Professional Documents

Culture Documents

BR-REINF As Per 31 - 3

Uploaded by

Troy HooperOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR-REINF As Per 31 - 3

Uploaded by

Troy HooperCopyright:

Available Formats

Project :

COMED009

Metric Units

BRANCH REINFORCING CALCULATION IN ACC. WITH ASME B 31.3

Branch Angle :

By : Date :

PVP008 25-Oct-2011

Line Number : Pipe spec. : AS

45

(degrees)

Design Pressure P= 15.9 Bar(g) Design Temperature Td= 38 C Note : Suffices "h" and "b" in anotations below are for header and branch respectively. Header Pipe Material Outside Diameter Specified Wall Thickness Allowable Design Stress Temperature coef. Joint Efficiency Corrosion Allowance Mill Tolerance Reinf. Pad Thk (max. 1.5 * t) Reinf. Pad Wide ASME A358 Gr 316L D t S Y E c 508 5.54 115.1424 0.4 0.8 0 12.5 5.54 610 Branch A358 Gr 316L 273 (mm) 4.19 (mm) 115.1424 0.4 0.8 0 12.5 ******** ******** (MPa) (mm) (%) (mm) (mm)

Calculated Data

Pressure Design Thickness Min. Req. Wallthk. Straight pipe t (t+c)/0.875 4.35 4.98 OK Header 4.85 4.35 0.49 4.85 2.34 2.67 OK Branch 3.67 2.34 1.33 (mm)

Min Measured Thk. Per Purch. Spec Min. Used Excess Thickness (header and branch) Effective ( Min ) Reinf. Pad Thk.

t+c T-t-c Tr

(mm) (mm) (mm) (mm)

Eff. Length removed from Hdr. Half Width of Reinforcing Zone Or But Height of Reinforcing Zone outside of run pipe Reinf. Area Required Reinf. Area Available And

d1=(Db-2(Tb-c))/sin d2=(Tb-c)+(Th-c)+(0.5*d1) d2=d1 if d1>d2 d2 max. = Dh Hence L4=2.5 x (Th-c) L4=2.5 x (Tb-c)+ Tr Use Lowest L4 th x d1 x (2-sin) (2*d2-d1)x(Th-th-c) 2*L4*(Tb-tb-c)/sin

= = d2 = = = A1 =

375.73 196.38 375.73 375.73 12.12 14.01 12.12 2115.3 185.3 45.5 231

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm2) (mm2) (mm2) (mm2)

A2 = A3 = =A2+A3=

Total reinf. area available without pad=

Area available without pad is not sufficient ,additional reinforcement required. IF PAD IS PROVIDED : Effective Reinforcing Pad area Smallest of L4 or min Reinf pad thk Effective thickness of pad= 4.85 Smallest of pad width or d2-.5*Db Effective Width of pad= 239.23 Area available in reinforcing pad= Total available area with pad= A2+A3+A4 = A4 = 2319.3 2550 (mm) (mm) (mm2) (mm2)

PROVIDE REINFORCEMENT PAD AS PER GIVEN DIMENSIONS

new

Project :

Metric Units

BRANCH REINFORCING CALCULATION IN ACC. WITH ASME B 31.3

Branch Angle :

By : Date : (degrees)

Line Number : Pipe spec. :

Design Pressure P= 47.915 Bar(g) Design Temperature Td= -46 C Note : Suffices "h" and "b" in anotations below are for header and branch respectively. Header Pipe Material Outside Diameter Specified Wall Thickness Allowable Design Stress Temperature coef. Joint Efficiency Corrosion Allowance Mill Tolerance Reinf. Pad Thk (max. 1.5 * t) Reinf. Pad Wide ASME A333 GR.6 D t S Y E c 88.9 5.49 137.8951 0.4 1 1.5 12.5 0 0 Branch A333 GR.6 60.33 (mm) 5.54 (mm) 137.8951 0.4 1 1.5 12.5 ******** ******** (MPa) (mm) (%) (mm) (mm)

Calculated Data

Pressure Design Thickness Min. Req. Wallthk. Straight pipe t (t+c)/0.875 1.52 3.46 OK Header 4.80 3.02 1.78 0.00 1.03 2.90 OK Branch 4.85 2.53 2.31 (mm)

Min Measured Thk. Per Purch. Spec Min. Used Excess Thickness (header and branch) Effective ( Min ) Reinf. Pad Thk.

t+c T-t-c Tr

(mm) (mm) (mm) (mm)

Eff. Length removed from Hdr. Half Width of Reinforcing Zone Or But Height of Reinforcing Zone outside of run pipe Reinf. Area Required Reinf. Area Available And

d1=(Db-2(Tb-c))/sin d2=(Tb-c)+(Th-c)+(0.5*d1) d2=d1 if d1>d2 d2 max. = Dh Hence L4=2.5 x (Th-c) L4=2.5 x (Tb-c)+ Tr Use Lowest L4 th x d1 x (2-sin) (2*d2-d1)x(Th-th-c) 2*L4*(Tb-tb-c)/sin

= = d2 = = = A1 =

#VALUE! #VALUE! #VALUE! #VALUE! 8.26 8.37 8.26 #VALUE! #VALUE! #VALUE! #VALUE!

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm2) (mm2) (mm2) (mm2)

A2 = A3 = =A2+A3=

Total reinf. area available without pad= #VALUE!

IF PAD IS PROVIDED : Effective Reinforcing Pad area Smallest of L4 or min Reinf pad thk Effective thickness of pad= 0.00 Smallest of pad width or d2-.5*Db Effective Width of pad= 0.00 Area available in reinforcing pad= Total available area with pad= #VALUE! 173243864.xls.ms_office A2+A3+A4 = A4 = 0.0 #VALUE!

(mm) (mm) (mm2) (mm2)

You might also like

- Engtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceDocument32 pagesEngtech, Ieng and Ceng: Uk Standard For Professional Engineering CompetenceMuhammad ArshadNo ratings yet

- Common Causes and Effects of Piping Vibration - A Short Article - What Is PipingDocument5 pagesCommon Causes and Effects of Piping Vibration - A Short Article - What Is PipingTroy HooperNo ratings yet

- Omr PDFDocument63 pagesOmr PDFaeliusmanoNo ratings yet

- Seismic Design of Buried PipeDocument105 pagesSeismic Design of Buried Pipetnvish100% (4)

- Steam Turbines A Full Range To Fit Your NeedsDocument20 pagesSteam Turbines A Full Range To Fit Your NeedsManikandan Vijayan0% (1)

- Disclosure To Promote The Right To InformationDocument289 pagesDisclosure To Promote The Right To InformationAshish Pattanaik100% (1)

- Engg - Ref - Book (Steel Weight Cal.)Document246 pagesEngg - Ref - Book (Steel Weight Cal.)Anonymous Iev5ggSRNo ratings yet

- The Indian War of Independence 1857Document400 pagesThe Indian War of Independence 1857anuraggupta74@gmail.comNo ratings yet

- Burner Pid 1Document1 pageBurner Pid 1Troy HooperNo ratings yet

- The Indian War of Independence 1857Document400 pagesThe Indian War of Independence 1857anuraggupta74@gmail.comNo ratings yet

- Dimensions, Sizes and Specification of BS 3293 Slip On Flanges PDFDocument5 pagesDimensions, Sizes and Specification of BS 3293 Slip On Flanges PDFTroy HooperNo ratings yet

- OISD 117 CoverpageDocument1 pageOISD 117 CoverpageTroy HooperNo ratings yet

- My Trading JournalDocument54 pagesMy Trading JournalUma MamadapurNo ratings yet

- The Indian War of Independence 1857Document400 pagesThe Indian War of Independence 1857anuraggupta74@gmail.comNo ratings yet

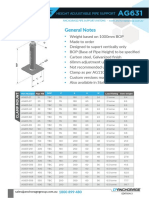

- Adjustable Pipe SupportDocument1 pageAdjustable Pipe SupportTroy HooperNo ratings yet

- Asme PTC 19.3 Temp MSRMTDocument142 pagesAsme PTC 19.3 Temp MSRMTTroy HooperNo ratings yet

- Solar General GuidelinesDocument2 pagesSolar General GuidelinesRakNo ratings yet

- Setting Up and Running A Small Scale Dairy Processing Business - CTA - OFP-Dairy - PRF - Amended (L-R)Document188 pagesSetting Up and Running A Small Scale Dairy Processing Business - CTA - OFP-Dairy - PRF - Amended (L-R)jliu878100% (1)

- The Indian War of Independence 1857Document400 pagesThe Indian War of Independence 1857anuraggupta74@gmail.comNo ratings yet

- Setting Up and Running A Small Scale Dairy Processing Business - CTA - OFP-Dairy - PRF - Amended (L-R)Document188 pagesSetting Up and Running A Small Scale Dairy Processing Business - CTA - OFP-Dairy - PRF - Amended (L-R)jliu878100% (1)

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- Drain Pit Detail DrawingDocument1 pageDrain Pit Detail DrawingTroy HooperNo ratings yet

- Painting SpecDocument10 pagesPainting SpecTroy HooperNo ratings yet

- WPS PQR Api570Document5 pagesWPS PQR Api570Troy HooperNo ratings yet

- Indian Explosive Rules 2008Document163 pagesIndian Explosive Rules 2008sham7523100% (1)

- Tariff Advisory Committee ManualDocument113 pagesTariff Advisory Committee ManualArunTomar100% (4)

- Luck PresentationDocument1 pageLuck Presentationmanojpatil186No ratings yet

- Lect 3Document43 pagesLect 3Mahesh KumarNo ratings yet

- Chimney DesignDocument8 pagesChimney DesignTroy HooperNo ratings yet

- The 48 Laws of Power - SummaryDocument2 pagesThe 48 Laws of Power - SummaryTroy Hooper57% (7)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Affidavit of Change ColorDocument1 pageAffidavit of Change ColorDOJ orp09No ratings yet

- Kent Ridge Campus GuideDocument2 pagesKent Ridge Campus Guiderevo17No ratings yet

- Sonata™: Dual Pulse OutputDocument2 pagesSonata™: Dual Pulse OutputPra YugoNo ratings yet

- Daniefer M - Best BuyDocument6 pagesDaniefer M - Best BuyArchana mittalNo ratings yet

- Commercial Cold Test ProColdDocument8 pagesCommercial Cold Test ProColdpolNo ratings yet

- Marina Mall Work Permit (20369)Document1 pageMarina Mall Work Permit (20369)Shahid FarooqNo ratings yet

- Database Management System Lab Course Code: CSE 312: Instructor: Tasnim Tarannum Lecturer CSE DepartmentDocument15 pagesDatabase Management System Lab Course Code: CSE 312: Instructor: Tasnim Tarannum Lecturer CSE DepartmentNirban MitraNo ratings yet

- MT131 TMA 1st 2023-2024Document6 pagesMT131 TMA 1st 2023-2024kareem978No ratings yet

- Wago Io Programing ManualDocument306 pagesWago Io Programing ManualtarekamininfoNo ratings yet

- Each of 2 Marks. There Will Be Negative Marking of 0.25 Marks From Question 1 To 20 and 0.50 Marks From Question 20 To 25 For Each Wrong AnswerDocument2 pagesEach of 2 Marks. There Will Be Negative Marking of 0.25 Marks From Question 1 To 20 and 0.50 Marks From Question 20 To 25 For Each Wrong AnswerkrishNo ratings yet

- Manlapaz Final Done V2Document66 pagesManlapaz Final Done V2Herobrine CosmoNo ratings yet

- Av74 0018Document39 pagesAv74 0018Franco PugaNo ratings yet

- LKinLang Changelog V1 5 0Document12 pagesLKinLang Changelog V1 5 0Zine eddine Hadj mokhnachrNo ratings yet

- Curriculam Vitae: Ecoleaf Energies PVT - LTDDocument4 pagesCurriculam Vitae: Ecoleaf Energies PVT - LTDJay Kumar BhattNo ratings yet

- ICT Prototype - PDF 022727Document50 pagesICT Prototype - PDF 022727Nabukeera MugaggaNo ratings yet

- Electrical Protection Relay IntroductionDocument200 pagesElectrical Protection Relay IntroductionmlutfimaNo ratings yet

- FUNCTIONAL REQUIREMENTSDocument5 pagesFUNCTIONAL REQUIREMENTSPhúc HoàngNo ratings yet

- Conditional Statements 2Document10 pagesConditional Statements 2Abigel judith PeterNo ratings yet

- Marca - Xiaomi (Eco Sistem) - 29 - 09 - 2023 - 07 - 20 - 52 - 49 - ListaDocument12 pagesMarca - Xiaomi (Eco Sistem) - 29 - 09 - 2023 - 07 - 20 - 52 - 49 - ListaElias MoraisNo ratings yet

- Data Analysis and Time Series for Environmental ApplicationsDocument60 pagesData Analysis and Time Series for Environmental Applicationskk chanNo ratings yet

- Military Institute of Science and Technology Department of Computer Science and Engineering CSE-305 Array & String Practice ProblemsDocument2 pagesMilitary Institute of Science and Technology Department of Computer Science and Engineering CSE-305 Array & String Practice ProblemsDurba Binte KalamNo ratings yet

- Sony TV LCD AZ1-L CHASSISDocument5 pagesSony TV LCD AZ1-L CHASSISmontezumaNo ratings yet

- Buckstay SystemDocument15 pagesBuckstay SystemAssistente Engenharia HNRNo ratings yet

- Installing Current Transformer (CT)Document4 pagesInstalling Current Transformer (CT)feryNo ratings yet

- AMC Perfect Validation 2019-2020Document2 pagesAMC Perfect Validation 2019-2020Dhanasekaran VaiyapuriNo ratings yet

- Electronic Cash Register Programming-ManualDocument27 pagesElectronic Cash Register Programming-ManualRendy Adam FarhanNo ratings yet

- Zip HydroTap G4 BC PI enDocument8 pagesZip HydroTap G4 BC PI enRicardoNo ratings yet

- (Tab) Ge-Piwat:: Process?Document6 pages(Tab) Ge-Piwat:: Process?omkarNo ratings yet

- Geostat TugasAkhir Kelompok19Document14 pagesGeostat TugasAkhir Kelompok19MuzaimatulNo ratings yet

- Java Buzz WordsDocument2 pagesJava Buzz WordsmanoharNo ratings yet