Professional Documents

Culture Documents

Functional Modeling Applied To HAZOP Automation

Uploaded by

Rodrigo VieiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Functional Modeling Applied To HAZOP Automation

Uploaded by

Rodrigo VieiraCopyright:

Available Formats

I.A.

Karimi and Rajagopalan Srinivasan (Editors), Proceedings of the 11th International Symposium on Process Systems Engineering, 15-19 July 2012, Singapore. 2012 Elsevier B.V. All rights reserved.

Functional modeling applied to HAZOP automation

Jos Luis de la Mata,a Manuel Rodrgueza

a

Technical University of Madrid, Jos Gutirrez Abascal 2, 28006 Madrid, Spain

Abstract

In this paper we present a new tool to perform guided HAZOP analyses. This tool uses a functional model of the process that merges its functional and its structural information in a natural way. The functional modeling technique used is called D-higraphs. This tool solves some of the problems and drawbacks of other existing methodologies for the automation of HAZOPs. The applicability and easy understanding of the proposed methodology is shown in an industrial case. Keywords: Functional modeling; HAZOP; Risk assessment.

1. Introduction

Currently, due to economical optimization of process plants, they are working at extreme conditions of pressure and temperature. This situation makes them more likely to fail and, even worse, the consequences of accidents are more severe. In addition, the Chemical Industry is facing tighter regulations and a growing attention of the media towards industrial accidents. Of course, we have also to consider the economical losses associated to accidents in terms of shutdowns, reparations, compensations and fines. In the design stage of the process plant, Process Hazard Analyses (PHA) are carried out to identify potential sources of accidents and propose some solutions that enhance the safety of the plant. One of the most used of all of the existing PHA techniques is the Hazard and Operability Study (HAZOP) (Zhao et al., 2005). However, this approach consumes a lot of effort, time and, hence, money. For these reasons, in the last two decades a lot of effort has been devoted to the implementation of tools and methodologies that can lead to the automation of these studies. In this work we present a new tool based on a functional modeling technique called D-higraphs. This approach takes into account in a natural way the structure as well as the functionality of the system (process and control system).

2. D-higraphs: merging function and structure

2.1. Dualization: from Higraphs to D-higraphs Higraphs were first presented by Harel (1987) and they are a general kind of diagramming that can be understood as a combination and extension of Graphs, Euler/Venn diagrams and the Cartesian Product. They are well suited to specify complex concurrent systems but not process systems. However, they can be adapted to process specification by the dualization of their properties and relations. This dualization has led to D-higraphs that were first presented in Rodrguez & Sanz (2009). Higraphs and D-higraphs consist of blobs and edges connecting them. It should be noted that the term dualization is used in a different way than the one used in Dual-Graphs or Digraphs; it is only applied to the properties and not to the elements.

X1 , X2 X n Y1 ,Y2 Ym

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jarless Con Door DriveDocument16 pagesJarless Con Door DriveRoyal Akash100% (6)

- Hiren Boot CDDocument20 pagesHiren Boot CDGabriel Illanes BurgoaNo ratings yet

- Project Management Methodologies PDFDocument7 pagesProject Management Methodologies PDFsolebNo ratings yet

- FMDS0129Document49 pagesFMDS0129hhNo ratings yet

- Argonne NL-CSE-19-2 - BatPaC Manual 3rd Ed - 27march2019Document130 pagesArgonne NL-CSE-19-2 - BatPaC Manual 3rd Ed - 27march2019Rodrigo VieiraNo ratings yet

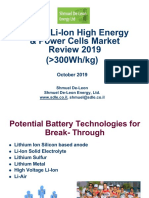

- Beyond Li-Ion Battery High Energy and Power Cells Market For ConferencesDocument34 pagesBeyond Li-Ion Battery High Energy and Power Cells Market For ConferencesRodrigo VieiraNo ratings yet

- Argonne NCM Production CostDocument28 pagesArgonne NCM Production CostRodrigo VieiraNo ratings yet

- Comparison Between Cylindrical and Prismatic Lithium-Ion Costs - ARTIGODocument9 pagesComparison Between Cylindrical and Prismatic Lithium-Ion Costs - ARTIGORodrigo VieiraNo ratings yet

- Argonne NL-CSE-19-2 - BatPaC Manual 3rd Ed - 27march2019Document130 pagesArgonne NL-CSE-19-2 - BatPaC Manual 3rd Ed - 27march2019Rodrigo VieiraNo ratings yet

- Lithium-Ion Battery Cell Production Process: February 2019Document23 pagesLithium-Ion Battery Cell Production Process: February 2019sayan halderNo ratings yet

- Battery-2030 Roadmap Version2.0Document82 pagesBattery-2030 Roadmap Version2.0Rodrigo Vieira100% (1)

- A Comparison of 186650x21700 Energy - Density - of - Cylindrical - Li-Ion - CellsDocument8 pagesA Comparison of 186650x21700 Energy - Density - of - Cylindrical - Li-Ion - CellsRodrigo VieiraNo ratings yet

- All-Solid-State Lithium-Ion and Lithium Metal Batteries-2018schnellDocument16 pagesAll-Solid-State Lithium-Ion and Lithium Metal Batteries-2018schnellRodrigo VieiraNo ratings yet

- Advanced Lithium Sulphur Battery For xEV - ALISEbyCAucherDocument28 pagesAdvanced Lithium Sulphur Battery For xEV - ALISEbyCAucherRodrigo VieiraNo ratings yet

- BersteinResearch Tesla & The Falling Costs - Longviewelectriccars-141002055755-Phpapp02Document47 pagesBersteinResearch Tesla & The Falling Costs - Longviewelectriccars-141002055755-Phpapp02Rodrigo VieiraNo ratings yet

- Argonne - BatPac Model Development Ahmed - 2016 - o - PPTDocument25 pagesArgonne - BatPac Model Development Ahmed - 2016 - o - PPTRodrigo VieiraNo ratings yet

- Exploring The Economic Potential of Na-Batteries-05-00010-V2Document15 pagesExploring The Economic Potential of Na-Batteries-05-00010-V2Rodrigo VieiraNo ratings yet

- CO2 Separation - ArtigoDocument128 pagesCO2 Separation - ArtigoRodrigo VieiraNo ratings yet

- Water Vision Company & ProductsDocument21 pagesWater Vision Company & ProductsRodrigo VieiraNo ratings yet

- Selection of Hazard Evaluation Techniques PDFDocument16 pagesSelection of Hazard Evaluation Techniques PDFdediodedNo ratings yet

- Insight Governanca Da Internet AXUR PDFDocument6 pagesInsight Governanca Da Internet AXUR PDFRodrigo VieiraNo ratings yet

- ISO 55000 Asset Management PolandDocument37 pagesISO 55000 Asset Management PolandRodrigo Vieira100% (9)

- Ch0 AcknowlegmentsDocument2 pagesCh0 AcknowlegmentsRodrigo VieiraNo ratings yet

- Ch0 GlossaryDocument7 pagesCh0 GlossaryRodrigo VieiraNo ratings yet

- Integrating Hazop and Sil/Lopa Analysis: Best Practice RecommendationsDocument10 pagesIntegrating Hazop and Sil/Lopa Analysis: Best Practice Recommendationsavinash_mokashi7073100% (1)

- The Integration of HAZOP Expert System and Piping andDocument8 pagesThe Integration of HAZOP Expert System and Piping andRodrigo Vieira100% (1)

- Flyer Integrated Engineering enDocument8 pagesFlyer Integrated Engineering enRodrigo VieiraNo ratings yet

- Learning in Intelligent Systems For Process Safety AnalysisDocument6 pagesLearning in Intelligent Systems For Process Safety AnalysisRodrigo VieiraNo ratings yet

- Process News 2-2013 enDocument36 pagesProcess News 2-2013 enRodrigo VieiraNo ratings yet

- Minerals Focus 1 2012 enDocument68 pagesMinerals Focus 1 2012 enRodrigo VieiraNo ratings yet

- Integrating Hazop and Sil/Lopa Analysis: Best Practice RecommendationsDocument10 pagesIntegrating Hazop and Sil/Lopa Analysis: Best Practice Recommendationsavinash_mokashi7073100% (1)

- M6 2020 Binomial Distribution Lecture NotesDocument27 pagesM6 2020 Binomial Distribution Lecture Notescoyite8695No ratings yet

- Inferential Statistics: Estimation and Confidence IntervalsDocument19 pagesInferential Statistics: Estimation and Confidence IntervalsHasan HubailNo ratings yet

- Database Classification TypesDocument10 pagesDatabase Classification TypesBhiea Mische MatilacNo ratings yet

- Onishi T Ed Quantum Science The Frontier of Physics and ChemDocument498 pagesOnishi T Ed Quantum Science The Frontier of Physics and ChemStrahinja DonicNo ratings yet

- RMA 3000 Remote Meter Assemblies Specifications: 34-ST-03-81, July 2017Document8 pagesRMA 3000 Remote Meter Assemblies Specifications: 34-ST-03-81, July 2017Amir LopezNo ratings yet

- LC IN SCIENCE and MathDocument14 pagesLC IN SCIENCE and MathCharity Anne Camille PenalozaNo ratings yet

- CH 07Document27 pagesCH 07Jessica Ibarreta100% (1)

- Introduction To Oracle GroovyDocument53 pagesIntroduction To Oracle GroovyDeepak BhagatNo ratings yet

- Design & Fabrication of a Cost-Effective Agricultural DroneDocument57 pagesDesign & Fabrication of a Cost-Effective Agricultural DroneFatima Nasir R:29No ratings yet

- Alpha New Bp12Document54 pagesAlpha New Bp12AUTO HUBNo ratings yet

- MITRES 6 002S08 Chapter2Document87 pagesMITRES 6 002S08 Chapter2shalvinNo ratings yet

- Probability Statistics and Random Processes Third Edition T Veerarajan PDFDocument3 pagesProbability Statistics and Random Processes Third Edition T Veerarajan PDFbhavyamNo ratings yet

- Is A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsDocument6 pagesIs A Calorie Really A Calorie - Metabolic Advantage of Low-Carbohydrate DietsGustavo CastroNo ratings yet

- Canalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Document324 pagesCanalis KDP-KBA-KBB-KNA-KSA-20-1000A-2014Rubén González CabreraNo ratings yet

- FM Chapter2Document3 pagesFM Chapter2Drkumar SwamyNo ratings yet

- Excel Gantt Chart Template: Enter Your Project Details HereDocument14 pagesExcel Gantt Chart Template: Enter Your Project Details HereBarselaNo ratings yet

- Module 4 - What Is The Required Rate of ReturnDocument2 pagesModule 4 - What Is The Required Rate of ReturnEthics BAENo ratings yet

- Silo Cement CalculationDocument11 pagesSilo Cement CalculationFikriaraz AfifNo ratings yet

- Instrumentation Design UTHMDocument5 pagesInstrumentation Design UTHMAnis AzwaNo ratings yet

- ISCOM HT803 DatasheetDocument2 pagesISCOM HT803 Datasheetnmc79No ratings yet

- Homa 2 CalculatorDocument6 pagesHoma 2 CalculatorAnonymous 4dE7mUCIH0% (1)

- Turbine Buyers Guide - Mick Sagrillo & Ian WoofendenDocument7 pagesTurbine Buyers Guide - Mick Sagrillo & Ian WoofendenAnonymous xYhjeilnZNo ratings yet

- PTP - Level MethodsDocument23 pagesPTP - Level Methodssasikiran mNo ratings yet

- VLSI Design: Introduction & Motivation Introduction & MotivationDocument33 pagesVLSI Design: Introduction & Motivation Introduction & MotivationPriyanka SharmaNo ratings yet

- WebControls - TabStripDocument38 pagesWebControls - TabStripProkopis PrNo ratings yet

- Xenomai 3 DocumentationDocument673 pagesXenomai 3 DocumentationGuile BonafiniNo ratings yet

- Admix Load CellDocument6 pagesAdmix Load Cellmanil_5No ratings yet

- 997-3 CIP Safety Adapter: Single Point Lesson (SPL) - Configure CIP Safety Adapter and A-B PLCDocument18 pages997-3 CIP Safety Adapter: Single Point Lesson (SPL) - Configure CIP Safety Adapter and A-B PLCTensaigaNo ratings yet