Professional Documents

Culture Documents

STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTD

Uploaded by

Александр АндриановOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTD

Uploaded by

Александр АндриановCopyright:

Available Formats

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

STR2A100 Series Application Note

(Rev.0.3)

The contents in this application note are preliminary, and are subject to changes without notice.

SANKEN ELECTRIC CO., LTD. http://www.sanken-ele.co.jp

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.1

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

Contents 1. General Descriptions -----------------------------------------------------------------------3 2. Features and Production lineup----------------------------------------------------------3 3. Functional Block Diagram and Terminal List ----------------------------------------4 4. Package Information -----------------------------------------------------------------------5 5. Electrical Characteristics ------------------------------------------------------------------6 6. Typical Application Circuit ---------------------------------------------------------------8 7. Functional Descriptions --------------------------------------------------------------------9 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 Startup Operation-------------------------------------------------------------------9 Constant Output Voltage Control --------------------------------------------- 11 Soft-Start Function---------------------------------------------------------------- 12 Automatic Standby Mode Function ------------------------------------------- 12 Random Switching Function---------------------------------------------------- 13 Latch Function --------------------------------------------------------------------- 13 Overcurrent Protection Function (OCP) ------------------------------------- 13 Overvoltage Protection Function (OVP) ------------------------------------- 14

7.9 Overload Protection Function (OLP) ----------------------------------------- 15 7.10 Thermal Shutdown Protection Function (TSD) ---------------------------- 15 8. Design Notes -------------------------------------------------------------------------------- 16

WARNING The contents in this document are subject to changes, for improvement and other purposes, without notice. Make sure that this is the latest version of the document before use. The operation and circuit examples in this document are provided for reference purposes only. Sanken assumes no liability for violation of industrial property, intellectual property, or other rights of Sanken or third parties, that stem from these examples. The user must take responsibility for considering and determining which objects the products in this document are used with. Although Sanken will continue to improve the quality and reliability of its products, semiconductor products, by their nature, have certain fault and failure rates. The user must take responsibility for designing and checking to secure the device and system so that a part failure may not lead to human injury, fire, damages, or other losses. The products in this document are intended for normal electronic devices (such as home appliances, office equipment, communication terminals, or measurement devices). If you are considering using Sankens products for a device that requires high reliability (such as transport machines and their control units, traffic light control systems, disaster prevention, and security equipment or any kind of safety equipment), make sure that you consult Sanken sales representative. Do not use these products for devices that require extremely high reliability (such as aerospace instruments, nuclear power control units, or life support systems) without Sankens written consent. The products in this document are not designed to be radiation-proof. The contents in this document must not be transcribed or copied without Sankens written consent.

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.2

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

1. General Descriptions

The STR2A100 series are power ICs for switching power supplies, incorporating a power MOSFET and a current mode PWM controller IC in one package. Including a startup circuit and a standby function in the controller, the product achieves low power consumption, low standby power and high cost-effectiveness power supply systems with few external components.

2. Features and Production lineup

Features and benefits include the following

DIP8 package, connecting one side (pin5 to pin8) with a power MOSFET drain. The distance between high voltage terminal and low voltage terminal is 0.762mm (0.3inches), and the wider drain trace is available to enhance thermal dissipation of the IC. Current Mode PWM control Built-in Random Switching Function, reducing EMI noise, and simplifying EMI filters, by the slight random change of PWM frequency, fOSC. Auto Standby Function (Input Power, PIN < 25mW at no load) Normal load operation ----------- PWM mode Light load operation -------------- Standby mode (Burst oscillation) Built-in Audible Noise Suppression Function for standby mode Built-in Startup Circuit, reducing power consumption in standby operation, and eliminating external components. Bias Assist Function, improving startup operation, suppressing VCC voltage drop in operation, and allowing use of smaller VCC capacitor. Soft Start Function, reducing stress of a power MOSFET and secondary rectifiers at startup Built-in Leading Edge Blanking Function Built-in Slope Compensation Function, avoiding subharmonic oscillation. Two Chip Structure, with a controller and a power MOSFET guaranteed Avalanche Energy which is available to simplify surge absorber circuits Protection Functions Overcurrent Protection Function (OCP) ------------------Pulse-by-pulse, built-in compensation circuit to minimize OCP point variation for AC input voltage Overload Protection Function (OLP) ----------------------Auto restart, built-in delay timer to reduce temperature rise Overvoltage Protection Function (OVP) -------------------Shutdown with latch mode Thermal Shutdown Protection Function (TSD)-----------Shutdown with latch mode

Product Lineup

Part Number STR2A152 STR2A153 STR2A155 67 650 fOSC (kHz) MOSFET VDSS MIN (V) RDS(ON) 2 MAX 3.0 1.9 1.1 POUT 1 2 230VAC / 85VAC to 265VAC 30W / 23W 36W / 30W 43W / 35W Status Planning Sample available Planning

1 The open frame conditions. The listed output power is based on the thermal ratings, and the peak output power is obtained by 120 to 140% of the value stated here. In low output voltage and narrow ON-duty cycle, the output power may be less than the value stated here. 2 The preliminary values on IC development

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.3

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

3. Functional Block Diagram and Terminal List

Functional Block Diagram

2

VCC STRATUP

5~8

D/ST

UVLO

REG

VREG

OVP

TSD

PWM OSC

SQ R

DRV OCP

VCC

OLP

Drain Peak current Compensation

4

FB/OLP Slop Compensation

Feedback Control

1

LEB S/OCP

3

GND

Terminal List Table

Number 1 2 3 4 5 6 D/ST 7 8 MOSFET drain / Startup current input Name S/OCP VCC GND FB/OLP Functions MOSFET source / Overcurrent protection control pulse input Power supply input for control circuit Ground Constant voltage control signal input / Overload protection signal input

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.4

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

4. Package Information

DIP8 package

a SK b

Material of terminal: Cu Treatment of terminal: solder plating Weight: Approx. 0.51g Unit: mm

a. Type Number : 2AXXX b. Lot Number 1st letter : The last digit of year 2nd letter : Month 1 to 9 for Jan. to Sept. O for Oct. N for Nov. D for Dec. 3rd letter : Week 1st10th : 1 11th20th : 2 21st31st : 3 c. Sanken Registration Number

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.5

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

5. Electrical Characteristics

The STR2A153 of STR2A100 series is used as an example. Certain details vary among the individual products. The preliminary values at IC development

5.1 Absolute Maximum Ratings

Parameter Drain peak current Avalanche energy S/OCP terminal voltage Controller IC (MIC) input voltage FB/OLP terminal voltage FB/OLP terminal sink current

1 1

Ta= 25C, unless otherwise specified Terminal 81 81 13 23 43 43 Symbol IDPEAK EAS ILPEAK VOCP VCC VFB IFB PD1 PD2 TOP Tstg Tch Ratings 4.4 72 2.46 26 32 0.314 1.0 1.76 1.3 20+115 40+125 +150 Unit A mJ A V V V mA W W C C C Notes Single Pulse Single Pulse VDD=99V, L=20mH Recommended internal frame temperature TF= 115(Max)

MOSFET power dissipation Controller IC (MIC) power dissipation Operating ambient temperature Storage temperature Channel temperature

81 23

1 Refer to individual product datasheet for details because these values differ among the various product types. 2 The condition mounted on 15mm15mm printed circuit board. Current characteristics are defined based on IC as Sink:+, Source:.

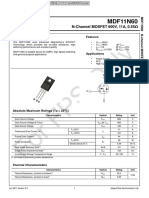

5.2 MOSFET Electrical Characteristics Ta= 25C, unless otherwise specified

Parameter Drain-to-Source breakdown voltage Drain leakage current On-resistance Switching time

1 1 1

Terminal 81 81 81 81

3

Symbol VDSS IDSS RDS(ON) tf chF chC

MIN 650

Ratings TYP

MAX 300 1.9 250 20 30

Unit V A ns C/W

Thermal resistance

3 chF is the thermal resistance between channel and internal frame. chC is the thermal resistance between channel and case. Case temperature (TC) is measured at the center of the marking side.

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.6

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

5.3 Electrical Characteristics Ta= 25C, VCC= 18 V, unless otherwise specified

Parameter Operation start voltage Operation stop voltage Circuit current in operation Minimum startup voltage Startup current Startup current supply threshold Average switching frequency Frequency modulation deviation Maximum on-duty cycle Leading edge blanking time OCP compensation coefficient OCP compensation duty cycle limit OCP threshold voltage at zero duty cycle OCP threshold voltage at 36% duty cycle Maximum feedback current Minimum feedback current Oscillation stop FB/OLP voltage OLP threshold voltage Operation current after OLP OLP delay time FB/OLP terminal clamp voltage OVP threshold voltage Thermal shutdown operating temperature

4 4

Terminal 2 3 2 3 2 3 8 3 8 3 2 3 8 3 8 3 8 3 1 3 1 3 4 3 4 3 4 3 4 3 2 3 4 3 2 3

Symbol VCC(ON) VCC(OFF) ICC(ON) VST(ON) Istartup VCC(BIAS) fOSC(AVE) f DMAX tBW DPC DDPC VOCP(L) VOCP(H) IFB(MAX) IFB(MIN) VFB(OFF) VFB(OLP) ICC(OLP) tOLP VFB(CLAMP) VCC(OVP) T(TSD)

MIN 13.8 7.3 3.9 8.5 60 65 0.69 0.79 280 30 1.05 7.3 54 11 26 135

Ratings TYP 15.3 8.1 40 2.5 9.5 67 5 74 350 17 36 0.78 0.88 170 15 1.15 8.1 230 68 12.8 29

MAX 16.8 8.9 2.5 1.1 10.5 74 83 0.87 0.97 90 7 1.25 8.9 82 14 32

Unit V V mA V mA V kHz kHz % ns mV/s % V V A A V V A ms V V

4 The relationship between VCC(BIAS) and VCC(OFF) consists of VCC(OFF) < VCC(BIAS). Current characteristics are defined based on IC as Sink:+, Source:.

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.7

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

6. Typical Application Circuit

A typical application circuit is shown below. The following design features should be considered: D/ST terminals (pin 5 to pin8) are on one side of the IC. The PCB traces from them should be as wide as possible, in order to enhance thermal dissipation. In applications having a power supply specified such that VDS voltage between D/T terminal and S/OCP terminal has large transient surge voltages, a clamp snubber circuit of a capacitor-resistor-diode (CRD) combination should be added between both sides of a winding P, or a damper snubber circuit of a capacitor (C) or a resistor-capacitor (C, RC) combination should be added between D/ST terminal and S/OCP terminal.

CRD clamp snubber

T1 VAC C1 C8 D3 R1 P S R5 C7 R8

8 7 6 5

D2 R4 C5

L2

VOUT

PC1 R6 C6

Z2 D1 R2 D C2 R7 GND

C4

D/ST D/ST D/ST D/ST

Z1

STR2A100

Damper snubber

S/OCP Vcc GND FB/OLP

ROCP

C3 PC1

C9

Figure 6

Typical application circuit example

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.8

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

7. Functional Descriptions

The parameter values in this section are based on the STR2A153 specification, unless otherwise specified. The polarity of current is shown as +for sink current and for source current based on IC

7.1

Startup Operation

The startup circuit is connected to D/ST terminal. VAC During the startup process, the constant current, ISTARTUP= 2.5mA(TYP), charges C2 at VCC terminal in figure 7-1, and when VCC terminal voltage increases to VCC(ON)= 15.3V(TYP), the control circuit starts switching operation. After switching operation begins, the startup circuit turns off automatically, to zero its current consumption. 58 The approximate startup time, tSTART, is calculated as follows D/ST

C1

P

D1 2 C2

R2 D

tSTART

VCC( ON )VCC( INT ) = C2 ISTARTUP

Vcc

------(1)

GND

where tSTART is in sec, and VCC(INT) is the initial voltage on VCC terminal, in V. C2 value is 10 to 47F for general power supply applications.

STR2A100

Figure 7-1 VCC peripheral circuit

Figure 7-2 shows the relationship of VCC and ICC. When VCC terminal voltage increases to VCC(ON)= 15.3V(TYP), the control circuit starts switching operation and the circuit current, ICC, increases. In operation, when VCC terminal voltage decreases to VCC(OFF)= 8.1V(TYP), the control circuit stops operation by UVLO (Undervoltage Lockout) circuit, and reverts to the state before startup. The voltage from the auxiliary winding D in figure 7-1 becomes a power source to the control circuit in operation. The auxiliary winding voltage needs to be adjusted to about 15 to 20 V, taking account of the winding turns of the winding D so that VCC terminal voltage should become as follows within the specification of input voltage range and the output load range of power supply.

VCC ( BIAS ) = 10.5V ( MAX ) < VCC < VCC ( ON ) = 26.0V ( MIN )

Circuit current ICC 2.5mA(MAX) Startup Bias Assist period VCC(ON) 15.3V(TYP) 9.5V(TYP) VCC(BIAS) 8.1V(TYP) VCC(OFF)

Target operating voltage Startup failure event Start of normal operation

VCC(OFF) VCC(ON) 8.1V(TYP 15.3V(TYP) Figure 7-2 Relationship of VCC and ICC at startup and shutdown

Figure 7-3 shows VCC terminal voltage behavior during the startup period. After VCC terminal voltage increases to VCC(ON) at startup, the auxiliary winding voltage on the winding D does not rise to the target operating voltage immediately (which is set by the transformer ratio between the auxiliary winding and the secondary winding), and may fall down. When VCC terminal voltage decreases to VCC(BIAS)= 9.5V(TYP), Bias Assist Function is activated so that the decrease of VCC terminal voltage is suppressed by ISTARTUP provided from the startup circuit. In addition, Bias Assist Function allows C2 value to be reduced and allows the startup time to be shorter, and this function allows the response of overvoltage detection in VCC terminal to be faster.

Copy Right: SANKEN ELECTRIC CO., LTD.

Stop

VAC ON Figure 7-3

Time VCC behavior during startup

Page.9

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

In actual power supply circuits, VCC voltage often fluctuates according to the output currents of power supply as shown in figure 7-4. This happens because C2 is charged to a peak voltage on the winding D, which is caused by the transient surge voltage coupled from the primary winding when a power MOSFET turns off. Suppressing C2 peak charging, it is effective to add R2, of several ohms to several tenths of an ohm, in series with D1 as shown in figure 7-5. The optimum value of R2 should be determined on actual operation with a transformer matching the power supply application, because the variation of the auxiliary winding voltage is determined by the transformer structure design. The variation becomes worse on the following conditions, The coupling between the primary winding and the secondary winding of transformer get worse, for example, a transformer for power supply specifications with low output voltage and/or large output current. The coupling between the auxiliary winding D and the stabilizing output winding (which is controlled as a constant voltage) gets worse.

VCC

Without R2

2 V CC STR2A100 C5

D1

R2 D

Addition

WithR2 IOUT Figure 7-4 Variation of VCC terminal voltage and power supply output current with / without R2 resistor

GND 3

Figure 7-5 VCC external circuit that is not susceptible to fluctuation in power supply output current

Figure 7-6 and figure 7-7 show alternative designs for the location of auxiliary winding D as examples of transformer structural designs. Auxiliary winding D is away from the primary windings P1and P2 (sandwich structure) as shown in figure 7-6 (Transformer structure example ). Auxiliary winding D is within a stabilizing winding S1 (which is controlled as a constant voltage) as shown in figure 7-7 (Transformer structure example ).

P1, P2: Primary winding P1, P2 are sandwich structure winding S1: Secondary control winding S2: Secondary output winding D: Auxiliary winding Figure 7-6 Transformer structure example

P1, P2: Primary winding P1, P2 are sandwich structure winding S1: Secondary control winding S2: Secondary output winding D: Auxiliary winding Figure 7-7 Transformer structure example

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.10

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

7.2

Constant Output Voltage Control

The constant output voltage control of the power supply uses the current-mode control method (the peak current-mode), which enhances response speed and provides stable operation.

STR2A100

S/OCP GND FB/OLP 1 3 4 PC1

When load conditions become smaller, the output voltage, R OCP VOUT, rises, and a feedback current from an error amplifier on IFB C3 the secondary side also rises. This current corresponded to the VR1 feedback current is sunk by a photo-coupler at FB/OLP terminal as shown in figure 7-8, and thus FB/OLP terminal Figure 7-8 FB/OLP peripheral circuit voltage decreases. This voltage is fed to Feedback Control block in 3. Functional Block Diagram and Terminal List section, and Target voltage added slope is added the slope compensation signal to create the target compensation signal voltage, VSC, in figure 7-9. VSC is fed to the negative input VSC of FB comparator. The peak detection signal, VR1, converted from Drain + VR1 current, ID, with ROCP is fed to the positive input of FB S/OCP terminal voltage comparator. (Both sides voltage of ROCP) FB comparator The control circuit performs to decrease the peak current of ID so that VR1 comes close to VSC. Drain current ID And this control prevents the output voltage from increasing. Figure 7-9 Drain current, ID, and FB comparator in steady operation When load conditions become bigger, the control circuit performs reverse operations to the former, and increases the peak current of ID so that VR1 comes close to VSC. And this control prevents the output voltage from decreasing.

Target voltage without slope compensation

Generally, in the current-mode control method, some subharmonic oscillations shown in figure 7-10 occur theoretically. ID It is called the subharmonic phenomenon. When the drain current waveform becomes a trapezoid in contON1 tON2 tinuous operating mode, the ON-duty cycle can not become Cycle Cycle Cycle stable in each cycle, and thus subharmonic oscillations occur in multiples of the fundamental operating frequency, according to Figure 7-10 Drain current waveform the initial value of drain current, even if the peak current level in subharmonic oscillation set by the target voltage is constant. In order to avoid this, the IC incorporates Slope Compensation Function. Because the target voltage, VSC, in figure 7-9 is added the down-slope compensation signal, the wider the ON-duty cycle becomes, the smaller the peak drain current becomes to suppress subharmonic oscillations.. Even if subharmonic oscillations occur when the IC has some excess supply being out of feedback control, such as during startup and load shorted, this does not affect performance during normal operation. In the current-mode control method, FB comparator and/or OCP comparator may respond to the surge voltage resulting from the drain surge current in turning on a power MOSFET, and may turn off the power MOSFET irregularly. Leading Edge Blanking, tBW= 350ns(TYP), is built-in to prevent OCP comparator from malfunction caused by surge voltage in turning on the power MOSFET.

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.11

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

7.3 Soft-Start Function

Figure 7-11 shows the operation image waveform at startup. Soft-Start Function is built-in to reduce stress of voltage and current of a power MOSFET, secondary rectifiers and so on. The period of Soft-Start Function is fixed to 7ms internally. In this period, OCP threshold voltages increase with five steps. It is necessary to check or adjust the followings at startup; VCC terminal voltage should be more than VCC(OFF), The period when FB/OLP terminal voltage increases to OLP threshold voltage, VFB(OLP)= 8.1V(TYP), should be shorter enough than OLP delay time, tOLP=68ms(TYP). VCC terminal voltage VCC(ON) VCC(OFF) Time Drain current ID This ID is limited by OCP operation.

Startup

Steady state

Time Soft-start period with 7ms fixed internally Figure 7-11 Operation image waveform at startup

7.4

Automatic Standby Mode Function

Automatic Standby Mode is activated automatically when the drain current, ID, reduces in light load condition and S/OCP terminal voltage decreases to less than 15% to 20% of the voltage of the maximum drain current (it is overcurrent protection state). And this operation becomes the burst-oscillation as shown in figure 7-12. The burst-oscillation reduces switching losses and improves power supply efficiency because there are interval periods. Generally the frequency of the burst-oscillation is set at just a few kHz, such frequencies are in the range of human hearing, to improve the efficiency in light load condition, and thus it may cause audible noises from a transformer. Because the IC series limit the drain current to less than 15% to 20% during the burst-oscillation, audible noises are well-suppressed. Output current IOUT Burst-oscillation

Drain current ID

Limit of less than 15% to 20 % of the maximum drain current

Normal load Figure 7-12

Copy Right: SANKEN ELECTRIC CO., LTD.

Standby load Automatic standby mode operation Page.12

Normal load

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

During the transition to the burst-oscillation, if VCC terminal voltage decreases to VCC(BIAS)= 9.5V(TYP), Bias Assist Function is activated and stabilizes the standby mode operation, because ISTARTUP is provided to VCC terminal so that VCC terminal voltage does not decrease to VCC(OFF). However, if Bias Assist Function is always activated during standby mode, the power loss increases. Therefore VCC terminal voltage should be more than VCC(BIAS), for example, by adjusting the turns ratio between auxiliary winding and secondary winding and/or R2 in figure 7-5.

7.5

Random Switching Function

The IC modulates its switching frequency randomly within f= 5kHz of Average Switching Frequency, fOSC(AVE= 67kHz(TYP), by superposing the modulating frequency on fOSC(AVE) in normal operation. The conduction noise with this function is smaller than that without this function, and this function simplifies noise filtering of the input lines of power supply.

7.6

Latch Function

The latch function stops switching operation and a protection state is latched when OVP and/or TSD protection functions activate. After stopping switching operation with latch mode, VCC terminal voltage drops. When VCC terminal voltage decreases to VCC(BIAS)= 9.5V(TYP), Bias Assist Function is activated to prevent VCC terminal voltage from reaching VCC(OFF), and then the latch function is maintained. Releasing the latch function can be done when VCC terminal voltage reaches VCC(OFF) or less by simply turning off the AC input.

7.7

Overcurrent Protection Function (OCP)

Overcurrent Protection Function (OCP) detects each drain peak current level of a power MOSFET on pulse-by-pulse basis, and limits the output power. This function incorporates AC Input Compensation Function to reduce OCP point variation for AC input voltage, without any additional external components. This OCP function detects the drain current by a current detection resistor, ROCP, which is connected between S/OCP terminal and GND terminal. When the voltage drop on both sides of ROCP increases to internal OCP threshold voltage, the power MOSFET is turned off. PWM control ICs usually have some detection delay time on OCP detection. The steeper the slope of actual drain current in high AC input voltage is, the longer the actual detection point is, compared with internal OCP threshold voltage. And thus the actual OCP point limited the output current usually has some variation depending on AC input voltage as shown in figure 7-13. The IC incorporates a built-in Input Compensation Function that superposes a signal with a defined slope to the detection signal on S/OCP terminal as shown in figure 7-14. When AC input voltage is lower and the ON-duty cycle is wider, the OCP compensation level increases. And thus the OCP point in low AC input voltage increases to minimize the difference of OCP points between low AC input voltage and high AC input voltage.

Variation resulting from detection delay time Output voltage, VOUT Low AC input

High AC input

Output current, IOUT Figure 7-13 Output current at OCP without input compensation

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.13

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

Because the compensation signal level is designed to depend upon ON Time, OCP threshold voltage after compensation, VOCP(ONTime), is calculated as follows.

VOCP( ONTime )( V ) = VOCP( )( V ) + DPC( mV / s ) ONTime( s )

------(2)

where DPC is OCP compensation coefficient shown in Electrical Characteristics table. However, in the ON Time when ON-duty cycle becomes 36% or more, OCP threshold voltage after compensation remains VOCP(H)= 0.88V(TYP) constantly. For example, when AC input voltage is 85VAC and the transformer is designed to become ON-duty cycle of 36% on maximum load condition, ON Time becomes about 5.6s. And thus OCP threshold after compensation, VOCP(5.6s), becomes about 0.88V, resulting from the equation (2).

265VAC(for example) 0.88V(TYP) About 0.82V VOCP(ONTime) (V) After compensation

85VAC(for example)

0.50

0 0% 15%

36% ON-duty cycle

80%

100%

Figure 7-14

Relationship of ON-duty cycle and VOCP(ONTime) at fOSC(AVE)= 67kHz(TYP)

7.8

Overvoltage Protection Function (OVP)

When a voltage between VCC terminal and GND terminal increases to VCC(OVP)= 29V(TYP) or more, OVP Function is activated and stops switching operation by Latch Function. When the auxiliary winding provides VCC terminal voltage, OVP Function is available to detect the overvoltage of the output voltage, such as the detection circuit for output control is open in the secondary side, because VCC terminal voltage is proportional to the output voltage. The output voltage of the secondary side at OVP operation, VOUT(OVP), is calculated approximately as follows.

VOUT(OVP)

VOUT terminal voltage at normal operation 29 ( TYP ) VCC terminal voltage at normal operation

----- (3)

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.14

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

7.9

Overload Protection Function (OLP)

When the drain peak current is limited by OCP operation, the output voltage, VOUT, decreases and the feedback current from the secondary photo-coupler becomes zero. As a result, FB/OLP terminal voltage increases. When FB/OLP terminal voltage increases to VFB(OLP)= 8.1V(TYP) or more and remains for OLP delay time, tOLP= 68ms or more, OLP function is activated, stops switching operation and reduce stress of a power MOSFET, secondary rectifiers and so on. Each waveform on OLP Function is shown in figure 7-15. When OLP Function is activated, Bias Assist Function is disabled and thus VCC terminal voltage decreases to VCC(OFF)= 8.1V(TYP). After that, the IC reverts to the initial state by UVLO (Undervoltage Lockout) circuit, and the IC starts operation when VCC terminal voltage increases to VCC(ON)= 15.3V(TYP). And thus the intermittent operation by UVLO is repeated. This operation reduces power dissipation because the switching period in this intermittent operation is short. When such an abnormal condition is removed, the IC returns to normal operation automatically.

Oscillation turns off VCC terminal voltage VCC(OFF)= 8.1V(TYP) VFB(OLP)= 8.1V(TYP) FB/OLP terminal voltage VFB Drain current ID tOLP OLP delay time Oscillation interval period

V CC STR2A100

GND FB/OLP 3 C3 4 IFB

PC1

Figure 7-15

Each waveform on OLP operation and FB/OLP peripheral circuit

7.10 Thermal Shutdown Protection Function (TSD)

When the temperature of the control part (MIC) of the IC increases to Tj(TSD)= 135C(MIN) or more, Thermal Shutdown Protection Function is activated and stops switching operation by Latch Function.

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.15

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

8. Design Notes

8.1 Peripheral Components

Take care to use properly rating and proper type of components. Input and output electrolytic capacitors Apply proper design margin to ripple current, voltage and temperature rise. Use of high ripple current and low impedance types, designed for switch mode power supplies, is recommended. Transformer Apply proper design margin to temperature rise by core loss and copper loss. Because switching currents contain high frequency currents, the some temperature rise may result from the skin-effect. If the influence of skin-effect can not be minimized, choose suitable wire gauge in consideration of RMS current in the current density of about 3 to 4A/mm2. If measures to further reduce temperature is still necessary, use paralleled wires or litz wires to increase surface area of wires. Current detection resistor, ROCP A high frequency switching current flows to ROCP, and may cause poor operation if a high inductance resistor is used. Choose a low inductance and surge-proof type.

8.2

Phase Compensation

A typical error amplifier circuit with a shunt regulator (Z2) of secondary side is shown in figure 8-1. C7 is recommended about 0.047 to 0.47F, and should be adjusted on actual operation. C3 between FB/OLP terminal and GND terminal shown in figure 8-2 is for high frequency noise reduction and phase compensation. C3 is recommended about 470pF to 0.01F. C3 should be connected close to FB/OLP terminal and GND terminal, and should be adjusted on actual operation.

T1 D2 R4 C5 S L2 PC1 R6 R5 C7 R8 C6

VOUT

D1 R2 58 D/ST 2 VCC C2

T1 D

STR2A100

S/OCP GND FB/OLP 1 3 4 PC1

Z2

R7 GND

R OCP C3

Figure 8-1 Peripheral circuit around secondary shunt regulator

Figure 8-2

FB/OLP peripheral circuit

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.16

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

8.3

EMI Measure of the secondary rectifier

A general EMI measure of the secondary rectifier is shown in figure 8-3. A snubber capacitor, Cdi, in parallel to the secondary rectifier, is for noise reduction. If ringing waveforms occur on the drain current, it is recommended to connect a damper resistor, Rdi, in series to Cdi as shown in figure 8-4, in order to reduce ringing waveforms, and to stabilize switching operation. It is necessary to check temperature rise of Rdi and Cdi.

Cdi

Drain current ID P

D1 R2 C2 D2

Rdi Cdi

D2

C5

Drain current ID P

D1 R2

C5

T1

C2

T1

Figure 8-3

Rectifier measure example

Figure 8-4

Damper resistor example

8.4

PCB trace layout and Component placement

PCB circuit trace design and component layout affect proper functioning during operation. Unless they are proper, malfunction, large noise and large power dissipation may occur. Circuit loop traces flowing high frequency current, as shown in figure 8-5, should be designed as wide, short and small as possible to reduce trace impedance. In addition, earth ground traces affect radiation noise, and thus it should be designed as wide and short as possible. Switching mode power supplies consist of current traces with Figure 8-5 High frequency current high frequency and high voltage, and thus trace design and loops (hatched areas) component layout should be done to comply with all safety guidelines. Furthermore, because an integrated power MOSFET is being used as the switching device, take account of the positive thermal coefficient of RDS(ON) for thermal design. Figure 8-6 shows a circuit layout design example. (1) S/OCP Trace Layout: S/OCP terminal to ROCP to C1 to T1 (winding P) to D/ST terminal This is the main trace containing switching currents, and thus it should be as wide and short as possible. If the trace distance between C1 and the IC is lengthy, an additional capacitor near the IC or the transformer is recommended to reduce impedance of high frequency current loop, and is recommended either electrolytic or film type capacitors, around 0.1F, in the withstand voltage suitable for an applied maximum voltage. (2) GND Trace Layout: GND terminal to C2 (negative terminal) and T1 (winding D) to R2 to D1 to C2 (positive terminal) to VCC terminal This trace also needs to be as wide and short as possible. If the trace distance between C2 and the IC is lengthy, placing a capacitor around 0.1F to 1uF (50V) with high frequency property is recommended close to VCC terminal and GND terminal.

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.17

STR2A100 SERIES APPLICATION NOTE

Rev. 0.3

(3) ROCP Trace Layout ROCP should be placed as close as possible to S/OCP terminal. The connection between the power ground of main trace and the control circuit ground should be connected by a single point (A mark in figure 8-6) to remove common impedance, and to avoid interference of the control circuit resulting from switching currents. Figure 8-6 also shows a circuit layout design example for the secondary side. (1) Secondary Smoothing Circuit Trace Layout: T1 (winding S) to D2 to C5 This trace should be as wide and short as possible. If the loop length is lengthy, surge voltage may increase at turning off a power MOSFET because leakage inductance resulting from the long loop may increase. Taking the secondary trace layout into account is available to increase the voltage strength margin of the power MOSFET, and to reduce stress and power dissipation of the clamp snubber circuit.

T1

C8 C1 D3

R1

D2

S

D1 R2

C5

7

D/ST

6

D/ST

5

D/ST

C2

C4

D/ST

Z1

STR2A100

S/OCP Vcc GND FB/OLP

ROCP

C3

PC1

Main power circuit trace GND trace for the IC

A

C9

Figure 8-6

Peripheral circuit example around the IC

Copy Right: SANKEN ELECTRIC CO., LTD.

Page.18

You might also like

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Data SheetDocument7 pagesData SheetOvi PanteaNo ratings yet

- Str-A606xh Ds enDocument28 pagesStr-A606xh Ds enGiovanni Carrillo VillegasNo ratings yet

- Universal-Input Flyback Switching Regulators Data SheetDocument7 pagesUniversal-Input Flyback Switching Regulators Data SheetVidal VelasquezNo ratings yet

- STR-A6251 AND STR-A6252 UNIVERSAL-INPUT REGULATORSDocument7 pagesSTR-A6251 AND STR-A6252 UNIVERSAL-INPUT REGULATORSGiovanni Carrillo VillegasNo ratings yet

- STRW6754Document9 pagesSTRW6754electronicaliderNo ratings yet

- Tps 22960Document28 pagesTps 22960Luis SantosNo ratings yet

- STR-A6151 Al 6159 PDFDocument7 pagesSTR-A6151 Al 6159 PDFJosé BenavidesNo ratings yet

- Lmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionDocument23 pagesLmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionAlonso Herrera SeguraNo ratings yet

- Panasonic SA UX100PPDocument21 pagesPanasonic SA UX100PPboroda2410100% (3)

- Lmc555 Cmos TimerDocument25 pagesLmc555 Cmos TimerCataNo ratings yet

- A6251m PDFDocument7 pagesA6251m PDFYudi ElektroNo ratings yet

- LA4630NDocument9 pagesLA4630NekinetNo ratings yet

- 12 Volt Smps Circuit DiagramDocument7 pages12 Volt Smps Circuit DiagramAnura MaddumageNo ratings yet

- Allegro STR-W6765 PDFDocument15 pagesAllegro STR-W6765 PDFcomportNo ratings yet

- STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDDocument18 pagesSTR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDBertrand Soppo YokiNo ratings yet

- LM3243 High-Current Step-Down Converter For 2G, 3G, and 4G RF Power AmplifiersDocument32 pagesLM3243 High-Current Step-Down Converter For 2G, 3G, and 4G RF Power Amplifiersgotcha75No ratings yet

- LM2621 Low Input Voltage, Step-Up DC-DC Converter: 1 Features 3 DescriptionDocument17 pagesLM2621 Low Input Voltage, Step-Up DC-DC Converter: 1 Features 3 DescriptionSatyashiba Sundar JenaNo ratings yet

- Semikron Datasheet Board 1 Skyper 32 R l6100131Document7 pagesSemikron Datasheet Board 1 Skyper 32 R l6100131machadofelipe88No ratings yet

- SuperAE - Technical Catalogue Y-0446-K (03.99) - MitsubishiDocument66 pagesSuperAE - Technical Catalogue Y-0446-K (03.99) - MitsubishiNanang FebriNo ratings yet

- DatasheetDocument10 pagesDatasheettenisonNo ratings yet

- La4628 PDFDocument8 pagesLa4628 PDFRICHIHOTS2No ratings yet

- lm2937 DatasheetDocument30 pageslm2937 Datasheetanon_660018118No ratings yet

- Data SheetDocument12 pagesData SheetMarcoAntonioCamanTraihuelNo ratings yet

- STR A6169Document2 pagesSTR A6169Hanif Rathore PrinceNo ratings yet

- LM 2623Document21 pagesLM 2623alejo0091No ratings yet

- lp2985 NDocument41 pageslp2985 NCarlos AlexandreNo ratings yet

- AN17810A PanasonicDocument7 pagesAN17810A PanasonicManikmoyoNo ratings yet

- BD9893FDocument5 pagesBD9893FAriel NavarreteNo ratings yet

- Samsung HT x30 HT x40 HT Tx35 HT Kx30 HT Tkx35Document41 pagesSamsung HT x30 HT x40 HT Tx35 HT Kx30 HT Tkx35Dan DumbravescuNo ratings yet

- LM123/LM323A/LM323 3-Amp, 5-Volt Positive Regulator: General DescriptionDocument8 pagesLM123/LM323A/LM323 3-Amp, 5-Volt Positive Regulator: General DescriptionYoexis Domínguez ÁlvarezNo ratings yet

- La 4525Document10 pagesLa 4525richie1479No ratings yet

- HCPL 7601 AvagoDocument13 pagesHCPL 7601 AvagoSyed Khawar MukhtarNo ratings yet

- NPN Medium Power Transistor: FeaturesDocument9 pagesNPN Medium Power Transistor: FeaturesRobert SepulvedaNo ratings yet

- ULN2004APG Datasheet en 20101203Document13 pagesULN2004APG Datasheet en 20101203Kirk Freire LópezNo ratings yet

- RN4910FE: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsDocument6 pagesRN4910FE: Switching, Inverter Circuit, Interface Circuit and Driver Circuit ApplicationsSimbarashe MarisaNo ratings yet

- 80W 3-channel audio amplifier ICDocument13 pages80W 3-channel audio amplifier ICAnonymous r68sPjNo ratings yet

- Tps 54332Document34 pagesTps 54332Giovanni Carrillo VillegasNo ratings yet

- DatasheetDocument2 pagesDatasheetLesley HoodNo ratings yet

- OZ9939GNDocument12 pagesOZ9939GNEduardo SierraNo ratings yet

- bq27520 g4Document19 pagesbq27520 g4Cao Quang HưngNo ratings yet

- Low Noise, Low Power PWM Controller ICDocument2 pagesLow Noise, Low Power PWM Controller ICHernan GomezNo ratings yet

- 9441 Panasonic SA-AKX36PH PN Sistema Audio CD-USB Manual de ServicioDocument90 pages9441 Panasonic SA-AKX36PH PN Sistema Audio CD-USB Manual de ServicioJdoom Khan Ijk100% (1)

- Sharp 32le350mDocument70 pagesSharp 32le350mJorge Tom Simpson CruzNo ratings yet

- Semikron Datasheet Board 1 Skyper 32pro R l6100231Document12 pagesSemikron Datasheet Board 1 Skyper 32pro R l6100231rizcst9759No ratings yet

- 5101 Motor DriverDocument11 pages5101 Motor DriverMoise CristinaNo ratings yet

- Title Specification Application Author Document Number Date RevisionDocument40 pagesTitle Specification Application Author Document Number Date Revisionbsudeep7993No ratings yet

- STR W6000S Series Application NoteDocument20 pagesSTR W6000S Series Application NoteSutrisno OkNo ratings yet

- TLV 702Document31 pagesTLV 702yamaha640No ratings yet

- REH985b AllDocument91 pagesREH985b AllAndrew MaverickNo ratings yet

- UCC28880 700-V Lowest Quiescent Current Off-Line Switcher: 1 Features 3 DescriptionDocument35 pagesUCC28880 700-V Lowest Quiescent Current Off-Line Switcher: 1 Features 3 DescriptionFrancisReisNo ratings yet

- Av 29fh1sug JVC, 100hzDocument48 pagesAv 29fh1sug JVC, 100hzQ-EntityNo ratings yet

- Sa Ux100gsDocument24 pagesSa Ux100gssaxsimNo ratings yet

- pdp4273m PDFDocument74 pagespdp4273m PDFtheduddNo ratings yet

- SB-WA500PP: Wireless Subwoofer UnitDocument41 pagesSB-WA500PP: Wireless Subwoofer UnitMarceloNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- KDL-40BX450 Az3fk 9-883-873-01Document37 pagesKDL-40BX450 Az3fk 9-883-873-01Александр АндриановNo ratings yet

- Features General Description: 18V 3A 300Khz Buck ConverterDocument13 pagesFeatures General Description: 18V 3A 300Khz Buck ConverterАлександр АндриановNo ratings yet

- Tea1610 S An99011Document27 pagesTea1610 S An99011Александр АндриановNo ratings yet

- Str-A6051 52 53 59 61 62 69 79Document13 pagesStr-A6051 52 53 59 61 62 69 79Александр АндриановNo ratings yet

- F3 PWM Controller: Ice3Bs03LjgDocument25 pagesF3 PWM Controller: Ice3Bs03LjgАлександр АндриановNo ratings yet

- 25Q32BVDocument78 pages25Q32BVVictor GarciaNo ratings yet

- High Efficiency 400Khz, 3A, 16V Input Synchronous Step Down RegulatorDocument4 pagesHigh Efficiency 400Khz, 3A, 16V Input Synchronous Step Down RegulatorАлександр АндриановNo ratings yet

- ApplicationNote Philips Elenota - PLDocument27 pagesApplicationNote Philips Elenota - PLАлександр АндриановNo ratings yet

- Styling Sheet: Colour Television Styling: MG8Document4 pagesStyling Sheet: Colour Television Styling: MG8Александр АндриановNo ratings yet

- FSFR1700XSLDocument14 pagesFSFR1700XSLАлександр АндриановNo ratings yet

- Fa5590n Fa5591nDocument21 pagesFa5590n Fa5591nАлександр АндриановNo ratings yet

- Smc5.0 Thru Smc170ca SuppressorsDocument4 pagesSmc5.0 Thru Smc170ca SuppressorsАлександр АндриановNo ratings yet

- TPS65198RUYTDocument4 pagesTPS65198RUYTАлександр АндриановNo ratings yet

- An 84 FDocument160 pagesAn 84 FАлександр АндриановNo ratings yet

- Tsumv26k (E - U) Ver1.0 Ls07Document33 pagesTsumv26k (E - U) Ver1.0 Ls07Александр АндриановNo ratings yet

- FSP-242-277-282-4F01 LT4018Document2 pagesFSP-242-277-282-4F01 LT4018Александр АндриановNo ratings yet

- GM 5221-LF-BC GENESIS VGA+DVI+Video Multi-Function LCD Monitor ControllerDocument47 pagesGM 5221-LF-BC GENESIS VGA+DVI+Video Multi-Function LCD Monitor ControllerАлександр АндриановNo ratings yet

- Appendix IDocument3 pagesAppendix I黃啟倫No ratings yet

- A 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsDocument4 pagesA 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsRamanathanNo ratings yet

- The Lang 20W Class-A Mosfet AmplifierDocument7 pagesThe Lang 20W Class-A Mosfet AmplifiermoisesNo ratings yet

- Low-Voltage Low-Power CMOS Voltage Reference Design MethodologyDocument11 pagesLow-Voltage Low-Power CMOS Voltage Reference Design MethodologyVenkatesh DonepudiNo ratings yet

- The Analysis of Dead Time On Switching Loss in High and Low Side MOSFETs of ZVS Synchronous Buck ConverterDocument6 pagesThe Analysis of Dead Time On Switching Loss in High and Low Side MOSFETs of ZVS Synchronous Buck ConverterIDESNo ratings yet

- EPS ReportDocument58 pagesEPS ReportAyush GhoshNo ratings yet

- NTE454 MOSFET Datasheet - TV UHF/RF Amp, Gate ProtectedDocument4 pagesNTE454 MOSFET Datasheet - TV UHF/RF Amp, Gate Protecteddevon39No ratings yet

- VLSICMOS Course Outline at Independent University BangladeshDocument6 pagesVLSICMOS Course Outline at Independent University BangladeshOvi SahaNo ratings yet

- 650V 7A N-Channel MOSFET SpecificationDocument2 pages650V 7A N-Channel MOSFET SpecificationAris RomdoniNo ratings yet

- MC 33186Document21 pagesMC 33186Olga PlohotnichenkoNo ratings yet

- JNTUK M.Tech I Sem Course Structure for Instrumentation & Control Systems SpecializationDocument15 pagesJNTUK M.Tech I Sem Course Structure for Instrumentation & Control Systems Specializationchakri474No ratings yet

- EC6601-VLSI Design 2 Mark QuestionsDocument21 pagesEC6601-VLSI Design 2 Mark QuestionsArun ChezianNo ratings yet

- Silicon On Insulator (Sol) TechnologyDocument17 pagesSilicon On Insulator (Sol) TechnologyCharan MsdNo ratings yet

- UC3845 Technical ExplanationDocument15 pagesUC3845 Technical ExplanationankurmalviyaNo ratings yet

- 3.5 MOSFET Scaling and Small-Geometry EffectsDocument19 pages3.5 MOSFET Scaling and Small-Geometry Effectspraritlamba25No ratings yet

- High Voltage Impulse Generator Using HV-IGBTsDocument5 pagesHigh Voltage Impulse Generator Using HV-IGBTsMusharaf Saeed100% (1)

- ALD Al2O3 Passivation Reduces GaN MOS-HEMT Current CollapseDocument6 pagesALD Al2O3 Passivation Reduces GaN MOS-HEMT Current Collapseoğuz odabaşıNo ratings yet

- Virtuoso Layout Design OverviewDocument20 pagesVirtuoso Layout Design OverviewMasud SarkerNo ratings yet

- BKU B.Tech Electrical Program DetailsDocument49 pagesBKU B.Tech Electrical Program DetailsBilalNo ratings yet

- Chapter Wise QuestionsDocument2 pagesChapter Wise QuestionshjjhghgNo ratings yet

- Survey Low Power Techniques ROMsDocument5 pagesSurvey Low Power Techniques ROMsParul JohariNo ratings yet

- The MOSFET Transistor in SubthresholdDocument3 pagesThe MOSFET Transistor in SubthresholdVictorNo ratings yet

- REN Hip2210 211 DST 20200206-2930767Document29 pagesREN Hip2210 211 DST 20200206-2930767Christos PexliNo ratings yet

- MDF11N60 - 600V 11A 0.55Ω N-Channel MOSFETDocument6 pagesMDF11N60 - 600V 11A 0.55Ω N-Channel MOSFETAriel MercochaNo ratings yet

- VLSI Design: A Basic RISC ProcessorDocument54 pagesVLSI Design: A Basic RISC Processorhcg0206No ratings yet

- An 6005Document9 pagesAn 6005Anonymous QakmLc3kTINo ratings yet

- Make This Electric Scooter/Rickshaw CircuitDocument25 pagesMake This Electric Scooter/Rickshaw CircuitAnantha KeshavaNo ratings yet

- AOZ1031AIDocument15 pagesAOZ1031AIrachnologistNo ratings yet

- Ic Mr4000 Appnote-EnDocument43 pagesIc Mr4000 Appnote-EnNguyen Lan RivaretNo ratings yet

- TN40CMSP002 2 0 2Document192 pagesTN40CMSP002 2 0 2emmasustechNo ratings yet