Professional Documents

Culture Documents

Internal Quality Audit Checklist FOR Control of Monitoring & Measuring Devices

Uploaded by

alokjaseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Internal Quality Audit Checklist FOR Control of Monitoring & Measuring Devices

Uploaded by

alokjaseCopyright:

Available Formats

INTERNAL QUALITY AUDIT CHECKLIST

FOR

CONTROL OF MONITORING & MEASURING

DEVICES

Document: IQAC-018

Issue: 1

Revision: 0

Date: November 23, 2001

QUALITY AUDIT CHECKLIST FOR QMP-018 ISS: 1 REV: 0 Page: 1 of 7

REVIEWED BY: APPROVED BY: November 23, 2001

DOC: IQAC-018 REPORT No.: DATE: AUDITOR(s):

DETAILS

REV

LEVEL

REV

DATE

Page Para.

DESCRIPTION OF CHANGE

0 Nov. 23, 2001 All All Original Issue

QUALITY AUDIT CHECKLIST FOR QMP-018 ISS: 1 REV: 0 Page: 2 of 7

REVIEWED BY: APPROVED BY: November 23, 2001

DOC: IQAC-018 REPORT No.: DATE: AUDITOR(s):

INTERNAL AUDIT NOTIFICATION

TO:

FROM: QUALITY DEPARTMENT

DATE:

SUBJECT: INTERNAL QUALITY MANAGEMENT AUDIT

Please be advised that based on the annual internal audit schedule developed for the company,

the Quality department will be conducting an internal quality audit of CONTROL OF MONITORING

& MEASURING DEVICES on __________________________________.

The scope of this audit shall encompass all aspects and requirements defined within Quality

Management Procedure QMP-018, Issue: 1, Revision: Level O and shall be conducted in

accordance with procedure QMP-020.

The auditor(s) will be __________________________________________________________.

This audit is to start at ___________ a.m., take approximately ________ hrs. and be completed by

___________ p.m.

Please ensure those individuals responsible for the processes covered by the above procedure

are made available and that an Audit Guide is provided.

Thank you for your assistance in this matter.

Should you have any questions regarding the above, please contact the undersigned.

(Insert Name and Title of Quality Mgmt. Rep.)

QUALITY AUDIT CHECKLIST FOR QMP-018 ISS: 1 REV: 0 Page: 3 of 7

REVIEWED BY: APPROVED BY: November 23, 2001

DOC: IQAC-018 REPORT No.: DATE: AUDITOR(s):

EVALUATION CODE: AC = Acceptable IR = Improvement Required UN = Unacceptable N/A = Not Applicable

CONTROL OG MONITORING & MEASURING DEVICES (QMP-018)

Para. AUDIT QUESTION CODE OBSERVATIONS

4.0 RESPONSIBILITIES

4.1

Is the Quality Manager responsible for establishing a

system to ensure that Standards, Masters and monitoring

and measuring devices, necessary to evaluate contract

and quality requirements, are available and are of the

accuracy, stability and range appropriate for the use

intended?

4.2 Is the Quality Manager responsible for the development

and approval of all required calibration instructions?

4.3 Is the Quality department responsible for ensuring

required calibrations are performed and for recalling all

monitoring and measuring devices due for calibration?

4.4 Is Production responsible for returning all monitoring and measuring devices for calibration when:

a) notified by the Quality department?

b) the accuracy and precision of an instrument or device is

suspect?

c) calibration performed is believed to be imprecise?

d) the calibration due date is expired?

5.0 PROCEDURE

5.1 General

5.1.1 Are all purchased as well as fabricated monitoring and

measuring devices used within (Insert Company Name)

subject to calibration by the Quality department?

5.2 Personally Owned Equipment

5.2.1

Is the use of personally owned tools and gauges used for

the purpose of evaluating product during production

processing permissible provided that these tools or

gauges have been calibrated and entered into the

Employee Equipment Calibration Log, FRM-727?

5.3 Production Tooling

5.3.1 Are production tools such as jigs, fixtures or templates

subject to accuracy verification by production personnel

prior to usage?

5.4 Calibration Instructions

5.4.1 Is internal calibration of monitoring and measuring

devices performed in accordance with calibration

instructions developed by the Quality department using

form FRM-725 and approved by the Quality Manager in

accordance with procedure QMP-003?

QUALITY AUDIT CHECKLIST FOR QMP-018 ISS: 1 REV: 0 Page: 4 of 7

REVIEWED BY: APPROVED BY: November 23, 2001

DOC: IQAC-018 REPORT No.: DATE: AUDITOR(s):

EVALUATION CODE: AC = Acceptable IR = Improvement Required UN = Unacceptable N/A = Not Applicable

CONTROL OG MONITORING & MEASURING DEVICES (QMP-018)

Para. AUDIT QUESTION CODE OBSERVATIONS

5.4.2 Do instructions include the specific measurements to be

made, the acceptance criteria to achieve, the master or

comparator to be used and the environmental

requirements to be maintained during calibration?

5.5 Calibration

5.5.1 Is each monitoring and measuring device employed by

(Insert Company Name) for the purpose of verifying

product quality or monitoring processes assigned a

unique identification control number by the Quality

department and entered into the Monitoring and

Measuring Device Log, FRM-726?

5.5.2 Are Standards and Masters used for the internal

calibration of monitoring and measuring devices

maintained by the Quality department under lock and key

with access restricted to only authorized personnel

performing calibrations?

5.5.3

Are calibration of Standards or Masters performed

Externally by a qualified metrology laboratory with

Traceability to recognized national or international

Standards?

a)

Is the calibration of monitoring and measuring devices

also subcontracted to these same facilities, as required?

5.5.4 Are the certified calibration Standards or Masters, used

expressly for the purpose of calibrating monitoring and

measuring devices, utilized for the verification, measuring

or testing of manufactured items?

5.6 Calibration Frequency

5.6.1 Are all monitoring and measuring devices assigned a

specific calibration frequency?

5.6.2 Are calibration frequencies for new and/or existing

devices established by the Quality department based on

the stability, purpose and degree of usage and increased

or reduced periodically based on comparative analysis of

calibration results obtained to those previously recorded

for the same instrument?

5.6.3 Is computer software used for monitoring and measuring

of specified requirements validated prior to initial use and

reconfirmed every three (3) months while in use?

5.6.4

Are all calibration frequencies defined within the

Calibration Schedule, FRM-723?

QUALITY AUDIT CHECKLIST FOR QMP-018 ISS: 1 REV: 0 Page: 5 of 7

REVIEWED BY: APPROVED BY: November 23, 2001

DOC: IQAC-018 REPORT No.: DATE: AUDITOR(s):

EVALUATION CODE: AC = Acceptable IR = Improvement Required UN = Unacceptable N/A = Not Applicable

CONTROL OG MONITORING & MEASURING DEVICES (QMP-018)

Para. AUDIT QUESTION CODE OBSERVATIONS

a)

Does the calibration schedule reflect the current status of

all monitoring and measuring devices used within (Insert

Company Name)?

5.7 Calibration Environment

5.7.1 Is calibration of all monitoring and measuring devices

performed in an environment conducive to assuring

continued measurement of the accuracy required and in

accordance with environmental conditions defined within

approved calibration instructions?

5.8 Calibration Records

5.8.1 Is the calibration schedule used for inventory, recall and

calibration status control?

5.8.2 Are all monitoring and measuring devices recalled by the

Quality department and removed from use by the date

that calibration is due?

5.8.3 Upon completion of calibration, is an Instrument

Calibration Test Report completed using form FRM-724

and filed under the equipment identification control

number?

5.8.4 Are calibration records maintained throughout the life of

each monitoring and measuring device?

a)

Do these records reflect the dates on which calibrations

were performed, the accuracy of results obtained during

calibration and any adjustments or re-adjustments

made?

5.8.5 Are calibration certificates received from outside

laboratories and internally generated Calibration Test

Reports retained on file by the Quality department as

defined within procedure QMP-004 as objective evidence

that all monitoring and measuring devices have been

calibrated and are capable of verifying the acceptability of

item(s) purchased or produced by (Insert Company

Name)?

5.8.6 Are calibration records made available to the customer

by the Quality department upon request?

5.9 Calibration Status

5.9.1

Upon completion of required calibration, is the calibration

status of each device identified by affixing a

calibration sticker to the item calibrated or its container?

QUALITY AUDIT CHECKLIST FOR QMP-018 ISS: 1 REV: 0 Page: 6 of 7

REVIEWED BY: APPROVED BY: November 23, 2001

DOC: IQAC-018 REPORT No.: DATE: AUDITOR(s):

EVALUATION CODE: AC = Acceptable IR = Improvement Required UN = Unacceptable N/A = Not Applicable

CONTROL OG MONITORING & MEASURING DEVICES (QMP-018)

Para. AUDIT QUESTION CODE OBSERVATIONS

a)

Does the sticker indicate the equipment or Instrument

identification control number, the date on which

calibration was performed, the individual who performed

the calibration and the next date on which calibration is

due?

5.9.2 To ensure that only appropriate monitoring and

measuring devices are used in accordance with their

measurement capability, are measuring uncertainty,

limitations or restrictions regarding usage identified on

each device, or its container, when so required?

5.10 Nonconformities

5.10.1 Is any monitoring and measuring device identified during

calibration as beyond the acceptance criteria limits

established for that equipment type or group, removed

from service and processed in accordance with

procedure QMP-023?

5.10.2 Are previous documented inspection, measuring and test

results generated for which the device was used, re-

evaluated to assess the validity of the results obtained?

a)

Are these re-evaluations documented and, when

required, is corrective action initiated as defined within

procedure QMP-026?

5.11 Invalidation of Calibration

5.11.1 Are monitoring and measuring devices removed immediately from use and forwarded to the Quality

department for verification or calibration when:

a) a failure in operation occurs?

b) There is evidence of physical damage?

c) the accuracy is suspect?

d) the calibration due date has passed?

e) Notified by the Quality department?

5.12 Reference Standards

5.12.1 Are monitoring and measuring devices calibrated against

Standards and/or Masters whose calibration is certified

as traceable to a nationally or internationally recognized

standard?

5.12.2 Is equipment that cannot be calibrated internally by

(Insert Company Name) sent to a specialized laboratory

having adequate proof that all Standards and Masters

used to perform calibration have been calibrated and are

QUALITY AUDIT CHECKLIST FOR QMP-018 ISS: 1 REV: 0 Page: 7 of 7

REVIEWED BY: APPROVED BY: November 23, 2001

DOC: IQAC-018 REPORT No.: DATE: AUDITOR(s):

EVALUATION CODE: AC = Acceptable IR = Improvement Required UN = Unacceptable N/A = Not Applicable

CONTROL OG MONITORING & MEASURING DEVICES (QMP-018)

Para. AUDIT QUESTION CODE OBSERVATIONS

traceable to recognized standards?

5.12.3 Does each piece of equipment sent out for calibration

require a calibration certificate to be issued to (Insert

Company Name)?

5.12.4

For equipment for which no nationally or internationally recognized standard exists, is the basis for calibration

documented and one of the following:

a)

The manufacturer's recommended method for

calibration?

b)

The comparison to a standard of which the accuracy and

precision has been confirmed?

c)

Customer requirements?

5.13 Storage and Handling

5.13.1 Are all monitoring and measuring devices including test

hardware and software kept in a designated area within

the Quality department when not in use?

5.13.2 While in use, are monitoring and measuring devices

safeguarded from adjustments that would invalidate the

measurement results and protected against damage or

deterioration by the responsible individual during handling

and maintenance?

5.14 Control of Suppliers

5.14.1 Does the Quality Manager verify that all major suppliers

have an adequately maintained calibration system that

essentially meets the requirements of this procedure?

5.14.2 Is registration of a supplier's quality management system

by an accredited Registrar accepted as objective

evidence that the supplier's calibration system is

compliant?

NOTE TO AUDITOR(S)

Upon completion of this audit, you must:

1) Ensure that this checklist has been completed and all observations have been entered;

2) Complete a Quality Audit Summary Report using form FRM-811; and

3) Complete any necessary CARs to be issued using form FRM-836.

You might also like

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- ISO - Control of Inspection, Measuring & Test EquipmentDocument4 pagesISO - Control of Inspection, Measuring & Test EquipmentAlmario SagunNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Standard Operating Procedure: CalibrationDocument22 pagesStandard Operating Procedure: CalibrationMaryanthony NamyaloNo ratings yet

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19From EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19No ratings yet

- Control of Quality Control ManualDocument25 pagesControl of Quality Control ManualWahyu HarisantoNo ratings yet

- Calibration Procedure.Document7 pagesCalibration Procedure.Mohammed Kamal71% (7)

- Calibration Master PlanDocument18 pagesCalibration Master PlanDoan Chi Thien100% (3)

- Calibration Procedure: ObjectiveDocument10 pagesCalibration Procedure: ObjectiveManjula_n2010100% (3)

- Master Validation of All Equipment in ProductionDocument5 pagesMaster Validation of All Equipment in ProductionNaci TürüközüNo ratings yet

- PM - 7.11 Monitoring and Measuring Equipment ControlDocument3 pagesPM - 7.11 Monitoring and Measuring Equipment ControlMangBedjoNo ratings yet

- Acceptance Criteria For Inspections and Inspection Agencies (AC304)Document4 pagesAcceptance Criteria For Inspections and Inspection Agencies (AC304)Sathiaram Ram100% (1)

- 6.2 Equipment Maintenance Preventive MaintenanceDocument7 pages6.2 Equipment Maintenance Preventive MaintenanceBALAJI100% (1)

- Tandard Perating Rocedure: Authorised by Number Effective Date Pages AuthorDocument5 pagesTandard Perating Rocedure: Authorised by Number Effective Date Pages Authoryousaf_zai_khan81995No ratings yet

- 10-Sec 5 - Exam & InspDocument3 pages10-Sec 5 - Exam & InspMo ZeroNo ratings yet

- Automotive Auditor TrainingDocument46 pagesAutomotive Auditor TrainingJoherNo ratings yet

- QSP 05 Internal Audits REV 1Document7 pagesQSP 05 Internal Audits REV 1kmvimal36No ratings yet

- Standard Operating Procedure: Qualification and Verification For Hvac System and AreasDocument64 pagesStandard Operating Procedure: Qualification and Verification For Hvac System and AreasMaryanthony NamyaloNo ratings yet

- WI-G-001 Inspection Measurment and Test Equipment Rev ADocument4 pagesWI-G-001 Inspection Measurment and Test Equipment Rev AAnil Chowadary Anil ChowadaryNo ratings yet

- Proficiency Testing 17020Document11 pagesProficiency Testing 17020ss1222100% (1)

- QM 11.2.10 CalibrationDocument3 pagesQM 11.2.10 CalibrationEtta JeneeNo ratings yet

- AC304 Effect Jan 2014Document3 pagesAC304 Effect Jan 2014Golden RosesNo ratings yet

- Calibration of Instruments in Production and Quality Control.Document2 pagesCalibration of Instruments in Production and Quality Control.Kike KikinNo ratings yet

- 2 Ia Qam3Document24 pages2 Ia Qam3Alberto TeránNo ratings yet

- Model SOP: Standard Operating ProcedureDocument7 pagesModel SOP: Standard Operating ProcedureahmedNo ratings yet

- Quality Assurance Requirements For Licensees-07162010Document4 pagesQuality Assurance Requirements For Licensees-07162010Norma GarciaNo ratings yet

- SOP For Equipment Calibration by External AgencyDocument4 pagesSOP For Equipment Calibration by External Agency王仁宏No ratings yet

- AC10 (January 2019) .PDFDocument10 pagesAC10 (January 2019) .PDFGolden RosesNo ratings yet

- Calibration ProcedureDocument1 pageCalibration Procedurechrisbulman5474100% (1)

- SOP On Calibration PolicyDocument3 pagesSOP On Calibration PolicyYousifNo ratings yet

- AC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Document9 pagesAC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Ravi Kumar100% (1)

- 02-Calibration & Control of Measuring & Monitoring DevicesDocument1 page02-Calibration & Control of Measuring & Monitoring DeviceskitekNo ratings yet

- Flight Synthetic Training Device (JAR FSTD A) - Audit Check List JAN 12Document24 pagesFlight Synthetic Training Device (JAR FSTD A) - Audit Check List JAN 12Bouchaib DollaNo ratings yet

- Calibaration Procedure Rev3Document4 pagesCalibaration Procedure Rev3Zubair Ahmed KhaskheliNo ratings yet

- Instrumentation Procedure ISODocument12 pagesInstrumentation Procedure ISOAhmad Adel El Tantawy100% (1)

- Cal ChecklistDocument9 pagesCal ChecklistImad AghilaNo ratings yet

- 15 IMS Performance AsssesmentDocument4 pages15 IMS Performance AsssesmentantivariNo ratings yet

- Quality ManualDocument16 pagesQuality Manualtary_nuryanaNo ratings yet

- 123Document30 pages123Pinkoo QualityNo ratings yet

- Operating QualificationDocument6 pagesOperating QualificationEnko Šatrović75% (4)

- Guidelines For The Acceptance of Manufacturer's Quality Assurance Systems For Welding Consumables No. 17Document6 pagesGuidelines For The Acceptance of Manufacturer's Quality Assurance Systems For Welding Consumables No. 17Marlon Alejandro Arboleda TapiaNo ratings yet

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Document12 pagesChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalNo ratings yet

- PRO-CAL-01 Measuring Equipment Calibration ProgramDocument2 pagesPRO-CAL-01 Measuring Equipment Calibration ProgramChiekoi PasaoaNo ratings yet

- SOP 006 Rev - NC Calibration & Verification of EquipmentDocument5 pagesSOP 006 Rev - NC Calibration & Verification of EquipmentmeongNo ratings yet

- Lab Equipment CalibrationDocument3 pagesLab Equipment Calibrationjohn100% (1)

- Tridecs: Quality Assurance ManualDocument35 pagesTridecs: Quality Assurance Manualzahid_497No ratings yet

- AC7140 Rev CDocument73 pagesAC7140 Rev CRanga100% (1)

- ISO/TS16949-Self Audit ChecklistDocument14 pagesISO/TS16949-Self Audit ChecklistBharathNo ratings yet

- 15 IMS Performance AsssesmentDocument4 pages15 IMS Performance AsssesmentPriyasha Ray100% (1)

- Control and Calibration of Inspection, Measuring and Test EquipmentDocument5 pagesControl and Calibration of Inspection, Measuring and Test EquipmentarylananylaNo ratings yet

- SOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical GuidelinesDocument2 pagesSOP For Calibration of Instruments in Production and Quality Control - Pharmaceutical GuidelinesPalak AgarwalNo ratings yet

- Section - 8 Examination and Inspection ProgramDocument3 pagesSection - 8 Examination and Inspection ProgramBayu JatmikoNo ratings yet

- 02-7 QCS 2014Document5 pages02-7 QCS 2014Raja Ahmed Hassan0% (1)

- ETA-QA001: Lectric Ransportation PplicationsDocument21 pagesETA-QA001: Lectric Ransportation PplicationsRangga K NegaraNo ratings yet

- Sun Industries Doc No: SI/QWI/ 001 Page No: 1 of 1 1.0 PurposeDocument1 pageSun Industries Doc No: SI/QWI/ 001 Page No: 1 of 1 1.0 PurposeJamil VoraNo ratings yet

- Section 8 - Quality Assurance/Quality Control PlanDocument3 pagesSection 8 - Quality Assurance/Quality Control PlanJoemon T JoyNo ratings yet

- Calibration CertificateDocument3 pagesCalibration CertificateMARIBETH AGUBANo ratings yet

- 81W 27244 0 CalbrationDocument4 pages81W 27244 0 CalbrationSrikant SuruNo ratings yet

- IAPMO Quality Management System Review Procedures For Certified Manufacture's Quality Manual ES-010Document5 pagesIAPMO Quality Management System Review Procedures For Certified Manufacture's Quality Manual ES-010Jasneil SidhuNo ratings yet

- CalibrationDocument13 pagesCalibrationKedar PradhanangNo ratings yet

- Fraud Risk ManagementDocument82 pagesFraud Risk ManagementdigitalbooksNo ratings yet

- Notes On ActivitiesDocument2 pagesNotes On ActivitiesalokjaseNo ratings yet

- Disa Fafd PDFDocument107 pagesDisa Fafd PDFAnuNo ratings yet

- Helpdesk For CompliancesDocument11 pagesHelpdesk For CompliancesalokjaseNo ratings yet

- S.no Company Name Auditor's Name Type Topic Particulars Principle Auditor's ResponseDocument56 pagesS.no Company Name Auditor's Name Type Topic Particulars Principle Auditor's ResponsealokjaseNo ratings yet

- ICAI Study Notes Forensic Accounting and Fraud DetectionDocument225 pagesICAI Study Notes Forensic Accounting and Fraud DetectionSBI RSETI NATHDWARA100% (1)

- 10 RR Form For M Com 2nd Year (Eng)Document2 pages10 RR Form For M Com 2nd Year (Eng)alokjaseNo ratings yet

- IBC Cases PDFDocument205 pagesIBC Cases PDFAvishek PathakNo ratings yet

- Disa Fafd PDFDocument107 pagesDisa Fafd PDFAnuNo ratings yet

- ICAIIBCFaqs 2019Document210 pagesICAIIBCFaqs 2019SENTHIL1961No ratings yet

- ICAI Study Notes Forensic Accounting and Fraud DetectionDocument225 pagesICAI Study Notes Forensic Accounting and Fraud DetectionSBI RSETI NATHDWARA100% (1)

- Subject CT6 Statistical Methods Core Technical Syllabus: For The 2014 ExamsDocument7 pagesSubject CT6 Statistical Methods Core Technical Syllabus: For The 2014 ExamsalokjaseNo ratings yet

- Newsletter GST PDFDocument24 pagesNewsletter GST PDFRajanNo ratings yet

- Audit Checklist PDFDocument33 pagesAudit Checklist PDFHector Eduardo ErmacoraNo ratings yet

- Subject CA2 Model Documentation, Analysis and Reporting SyllabusDocument2 pagesSubject CA2 Model Documentation, Analysis and Reporting SyllabusalokjaseNo ratings yet

- Subject CT3 Probability and Mathematical Statistics Core Technical SyllabusDocument7 pagesSubject CT3 Probability and Mathematical Statistics Core Technical SyllabusRochak JainNo ratings yet

- Check 20Document0 pagesCheck 20alokjaseNo ratings yet

- Audit of HR DepartmentDocument52 pagesAudit of HR DepartmentMahabubur Rahman সম্রাট100% (6)

- ECR Europe Store Checklist White PaperDocument12 pagesECR Europe Store Checklist White PapervvkantNo ratings yet

- HR Audit ChecklistDocument10 pagesHR Audit ChecklistIbrah1mov1chNo ratings yet

- Iandfca32013 2014sylDocument6 pagesIandfca32013 2014sylalokjaseNo ratings yet

- Iandfca 12014 SylDocument11 pagesIandfca 12014 SylalokjaseNo ratings yet

- ct8 SyllabusDocument7 pagesct8 SyllabusRishav KhaitanNo ratings yet

- TICLETDocument2 pagesTICLETalokjaseNo ratings yet

- Presentation 1Document1 pagePresentation 1alokjaseNo ratings yet

- 147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComDocument4 pages147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComjeyesbelmenNo ratings yet

- str-w6754 Ds enDocument8 pagesstr-w6754 Ds enAdah BumbonNo ratings yet

- Consecration of TalismansDocument5 pagesConsecration of Talismansdancinggoat23100% (1)

- Unit 1 PrinciplesDocument17 pagesUnit 1 PrinciplesRohit YadavNo ratings yet

- Atoma Amd Mol&Us CCTK) : 2Nd ErmDocument4 pagesAtoma Amd Mol&Us CCTK) : 2Nd ErmjanviNo ratings yet

- There Will Come Soft RainsDocument8 pagesThere Will Come Soft RainsEng ProfNo ratings yet

- Approvals Management Responsibilities and Setups in AME.B PDFDocument20 pagesApprovals Management Responsibilities and Setups in AME.B PDFAli LoganNo ratings yet

- Transfert de Chaleur AngDocument10 pagesTransfert de Chaleur Angsouhir gritliNo ratings yet

- Halloween EssayDocument2 pagesHalloween EssayJonathan LamNo ratings yet

- Raiders of SuluDocument1 pageRaiders of SuluBlexx LagrimasNo ratings yet

- Maximum and Minimum PDFDocument3 pagesMaximum and Minimum PDFChai Usajai UsajaiNo ratings yet

- (EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing SteelDocument24 pages(EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing Steelbagusu_6No ratings yet

- Blake Mouton Managerial GridDocument3 pagesBlake Mouton Managerial GridRashwanth Tc100% (1)

- OTP User Manual For English) v1,0Document15 pagesOTP User Manual For English) v1,0auyinNo ratings yet

- MPI Unit 4Document155 pagesMPI Unit 4Dishant RathiNo ratings yet

- TPDocument10 pagesTPfaisal gaziNo ratings yet

- Inverter 2 chiềuDocument2 pagesInverter 2 chiềuKhánh Nguyễn MinhNo ratings yet

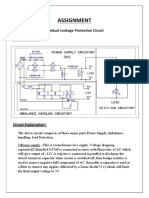

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocument2 pagesAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaNo ratings yet

- Code of Ethics For Civil Engineers PiceDocument3 pagesCode of Ethics For Civil Engineers PiceEdwin Ramos Policarpio100% (3)

- Governance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REDocument6 pagesGovernance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REBob SolísNo ratings yet

- Analisis Kebutuhan Bahan Ajar Berbasis EDocument9 pagesAnalisis Kebutuhan Bahan Ajar Berbasis ENur Hanisah AiniNo ratings yet

- Management PriniciplesDocument87 pagesManagement Priniciplesbusyboy_spNo ratings yet

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- Fundasurv 215 Plate 1mDocument3 pagesFundasurv 215 Plate 1mKeith AtencioNo ratings yet

- Understanding The Contribution of HRM Bundles For Employee Outcomes Across The Life-SpanDocument15 pagesUnderstanding The Contribution of HRM Bundles For Employee Outcomes Across The Life-SpanPhuong NgoNo ratings yet

- Electronic Diversity Visa ProgrambDocument1 pageElectronic Diversity Visa Programbsamkimari5No ratings yet

- For Accuracy and Safety: Globally ApprovedDocument4 pagesFor Accuracy and Safety: Globally ApprovedPedro LopesNo ratings yet

- Naval TV SystemDocument24 pagesNaval TV Systemsharmasandeep0010No ratings yet

- Vetoset CA541: Thickbed Cementitious Tile AdhesiveDocument2 pagesVetoset CA541: Thickbed Cementitious Tile Adhesivemus3b1985No ratings yet

- Core CompetenciesDocument3 pagesCore Competenciesapi-521620733No ratings yet