Professional Documents

Culture Documents

Pump Branch Design

Uploaded by

Marcelo PerettiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Branch Design

Uploaded by

Marcelo PerettiCopyright:

Available Formats

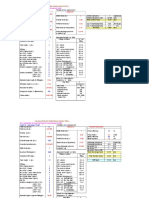

DUTY / CASE

Total duty: from storage to pump discharge Information highlighted in BLUE are required entries Values Highlighted in GREEN are calculated values 33.0 131 0 0 1000 40 2 52.5 Max pump discharge pressure required 59.6164214

CONDITIONS Material Pumped Phosphorus Trichloride P.T=Pumping Temperature (C) 20 Q=Flowrate (m3/h) Design 41.0 Normal # Density (kg/m3) 1585 u=Viscosity (cP) 0.64 Pvp*=Vapour Pressure (mbar) Vessel Press (barA) Suction 1 Discharge Ctrl Vlv Loss (bar) 0.00 Equip.Loss (bar) Orifice (mm) Pipe (Material) CS Schedule Nominal Size (ins) Suction 2 Discharge d,Actual ID (mm) Suction 52.5 Discharge * At Pumping Temperature

See notes for Actual pipe diameters

FRICTION HEAD LOSS ON SUCTION Fluid Velocity (m/s) = 5.266 Reynolds No. = 6.847E+05 Friction Factor = 0.020 Pressure Drop - m fluid / 100m eq. length =

* * * * * See notes for Calculation Method 54.299 12.414 (m)

SUCTION FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 2 3 90 deg Elbow 0.76 2 4 Std T Side 1.52 2 1 2 2 Total Suct. Val&Fit Eq. Lengths (m)

HEAD(m) 2.76 6.08 3.04 0 0 11.88 8 19.88 HEAD(m) 0 0 1.04 0 0 1.04 5 6.04

Total Friction Head loss (including 15% safety factor) = FRICTION HEAD LOSS ON DISCHARGE Fluid Velocity (m/s) = 5.266 Reynolds No. = 6.847E+05 Friction Factor = 0.020 Pressure Drop - m fluid / 100m eq. length =

* Length of Suct. straight pipe (m) Total Equivalent Suct. length (m) DISCHARGE FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 2 0 90 deg Elbow 0.76 2 Std T S-Thru 0.52 2 1 Flowmeter 0.46 2 0 2 Total Disch. Val&Fit Eq. Lengths (m)

See notes for Calculation Method 54.299 3.772 (m)

* * * * *

Total Friction Head loss (including 15% safety factor) = Branch pressure SUCTION & DISCHARGE HEADS Vessel Pressure m Liq. Level (above pump +; below -) m Stat Head (above pump+ ;below -) m Total Fric. Head Loss(plus Vel Head)m Control Valve (see notes 1 and 2) m Orifice (see note 2 and 3) m Equipment (see note 2) m Suc. Head Sum,metres of Fluid,abs. Dis. Head Sum,metres of Fluid,abs. DYNAMIC HEAD Discharge Head Sum Suction Head Sum TDH=Total Dynamic Head NPSH Suction Head Sum Pvp NPSH Available -5.39 m -0.84 m -6.23 m

* Length of Disch. straight pipe (m) Total Equivalent Disch. length (m) SUCTION DISCHARGE 6.435 0.000 2.000 -13.827 0.000 0.000 0.000 -5.392 5.185 0.000 0.000 0.000 64.801 64.80 m 5.39 m 70.19 m SYSTEM POWER * Efficiency(note4)= 0.6 (<1) Estimated Power= 20.66 (KW) NOTES 1.Assume control valve loss to be 70% to 100% of piping plus equipment friction loss for initial calculation. Consult instrument engineer for final selection. 2.All suction side values to be input negatively, and discharge side values to be input positively 3.Control valves and orifices not normally used in pump suction. 4.Use combined efficiency of pump and drive.

DUTY / CASE

Duty 1: Transfer of Trichloride from storage to Head Tank(Drumming)/Tanker Loading Information highlighted in BLUE are required entries Values Highlighted in GREEN are calculated values 11 131 1 0 1000 40 1.5 40.89

CONDITIONS Material Pumped Phosphorus Trichloride P.T=Pumping Temperature (C) 20 Q=Flowrate (m3/h) Design 11.0 Normal # Density (kg/m3) 1585 u=Viscosity (cP) 0.64 Pvp*=Vapour Pressure (mbar) Vessel Press (barA) Suction Discharge Ctrl Vlv Loss (bar) 0.00 Equip.Loss (bar) Orifice (mm) Pipe (Material) CS Schedule Nominal Size (ins) Suction Discharge d,Actual ID (mm) Suction Discharge * At Pumping Temperature

See notes for Actual pipe diameters

FRICTION HEAD LOSS ON SUCTION Fluid Velocity (m/s) = #DIV/0! Reynolds No. = #DIV/0! Friction Factor = #DIV/0! Pressure Drop - m fluid / 100m eq. length =

* * * * * See notes for Calculation Method #DIV/0! #DIV/0! (m)

SUCTION FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 0 90 deg Elbow 0.76 0 Std T Side 1.52 0 0 0 Total Suct. Val&Fit Eq. Lengths (m)

HEAD(m) 0 0 0 0 0 0 8 8 HEAD(m) 2.76 22.8 3.12 0.69 0 29.37 81 110.37

Total Friction Head loss (including 15% safety factor) = FRICTION HEAD LOSS ON DISCHARGE Fluid Velocity (m/s) = 2.329 Reynolds No. = 2.358E+05 Friction Factor = 0.022 Pressure Drop - m fluid / 100m eq. length =

* Length of Suct. straight pipe (m) Total Equivalent Suct. length (m) DISCHARGE FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 1.5 4 90 deg Elbow 0.76 1.5 20 Std T S-Thru 0.52 1.5 4 Flowmeter 0.46 1.5 1 1.5 Total Disch. Val&Fit Eq. Lengths (m)

See notes for Calculation Method 14.835 18.830 (m)

* * * * *

Total Friction Head loss (including 15% safety factor) =

* Length of Disch. straight pipe (m) Total Equivalent Disch. length (m) SUCTION & DISCHARGE HEADS Vessel Pressure m Liq. Level (above pump +; below -) m Stat Head (above pump+ ;below -) m Total Fric. Head Loss(plus Vel Head)m Control Valve (see notes 1 and 2) m Orifice (see note 2 and 3) m Equipment (see note 2) m Suc. Head Sum,metres of Fluid,abs. Dis. Head Sum,metres of Fluid,abs. DYNAMIC HEAD Discharge Head Sum Suction Head Sum TDH=Total Dynamic Head NPSH Suction Head Sum Pvp NPSH Available m m m SUCTION DISCHARGE 6.435 3.000 19.106 0.000 0.000 0.000 28.541 28.54 m 0.00 m 28.54 m SYSTEM POWER * Efficiency(note4)= 0.6 (<1) Estimated Power= 2.254 (KW) NOTES

1.Assume control valve loss to be 70% to 100% of piping plus equipment friction loss for initial calculation. Consult instrument engineer for final selection. 2.All suction side values to be input negatively, and discharge side values to be input positively 3.Control valves and orifices not normally used in pump suction. 4.Use combined efficiency of pump and drive.

DUTY / CASE

Duty 2: Transfer of Trichloride from storage to Recycle Information highlighted in BLUE are required entries Values Highlighted in GREEN are calculated values 11 130 1 0 25 40 1.5 40.89

CONDITIONS Material Pumped Phosphorus Trichloride P.T=Pumping Temperature (C) 15.5 Q=Flowrate (m3/h) Design 15.0 Normal # Density (kg/m3) 1585 u=Viscosity (cP) 5 Pvp*=Vapour Pressure (mbar) Vessel Press (barA) Suction Discharge Ctrl Vlv Loss (bar) 0.00 Equip.Loss (bar) Orifice (mm) Pipe (Material) CS Schedule Nominal Size (ins) Suction Discharge d,Actual ID (mm) Suction Discharge * At Pumping Temperature

See notes for Actual pipe diameters

FRICTION HEAD LOSS ON SUCTION Fluid Velocity (m/s) = #DIV/0! Reynolds No. = #DIV/0! Friction Factor = #DIV/0! Pressure Drop - m fluid / 100m eq. length =

* * * * * See notes for Calculation Method #DIV/0! #DIV/0! (m)

SUCTION FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 0 90 deg Elbow 0.76 0 Std T Side 1.52 0 0 0 Total Suct. Val&Fit Eq. Lengths (m)

HEAD(m) 0 0 0 0 0 0 8 8 HEAD(m) 2.76 6.84 0.78 0 0 10.38 14 24.38

Total Friction Head loss (including 15% safety factor) = FRICTION HEAD LOSS ON DISCHARGE Fluid Velocity (m/s) = 3.176 Reynolds No. = 4.117E+04 Friction Factor = 0.025 Pressure Drop - m fluid / 100m eq. length =

* Length of Suct. straight pipe (m) Total Equivalent Suct. length (m) DISCHARGE FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 1.5 4 90 deg Elbow 0.76 1.5 6 Std T S-Thru 0.52 1.5 1 Flowmeter 0.46 1.5 0 1.5 Total Disch. Val&Fit Eq. Lengths (m)

See notes for Calculation Method 31.819 8.921 (m)

* * * * *

Total Friction Head loss (including 15% safety factor) =

* Length of Disch. straight pipe (m) Total Equivalent Disch. length (m) SUCTION & DISCHARGE HEADS Vessel Pressure m Liq. Level (above pump +; below -) m Stat Head (above pump+ ;below -) m Total Fric. Head Loss(plus Vel Head)m Control Valve (see notes 1 and 2) m Orifice (see note 2 and 3) m Equipment (see note 2) m Suc. Head Sum,metres of Fluid,abs. Dis. Head Sum,metres of Fluid,abs. DYNAMIC HEAD Discharge Head Sum Suction Head Sum TDH=Total Dynamic Head NPSH Suction Head Sum Pvp NPSH Available 0.00 m -0.84 m -0.84 m SUCTION DISCHARGE 6.435 6.000 9.435 0.000 9.867 0.000 31.737 31.74 m 0.00 m 31.74 m SYSTEM POWER * Efficiency(note4)= 0.6 (<1) Estimated Power= 3.417 (KW) NOTES

1.Assume control valve loss to be 70% to 100% of piping plus equipment friction loss for initial calculation. Consult instrument engineer for final selection. 2.All suction side values to be input negatively, and discharge side values to be input positively 3.Control valves and orifices not normally used in pump suction. 4.Use combined efficiency of pump and drive.

DUTY / CASE

Duty 3: Transfer of Trichloride from storage to Drum Filling Information highlighted in BLUE are required entries Values Highlighted in GREEN are calculated values 11 130 1 0 25 40 1.5 40.89

CONDITIONS Material Pumped Phosphorus Trichloride P.T=Pumping Temperature (C) 15.5 Q=Flowrate (m3/h) Design 15.0 Normal # Density (kg/m3) 1585 u=Viscosity (cP) 5 Pvp*=Vapour Pressure (mbar) Vessel Press (barA) Suction Discharge Ctrl Vlv Loss (bar) 0.00 Equip.Loss (bar) Orifice (mm) Pipe (Material) CS Schedule Nominal Size (ins) Suction Discharge d,Actual ID (mm) Suction Discharge * At Pumping Temperature

See notes for Actual pipe diameters

FRICTION HEAD LOSS ON SUCTION Fluid Velocity (m/s) = #DIV/0! Reynolds No. = #DIV/0! Friction Factor = #DIV/0! Pressure Drop - m fluid / 100m eq. length =

* * * * * See notes for Calculation Method #DIV/0! #DIV/0! (m)

SUCTION FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 0 90 deg Elbow 0.76 0 Std T Side 1.52 0 0 0 Total Suct. Val&Fit Eq. Lengths (m)

HEAD(m) 0 0 0 0 0 0 8 8 HEAD(m) 5.52 22.8 1.56 0.69 0 30.57 70 100.57

Total Friction Head loss (including 15% safety factor) = FRICTION HEAD LOSS ON DISCHARGE Fluid Velocity (m/s) = 3.176 Reynolds No. = 4.117E+04 Friction Factor = 0.025 Pressure Drop - m fluid / 100m eq. length =

* Length of Suct. straight pipe (m) Total Equivalent Suct. length (m) DISCHARGE FITTINGS & VALVES TYPE FACTOR NB " No. Plug Valve 0.46 1.5 8 90 deg Elbow 0.76 1.5 20 Std T S-Thru 0.52 1.5 2 Flowmeter 0.46 1.5 1 1.5 Total Disch. Val&Fit Eq. Lengths (m)

See notes for Calculation Method 31.819 36.800 (m)

* * * * *

Total Friction Head loss (including 15% safety factor) =

* Length of Disch. straight pipe (m) Total Equivalent Disch. length (m) SUCTION & DISCHARGE HEADS Vessel Pressure m Liq. Level (above pump +; below -) m Stat Head (above pump+ ;below -) m Total Fric. Head Loss(plus Vel Head)m Control Valve (see notes 1 and 2) m Orifice (see note 2 and 3) m Equipment (see note 2) m Suc. Head Sum,metres of Fluid,abs. Dis. Head Sum,metres of Fluid,abs. DYNAMIC HEAD Discharge Head Sum Suction Head Sum TDH=Total Dynamic Head NPSH Suction Head Sum Pvp NPSH Available 0.00 m -0.84 m -0.84 m SUCTION DISCHARGE 6.435 6.000 37.315 0.000 9.867 0.000 0.000 59.616 59.62 m 0.00 m 59.62 m SYSTEM POWER * Efficiency(note4)= 0.6 (<1) Estimated Power= 6.419 (KW) NOTES

1.Assume control valve loss to be 70% to 100% of piping plus equipment friction loss for initial calculation. Consult instrument engineer for final selection. 2.All suction side values to be input negatively, and discharge side values to be input positively 3.Control valves and orifices not normally used in pump suction. 4.Use combined efficiency of pump and drive.

Flow m3/h 0.0 2.0 4.0 6.0 8.0 10.0 12.0 8.00 7.00

Pump Curve m 18.0 18.0 18.0 17.9 17.9 17.7 17.6

System Case Max.Level Min.Level m m 0.0 0.0 3.2 6.2 6.4 9.4 11.4 14.4 18.1 21.1 26.6 29.6 36.9 39.9 18.11 17.52 Design Point 1 Design Point 2

Pump vs System Head Curves Case:_________________________________

45.0

40.0

35.0 30.0 Head (m) 25.0 20.0 15.0 10.0 5.0 0.0

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

Flow (m3/h)

Pump Curve Design Point 1 Design Point 2 Max.Level Min.Level

CENTRIFUGAL PUMP CALCULATION SHEET Notes and Assumptions

DATA ENTRY Information highlighted in BLUE are required entries Values Highlighted in GREEN are calculated values

ACTUAL PIPE DIAMETERS Nominal Pipe Size In 1 1.5 2 3 4 5 6 8 10 Actual Inside Diameter Schedule 80 In mm 0.957 24.31 1.500 38.10 1.939 49.25 2.900 73.66 3.826 97.18 4.810 122.17 5.761 146.33 7.625 193.68 9.564 242.93

Schedule 40 In mm 1.049 26.64 1.610 40.89 2.067 52.50 3.068 77.92 4.026 102.26 5.047 128.19 6.065 154.05 7.981 202.72 10.020 254.51

PTFE Lined In mm 0.78 19.81 1.31 33.27 1.82 46.23 2.80 71.12 3.76 95.50 -

EQUIVALENT LENGTHS Factors 0.34 8.54 4.27 4.27

Gate Globe wye Angle

Enter type and factor for each Valve or Fitting followed by the Number. for Valves (open) and Fittings Diaphr 4.27 Swing Chk 3.35 Plug Valve 0.46 90 l.r. or WEld ell 0.52 90 std Elb. 0.76 Std Tee(side out) 1.52 45 std Elb. 0.4

FRICTION HEAD LOSS CALCULATIONS Reynolds No. = Fluid Velocity x Fluid Density x Fluid Viscosity Actual Diameter

If Re > 2100 (Formula taken from Std T2.3 Std 5, Approximate Moody Formula) Friction Factor or If Re < 2100 Friction Factor = 64 Reynolds No. = 0.0055 x [ 1 + ( 20,000 x Pipe Roughness + 1000000 [ ( Pipe Diameter Reynolds No. )] )]^0.33

Pressure Drop

5100 x Friction Factor x Velocity^2 Diameter

Type of Pipe Pipe Roughness (mm) Drawn Tubing (Copper, Glass, Stainless Steel, etc.) 0.0015 Commercial Steel Pipe 0.046 Asphalt Dipped Cast Iron Pipe 0.122 Galvinised Iron Pipe 0.152 Bare Cast Iron Pipe 0.26 Concrete Pipe 0.3 - 3.0 Riveted Steel Pipe 0.9 - 9.0

You might also like

- Pump Desing SpreadsheetDocument10 pagesPump Desing SpreadsheetAnonymous a4Jwz14WNo ratings yet

- 1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetDocument4 pages1) Flow: 239869283.xls - Ms - Office Piping Pressure Drop and Pump Design Calculation SheetHemantk8731100% (1)

- PUMP SIZING SPREADSHEET FOR KEROSENE TRANSFERDocument30 pagesPUMP SIZING SPREADSHEET FOR KEROSENE TRANSFEREbby Onyekwe100% (1)

- RNZ Integrated (M) SDN BHD: Calculation SheetDocument14 pagesRNZ Integrated (M) SDN BHD: Calculation SheetNhantran VanNo ratings yet

- Calculate Pressure DropDocument1 pageCalculate Pressure DropAJNo ratings yet

- Tri P10Document10 pagesTri P10Dvd Davide La CruzNo ratings yet

- Centrifugal Pump Calculation Summary Sheet: ConfidentialDocument3 pagesCentrifugal Pump Calculation Summary Sheet: ConfidentialPrafitri KurniawanNo ratings yet

- CCC1Document5 pagesCCC1Uok RitchieNo ratings yet

- Cent PumpDocument1 pageCent PumpChem.EnggNo ratings yet

- Sizing Calculations RW CW HD ADDocument27 pagesSizing Calculations RW CW HD ADBhavesh Panchal100% (1)

- Prepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaDocument2 pagesPrepd. by - Dhananjay Thorat Blue: Ref.-Introduction To Chemical Engg. by Ghosal, Sanyal & DattaJojolasNo ratings yet

- Calculate total pipe lengthDocument6 pagesCalculate total pipe lengthImtinan MohsinNo ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignAbhijeet JhaNo ratings yet

- CW Pump CalculationDocument22 pagesCW Pump Calculationzamijaka100% (1)

- Process Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsDocument1 pageProcess Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsamitkrayNo ratings yet

- Centrifugal Pump Calculation SpreadsheetDocument8 pagesCentrifugal Pump Calculation SpreadsheetsamvendanNo ratings yet

- Pump SizingDocument31 pagesPump SizingTuấn VũNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiNo ratings yet

- P&ID FOR CW CHLORINATION SYSTEMDocument32 pagesP&ID FOR CW CHLORINATION SYSTEMBhavesh Panchal100% (1)

- Pipe Sizing Criteria Schedule 40 Steel S-40 Steel: 198962529.xls - Ms - OfficeDocument34 pagesPipe Sizing Criteria Schedule 40 Steel S-40 Steel: 198962529.xls - Ms - Officeangel darioNo ratings yet

- Trunnion CalculationDocument92 pagesTrunnion CalculationkarunaNo ratings yet

- PUMP CALCULATION SHEETDocument4 pagesPUMP CALCULATION SHEETMuhammad BilalNo ratings yet

- Pump NPSHA calculation sheetDocument2 pagesPump NPSHA calculation sheetNena Jessi Love100% (1)

- Discharge PR Drop Pipe SizeDocument5 pagesDischarge PR Drop Pipe SizemohdnazirNo ratings yet

- Pressure Drop Caln - 1Document390 pagesPressure Drop Caln - 1Prashant SinghNo ratings yet

- Location: By: Date: Chk. By: Date:: ProjectDocument4 pagesLocation: By: Date: Chk. By: Date:: ProjectalvinchuanNo ratings yet

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Document3 pagesFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnNo ratings yet

- Reactor Geometry and Agitator SizingDocument26 pagesReactor Geometry and Agitator SizingNeeraj BhallaNo ratings yet

- Pipes. Maxi 1Document1 pagePipes. Maxi 1Nasrul AdliNo ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- 1 Darcy Friction CalculatorDocument2 pages1 Darcy Friction CalculatorTheodoros AtheridisNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- Line Size & Pressure Drop CalculationDocument3 pagesLine Size & Pressure Drop Calculationsj_scribdNo ratings yet

- 06 - CompressorsDocument16 pages06 - CompressorsSrinivasa Rao Venkumahanthi100% (1)

- ParalDocument9 pagesParalTahirJabbarNo ratings yet

- NPSH Calculation PumpDocument3 pagesNPSH Calculation PumpYosses Sang NahkodaNo ratings yet

- Pump Head Calculation-IDocument10 pagesPump Head Calculation-IXplore EnggNo ratings yet

- Pressure DropDocument4 pagesPressure Dropmartin.rubenNo ratings yet

- Pipe thickness calculationDocument1,287 pagesPipe thickness calculationShantanu JalgaonkarNo ratings yet

- Steam Trap Calculation Sheet - 02Document9 pagesSteam Trap Calculation Sheet - 02Erwin Firmansyah Saputro0% (1)

- Blow Off Pipe SizingDocument13 pagesBlow Off Pipe Sizinggopaltry100% (1)

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitNo ratings yet

- Heat Exchanger Ball Cleaning Package Data SheetDocument2 pagesHeat Exchanger Ball Cleaning Package Data SheetEDUARDONo ratings yet

- 62577A Calculation of Orifice Coefficient Si UnitsDocument18 pages62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioNo ratings yet

- Valve Sizing CalculationDocument7 pagesValve Sizing CalculationSteve Wan100% (1)

- Fire PumpDocument1 pageFire PumpPaijo TejoNo ratings yet

- Centrifugal Pumps Excel Data Calculation'Document30 pagesCentrifugal Pumps Excel Data Calculation'Anoif Naputo AidnamNo ratings yet

- Head loss and pressure drop calculation using Colbrook formulaDocument1 pageHead loss and pressure drop calculation using Colbrook formulaNghiaNo ratings yet

- Pump specifications and sizing for sewage treatment plantDocument3 pagesPump specifications and sizing for sewage treatment plantbharathNo ratings yet

- Values Highlighted in GREEN Are Calculated ValuesDocument1 pageValues Highlighted in GREEN Are Calculated ValuesOkky Putra Widodo OkkyNo ratings yet

- VENTILATION SYSTEM DUCT SIZING CALCULATIONSm/spammpa/m0.1606738.60 paDocument10 pagesVENTILATION SYSTEM DUCT SIZING CALCULATIONSm/spammpa/m0.1606738.60 paArshavin Watashi WaNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetsyamsudin200683% (6)

- Air Pressure Loss in Piping and DuctsDocument5 pagesAir Pressure Loss in Piping and DuctsPhyu Mar Thein KyawNo ratings yet

- Extraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)Document17 pagesExtraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)weeseongNo ratings yet

- Values Highlighted in GREEN Are Calculated ValuesDocument1 pageValues Highlighted in GREEN Are Calculated ValuesOkky Putra Widodo OkkyNo ratings yet

- Values Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesDocument7 pagesValues Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesaltruismNo ratings yet

- Slurry pump sizing and selectionDocument41 pagesSlurry pump sizing and selectionyuli_o2100% (7)

- Power Calc. of Emergency FWPDocument2 pagesPower Calc. of Emergency FWPWaqar A. KhanNo ratings yet

- Burner CalculationDocument6 pagesBurner CalculationAnonymous 3ESYcrKP100% (4)

- WA Building and Energy Vegetation Code AssessmentDocument24 pagesWA Building and Energy Vegetation Code AssessmentMarcelo PerettiNo ratings yet

- SEM-DG Approximation For Elasto-Acoustics: Hélène Barucq, Henri Calandra, Aurélien Citrain, Julien Diaz, Christian GoutDocument53 pagesSEM-DG Approximation For Elasto-Acoustics: Hélène Barucq, Henri Calandra, Aurélien Citrain, Julien Diaz, Christian GoutMarcelo PerettiNo ratings yet

- Cooling Tower Fundamentals PDFDocument117 pagesCooling Tower Fundamentals PDFsoumenhazraNo ratings yet

- Computer Aided Chemical Process Design: The Flowtran SystemDocument11 pagesComputer Aided Chemical Process Design: The Flowtran SystemMarcelo PerettiNo ratings yet

- Checklist Question Checklist Response Evidence/CommentsDocument3 pagesChecklist Question Checklist Response Evidence/CommentsMarcelo PerettiNo ratings yet

- UntitledDocument15 pagesUntitledMarcelo PerettiNo ratings yet

- DG RdsoDocument14 pagesDG RdsoMarcelo PerettiNo ratings yet

- Epd 0011Document11 pagesEpd 0011Marcelo PerettiNo ratings yet

- AgitatorDocument3 pagesAgitatorMarcelo PerettiNo ratings yet

- MixerDocument4 pagesMixerMarcelo PerettiNo ratings yet

- High Density Polyethylene: TipelinDocument10 pagesHigh Density Polyethylene: TipelinMarcelo PerettiNo ratings yet

- AgitatorDocument3 pagesAgitatorMarcelo PerettiNo ratings yet

- Quality Control of HDPE, LDPE, and PP: Non-Destructive Determination of Polymers Within One Minute With NIRSDocument5 pagesQuality Control of HDPE, LDPE, and PP: Non-Destructive Determination of Polymers Within One Minute With NIRSMarcelo PerettiNo ratings yet

- Arkema MP Chemical Process Industry Market PresentationDocument17 pagesArkema MP Chemical Process Industry Market PresentationMarcelo PerettiNo ratings yet

- AgitatorDocument3 pagesAgitatorMarcelo PerettiNo ratings yet

- Coletores de Condensados e Distribuicao de Vapor Ari Codi S B 136Document10 pagesColetores de Condensados e Distribuicao de Vapor Ari Codi S B 136Marcelo PerettiNo ratings yet

- Sulzer Centrifugal Pumps - Basic OperationDocument26 pagesSulzer Centrifugal Pumps - Basic OperationMarcelo PerettiNo ratings yet

- Corn OilDocument24 pagesCorn OilAmol RautNo ratings yet

- Coletores de Condensados e Distribuicao de Vapor Ari Codi S B 136Document10 pagesColetores de Condensados e Distribuicao de Vapor Ari Codi S B 136Marcelo PerettiNo ratings yet

- Mechanical - Pumps KSB Centrifugal Pump DesignDocument44 pagesMechanical - Pumps KSB Centrifugal Pump DesignkichasNo ratings yet

- Kimre Aiche 2008Document12 pagesKimre Aiche 2008Marcelo PerettiNo ratings yet

- مضخة الطرد المركزى- كتيب للتحميلDocument128 pagesمضخة الطرد المركزى- كتيب للتحميلGrundfosEgypt100% (4)

- Alfa Laval Principles of Cleaning and CipDocument43 pagesAlfa Laval Principles of Cleaning and CipMarcelo PerettiNo ratings yet

- مضخة الطرد المركزى- كتيب للتحميلDocument128 pagesمضخة الطرد المركزى- كتيب للتحميلGrundfosEgypt100% (4)

- Analyzing Centrifugal-Pump CircuitsDocument12 pagesAnalyzing Centrifugal-Pump CircuitsMarcelo PerettiNo ratings yet

- STP For WebDocument11 pagesSTP For WebMarcelo PerettiNo ratings yet

- Kimre Aiche 2008Document12 pagesKimre Aiche 2008Marcelo PerettiNo ratings yet

- Engineering Guide to Sizing Centrifugal PumpsDocument5 pagesEngineering Guide to Sizing Centrifugal PumpsMarcelo Peretti100% (1)