Professional Documents

Culture Documents

Answers

Uploaded by

jeevarvinderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Answers

Uploaded by

jeevarvinderCopyright:

Available Formats

Direct seeding, like no-till, is a cropping system which aims to improve soil and soil moisture conservation.

Direct seeding is more flexible than no-till; it allows some tillage to solve immediate weed problems and to deal with high moisture and heavy clay soil conditions. In direct seeding, soil is not tilled in the spring before planting. This is to conserve soil moisture in the seedbed. Any fall tillage must leave the soil surface compact and level to preserve soil moisture. Most of the crop residue remains on the surface with at least half the stubble remaining upright and anchored to trap as much snow as possible. Typical operations are fall fertilizer banding with knives, and redistributing crop residue and incorporating herbicides with heavy or rotary harrows. The distance between seeds and depth of seeds to be sowed is technically tried and instructed to farmers and the farming equipments are specifically tuned to achive this.

Drip irrigation, also known as trickle irrigation or micro irrigation or localized irrigation, is an irrigation method which saves water and fertilizer by allowing water to drip slowly to the roots of plants, either onto the soil surface or directly onto the root zone, through a network of valves, pipes, tubing, and emitters. It is done with the help of narrow tubes which deliver water directly to the base of the plant. Direct seeding is the sowing of seeds directly in the soil, by-passing the need for nurseries and irrigation. This fulfils two goals the farmers have in mind, namely to produce food and to do this economically by conserving water, nutrients, etc. Plant nurseries by comparison, require watering, plastic sacs (which are expensive for the farmers and pollute the environment), transport of the seedlings to planting sites and labour to look after the seedlings.

Solar panel Asias largest solar power field, 600 megawatt solar energy. The Gujarat Solar Park, Charanka, in North Gujarat commissioning of its 10 mw solar power project The worlds first canal-top project on Sanand branch canal of the Sardar Sarovar Nigam Ltd generating one-MW electricity from solar panels atop the Narmada branch canal was inaugurated by Gujarat Chief Minister Narendra Modi. A project that has the potential of generating 2,200 MW electricity from solar panels, give clean, pollution-free energy, save 11,000 acres of land and also prevent water in irrigational canals from evaporating, does indeed sound like a DREAM project. But if the new canal-top project in Narmada is to be followed, that dream might become Gujarats reality.

To produce solar power and avoid water evaporation, solar panels have been set up atop the Narmada branch canal. The 19,000-km-long Narmada canal network in Gujarat is a potential powerhouse and it is estimated that even if 10 percent of the canal top is used for setting up solar panels, it could help generate 2,200 MW of power, save large acres of land and prevent Rs 2,000 crore of precious water from evaporation annually. Gujarats solar power initiative could help the nation save Rs 500 crore over the next 25 years, besides reducing carbon emissions to the tune of 8 lakh tones.

PepsiCo Community CheckDam Project Paithan, Aurangabad The initiative PepsiCo conducted a water resource assessment study near its Aurangabad plant replenish ground water. PepsiCo India then constructed 13 check-dams and recharged over 100 wells.

Impact The project created the potential to recharge more than 1 billion liters of water. It benefits nearly 12,000 community members through improved access to water, additional crops, increase in yield of rain-fed crops and the opportunity for a second cultivation cycle during the Rabi season due to improved availability of water

Replenishing Water Through Community Water Harvesting Project, Neelamangala The initiative In Neelamangala, Bangalore Rural, PepsiCo creation of water harvesting structures by introducing artificial recharge systems within water bodies. installation of a roof-top rainwater harvesting structure in the T. Begur village. The goal of the project is to improve water resources in the community, recharge wells and increase the production of rainfed crops.

Impact The project has created the potential to recharge 908 million liters of water per year.

This benefits 4000 people through improved water resources in the community, recharging wells and also improved water availability for rainfed crops.

Water Harvesting Project, Panipat The initiative The project focuses on the rejuvenation and creation of water recharge structures aimed to improve the water availability for the neighboring community. enhance ground water recharge, with the potential to recharge 175 million liters of water.

Impact The project benefits nearly 10,000 people in and around Panipat.

global warming is related to anthropogenic Green House Gases (GHGs). GHGs include, the common gases namely , carbon dioxide and water vapor, and rarer gases such as nitrous oxide, methane and chlorofluorocarbons (CFCs) whose properties relate to the transmission or reflection of different types of solar radiations. The increase in such gases in the atmosphere is a result of the burning of fossil fuels, emission of pollutants into the atmosphere by power plants and vehicle engines, etc. Of all human activities, driving motor vehicles produces the most intensive CO2 emissions and other toxic gases per capita.

CNG Natural gas is a mixture of hydrocarbons mainly methane (CH4) and is produced either from gas wells or in conjunction with crude oil production. Natural Gas offers a significant potential for reducing harmful emissions from vehicles, especially those of fine particulates, compared to conventional fuel. It stands substantially better than conventional fuels both in life cycle emissions and vehicle exhaust emissions.

Liquefied Petroleum Gas (LPG) LPG is a by-product of natural gas processing or a product that comes from crude oil refining and is composed primarily of propane and butane with smaller amounts of propylene and butylenes. Liquefied petroleum gas (LPG) consists mainly of propane, propylene, butane, and butylene in various mixtures. Lower carbon-to-hydrogen ratio, higher octane rating and its ability to form a homogeneous mixture inside the combustion chamber enable it to produce lesser emissions.

CNG direction by the Honble Supreme Court to Delhi transport Cooperation to convert at least 1/5th of its bus fleet every year to CNG and to purchase henceforth only new buses that use CNG as fuel and if licenses are issued to private buses those should be issued only for buses running on CNG or on batteries in Delhi; Due to its low energy density for use as a vehicular fuel, it is compressed to a pressure of 200 - 250 bars to facilitate storage in cylinders mounted in vehicle and so it is called compressed natural gas (CNG). By November of 2002, all diesel busses and non-CNG two-stroke three-wheelers of the city were removed from the streets of Delhi. The city today has the worlds largest CNG vehicle fleet.

Diesel Alcohol Blends The alcohol may be blended with diesel fuel to produce dies-ohol, (or) the alcohol may be added to the air intake of the diesel engine. But, control of the quantity of alcohol added to the air intake may be difficult and could cause erratic engine operation and/or failure if a large quantity of alcohol was added to the air intake. Methyl alcohol, because of its highly polar nature, does not mix with diesel fuel. Ethanol can be mixed with diesel fuel provided there is little water in the ethanol. Another problem with adding ethanol to diesel fuel is that the cetane number (ignition characteristic) may decrease below the level recommended by the engine manufacturer. Butyl alcohol can be mixed with diesel fuel in virtually any concentration.

A fuel cell is a device that converts the chemical energy from a fuel into electricity through a chemical reaction with oxygen or another oxidizing agent. Hydrogen is the most common fuel, but hydrocarbons such as natural gas and alcohols like methanol are sometimes used. Fuel cells are different from batteries in that they require a constant source of fuel and oxygen to run, but they can produce electricity continually for as long as these inputs are supplied

[1]

Topologies can be parallel hybrid, series hybrid , power-split hybrid (as per powertrain) Full hybrid, mild hybrid (degree of hybridization) Examples: Toyota prius (full hybrid)

Hybrid electric vehicles can be classified according to the way in which power is supplied to the drivetrain:

In parallel hybrids, the ICE and the electric motor are both connected to the mechanical transmission and can simultaneously transmit power to drive the wheels, usually through a conventional transmission. Honda's Integrated Motor Assist (IMA) system as found in the Insight, Civic, Accord, as well as the GM Belted Alternator/Starter (BAS Hybrid) system found in the Chevrolet Malibu hybrids are examples of [17] production parallel hybrids. Current, commercialized parallel hybrids use a single, small (<20 kW) electric motor and small battery pack as the electric motor is not designed to be the sole source of motive power from launch. Parallel hybrids are also capable of regenerative braking and the internal combustion engine can also act as a generator for supplemental recharging. Parallel hybrids are more efficient than comparable non-hybrid vehicles especially during urban stop-and-go conditions and at times during highway operation [17] where the electric motor is permitted to contribute. In series hybrids, only the electric motor drives the drivetrain, and the ICE works as a generator to power the electric motor or to recharge the batteries. The battery pack can be recharged through regenerative braking or by the ICE. Series hybrids usually have a smaller combustion engine but a larger battery pack as compared to parallel hybrids, which makes them more expensive than parallels. This configuration makes

series hybrids more efficient in city driving. The Chevrolet Volt is a series plug-in hybrid, although GM prefers to describe the Volt as an electric vehicle equipped with a "range extending" gasoline powered ICE [18] [18][19][20] as a generator and therefore dubbed an "Extended Range Electric Vehicle" or EREV.

[17]

Power-split hybrids have the benefits of a combination of series and parallel characteristics. As a result, they are more efficient overall, because series hybrids tend to be more efficient at lower speeds and parallel tend to be more efficient at high speeds; however, the power-split hybrid is higher than a pure [17] parallel. Examples of power-split (referred to by some as "series-parallel") hybrid powertrains include [17][21] current models of Ford,General Motors, Lexus, Nissan, and Toyota.

Types by degree of hybridization

Full hybrid, sometimes also called a strong hybrid, is a vehicle that can run on just the engine, just the [22] batteries, or a combination of both. Ford's hybrid system, Toyota's Hybrid Synergy Drive and General [23] Motors/Chrysler's Two-Mode Hybrid technologies are full hybrid systems. The Toyota Prius, Ford Escape Hybrid, and Ford Fusion Hybrid are examples of full hybrids, as these cars can be moved forward on battery power alone. A large, high-capacity battery pack is needed for battery-only operation. These vehicles have a split power path allowing greater flexibility in the drivetrain by interconverting mechanical and electrical power, at some cost in complexity. Mild hybrid, is a vehicle that can not be driven solely on its electric motor, because the electric motor does [22][23] not have enough power to propel the vehicle on its own. Mild hybrids only include some of the features found in hybrid technology, and usually achieve limited fuel consumption savings, up to 15 percent in urban [22][23] driving and 8 to 10 percent overall cycle. A mild hybrid is essentially a conventional vehicle with oversize starter motor, allowing the engine to be turned off whenever the car is coasting, braking, or stopped, yet restart quickly and cleanly. The motor is often mounted between the engine and transmission, taking the place of the torque converter, and is used to supply additional propulsion energy when accelerating. Accessories can continue to run on electrical power while the gasoline engine is off, and as in other hybrid designs, the motor is used for regenerative braking to recapture energy. As compared to full hybrids, mild hybrids have smaller batteries and a smaller, weaker motor/generator, which allows [23] manufacturers to reduce cost and weight. Honda's early hybrids including the first generation Insight used this design,

[23]

leveraging their

reputation for design of small, efficient gasoline engines; their system is dubbed Integrated Motor Assist (IMA). Starting with the 2006 Civic Hybrid, the IMA system now can propel the vehicle solely on electric power during medium speed cruising. Another example is the 2005-2007 Chevrolet Silverado Hybrid, a full-size pickup truck.

[23]

Chevrolet was able to get a 10% improvement on the Silverado's fuel

efficiency by shutting down and restarting the engine on demand and using regenerative braking. General Motors has also used its mild BAS Hybrid technology in other models such as the Saturn Vue Green Line, the Saturn Aura Greenline and the Mailbu Hybrid.

[23]

Plug-in hybrids (PHEVs)

The Chevrolet Volt is a plug-in hybrid able to run in all-electric mode up to 35 miles.

A plug-in hybrid electric vehicle (PHEV), also known as a plug-in hybrid, is a hybrid electric vehicle with rechargeable batteries that can be restored to full charge by connecting a plug to an external electric powersource. A PHEV shares the characteristics of both a conventional hybrid electric vehicle, having an electric motor and an internal combustion engine; and of an all-electric vehicle, also having a plug to connect to the electrical grid. PHEVs have a much larger all-electric range as compared to conventional gasoline-electric hybrids, and also eliminate the "range anxiety" associated with all-electric vehicles, [22][24][25] because the combustion engine works as a backup when the batteries are depleted.

Chinese battery manufacturer and automaker BYD Auto released the F3DM PHEV-62 (PHEV100 km) hatchback to the Chinese fleet market on December 15, 2008, for 149,800 yuan (US [26][27] [28][29] $22,000). General Motors launched the 2011 Chevrolet Volt series plug-in in December 2010. The [30][31] Volt displaced the Toyota Prius as the most fuel-efficient car sold in the United States.

In 1900, while employed at Lohner Coach Factory, Ferdinand Porsche developed the Mixte, a 4WD serieshybrid version of "System Lohner-Porsche" electric carriage previously appeared in 1900 Paris World Fair. The Mixte included a pair of generators driven by 2.5-hp Daimler IC engines to extend operating range and it could [2][33][34] travel nearly 65 km on battery alone. It was presented in the Paris Auto Show in 1901. The Mixte broke several Austrian speed records, and also won the Exelberg Rally in 1901 with Porsche himself driving. The Mixte used a gasoline engine powering agenerator, which in turn powered electric hub motors, with a small battery pack for reliability. It had a top speed of 50 km/h and a power of 5.22 kW during 20 minutes. George Fischer sold hybrid buses to England in 1901

[2][32]

Bioethanol is an alcohol made by fermentation, mostly from carbohydrates produced in sugar or starch crops such as corn or sugarcane. Cellulosic biomass, derived from non-food sources such as trees and grasses, is also being developed as a feedstock for ethanol production. Ethanol can be used as a fuel for vehicles in its pure form, but it is usually used as a gasoline additive to increase octane and improve vehicle emissions. Bioethanol is widely used in the USA and in Brazil. Current plant design does not provide for converting the lignine portion of plant raw materials to fuel components by fermentation. Ethanol fuel is the most common biofuel worldwide, particularly in Brazil. Alcohol fuels are produced by fermentation of sugars derived from wheat, corn, sugar beets, sugar cane, molasses and any sugar or starch that alcoholic beverages can be made from (like potato and fruit waste, etc.).

Biodiesel is made from vegetable oils and animal fats. Biodiesel can be used as a fuel for vehicles in its pure form, but it is usually used as a diesel additive to reduce levels of particulates, carbon monoxide, and hydrocarbons from diesel-powered vehicles. Biodiesel is produced from oils or fats using transesterification and is the most common biofuel in Europe

Second generation biofuels are biofuels produced from sustainable feedstock. Sustainability of a feedstock is defined among others by availability of the feedstock, impact on GHG emissions and impact on biodiversity and land use.[28] Many second generation biofuels are under development such as Cellulosic ethanol, Algae fuel[29]., biohydrogen, biomethanol, DMF, BioDME, Fischer-Tropsch diesel, biohydrogen diesel, mixed alcohols and wood diesel.

Cellulosic ethanol production uses non-food crops or inedible waste products and does not divert food away from the animal or human food chain. Lignocellulose is the "woody" structural material of plants. This feedstock is abundant and diverse, and in some cases (like citrus peels or sawdust) it is in itself a significant disposal problem.

You might also like

- ABC of TaxDocument13 pagesABC of Taxjourneywithinself0No ratings yet

- Pepsico Community Check - Dam Project Paithan, Aurangabad The InitiativeDocument7 pagesPepsico Community Check - Dam Project Paithan, Aurangabad The InitiativejeevarvinderNo ratings yet

- Latest IssuesDocument7 pagesLatest IssuesjeevarvinderNo ratings yet

- Home Made Cakes: M.Prema Surendranath M.Prema SurendranathDocument4 pagesHome Made Cakes: M.Prema Surendranath M.Prema SurendranathAbhishek Singh ChauhanNo ratings yet

- UscgDocument5 pagesUscgjeevarvinderNo ratings yet

- Military QuotesDocument6 pagesMilitary QuotesjeevarvinderNo ratings yet

- R F Energy Propagation Through Atmosphere: by SLT Manikanta S OinamDocument16 pagesR F Energy Propagation Through Atmosphere: by SLT Manikanta S OinamjeevarvinderNo ratings yet

- Lic Surrender SamplerDocument4 pagesLic Surrender SamplerjeevarvinderNo ratings yet

- Revised SCDL Rate CardDocument1 pageRevised SCDL Rate CardjeevarvinderNo ratings yet

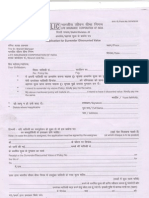

- Aadhar Enrolment Correction FormDocument2 pagesAadhar Enrolment Correction Formapi-249989744No ratings yet

- Grievance Redressal Policy PDFDocument3 pagesGrievance Redressal Policy PDFjeevarvinderNo ratings yet

- Course Description Physics Semester-II: Course Instructor Anuj Kumar Department of Physics, Email:anuj - Kumar@jiet - Ac.inDocument11 pagesCourse Description Physics Semester-II: Course Instructor Anuj Kumar Department of Physics, Email:anuj - Kumar@jiet - Ac.injeevarvinderNo ratings yet

- Lic Surrender SamplerDocument4 pagesLic Surrender SamplerjeevarvinderNo ratings yet

- Lic Surrender SamplerDocument4 pagesLic Surrender SamplerjeevarvinderNo ratings yet

- Distance learning enrollment and student services formDocument1 pageDistance learning enrollment and student services formjeevarvinderNo ratings yet

- Strategic Management PDFDocument6 pagesStrategic Management PDFjeevarvinderNo ratings yet

- Strategic ManagementDocument173 pagesStrategic Managementjirufeleke1428100% (2)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CamScanner Scanned PDF DocumentDocument205 pagesCamScanner Scanned PDF DocumentNabila Tsuroya BasyaNo ratings yet

- 150 C++ BitsDocument55 pages150 C++ BitsRavi Varma D V SNo ratings yet

- Beginning of Agriculture Northern Vindhyas Middle Gangetic PlainsDocument17 pagesBeginning of Agriculture Northern Vindhyas Middle Gangetic Plainsakshat aggarwal100% (1)

- Anectodal RecordsDocument10 pagesAnectodal RecordsSchahyda ArleyNo ratings yet

- DGS Mock Exam - Full AnswerDocument11 pagesDGS Mock Exam - Full AnswerSofia NicoriciNo ratings yet

- Boiler Instrumentation and Control SystemsDocument68 pagesBoiler Instrumentation and Control Systemstagne simo rodrigueNo ratings yet

- Medical ParasitologyDocument33 pagesMedical ParasitologyAlexander Luie Jhames SaritaNo ratings yet

- PCM320 IDM320 NIM220 PMM310 Base Release Notes 1210Document48 pagesPCM320 IDM320 NIM220 PMM310 Base Release Notes 1210Eduardo Lecaros CabelloNo ratings yet

- Install CH340 driver for ArduinoDocument8 pagesInstall CH340 driver for Arduinosubbu jangamNo ratings yet

- Cu Unjieng V MabalacatDocument6 pagesCu Unjieng V MabalacatMp CasNo ratings yet

- Sample COBOL ProgramsDocument35 pagesSample COBOL Programsrahul tejNo ratings yet

- Chapter 3 Theoretical ConsiderationsDocument8 pagesChapter 3 Theoretical Considerationsapi-3696675No ratings yet

- Procurement of Railway Infrastructure Projects - ADocument15 pagesProcurement of Railway Infrastructure Projects - ADan NanyumbaNo ratings yet

- 2.1-Islamic Law of Contract and SalesDocument39 pages2.1-Islamic Law of Contract and SalesAllauddinagha100% (1)

- All India CW Pricelist Wef 01.05.2021Document6 pagesAll India CW Pricelist Wef 01.05.2021Sameer PadhyNo ratings yet

- Business-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)Document8 pagesBusiness-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)nidayousafzaiNo ratings yet

- Essential Components of an Effective Road Drainage SystemDocument11 pagesEssential Components of an Effective Road Drainage SystemRaisanAlcebarNo ratings yet

- Accenture Faq For New JoinersDocument4 pagesAccenture Faq For New JoinersBaazinow Hack Brainbaazi Live AnswersNo ratings yet

- Orgin of Life and Organic EvolutionDocument74 pagesOrgin of Life and Organic Evolutionasha.s.k100% (5)

- Simplex-4004 Installation Operating Manual Rev C PDFDocument36 pagesSimplex-4004 Installation Operating Manual Rev C PDFElias Rangel100% (1)

- Technology Unit 1 UTUDocument19 pagesTechnology Unit 1 UTUDaNo ratings yet

- Msme'S Premium Product Catalogue Book 2020: Craft CategoryDocument50 pagesMsme'S Premium Product Catalogue Book 2020: Craft CategoryTomikoVanNo ratings yet

- Ashok LeylandDocument4 pagesAshok Leylandsodhiseema100% (1)

- Martina: Available Colors For This VersionDocument2 pagesMartina: Available Colors For This VersionUmeshNo ratings yet

- The Government-Created Subprime Mortgage Meltdown by Thomas DiLorenzoDocument3 pagesThe Government-Created Subprime Mortgage Meltdown by Thomas DiLorenzodavid rockNo ratings yet

- USB and ACPI Device IDsDocument10 pagesUSB and ACPI Device IDsKortiyarshaBudiyantoNo ratings yet

- Urinary: Rachel Neto, DVM, MS, DACVP May 28 2020Document15 pagesUrinary: Rachel Neto, DVM, MS, DACVP May 28 2020Rachel AutranNo ratings yet

- Danfoss DatasheetDocument74 pagesDanfoss DatasheetzansNo ratings yet

- Module 3 - Subsequent To AcquisitionDocument8 pagesModule 3 - Subsequent To AcquisitionRENZ ALFRED ASTRERONo ratings yet

- FS 1 Observations of Teaching-Learning in Actual School EnvironmentDocument8 pagesFS 1 Observations of Teaching-Learning in Actual School EnvironmentJessie PeraltaNo ratings yet