Professional Documents

Culture Documents

PFI-ES-07 (2000) NozzMinlengthspacing PDF

Uploaded by

Ramesh Kumar RamisettiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFI-ES-07 (2000) NozzMinlengthspacing PDF

Uploaded by

Ramesh Kumar RamisettiCopyright:

Available Formats

PFI Standard ES-7 (Reaffirmed January 2000)

MINIMUM LENGTH AND SPACING FOR WELDED NOZZLES

COPYRIGHT 2003; Pipe Fabrication Institute

--`,`````,,```,````````````,,-`-`,,`,,`,`,,`---

Prepared by Pipe Fabrication Institute Engineering Committee

All PFI Standards are advisory only. There is no agreement to adhere to any PFI Standard and their use by anyone is entirely voluntary.

Copyright by

PIPE FABRICATION INSTITUTE

Dedicoted

to

Technicnl Advnncements ond Stnndnrdizntion in the Pipe Fnbricniion Industry Since I913

USA PME 323

61 I Pennsylvnnin Avenue SE

CANADA

6SS.3ZId ave, suire 201

Lachine, Quebec HBT3G6

WEB S I T E

Wnshington. DC 20003

Iiitp://,c?~c.pfi-insiiiuie. org

Document provided by IHS Licensee=Aramco HQ/9980755100, User=, 03/06/2003 02:28:11 MST Questions or comments about this message: please call the Document Policy Management Group at 1-800-451-1584.

S T D - P P I ES-'I-ENGL

71bLi5Li4 00005b8 588 D

PFI Standard ES-7 (Reaffirmed January 2000)

MINIMUM LENGTH AND SPACING FOR WELDED NOZZLES

METRIC CONVERSIONS The conversion of quantities between systems of units involves a determination of the number of significant digits to be retained. All conversions depend upon the intended precision of the original and are rounded to the appropriate accuracy. Pipe sizes together with applicable wall thicknesses are not shown with metric equivalents. The SI (metric) values where included with the customary U. S. values in this Standard are the rounded equivalents of the U. S. values and are for reference only. Metric units were derived utilizing the following conversion factor: Conversion inches to millimeter Factor 25.4

5.2 All nozzle welds should be checked for compliance with the applicable Code requirements.

1. Scope

I

,

I

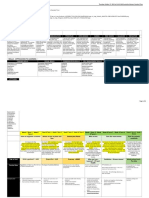

1.1 This Standard covers the minimum recommended length, distance from open end on run, and spacing dimensions of adjacent welded nozzles.

2. Nozzles without Saddles or Reinforcement

2.1 Dimensions recommended for nozzles without

5.3 It is preferred that multiple branch openings of in-line nozzles be spaced so that their reinforcement zones do not overlap. If closer spacing is necessary, the reinforcement requirements of the applicable construction Code shall be met.

5.4 Some configurations of integrally reinforced

saddles or reinforcements are as shown in Fig. 1 and Table 1.

3. Nozzles with Reinforcing Saddles or Rings

3.1 Dimensions recommended for nozzles with saddles or rings are as shown in Fig. 2 and Table 2.

--`,`````,,```,````````````,,-`-`,,`,,`,`,,`---

nozzles in combination with certain header sizes may present a problem in the radiographic examination of the attachment weld due to inability to meet the geometric unsharpness requirements of the construction Code.

4. Nozzles - Integrally Reinforced

4.1 Dimensions recommended for integrally reinforced nozzles are as shown in Fig. 3 and Table 3. These dimensions do not apply to integrally reinforced insert butt weld nozzles.

5.5 Where attachments such as flanges, fittings, valves and pipe insulation are involved, minimum dimensions tabulated may have to be increased to allow for required clearances.

5.6 In special cases, it may be possible to reduce the dimensions given in the tabulation. Such design should then be submitted to the fabricator for individual consideration, as close spacing may involve additional shop operations to prevent, or correct distortion. 5.7 Integrally reinforced nozzles are considered to be the commercially available types.

5. Design Considerations

5.1 Certain materials and combinations of nozzle and header pipe size and wall thickness together with multiple branch openings welded to a header may result in distortion of the header pipe. The elimination or reduction of such distortion is beyond the scope of this Standard.

5.8 In cases of different nozzle diameters, dimension "C", (Fig. & Tables 1 thni 3) should be determined on the basis of the larger of the two adjacent nozzles.

2

COPYRIGHT 2003; Pipe Fabrication Institute Document provided by IHS Licensee=Aramco HQ/9980755100, User=, 03/06/2003 02:28:11 MST Questions or comments about this message: please call the Document Policy Management Group at 1-800-451-1584.

S T D - P F I ES-7-ENGL

2000

7Lb4544 O0005b7 414

PFI Standard ES-7 (Reaffirmed January 2000)

MINIMUM RECOMMENDED DIMENSIONS FOR FIGURE 1 NOMINAL PIPE SIZE OF NOZZLE

(in)

1.D. OF RUN TO END OF NOZZLE B

O.D. TO O.D. OF NOZZLE

NOZZLES WITHOUT SADDLES OR RING REINFORCEMENT

2-112 3 4

5

6

8

IO

I2 14 I6 I8 20 24

FIGURE 1

MMIMUM RECOMMENDED DIMENSIONS FOR FIGURE 2 NOMINAL

OD. OF RUN TO END OF NOZZLE

A

in.

B

(m)

(114)

2-112

4-1/2

5

NOZZLES WITH REINFORCING SADDLES OR RINGS

3 4 5

6 8 10

5-112 6 6-112

8

9-112 II 12 13 14

15

(127) (140) (152) (165) (203) (241) (279) (305) (330) (356) (381) (406)

12

14

16

18

FIGURE 2

20 24

36

(914)

16

TABLE 2

I

NOMINAL PIPE SIZE 3 F NOZZLE

MINIMUM RECOMMENDED DIMENSIONS FOR FIGURE 3

TO END OF RUN

(in)

2-112

3

A

in. 5-112 (140)

OF NOZZLE B in. (nun) MANUFACTURERS STANDARDS

NOZZLES - INTEGRALLY REINFORCED

4

5

8 IO I2 14

16

V

18

20 24

23 26

(584) (660)

FIGURE 3

TABLE 3

*Minimurn dimension C should be that tabulated for the larger of two adjacent nozzles Dimensions: Inches (Millimeters).

3

COPYRIGHT 2003; Pipe Fabrication Institute Document provided by IHS Licensee=Aramco HQ/9980755100, User=, 03/06/2003 02:28:11 MST Questions or comments about this message: please call the Document Policy Management Group at 1-800-451-1584.

--`,`````,,```,````````````,,-`-`,,`,,`,`,,`---

TABLE 1

S T D - P F I ES-7-ENGL 2000

7Lb45qq 0000570 L3b

CHARTER MEMBERS

ACCORD PIPE FABRICATORS, INC. AIR CONDITIONING COMPANY, INC. FLO-RITE, INC. GEM INDUSTRIAL, INC. HPI CONSTRUCTION CO., INC. IDEAL WELDERS, LTD. IVOR J. LEE, INC. JOHN E. GREEN COMPANY

J. F. AHERN CO.

Jamaica, Glendale, Riviera Beach, Walbridge, Huntington, Delta, Masury, Highland Park, Fond du Lac, Longview, Freeport, Santa Clara, Gaithersburg, Tuscaloosa, Beaver Falls, Freeport,

EI Dorado,

St. Louis,

New York California Florida Ohio West Virginia British Columbia (Canada) Ohio Michigan Wisconsin Washington Texas California Maryland Alabama Pennsylvania Illinois Arkansas Missouri Alberta (Canada) Minnesota Wisconsin Wisconsin Ohio Ohio California West Virginia Wisconsin Michigan

J. H. KELLY LLC

J. S. MC KINNEY, INC. KINETIC SYSTEMS, INC. M & M WELDING AND FABRICATORS, INC.

MC ABEE CONSTRUCTION, INC. MC CARL'S, INC. MECHANICAL INCORPORATED MID STATES PIPE FABRICATING, INC. MURPHY COMPANY NARDE1 FABRICATORS, LTD. NEWMECH COMPANIES, INC. PHILLIPS, GETSCHOW COMPANY PIPING SYSTEMS, INC.

COPYRIGHT 2003; Pipe Fabrication Institute

--`,`````,,```,````````````,,-`-`,,`,,`,`,,`---

Cakasr, St. Paul, Oconto Falls, New London, Barberion, Dayton, San Leandro, Davisville, Kaukauna, Livonia,

S. A. COMUNALE COMPANY, INC. S&D / OSTERFELD MECHANICAL CONTRACTORS

SCOTT CO. OF CALIFORNIA SPECIALTY PIPING CORPORATION TEAM INDUSTRIES, INC. W. J. O'NEIL COMPANY

A current index of the latest revised ES Standards, Technical Bulletins and Safety Training Guideline is available from the Pipe Fabrication Institute.

PFI Safety Training Guideline, Standards and Technical Bulletins are published to serve proven needs of the pipe fabricating industry at the design level and in actual shop operations. Hence, such needs are continually considered and reviewed by the Engineering Committee of the Pipe Fabrication Institute to provide recommended procedures, which have been demonstrated by collective experiences to fulfill requirements in a manner for Code compliance. However, as the PFI Standards are for minimum requirements the designer or fabricator always has the option of specifying supplementary conditions in the form of requirements beyond the scope of the PFI publications.

Document provided by IHS Licensee=Aramco HQ/9980755100, User=, 03/06/2003 02:28:11 MST Questions or comments about this message: please call the Document Policy Management Group at 1-800-451-1584.

You might also like

- PFI ES-2-2000 Method of Dimension Ing Piping AssembliesDocument4 pagesPFI ES-2-2000 Method of Dimension Ing Piping Assembliessekharsappa2100% (3)

- Pfi-Es-3 (2000) PDFDocument4 pagesPfi-Es-3 (2000) PDFBarnum Pebble Darrel100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Pfi-Es-16 (2001)Document7 pagesPfi-Es-16 (2001)jothishNo ratings yet

- Pfi-Es-22 (1999)Document4 pagesPfi-Es-22 (1999)jothish100% (5)

- PFI-ES-01 (2001) IntMachBackRingsButtsDocument8 pagesPFI-ES-01 (2001) IntMachBackRingsButtsdon_romanticko281236No ratings yet

- Flange b16 47 Bs AwwaDocument24 pagesFlange b16 47 Bs AwwaVarun MalhotraNo ratings yet

- Pfi Es-5 2002Document2 pagesPfi Es-5 2002bayu212100% (1)

- ASTM F1545 Plastic Lined Pipe 0803 PDFDocument6 pagesASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesNo ratings yet

- Flans Chen Prospekt EngDocument2 pagesFlans Chen Prospekt Englorenzinho290No ratings yet

- ASME Section VIII, Division 2Document18 pagesASME Section VIII, Division 2Safont Rodrigo Carles100% (2)

- PFI Standard ES-7 - 2013Document6 pagesPFI Standard ES-7 - 2013HeiderHuerta100% (1)

- ANSI B 16.48 Flange Dimensions for Class 150, 300 and 600Document3 pagesANSI B 16.48 Flange Dimensions for Class 150, 300 and 600l kishoreNo ratings yet

- Navco Pipe Data LogDocument67 pagesNavco Pipe Data Logtucker-r100% (6)

- ASME B31.3 Process Piping Section Committee Meeting No. 143 Supplemental AgendaDocument118 pagesASME B31.3 Process Piping Section Committee Meeting No. 143 Supplemental AgendaYogi173No ratings yet

- Pfi Es-24Document10 pagesPfi Es-24kingstonNo ratings yet

- Bonney Forge SIFs VariousFittingsDocument45 pagesBonney Forge SIFs VariousFittingscamellias2010100% (2)

- Stub Ends Ansi b16.9Document1 pageStub Ends Ansi b16.9hisaj4uNo ratings yet

- Asme B16.47-2011Document120 pagesAsme B16.47-2011Asad100% (4)

- PFI - ES - 48 - 2008 - Random ExaminationsDocument5 pagesPFI - ES - 48 - 2008 - Random Examinationsespluisjavier100% (1)

- D10.4 R1986PVDocument7 pagesD10.4 R1986PVGabriela AxinteNo ratings yet

- PFI piping standards documentsDocument2 pagesPFI piping standards documentsgigiphi1No ratings yet

- WRC452Document76 pagesWRC452Mayank Singla100% (3)

- Asme Ccase - 2046Document2 pagesAsme Ccase - 2046ADAMJSRAONo ratings yet

- PipingDocument267 pagesPipingNurcahyo Djati W100% (1)

- PFI-ES-05 (1999) - Cleaning PDFDocument4 pagesPFI-ES-05 (1999) - Cleaning PDFRamesh Kumar Ramisetti100% (1)

- Asme B 16.34 InterpretacionDocument21 pagesAsme B 16.34 InterpretacionJuan Manuel Montoya G.No ratings yet

- Asme Ca-1 - 2014Document20 pagesAsme Ca-1 - 2014gabriel100% (1)

- History b16 34Document5 pagesHistory b16 34qazi12100% (1)

- Essential Elements of An Effective In-Service Welding Program - tcm153-574204Document14 pagesEssential Elements of An Effective In-Service Welding Program - tcm153-574204David Rodrigues100% (1)

- WRC Bulletin-297 Searchable PDFDocument89 pagesWRC Bulletin-297 Searchable PDFandrés morantes0% (1)

- ASTM A672 Welded Pipe Standard PDFDocument7 pagesASTM A672 Welded Pipe Standard PDFumeshNo ratings yet

- Comparison Between ASME B31.1 & 31.3 & 31.8Document10 pagesComparison Between ASME B31.1 & 31.3 & 31.8karuna346100% (2)

- ASME B31.4 Section Committee InterpretationsDocument93 pagesASME B31.4 Section Committee InterpretationsmaninventorNo ratings yet

- ASME B16.5 - List of Material SpecificationDocument3 pagesASME B16.5 - List of Material Specificationjr_satish6965No ratings yet

- Bs 4504Document54 pagesBs 4504bingipoliNo ratings yet

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsFrom EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (12)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Es2 PDFDocument4 pagesEs2 PDFmasimaha1379No ratings yet

- Air 5065Document11 pagesAir 5065niky186No ratings yet

- MSS SP 6Document6 pagesMSS SP 6d1a9v8i3d100% (1)

- 000-GC-P-009 R.3 Piping Installation PDFDocument35 pages000-GC-P-009 R.3 Piping Installation PDFJessica Torres100% (1)

- MSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001Document6 pagesMSS SP 6 - Standard Finishes For Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings - 2001vladmir18No ratings yet

- Codes and Standards ListDocument25 pagesCodes and Standards ListMochamad BhadawiNo ratings yet

- Process & Piping Design Section Plug Valves Technical SpecificationDocument14 pagesProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationNayan VyasNo ratings yet

- Sae Ams S 13165Document27 pagesSae Ams S 13165sabrunoNo ratings yet

- TGN-BC-01 Tack Welding of Reinforcement BarDocument8 pagesTGN-BC-01 Tack Welding of Reinforcement Barnaseema1No ratings yet

- FS4005 Cable TraysDocument8 pagesFS4005 Cable TraysRamesh AnanthanarayananNo ratings yet

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Designation B 828 - 002Document11 pagesDesignation B 828 - 002Raron1No ratings yet

- 1 Engg DBD ST 010Document11 pages1 Engg DBD ST 010sanketNo ratings yet

- Volume 2 Section 3 BA 36/90 Void FormingDocument3 pagesVolume 2 Section 3 BA 36/90 Void FormingchatxxnoirNo ratings yet

- Case Study For Structural Beam FailureDocument7 pagesCase Study For Structural Beam FailureRakesh RanjanNo ratings yet

- OETC-74 - 400kV Tower Design Inputs To AL-BABTAINDocument146 pagesOETC-74 - 400kV Tower Design Inputs To AL-BABTAINMohamed Gad67% (3)

- 01 Samss 035 API LinepipeDocument28 pages01 Samss 035 API Linepipemdsazidalam100% (2)

- الخليجDocument10 pagesالخليجmohamedNo ratings yet

- 00102W C G0 G000 PE SPC 0013 Rev 1 Standard Pipe SupportsDocument119 pages00102W C G0 G000 PE SPC 0013 Rev 1 Standard Pipe SupportsMurtadda MohammedNo ratings yet

- Soil InvestigationDocument269 pagesSoil InvestigationHari Kishore100% (2)

- PFI-ES-05 (1999) - Cleaning PDFDocument4 pagesPFI-ES-05 (1999) - Cleaning PDFRamesh Kumar Ramisetti100% (1)

- PFI-ES-04 (1985) Hydrotest PDFDocument4 pagesPFI-ES-04 (1985) Hydrotest PDFRamesh Kumar RamisettiNo ratings yet

- PFI-ES-05 (Cleaning 2006) PDFDocument2 pagesPFI-ES-05 (Cleaning 2006) PDFRamesh Kumar RamisettiNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- PFI-ES-01 (2001) IntMachBackRingsButtsDocument8 pagesPFI-ES-01 (2001) IntMachBackRingsButtsdon_romanticko281236No ratings yet

- All About LNG: Its Transport, Uses, and ImportanceDocument2 pagesAll About LNG: Its Transport, Uses, and ImportanceRamesh Kumar RamisettiNo ratings yet

- Step by Step Process To Run BEX Report in BackgroundDocument23 pagesStep by Step Process To Run BEX Report in Backgroundalcast007No ratings yet

- Model 2000 Flow ComputerDocument8 pagesModel 2000 Flow ComputerAdnan SalihbegovicNo ratings yet

- Medonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsDocument6 pagesMedonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsSubhanullah JalalNo ratings yet

- Estimating and Quantity Surveying Materials for Construction ProjectsDocument3 pagesEstimating and Quantity Surveying Materials for Construction ProjectsAldrin SerranoNo ratings yet

- MGI JETvarnish 3D EvoDocument6 pagesMGI JETvarnish 3D EvoSusanta BhattacharyyaNo ratings yet

- Validity Checks: Processing ControlsDocument3 pagesValidity Checks: Processing Controlsjhela18No ratings yet

- Catalogue PDFDocument5 pagesCatalogue PDFumeshgcNo ratings yet

- NV 24 Globe ActuatorDocument12 pagesNV 24 Globe ActuatorRodrigo AlvesNo ratings yet

- Cat Electronic Technician 2015A v1.0 Product Status ReportDocument5 pagesCat Electronic Technician 2015A v1.0 Product Status Reportcriman45No ratings yet

- Bennic (Bi-Polar Radial) PB-PX SeriesDocument3 pagesBennic (Bi-Polar Radial) PB-PX Seriesester853No ratings yet

- What is a Gear Motor? - An In-Depth GuideDocument15 pagesWhat is a Gear Motor? - An In-Depth GuidePuneet KumarNo ratings yet

- Call of Duty MG08/15 LMG Weapon WikiDocument1 pageCall of Duty MG08/15 LMG Weapon WikiSelin HNo ratings yet

- Cisco Catalyst Switching Portfolio (Important)Document1 pageCisco Catalyst Switching Portfolio (Important)RoyalMohammadkhaniNo ratings yet

- CADAM 2000 - Model ParametersDocument3 pagesCADAM 2000 - Model ParametersAqua MaNo ratings yet

- B.E. Civil Engineering Project ProposalDocument10 pagesB.E. Civil Engineering Project Proposalmahipal287No ratings yet

- Sda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Document1 pageSda-02-Dd-02 - Pile & Pile Cap - Sheet-1 - R0Himani PatelNo ratings yet

- 0751 VICTAULIC in Mechanical PipingDocument17 pages0751 VICTAULIC in Mechanical PipingsyafiqNo ratings yet

- Pinza Prova 5601Document2 pagesPinza Prova 5601Sublimec San RafaelNo ratings yet

- HazMat DOTDocument48 pagesHazMat DOTRenalyn TorioNo ratings yet

- Design of Coin Sorter Counter Based On MCU: Articles You May Be Interested inDocument5 pagesDesign of Coin Sorter Counter Based On MCU: Articles You May Be Interested inArchana BenkarNo ratings yet

- Sni+03 6868 2002Document3 pagesSni+03 6868 2002abanghasanNo ratings yet

- 3AH4 Breaker Cn (油品 P26)Document29 pages3AH4 Breaker Cn (油品 P26)kokonut1128No ratings yet

- Electronically Controlled On-Demand 4WDDocument32 pagesElectronically Controlled On-Demand 4WDjulio797No ratings yet

- TENDERSCHEDULE309532Document2 pagesTENDERSCHEDULE309532heavens indiaNo ratings yet

- Cross-Cultural Issues in Business Ethics: John Hooker Carnegie Mellon University June 2007Document28 pagesCross-Cultural Issues in Business Ethics: John Hooker Carnegie Mellon University June 2007modaloves1242100% (2)

- DTMF Proximity DetectorDocument1 pageDTMF Proximity DetectorAlagappan ArunachalamNo ratings yet

- 1st Term Exam Part 2 - QSDocument10 pages1st Term Exam Part 2 - QSMark Anthony TajonNo ratings yet

- Monitoring Critical Applications at SeaDocument3 pagesMonitoring Critical Applications at SeaMohamed AliNo ratings yet

- 2019 Planning OverviewDocument7 pages2019 Planning Overviewapi-323922022No ratings yet

- Detailed Statement: Transactions List - Squaircle Energy and Constructions Private Limited (Inr) - 677605600669Document3 pagesDetailed Statement: Transactions List - Squaircle Energy and Constructions Private Limited (Inr) - 677605600669ankit008dixitNo ratings yet