Professional Documents

Culture Documents

Appropriate Separator Sizing - A Modified Stewart and Arnold Method F. Boukadi, V. Singh, R. Trabelsi, F. Sebring, D. Allen, and V. Pai

Uploaded by

germangsilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appropriate Separator Sizing - A Modified Stewart and Arnold Method F. Boukadi, V. Singh, R. Trabelsi, F. Sebring, D. Allen, and V. Pai

Uploaded by

germangsilvaCopyright:

Available Formats

1

Appropriate Separator Sizing

A Modified Stewart and Arnold Method

F. Boukadi, V. Singh

*

, R. Trabelsi, F. Sebring, D. Allen, and V. Pai

**

University of Louisiana, Lafayette, Louisiana, USA

*

Statoil, Stavanger, Norway

**

Superior Energy, Lafayette, Louisiana, USA

Abstract

Oil and gas separators were one of the first pieces of production equipment to be used in

the oil and natural gas industry. Despite the longevity of their use the basic design of a separator

has not change much. According to Katapodis

1

a separator must perform four different phases of

separation. The different stages of separation are completed using a variety of the following

three physical principles: gravity, centrifugal force, and impingement.

The size of the oil droplets in the production water is based mainly on the choke valve

pressure drop. The choke valve pressure drop creates a shearing effect, which causes the oil

droplets to break down, and reduces the ability of the larger droplets to combine with other

droplets. One of the goals of oil separation is to reduce the shearing effect of the choke. Based

on Stokes Law the larger the oil droplet is the easier it will be to separate it.

During the lifetime of producing wells, gas, oil and water flow rates fluctuate.

Unfortunately, separators are conventionally designed based on initial flow rates only and as a

result, the separator is no longer able to accommodate totality of produced fluids. Separation

performance is hence no longer optimized. The changing fluid flow rates are not the only reason;

emulsion viscosity and the resulting effect of different flow rates on emulsion viscosity impede

design, if not taking into consideration.

The reduction in vessel performance results into recorded measurements that do not

match actual production levels inducing doubt into any history matching process and distorting

reservoir management programs.

In this paper, an augmented Stewart and Arnold

2

method has been developed. The new

model takes into account flow rates and emulsion viscosity. The generated vessel length, vessel

diameter, slenderness ratio monographs are used to select appropriate separator size based on

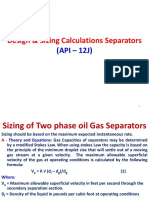

required retention time. Model results are compared to API 12J standards.

Keywords: Separator, Sizing, Modified, Stewart, Arnold, Emulsion, Viscosity

Introduction

With the advent of computers and commercial simulators, it is comparatively easier to

obtain the production forecast of a producing well, without having to rely on preset analytical

models which may or may not follow the exact field conditions. Unfortunately this advantage

has not been utilized in the design of Separators. The basic separator sizing is still being done on

2

the basis of API 12J specifications and the different flow rates that may arise during the

production lifetime are also not taken into account.

An obvious thought is to just use the production data obtained through the simulator and

use it in the simple API 12J calculations, but the flow rates are not enough. One of the major

problems in designing two- or three-phase separators relate to the problem of emulsion. This can

be taken into account using the correlations developed by Choi

3

to augment separator design as

specified by Stewart and Arnold

3

. According to Arnold and Stewart

2

, a preferred diameter of

water droplet (500 m) to be separated from oil and a diameter of liquid (water and oil) of 200

m to be separated from gas are preferred in the analysis. Furthermore, retention times of oil and

water are taken to be between 3 and 30 minutes, respectively

3

. Viscosity of oil is obtained by

using the Chew and Connolly correlation

4

of gas saturated viscosity (

ob

) with respect to dead oil

viscosity (

od

).

Oil-water Separation Theory

According to Choi

2

, the oil-water separation is governed by Stokes Law for terminal

velocity of spheres in a liquid medium. The terminal velocity of the continuous phase is defined

by,

( )

2

o w t

D

18

G

V

= (1)

As illustrated above, the terminal velocity is a function of an emulsion (oil-water)

viscosity that takes into account an oil-rich or a water-rich system. The viscosity of an emulsion

as given by Taylor is:

(

|

|

.

|

\

|

+

+

| + =

1 p

5 / 2 p

5 . 2 1

c em

(2)

where,

phase outer

phase inner

p

=

As production goes on, inversion from oil-dominant to water-dominant emulsion takes

place. This can be estimated by,

3 . 0

L H

H L

H

L

Q

Q

|

|

.

|

\

|

|

|

.

|

\

|

= u (3)

Table 1 summarizes types of emulsion based on the phase dispersion coefficient, .

3

Table 1. Emulsion type resulting from phase dispersion coefficient.

Phase dispersion coefficient, Result

< 0.3 Light phase always dispersed

0.3 - 0.5 Light phase probably dispersed

0.5 - 2.0 Phase inversion possible

2.0 3.3 Heavy phase probably dispersed

> 3.3 Heavy phase always dispersed

For all practical purposes, we use of 0.5 as an inversion point.

The emulsion viscosity obtained from the above procedure can only be used to calculate

the minimum capacity of the separator, therefore, there is no limit on the size of the separator as

viscosity does not directly influence the capacity of a separator. For this purpose, we use a new

retention time that is calculated using the following formula to yield a more direct correlation to

the size.

( ) ( ) base r

base

future

future r

T T

= (4)

The flow chart below illustrates the new methodology of sizing separators.

Example Field Sizing

For illustration purposes, an example was selected. The well produces from a fractured

carbonate reservoir, with most of the fractures connecting to an aquifer. Eclipse100 reservoir

simulator was used to model the reservoir and the following oil, water, and gas production

forecast for the well was produced.

Maximum

Flow Rate

Maximum

Emulsion

Viscosity

Separator

Capacity

Compare and

Select Maximum

Capacity

4

Figure 1. Simulated production forecast.

It is clear from the 22-year simulated forecast that the separator will not be able to

accommodate produced fluids if it is sized using a conventional design based on only initial flow

rates.

Taking into account emulsion viscosity and using a correlation developed by Taylor

4

,

emulsion viscosity as a function of simulation time plots as follows:

Figure 2. Emulsion viscosity evolution over time.

5

Here we can clearly see that the emulsion viscosity peaks at 9.1 cp, whereas the

calculated oil viscosity which is conventionally used in separator sizing is just 3.43 cp

5

.

The new retention time calculated using equation 4 for base retention times of 3, 5, 10, 15

and 20 minutes are: 8, 13, 26, 39, and 53 minutes, respectively.

As per the new proposed methodology these peak emulsion viscosities and the peak flow

rates were used to size the separators.

The sizes were calculated based on:

1. Conventional Method:

a. API 12 J minimum sizing requirements (initial flow rates only).

b. Arnold-Stewart Method (initial flow rates only).

2. New Method (Modified Arnold Stewart Method):

a. Based on flow rates.

b. Based on emulsion viscosity.

Figure 3. Sizing - API 12J.

6

Figure 4. Arnold Stewart Method.

Figure 5. Modified Arnold Stewart Method for peak flow rates.

7

Figure 6. Modified Arnold Stewart Method using peak emulsion viscosity.

Figures 3 to 6 offer a unique opportunity to select separators based on the appropriate

retention time. The charts offer envelopes enclosing vessel diameter, vessel length, and vessel

slenderness ratio for calculated retention times. Any combination within a selected envelope is

capable of handling a required capacity.

Now, as per the modified methodology we have to compare the sizes obtained from the

modified method using peak flow rates and peak emulsion viscosity, this is illustrated below in

Figure 7 using a Pareto chart (tr is retention time, MASem is Modified Arnold Stewart method

based on emulsion viscosity).

Figure 7. Pareto chart of sizes obtained from different methods.

8

The above pareto chart is based on bulk volumes of various sizes. Actual volumes have

been purposefully not considered as they may yield wrong sizing. The chart compares different

design methods and compares differences in design, indicating that the modified Arnold-Stewart

method for emulsion viscosity yields the largest vessels; automatically taking care of increased

total liquid flow rates that could be encountered later in the life of any production well.

Conclusions

1. The new model resulted in an oversized separator that yielded an optimum performance

throughout the life of the produced well.

2. The current design is based on 50% full capacity, however, separators maybe able to

accommodate up to 60~70% capacity while operating under optimal performance, in

such a case the separator may be downsized (based on maximum required diameter).

3. The generated vessel length - vessel diameter - slenderness ratio monographs make can

be used to select appropriate separator size, based on required retention time.

4. Despite the fact that computational fluid dynamics offer a much more comprehensive

design, developed methodology, on the other hand, is intended to address the already

existing stocks of separators.

5. Emulsion rheology model is based on Newtonian flow model. This holds true when

Newtonian fluids are very dilute (this study well), however, it may sometime not be the

case and a non-Newtonian flow model needs then to be incorporated.

6. Foam constraints have not been considered in the design due to lack of proved foam

rheology correlations.

References

1. Katapodis, L. 1977. Oil and Gas Separation Theory, Application and Design, Paper

SPE 6470.

2. Stewart, A.C., Chamberlain, N.P., and Irshad, M. 1998. A New Approach to Gas-Liquid

Separation, Paper 50685-MS.

3. Choi, M.S. 1998. Prediction of Separator Performance under Changing Field

Conditions, Paper SPE 20703.

4. Viles, J.C. 1992. Predicting Liquid Re-Entrainment in Horizontal Separators, Paper

SPE 25474.

5. Guo, B., Lyons, W.C., and Ghalambor, A. 2007. Petroleum Production Engineering: A

Computer-assisted Approach, 1

st

Edition, Houston: Gulf Publishing Company.

6. Arnold, K. E. and Koszola, P. J. 1990. Droplet-Settling vs. Retention-Time Theories for

Sizing Oil/Water Separator, Paper SPE 16640-PA.

7. Lawson, P.N.E. and Little, L.M. 1996. The Separator Design and Operation: Tools for

the Transferring - Best Practice, Paper SPE 36647-MS.

9

8. Arnold, K. and Stewart, M. 1999. Surface Production Operations, Vol. I, 3

rd

Edition,

Houston: Gulf Publishing Company.

9. Song, J. H., Jeong, B.E., Kim, H.J., and Gil, S.S. 2010. Three-Phase Separator Sizing

Using Drop Size Distribution, Paper SPE 20558-MS.

Nomenclature

API American Petroleum Institute

m micrometer

ob

viscosity of gas saturated oil (cp)

od

viscosity of dead oil (cp)

viscosity (cp)

V

t

terminal velocity (ft/sec)

G acceleration due to gravity (9.81 m/s

2

or 32 ft/sec

2

)

w

water density (lb/cuft)

o

oil density (lb/cuft)

D diameter of the separator (in)

em

emulsion viscosity (cp)

c

continuous phase viscosity (cp)

volumetric ratio of inner phase to outer phase

phase dispersion coefficient

Q

L

flow rate of light phase (stb/d)

Q

H

flow rate of heavy phase (stb/d)

T

r

retention time (min)

L

light phase density (lb/cuft)

H

heavy phase density (lb/cuft)

L

light phase viscosity (cp)

H

heavy phase viscosity (cp)

Q

o

oil flow rate (stb/d)

Q

w

water flow rate (stb/d)

Q

g

gas flow rate (MMscf/d)

LCC liquid capacity constraint

SR slenderness ratio

You might also like

- Diseño de SeparadoresDocument6 pagesDiseño de SeparadoresmegustabajarinfoNo ratings yet

- Research Article: Appropriate Separator Sizing: A Modified Stewart and Arnold MethodDocument4 pagesResearch Article: Appropriate Separator Sizing: A Modified Stewart and Arnold MethodRoyan ArabzzNo ratings yet

- SPE-174937-MS Optimizing Separation Efficiency of Produced Water Tanks by Installing CFD Designed InternalsDocument11 pagesSPE-174937-MS Optimizing Separation Efficiency of Produced Water Tanks by Installing CFD Designed InternalsSajad FalahNo ratings yet

- Water InjectionDocument11 pagesWater InjectionWaqas SaleemNo ratings yet

- Ahmed 2017Document16 pagesAhmed 2017Warren PuthNo ratings yet

- OTC-28132-MS Subsea Demulsifier Injection To Reduce Emulsion Viscosity and Enhance Crude Oil ProductionDocument9 pagesOTC-28132-MS Subsea Demulsifier Injection To Reduce Emulsion Viscosity and Enhance Crude Oil ProductionRajarshiPanigrahiNo ratings yet

- Heavy Oil Transportation As A SlurryDocument10 pagesHeavy Oil Transportation As A SlurryHomam MohammadNo ratings yet

- 2862-Article Text-16501-1Document14 pages2862-Article Text-16501-1BUN SaretNo ratings yet

- Experimental Study on Reducing Oil Circulation Rate in Rotary CompressorsDocument5 pagesExperimental Study on Reducing Oil Circulation Rate in Rotary CompressorsAnibal RiosNo ratings yet

- API-12J SpecificationDocument20 pagesAPI-12J Specificationgo251019920% (2)

- Efficiency of Gas Injection Scenarios For Intermediate Wettability: Pore-Network ModellingDocument6 pagesEfficiency of Gas Injection Scenarios For Intermediate Wettability: Pore-Network ModellingRosa K Chang HNo ratings yet

- Steam FloodingDocument5 pagesSteam FloodingchineduNo ratings yet

- A Novel Flotation Column For Oily Water CleanupDocument11 pagesA Novel Flotation Column For Oily Water CleanupmarcelohilarioNo ratings yet

- Separator SizingDocument16 pagesSeparator SizingMichael J. BaneNo ratings yet

- Hu Jse Gaea KandaDocument4 pagesHu Jse Gaea KandaPacet SenatorNo ratings yet

- Lecture 8 - 3phase Vertical SeparatorDocument23 pagesLecture 8 - 3phase Vertical SeparatorHadi Bapir SlemanNo ratings yet

- D1092Document8 pagesD1092rpajaro75No ratings yet

- D3342Document4 pagesD3342rimi7alNo ratings yet

- Correlations For Predicting Oil Recovery by Steamflood: SPE-AIME, Standard Oil Co. of CaliforniaDocument8 pagesCorrelations For Predicting Oil Recovery by Steamflood: SPE-AIME, Standard Oil Co. of CaliforniaVasundhara SinghNo ratings yet

- Res Eng Ch14 Parts 1-12Document37 pagesRes Eng Ch14 Parts 1-12AiwarikiaarNo ratings yet

- Experiment 8 - Falling Sphere Viscometer ExperimentDocument5 pagesExperiment 8 - Falling Sphere Viscometer ExperimentAhmed NabilNo ratings yet

- Medición Del Factor de Contracción Ó de Merma en El Sitio Del PozoDocument5 pagesMedición Del Factor de Contracción Ó de Merma en El Sitio Del PozoMagno GuzmanNo ratings yet

- Reservoir Fluid Sampling (Lulav)Document16 pagesReservoir Fluid Sampling (Lulav)Lulav BarwaryNo ratings yet

- Integrated - Solution of Emulsion Evaluatio by LogsDocument12 pagesIntegrated - Solution of Emulsion Evaluatio by Logsjlbarretoa0% (1)

- ECL ExercisesDocument4 pagesECL ExercisesBessam MeghdouriNo ratings yet

- Zhou Et Al. - 2010 - Investigation of Velocity Field and Oil Distribution in An Oil-Water Hydrocyclone Using A Particle Dynamics AnalyzeDocument7 pagesZhou Et Al. - 2010 - Investigation of Velocity Field and Oil Distribution in An Oil-Water Hydrocyclone Using A Particle Dynamics AnalyzeKu Esyra HaniNo ratings yet

- High Volume Centrifugal Oil-Water Separation 00526746Document5 pagesHigh Volume Centrifugal Oil-Water Separation 00526746Hanif HalimNo ratings yet

- VISCOSITY MEASUREMENTSDocument13 pagesVISCOSITY MEASUREMENTSENG/MOHAMMED BASElNo ratings yet

- Viscosity MeasurementsDocument13 pagesViscosity MeasurementsENG/MOHAMMED BASElNo ratings yet

- SPE 87070 The Investigation of Potential Residual Oil Tapping Technique in The Late Stage of High Water Cut Period in Daqing OilfieldDocument5 pagesSPE 87070 The Investigation of Potential Residual Oil Tapping Technique in The Late Stage of High Water Cut Period in Daqing OilfieldmsmsoftNo ratings yet

- TECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseDocument7 pagesTECHNOLOGY New Program Sizes Pressure-Relief Drums: CloseCalcetinNo ratings yet

- Oil Water Separation Efficiency and Fluid Mechanics of A HydrocycloneDocument7 pagesOil Water Separation Efficiency and Fluid Mechanics of A HydrocycloneBubaaNo ratings yet

- Separator SizingDocument3 pagesSeparator SizingMaryJane Ayisha Sado-ObahNo ratings yet

- ImportantDocument10 pagesImportantAdrian SetyadharmaNo ratings yet

- Integrated Solution For Emulsion Diagnosis in Horizontal Production LogsDocument15 pagesIntegrated Solution For Emulsion Diagnosis in Horizontal Production LogsmbwassefNo ratings yet

- Separator Design MethodologyDocument19 pagesSeparator Design Methodologyromdhan88100% (1)

- SPE-133985-MS-P - Quantifying The Effects of Well Type and and Hydraulic Fracture Selection On Recovery For Varios Reservoir Permeability Using A Numerical Reservoir Simulator - 2010Document13 pagesSPE-133985-MS-P - Quantifying The Effects of Well Type and and Hydraulic Fracture Selection On Recovery For Varios Reservoir Permeability Using A Numerical Reservoir Simulator - 2010Belen FourcadeNo ratings yet

- Oil Water Separator DesignDocument11 pagesOil Water Separator DesignAbhay BhoirNo ratings yet

- (13653075 - Pure and Applied Chemistry) Separation of Oil and Water in Oil Spill Recovery OperationsDocument7 pages(13653075 - Pure and Applied Chemistry) Separation of Oil and Water in Oil Spill Recovery Operationsطائر النورسNo ratings yet

- Iatmi 10-003Document9 pagesIatmi 10-003Renato SimanjuntakNo ratings yet

- Oil& Gas SeparationDocument9 pagesOil& Gas SeparationHomam MohammadNo ratings yet

- Mathematical Model of The Corrugated Plates Packing Oil-Water SeparatorDocument6 pagesMathematical Model of The Corrugated Plates Packing Oil-Water SeparatorGabriela Cutipa AlvarezNo ratings yet

- Emulsiones Experiencias Spe-93386-PaDocument7 pagesEmulsiones Experiencias Spe-93386-PaEdison GarciaNo ratings yet

- Purifier optimization lab resultsDocument8 pagesPurifier optimization lab resultspapaki2No ratings yet

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantDocument12 pagesQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantmofiyinfoluNo ratings yet

- OTCbservationDocument9 pagesOTCbservationlulalala8888No ratings yet

- O-W Separator LiteratureDocument8 pagesO-W Separator Literatureernesto_sugiharto100% (1)

- Spe 129515 StuDocument8 pagesSpe 129515 StuFatima Al-nNo ratings yet

- Separator SizingDocument11 pagesSeparator Sizingnandhamech25No ratings yet

- Hydrate Plug in Oil Dominated Systems by OLGADocument10 pagesHydrate Plug in Oil Dominated Systems by OLGAmahmoodnazeriNo ratings yet

- Lopez-VazquezandFall WatAirSoilPollut Improvementseparator 2004Document21 pagesLopez-VazquezandFall WatAirSoilPollut Improvementseparator 2004Ahmad Fauzan KamaludddinNo ratings yet

- Final Report EORDocument10 pagesFinal Report EORJwalin KainthNo ratings yet

- Água e Sedimentos - D2709Document3 pagesÁgua e Sedimentos - D2709Joel CunhaNo ratings yet

- ASTM D 3094 - 00 Seepage Rate of Aerosol ProductsDocument3 pagesASTM D 3094 - 00 Seepage Rate of Aerosol Productsalin2005No ratings yet

- New Method To Estimate Surface-Separator Optimum Operating PressuresDocument12 pagesNew Method To Estimate Surface-Separator Optimum Operating PressuresIkramullohNo ratings yet

- Process Design Conditions: Barg C M /H KG/M CP M /H KG/M CP Am /H Kg/amDocument1 pageProcess Design Conditions: Barg C M /H KG/M CP M /H KG/M CP Am /H Kg/amConnor SailorNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsFrom EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsNo ratings yet

- T1 Ug 90Document6 pagesT1 Ug 90germangsilvaNo ratings yet

- Aspen Tutorial SeriesDocument52 pagesAspen Tutorial Seriesximena.ceron4004100% (11)

- Masteroppgave Famisa 2016Document74 pagesMasteroppgave Famisa 2016ridhajamelNo ratings yet

- Chap14prac PDFDocument6 pagesChap14prac PDFgermangsilvaNo ratings yet

- Material BalanceDocument42 pagesMaterial Balancealireza_e_20% (1)

- Reklaitis - Parte 1 PDFDocument110 pagesReklaitis - Parte 1 PDFClaudia T.No ratings yet

- The Essential Oil Reference Book PDFDocument253 pagesThe Essential Oil Reference Book PDFNataribu OtsuguaNo ratings yet

- Phase Equilibria and Fluid Properties in The Chemical Industry Estimation and CorrelationDocument436 pagesPhase Equilibria and Fluid Properties in The Chemical Industry Estimation and CorrelationUmesh Kumar Sharma RamamoorthiNo ratings yet

- Camp BelDocument380 pagesCamp BelgermangsilvaNo ratings yet

- Calculation of Densities From Cubic Equations ofDocument5 pagesCalculation of Densities From Cubic Equations ofgermangsilvaNo ratings yet

- Thermo 5th Chap01P001 PDFDocument33 pagesThermo 5th Chap01P001 PDFHasan ÖzdemNo ratings yet

- Astm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementDocument25 pagesAstm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your Advertisementsachyn7No ratings yet

- PppmanDocument97 pagesPppmangermangsilvaNo ratings yet

- SPE Separacion AguaDocument8 pagesSPE Separacion AguagermangsilvaNo ratings yet

- Cleaning Times The Second Cleaning Process The Oil Skimmer Part IIDocument3 pagesCleaning Times The Second Cleaning Process The Oil Skimmer Part IIgermangsilvaNo ratings yet

- ASTM TablesDocument8 pagesASTM TablesgermangsilvaNo ratings yet

- 3 Phase SeparatorsDocument12 pages3 Phase Separatorsnkhamidy100% (1)

- CoalescerDocument18 pagesCoalescer112dharmesh0% (1)

- Oilpatch Orientation: Facilities PresentationDocument33 pagesOilpatch Orientation: Facilities PresentationgermangsilvaNo ratings yet

- Review Problems 1-85 A Hydraulic Lift Is Used To LiftDocument22 pagesReview Problems 1-85 A Hydraulic Lift Is Used To Liftpanalopee100% (5)

- Tank Battery Systems and Production Curve GuideDocument14 pagesTank Battery Systems and Production Curve Guidegermangsilva100% (2)

- Separator Design MethodologyDocument19 pagesSeparator Design Methodologyromdhan88100% (1)

- 3 (3) 2Document4 pages3 (3) 2germangsilvaNo ratings yet

- Applied Sciences: Launch Bar Dynamics Character Analysis of Carrier-Based Aircraft Catapult LaunchDocument17 pagesApplied Sciences: Launch Bar Dynamics Character Analysis of Carrier-Based Aircraft Catapult LaunchORLANDO CASTILLONo ratings yet

- Semester: 2 Subject: F M - I C: ME-121 C:3-0 C C:: Luid Echanics ODE Redit Hour Ourse OntentsDocument26 pagesSemester: 2 Subject: F M - I C: ME-121 C:3-0 C C:: Luid Echanics ODE Redit Hour Ourse OntentsNAJAMUL HassanNo ratings yet

- Fluid KinematicsDocument109 pagesFluid KinematicsLorence Gabayan100% (1)

- MODULE 5 - OrificeDocument20 pagesMODULE 5 - OrificeGrace MagbooNo ratings yet

- Assignment4 2019Document4 pagesAssignment4 2019iosfblufbmdqpqhztjNo ratings yet

- ASTM D8046 - 16aDocument3 pagesASTM D8046 - 16amancjaNo ratings yet

- Hydraulic Test Bench Circuit Construction Testing and AnalysisDocument12 pagesHydraulic Test Bench Circuit Construction Testing and Analysisarmando desoyoNo ratings yet

- Homework - 07-Dimensional - Analysis-FmDocument1 pageHomework - 07-Dimensional - Analysis-FmSALVADOR VARGAS DIAZNo ratings yet

- O Discharge Measur. Op. CH L 3rd CLDocument16 pagesO Discharge Measur. Op. CH L 3rd CLGerardus PudyastowoNo ratings yet

- NOTES+3+Calculations PEOP1009+ALL+Topics+v2Document34 pagesNOTES+3+Calculations PEOP1009+ALL+Topics+v2cn4dd4wy9cNo ratings yet

- FM Question Model 2Document8 pagesFM Question Model 2aadhanNo ratings yet

- Linear Algebraic Equations: - Direct MethodsDocument202 pagesLinear Algebraic Equations: - Direct Methodseegala100% (1)

- Turbulent Flow Over The Ahmed BodyDocument2 pagesTurbulent Flow Over The Ahmed BodymajiayaggNo ratings yet

- Haldex-Barnes 2-Stage Pump For Log SplittersDocument2 pagesHaldex-Barnes 2-Stage Pump For Log SplittersPer Akkamaan AgessonNo ratings yet

- Vortex Meters For GasDocument5 pagesVortex Meters For GasRicardo Zárate GodinezNo ratings yet

- Remote indicators for measuring signalsDocument11 pagesRemote indicators for measuring signalscaat_06No ratings yet

- UPSC Maths Syllabus BreakdownDocument3 pagesUPSC Maths Syllabus BreakdownNooman ShaikhNo ratings yet

- Dgca Module 12 Part 01Document21 pagesDgca Module 12 Part 01ahmedharfoushNo ratings yet

- 5 - Unsteady Flow in Rivers Pp. 122-157Document37 pages5 - Unsteady Flow in Rivers Pp. 122-157Anonymous 87xpkIJ6CFNo ratings yet

- Transients in Hydraulic Systems - Bentley HammerDocument52 pagesTransients in Hydraulic Systems - Bentley HammerEdwin Rafael Puma Coricaza100% (2)

- Newtons Law of Viscosity Chapter 1 BSLDocument29 pagesNewtons Law of Viscosity Chapter 1 BSLJaymee DelfinadoNo ratings yet

- AERODYNAMICS1 PRT 2 Basic Aerodynamics PrinciplesDocument66 pagesAERODYNAMICS1 PRT 2 Basic Aerodynamics PrinciplesZyrick Laurence Eslao TimmangoNo ratings yet

- Thermal Modeling of A Cylindrical Lithium-Ion Battery in 3DDocument30 pagesThermal Modeling of A Cylindrical Lithium-Ion Battery in 3DDigvijayNo ratings yet

- Gas Well PerformanceDocument107 pagesGas Well PerformanceEsther Lim100% (1)

- Ryan Navion Reporte FinalDocument34 pagesRyan Navion Reporte FinalRaul PazNo ratings yet

- Ansys CFX Intro 12.0 1st-Edition - WorkshopsDocument312 pagesAnsys CFX Intro 12.0 1st-Edition - Workshopskdennis_nguyenNo ratings yet

- PDAM Detail JunctionDocument4 pagesPDAM Detail JunctionC. A. ArdhaniNo ratings yet

- Report Vortex TubeDocument68 pagesReport Vortex TubePravinSharmaNo ratings yet

- Analysis and Design of Ducted PropellersDocument60 pagesAnalysis and Design of Ducted PropellersZiyadNo ratings yet

- Exercise-Design of Weir-Option 1Document6 pagesExercise-Design of Weir-Option 1ale hopeju2009No ratings yet