet

- Fire Risk of Cold Room PanelDocument6 pagesFire Risk of Cold Room Paneldarby1028No ratings yet

- Leak-Test-VacuumDocument1 pageLeak-Test-Vacuumdarby1028No ratings yet

- Impact of Drilling Fluid Viscosity, Velocity and Hole Inclination On Cuttings Transport in Horizontal and Highly Deviated WellsDocument8 pagesImpact of Drilling Fluid Viscosity, Velocity and Hole Inclination On Cuttings Transport in Horizontal and Highly Deviated Wellslord azraelNo ratings yet

- Refrigeration System Components: Compressors: LessonDocument44 pagesRefrigeration System Components: Compressors: LessonSuaid Tariq BalghariNo ratings yet

- Development of a T53 Engine Computer ModelDocument42 pagesDevelopment of a T53 Engine Computer ModelpcatruongNo ratings yet

- Volumetric Efficiency and Pressure Pulsations of A Triplex Reciprocating Supercritical CO PumpDocument24 pagesVolumetric Efficiency and Pressure Pulsations of A Triplex Reciprocating Supercritical CO PumpFrancesca CoattiNo ratings yet

- W4V23 - Feedstocks - Intermediates - HandoutDocument7 pagesW4V23 - Feedstocks - Intermediates - HandoutJessica KingNo ratings yet

- Axial & Centrifugal Compressor For LNG Services - GEDocument4 pagesAxial & Centrifugal Compressor For LNG Services - GETalwinder Singh100% (1)

- Gas Compression: A Primer on Rotary CompressorsDocument5 pagesGas Compression: A Primer on Rotary CompressorsLe Anh DangNo ratings yet

- High Pressure Components and Systems For Critical Ser Vice ApplicationsDocument24 pagesHigh Pressure Components and Systems For Critical Ser Vice ApplicationsdbmingoNo ratings yet

- Service Manual Refrigerator FR-631ND FR-710NDDocument21 pagesService Manual Refrigerator FR-631ND FR-710NDRata Ion0% (1)

- Boiler-Supercritical 8404673 PowerpointDocument31 pagesBoiler-Supercritical 8404673 PowerpointAnis SuryadiNo ratings yet

- European Patent Application: Process and Plant For Ammonia-Urea ProductionDocument16 pagesEuropean Patent Application: Process and Plant For Ammonia-Urea ProductionRashminda AttanayakeNo ratings yet

- Chemical Tanker OperationsDocument12 pagesChemical Tanker OperationsJeet Singh75% (4)

- Thermodynamic design of a fire-tube steam boilerDocument8 pagesThermodynamic design of a fire-tube steam boilerวรศิษฐ์ อ๋องNo ratings yet

- (Lab No. 1) Determination of Viscosity of A Given Liquid Using Viscometer.Document15 pages(Lab No. 1) Determination of Viscosity of A Given Liquid Using Viscometer.Haider AliNo ratings yet

- Nozzle LoadDocument14 pagesNozzle LoadOluwachidi100% (3)

- Piab Datasheet p6010 en 2010Document3 pagesPiab Datasheet p6010 en 2010Chico SantanaNo ratings yet

- Top Valve BrochureDocument2 pagesTop Valve BrochureJulio CésarNo ratings yet

- Gauges Calibration RegisterDocument14 pagesGauges Calibration RegisterNot GeniusNo ratings yet

- Convergent-Divergent Nozzle Boosts Engine ThrustDocument6 pagesConvergent-Divergent Nozzle Boosts Engine ThrustLONG HUYNH HOANGNo ratings yet

- BOGE S20 Screw Type Air Compressor: The Marketplace For Surface Technology. New and Used Process Equipment & MachineryDocument3 pagesBOGE S20 Screw Type Air Compressor: The Marketplace For Surface Technology. New and Used Process Equipment & MachineryJOKORIYANTONo ratings yet

- Chapter 8 Workover Completion Equipment PDFDocument97 pagesChapter 8 Workover Completion Equipment PDFbeicabNo ratings yet

- API Training-Relieve Device (API 520)Document24 pagesAPI Training-Relieve Device (API 520)Dimas Eko Prasetyo100% (6)

- Intro To Fluid and Thermal Transport - ME 331 Laboratory Assignment #3 C. J. Kobus Bernoulli Equation DemonstrationDocument3 pagesIntro To Fluid and Thermal Transport - ME 331 Laboratory Assignment #3 C. J. Kobus Bernoulli Equation DemonstrationFernando PintadoNo ratings yet

- Pelton Wheel Lab ReportDocument7 pagesPelton Wheel Lab Reportws100% (1)

- Dust Col L Ect Or: FI Lter SUB CatalogDocument10 pagesDust Col L Ect Or: FI Lter SUB CatalogHelmiNo ratings yet

- 1 Fundamental Concepts of Fluid Mechanics For Mine VentilationDocument29 pages1 Fundamental Concepts of Fluid Mechanics For Mine VentilationTeknologi Pertambangan Fakultas TeknikNo ratings yet

- Water & Gas Coning in Horizontal & Vertical WellDocument21 pagesWater & Gas Coning in Horizontal & Vertical WellNoraeen EleanorNo ratings yet

- MODINE Service TrainingDocument37 pagesMODINE Service TrainingSeshagiri DeenadayaluNo ratings yet

- Thesis 2016 GongDocument168 pagesThesis 2016 GongBrahimABDNo ratings yet

- L3-Similarity Laws and Specific Speed Impact of JetDocument22 pagesL3-Similarity Laws and Specific Speed Impact of JetRohan GuptaNo ratings yet