Professional Documents

Culture Documents

Information Memorandum Equipment List

Uploaded by

anamarocainOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Information Memorandum Equipment List

Uploaded by

anamarocainCopyright:

Available Formats

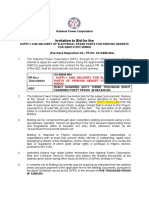

INFORMATIONMEMORANDUM:

WHIMCREEKSXEWPLANT 5TPDCOPPERCATHODE

UnderInstructionsfromWASCOMININGCOMPANYPTYLTD

MinascoAustraliaPtyLtd, 69EvansStreet,Sunbury,Victoria,3429,Australia. Phone:+61397408933 Fax:+61397409211 http://www.minasco.com.au Email:enquiries@minasco.com.au A.B.N.72925806199

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

CONTENTS: 1.0 2.0 3.0 4.0 5.0 5.1 5.2 5.3 INTRODUCTION ........................................................................................................... 3 GENERAL INFORMATION ........................................................................................... 3 INSPECTION................................................................................................................. 4 OFFERS ........................................................................................................................ 4 ATTACHMENTS ........................................................................................................... 6 EQUIPMENT LIST ..................................................................................................... 6 GENERAL ARRANGEMENT DRAWING REFER ATTACHED .................................. 13 PHOTOS REFER ATTACHED................................................................................... 13

_____________________________________________________________________________________________________ Page2of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

1.0

INTRODUCTION

This Information Memorandum has been prepared by Minasco Australia Pty Ltd (Minasco) in its capacity as agents for the vendors, Wasco Mining Company Pty Ltd (Wasco). The Memorandum is provided as a guide for prospective purchasers providing background information and technical details relating to the 5TPD SX-EW Plant assets offered for sale insitu at Whim Creek Mine in the Pilbara Region of Western Australia, Australia. Its content and descriptions do not form any part of subsequent documentation that would arise from purchase of the plant and other assets. Whilst every care has been taken in preparation of the Memorandum, it is the responsibility of intending purchasers to ensure to their own satisfaction, by on site inspection and verification, the accuracy of the information provided. No responsibility or liability is accepted by the vendors, Minasco or their staff for the accuracy of the information provided. Inspecting parties will be offered every assistance at inspection and access to all relevant documentation that may assist in their evaluation of the plant and equipment. We would be pleased to provide answers to any queries that may arise.

2.0

GENERAL INFORMATION

Wasco are offering their 5TPD SX-EW Plant to the market as a package for removal, currently located in-situ at Whim Creek Mine in the Pilbara Region of Western Australia. The plant was constructed new by Wasco and commissioned in October 2011. Operation was only for a short period during commissioning and production of 60 tonnes of copper cathode. A fire in the main generator caused the shutdown of operations. At the time of decommissioning the plant was in excellent condition, having operated only for a few months since new, with an industry standard care and maintenance programme put in place when it was decommissioned in February this year. The plant also includes a small package comprising all available spare parts on site. Dismantling of the plant and other assets for transport will be required to be completed by the purchaser, or their nominated contractor, and be planned and carried out in a safe, timely and efficient manner complying at all times with the mine site requirements. Wasco have offered to provide management services for relocation and commissioning of the plant. Minasco can assist with recommended contractors and service providers on all aspects of plant relocation from dismantling through to reinstallation and commissioning if required. Please contact Minasco for further details. The location, modular design and bolted construction of the plant will allow for ease of dismantling and relocation. A pre-emptive logistical package will ensure the plant can be delivered to any new project worldwide on a cost effective basis. Potential purchasers will have an adequate due diligence period to assess the plants suitability for their project under consideration. Engineering drawings, technical

_____________________________________________________________________________________________________ Page3of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

documentation and other intellectual property form part of the package providing considerable time cost benefits to new projects. All available engineering drawings, operation and maintenance manuals, maintenance procedures and records and other intellectual property (relevant to the design, construction and operation of the plant) is included as part of the sale. Potential buyers should note that all intellectual property, provided as part of the sale, will be subject to indemnification of Wasco under the Terms and Conditions of Agreement. A detailed Equipment List defining the scope of assets available, a General Arrangement Drawing and Photos of the plant are provided in the Attachments to this document.

3.0

INSPECTION

Inspection is strictly by appointment only through Minasco due to restricted access to the mine site. Minasco will require advance notice from enquiring parties to obtain access the plant and a mutually convenient time for inspection will be arranged to ensure appropriate personnel are available to facilitate your inspection requirements. All queries in relation to and arising from equipment inspection should be directed to Minasco.

4.0

OFFERS

Offers are invited for purchase of the complete plant as a single parcel lot and should be forwarded to Minasco for consideration. Offers are on a first in basis and will be considered at the time of receipt. The plant is offered in condition as is where is for removal from site and a complete logistical package can be provided for an international destination. All costs associated with dismantling to top of foundations and equipment removal works required for relocation of the equipment are to the purchasers expense and shall be carried out in accordance with the terms and conditions of Agreement, statutory legislation and regulations and the policies and procedures of the mine site and Wasco where applicable. This procedure is not a tender and parties making offers to purchase the plant will have the opportunity to negotiate their offer to a level acceptable to Minasco and Wasco. Parties who have inspected the plant and intend to submit an offer should consider the following points when structuring and presenting their offer: 1. The offer should provide a lump sum price, in Australian Dollars exclusive of any taxes, to purchase the package of equipment and assets specified in this documentation. 2. The offer submitted should be done so on a best and final price basis. We advise that a party submitting an offer at a level acceptable to both Minasco and Wasco will be given first right to negotiate a position to purchase the plant.

_____________________________________________________________________________________________________ Page4of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

3. The offer should detail any discrepancies observed in relation to the scope of equipment on offer, any terms and conditions the purchase may be subject to and an anticipated timeframe for removal of the equipment from its current location. In assessing offers consideration will be given to the terms of offer in addition to the offered price. 4. The payment terms relating to sale would be based on the following: Payment of a non-refundable 10% deposit upon signing of a Purchase Agreement. Payment of the remaining 90% prior to commencement of dismantling works and removal of equipment from the site or 30 days from signing of a Purchase Agreement, whichever is earlier.

5. Upon receipt of payment in full of the purchase price by Wasco, ownership and property in the plant would pass from the Wasco to the purchaser. At such time all risk and liability in the plant would transfer to the purchaser. 6. All offers should be made in writing (on company letterhead and signed by the appropriate authority) and submitted by fax, email or courier to: Wasco Mining Company Pty Ltd RE: Whim Creek SX-EW Plant, WA C/- Minasco Australia Pty Ltd PO Box 20 ( 69 Evans St ) Sunbury, 3429 Victoria, Australia AND an original forwarded as above. Minasco Australia Contacts: Sales and Marketing: Geoff Fields Mobile: +61-419-377 939 Geoff.Fields@minasco.com.au Technical: Robert Fields Mobile: +61-439-321 476 Robert.Fields@minasco.com.au Phone: Fax: E-mail: +61-3-9740 8933 +61-3-9740 9211 enquiries@minasco.com.au

_____________________________________________________________________________________________________ Page5of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

5.0

5.1

ATTACHMENTS

EQUIPMENT LIST

The Whim Creek SX-EW (5TPD Copper Cathode) Plant comprises the following major component equipment: 1x PLS Pump: Motor: 55Kw, 84Amp, 1480rpm IP44 Pump: 150-125-400, 250m3/h, 40m, Stainless steel housing, Ceramic seal, Rubber tyre coupling, Manufactured in China

1x Extract Mixer: Dimensions: 2.6m(D)x 3.5m(H) Motor: 15Kw, amp, 1160rpm, IP56 Capacity: Approximately 18Kl

1x Extract Settler: Dimensions: 6m(w)x9m(L)x1.2m(h) Capacity: Approximately 64Kl Features: 1 row picket fence at launder box, fixed aqueous weir, adjustable organic weir, 350mm organic outlet x2, 350mm aqueous outlet x1, 50mm drains x 4, domed fiberglass roof

1x Spent Aqueous Tank: Material: FRP Capacity: 22Kl Features: 350mm inlet up tank side, 200mm outlet at tank bottom

2x Spent Aqueous Pumps: Motor: 4Kw, 960rpm, 8.4Amp, IP56 Pump: Regent pumps type D150-214-TD64A, Stainless steel housing, Carbon seals, 75m3/h

1x Coalescing Tank: Material: FRP Capacity: 5Kl Features: 350mm inlet at tank bottom, 350mm and 200mm connecting outlets to Loaded organic tank

_____________________________________________________________________________________________________ Page6of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

1x Loaded Organic Tank: Material: FRP Capacity: 22Kl Features: 350mm and 200mm connecting inlets from coalescing tank, 200mm outlet at tank bottom

1x Loaded Organic Pump: Motor: 15Kw, 30Amp, 1460rpm, IP44 Pump: 125-100-315, 150m3/h, 18m, Stainless steel housing, Ceramic seal, VSD controlled, Manufactured in China

1x Strip Mixer Tank: Dimensions: 2.6m(D)x 3.5m(H) Motor: 15Kw, amp, 1160rpm, IP56 Capacity: Approximately 18Kl

1x Strip Settler: Dimensions: 6m(w)x9m(L)x1.2m(h) Capacity: Approximately 64Kl Features: 1 row picket fence at launder box, fixed aqueous weir, adjustable organic weir, 350mm organic outlet x2, 350mm aqueous outlet x1, 50mm drains x 4, domed fiberglass roof

1x Barren Organic Tank: Material: FRP Capacity: 5Kl Features: 350mm inlet at tank bottom, 200mm outlet at tank bottom, float level indicator

1x Barren Organic Pump: Motor: 55Kw,84Amp, 1480rpm,IP44 Pump: 150-1250-400, 250m3/h, 40m, Rubber tyre coupling, Stainless steel housing, Ceramic seal, VSD controlled, Manufactured in China

1x Strong Electrolyte Tank: Material: FRP Capacity: 22Kl Features: 350mm inlet at tank bottom, 200mm outlet to recirculating system, 100 outlet to 10Kl balance tank

_____________________________________________________________________________________________________ Page7of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

1x Strong Electrolyte Tank: Material: Poly Capacity: 10Kl Features: 100mm inlet at tank bottom from 22Kl Strong electrolyte tank, 100mm outlet at tank bottom

1x Strong Electrolyte Pump: Motor: 5.5Kw, 11.1Amp, 2900rpm, IP55 Pump: 65-50-160, 20m3/h, 30m, stainless steel housing, ceramic seal, manufactured in China

1x Recirculating Electrolyte Tank: Material: FRP Capacity: 22Kl Features: 350mm inlet up tank side, 200mm outlet balance pipe to Spent electrolyte system, 160mm outlet at tank bottom

1x Recirculating Electrolyte Pump: Motor: 18.5Kw, 35Amp, 1465rpm, IP55 Pump: Stork type CC80-400 R6M2L1, stainless steel housing, carbon ceramic seal, manufactured in Netherlands

1x Spent Electrolyte Tank: Material: FRP Capacity: 5Kl Features: 200mm balance pipe from Recirculating electrolyte tank, 100mm outlet at tank bottom, internal baffle at balance pipe system

1x Spent Electrolyte Pump: Motor: 3Kw, 6.5Amp, 2880rpm, IP55 Pump: 65-50-105, 20m3/h,15m, stainless steel housing, ceramic seal, manufactured in China

1x Dry Chemical Mixing Tank: Material: Poly Capacity: 3Kl Features: Fixed shaft mixing motor and elevated working platform

_____________________________________________________________________________________________________ Page8of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

1x Dry Chemical Distribution Pump: Motor: 1.1Kw, 2.25Amp, 2880rpm, IP56 Pump: Grundfos type CRN15-01 B-FGJ-G-V-HQQV, 17m3/h, 13.5m, Stainless steel housing, Carbon seal, vertical upright system

1x Air Compressor: Brand: Gardner Denver Compressor style: Rotary screw Type: ESS 18-8 EANA Capacity: 2.7m3/min Max. Pressure: 8Bar Motor power: 18.5Kw Voltage: 415V

1x Air Compressor: Brand: Ceccato Compressor style: Rotary screw Type: RCOMP10/8 Max. Pressure: 8Bar Motor power: 7.5Kw Voltage: 415V

Flow Meter- Electrolyte: Brand: ABB Flange: DN150/ AS2129 Table E Material: Steel/ PTFE/ Hastelloy C-4 Power supply: 240V AC Max flow: 600m3/h Method of measurement: Resistance Quantity: 63mm x 2, 110mm x 1, 160mm x 3

Flow Meter- Organic: Brand: Yokogawa Flange: DN150 Table E Material: Stainless steel Power supply: 10.5- 30V DC Method of measurement: Vortex Quantity: 160mm x 2

_____________________________________________________________________________________________________ Page9of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

Control Valve / Flow Valve: Brand: Tyco/ Keystone Operation: Air pneumatic, Butterfly Working pressure: 830Kpa Safety: Single acting 530Kpa fail close Quantity: o Control valve: 63mm x 3, 160mm x 3 o Flow valve: 63mm x 2, 110mm x 1, 160mm x 4, 200mm x 5

Manual Valves: Brand: Tyco/ Keystone Operation: Manual, Butterfly Quantity o 63mm x 1, 110mm x 3, 160mm x 3, 200mm x 8

1x Acid Tank: Material: Steel Capacity: 2.5Kl Features: 50mm inlet and outlet at tank bottom, conical roof with manhole cover

1x Acid Pump: Motor: 1.5Kw, 3.4Amp, 2850rpm, IP55 Pump: 40-32-125, 5m3/h, 2m, Stainless steel housing, Carbon seal, manufactured in China

1x Electrowinning Shed: Dimensions: 30mx 11.4mx 8m Features: Open sided shed, canted roof, gantry rail system with gantry crane, cyclone rating 5, complete walkway area around electrowin cells

1x Gantry Crane: Capacity: SWL 5t Hook: SWL 5t Operation: Hand held remote control

1x Cathode Wash Cell: Dimensions: 3445mmx 1200mmx 1450mm Material: Polymer concrete, resin coated

_____________________________________________________________________________________________________ Page10of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

10x Electrowinning Cell: Dimensions: 3445mmx 1200mmx 1450mm Material: Concrete, resin coated Features: Capacity for 34 Anodes, 33 Cathodes; Capping boards with Bus bar in place, electrolyte distribution system in cell bottom, fixed overflow weir

2x Cathode Hanging Rack: Material: Steel Capacity: 33 Cathodes each

363x Cathode Mother Plates: Dimensions: 1250mmx 1100mm Material: Stainless steel plate, Copper Bus bar

340x Anode Plates: Dimensions: 1200mmx 1000mm Material: Lead alloy, Copper Bus bar

1x Diesel Powered Generator: Engine: Cummins 375KVA, 6 cylinder turbo charged intercooler, high temperature cooling pack Generator: Stamford Features: Silent operation in 20 shipping container, belly diesel tank

1x Diesel Powered Generator: Engine: MTU 1125KVA, V18 cylinder twin turbo charged intercooler, high temperature cooling pack Generator: Stamford Features: Silent operation in 20 shipping container, belly diesel tank

1x MCC: 20 transportable room, air conditioned, fully operational switch board with PLC control for plant operation, plant parameter adjustment via touch screen panel

2x Rectifier Units: Input: 415V AC Output: 21V DC (Max), 10500Amp (Max) Manufactured in China

_____________________________________________________________________________________________________ Page11of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

Control System: Alan Bradley PLC control System.

Reverse Osmosis Plant: Pre-filter, Wavecyber Model 1465 automatic sand & gravel backwash filter. Vertex Hydropore J-64040 RO System housed in insulated, air conditioned container. Production rate of up to 1200 litres per hour. Six 4.0 x 40" thin film membranes. Microprocessor control for fully automatic operation including product tank level. Hydraulic control panel with recycle system to maximise recovery rate up to 80%. Stainless steel pump, pressure vessels, gauges, fittings and frame.

Laboratory: Notes: All flanges are joined using zinc M16 bolts, washers and nuts Operation area has lighting towers for night time operation There are 7 safety showers and eye wash stations attached to the plant There are a variety of stairway, walkway platforms and guard rail located around the operational area for access and safety Transportable 4 room Lab with office / wet lab / AA room / chemical store 2010 Varian SpectrAA 50B atomic absorption photospectrometer, with copper, gold and silver lamps, wide range PM tube and air/acetylene & nitro burners Digital analytical balance 6000gms Magnetic stirrers Glassware incl. beakers, pipettes, flasks, burettes, etc.

_____________________________________________________________________________________________________ Page12of13 03July12v1

WASCOMININGCOMPANYPTYLTD WHIMCREEKSXEWPLANT5TPDCOPPERCATHODEWA InformationMemorandum

5.2 5.3

GENERAL ARRANGEMENT DRAWING Refer Attached PHOTOS Refer Attached

_____________________________________________________________________________________________________ Page13of13 03July12v1

You might also like

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementFrom EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementNo ratings yet

- Firewater Pumps Package EOIDocument6 pagesFirewater Pumps Package EOIrenjithv_4No ratings yet

- Tender Documents - E Veh Items FinalDocument20 pagesTender Documents - E Veh Items FinalWajahat BukhariNo ratings yet

- SNCP QTNDocument4 pagesSNCP QTNBurning TrainNo ratings yet

- ACCD Rigging GuideDocument19 pagesACCD Rigging Guidegv Sathishkumar KumarNo ratings yet

- Flare System PDFDocument29 pagesFlare System PDFKamal SkNo ratings yet

- Expression of InterestDocument4 pagesExpression of InterestAzahari AbdullahNo ratings yet

- Investment File Iraq PetrochemDocument98 pagesInvestment File Iraq PetrochemsashaNo ratings yet

- UK Battery Strategy - Call For EvidenceDocument32 pagesUK Battery Strategy - Call For EvidenceRam PrakashNo ratings yet

- Kp1.9a.2.ot.055.ict.22-23 For Supply, Installation, Configuration and Commissioning of Sap S-4 Hana InfrastructureDocument114 pagesKp1.9a.2.ot.055.ict.22-23 For Supply, Installation, Configuration and Commissioning of Sap S-4 Hana Infrastructurebogo dispNo ratings yet

- Vssc-P-Advt-127-2014 - 19.08.2014Document88 pagesVssc-P-Advt-127-2014 - 19.08.2014kanchanabalajiNo ratings yet

- Daikin Heat PumpDocument8 pagesDaikin Heat PumprohitshetyeNo ratings yet

- Tender DocumentDocument282 pagesTender DocumentChrisNo ratings yet

- Visakhapatnam PDFDocument23 pagesVisakhapatnam PDFD.D.SharmaNo ratings yet

- DLF New Town Gurgaon Soicety Handbook RulesDocument38 pagesDLF New Town Gurgaon Soicety Handbook RulesShakespeareWallaNo ratings yet

- Newcross MANIFOLD PIG LAUNCHER 20220526Document3 pagesNewcross MANIFOLD PIG LAUNCHER 20220526Wale OyeludeNo ratings yet

- ACCC Discussion Paper About FANOC SAU - 21 Jun 07Document36 pagesACCC Discussion Paper About FANOC SAU - 21 Jun 07alifatehitqmNo ratings yet

- p9040 Fuel Cell Demonstration UnitDocument12 pagesp9040 Fuel Cell Demonstration UnitGhulam Murtaza ShahNo ratings yet

- Baker Manual # 1Document38 pagesBaker Manual # 1manuelaNo ratings yet

- 50T Drop Table SEC RailwayDocument28 pages50T Drop Table SEC RailwaymailbkraoNo ratings yet

- Attachment: Name Electrical Control Kit Group No. 523568B Serial No. E78872 AND UP Model NoDocument12 pagesAttachment: Name Electrical Control Kit Group No. 523568B Serial No. E78872 AND UP Model NoAngel Sanchez VilcaNo ratings yet

- EOI Plumbing Services IVP EOI 2023 007Document2 pagesEOI Plumbing Services IVP EOI 2023 007Seapara SathekgeNo ratings yet

- iraq - muthannacement الملف الاستثماري للمعمل PDFDocument190 pagesiraq - muthannacement الملف الاستثماري للمعمل PDFSadiq TurkiNo ratings yet

- Receipt of Machines: Machines Are EitherDocument63 pagesReceipt of Machines: Machines Are EitherjsaulNo ratings yet

- Po 001 Iciecpl Ankit Const. 3Document9 pagesPo 001 Iciecpl Ankit Const. 3Anjani KumarNo ratings yet

- Petroleum Development Oman L.L.CDocument11 pagesPetroleum Development Oman L.L.Cvishnu RajNo ratings yet

- Sections 1 To 5 5th Edition - September 2019 (1) - 004Document62 pagesSections 1 To 5 5th Edition - September 2019 (1) - 004Jaapar HassanNo ratings yet

- The Role of An Offshore Metocean AdvisorDocument8 pagesThe Role of An Offshore Metocean AdvisorMarios DiasNo ratings yet

- 0oleu2.36ulou Gs 07f 0097w Notifierpo034Document30 pages0oleu2.36ulou Gs 07f 0097w Notifierpo034Safetrol de MexicoNo ratings yet

- SCUBATECH ConformeDocument6 pagesSCUBATECH ConformeVal ClaudioNo ratings yet

- SPDC Provision of One 15K 3000HP Heavy Swamp Rig For Drilling and Work Over Operations 20231102Document3 pagesSPDC Provision of One 15K 3000HP Heavy Swamp Rig For Drilling and Work Over Operations 20231102wilsonNo ratings yet

- Es 13133-R1Document8 pagesEs 13133-R1Nic RicNo ratings yet

- ةراجتلل ميهاربلا نسحملا دبع دهف ةسسؤم Specialized Electrical SystemsDocument3 pagesةراجتلل ميهاربلا نسحملا دبع دهف ةسسؤم Specialized Electrical SystemsmohideenNo ratings yet

- Fertilizer North AreaDocument5 pagesFertilizer North AreascaaaNo ratings yet

- Screen CatalogueDocument73 pagesScreen CatalogueAkong KudetNo ratings yet

- VMS Installation and Maintenance StandardDocument10 pagesVMS Installation and Maintenance Standardtawe0441No ratings yet

- Location Aof Units MsmeDocument3 pagesLocation Aof Units MsmeSiva RockNo ratings yet

- Must 047 2016 2018 CCTVDocument48 pagesMust 047 2016 2018 CCTVAnne MwangiNo ratings yet

- Az Zour IWPP PDFDocument19 pagesAz Zour IWPP PDFchatuusumitava100% (1)

- Infrastructure Component of Abaca Fiber Production, Consolidation and Trading EnterpriseDocument13 pagesInfrastructure Component of Abaca Fiber Production, Consolidation and Trading EnterpriseLea MamaNo ratings yet

- SR 2026 2022 Beret Badge Belt Badge For Intake 39 Officer CadetsDocument6 pagesSR 2026 2022 Beret Badge Belt Badge For Intake 39 Officer CadetsDinithi BothejuNo ratings yet

- 001 Cones and Bollards Application Requirements and ChecklistDocument12 pages001 Cones and Bollards Application Requirements and Checklistengrabbas75No ratings yet

- Iraq KirkukcementDocument46 pagesIraq KirkukcementShyrah SaiNo ratings yet

- RFQ NGV Bus Emissions ExerciseDocument5 pagesRFQ NGV Bus Emissions ExerciseGaniyuNo ratings yet

- Aluminium Sulphate 840tons Document - C2018.116Document83 pagesAluminium Sulphate 840tons Document - C2018.116krishportNo ratings yet

- For Provision of Surface Wellhead Maintenance ServicesDocument13 pagesFor Provision of Surface Wellhead Maintenance ServicesEgitie GodswillNo ratings yet

- Ms Nit 1819 cpl1Document6 pagesMs Nit 1819 cpl1Raju PatilNo ratings yet

- FTWZDocument7 pagesFTWZchandan jhaNo ratings yet

- Schedule A. Scope of Works Hose Assembly TH005 EnglishDocument6 pagesSchedule A. Scope of Works Hose Assembly TH005 EnglishreguiiNo ratings yet

- Sco Copper OreDocument5 pagesSco Copper OreCarlos MartinezNo ratings yet

- Outline Scope of WorksDocument12 pagesOutline Scope of WorksMark TimkangNo ratings yet

- Mech SpecDocument49 pagesMech Spechusseint66No ratings yet

- Ravi Kasaudhan@chambal inDocument10 pagesRavi Kasaudhan@chambal inRavi KasaudhanNo ratings yet

- Pretoria NBG Security Services Tender - 1Document26 pagesPretoria NBG Security Services Tender - 1isaias.kuango9424No ratings yet

- RFP #2015-10: Site Preparation For Two DuplexesDocument9 pagesRFP #2015-10: Site Preparation For Two DuplexesSipekne'katikNo ratings yet

- Guide To Offshore WindfarmDocument72 pagesGuide To Offshore WindfarmJoe Dagner100% (1)

- Waterproofing Works For Intake Structure Method StatementDocument23 pagesWaterproofing Works For Intake Structure Method StatementMohammad Bader Al-DeinNo ratings yet

- PIA PurchasingDocument10 pagesPIA PurchasingLuis Roberto Guerrero VazquezNo ratings yet

- Supply and Replacement of Two Battery Banks For 802KA & 2002KDocument3 pagesSupply and Replacement of Two Battery Banks For 802KA & 2002KEhab Abd-allaNo ratings yet

- Chain Rexnord Qualitaetsketten (En)Document51 pagesChain Rexnord Qualitaetsketten (En)Suelen SantosNo ratings yet

- Pilot Product Catalogue 18Document28 pagesPilot Product Catalogue 18veerraju tvNo ratings yet

- The Charpy Impact Test and Its Applications: DR Brian LeisDocument16 pagesThe Charpy Impact Test and Its Applications: DR Brian Leisshasitha madushankaNo ratings yet

- Bag Filter CalculationDocument3 pagesBag Filter CalculationNITIN P SHAHNo ratings yet

- Kalina Cycle - Wikipedia, The Free EncyclopediaDocument3 pagesKalina Cycle - Wikipedia, The Free Encyclopediawilliam4132No ratings yet

- Rubric HM FR FR MotultechDocument2 pagesRubric HM FR FR MotultechNiang Abdoul malickNo ratings yet

- D1014 PDFDocument3 pagesD1014 PDFmohamed abd eldayemNo ratings yet

- HEAT PIPES Review, Opportunities and ChallengesDocument48 pagesHEAT PIPES Review, Opportunities and ChallengesMarco Antonio CovieloNo ratings yet

- Performance On Mechanics of Materials - MAE 243 (Section 002)Document18 pagesPerformance On Mechanics of Materials - MAE 243 (Section 002)Reivax50No ratings yet

- Prefabricated Vertical DrainsDocument26 pagesPrefabricated Vertical DrainsMayank Prakash100% (1)

- Calculation of Pigging Effectiveness For Petroleum (Product) PipelinesDocument7 pagesCalculation of Pigging Effectiveness For Petroleum (Product) PipelinesdddassddNo ratings yet

- 2003 ISJ Mersadetal Colorants PDFDocument15 pages2003 ISJ Mersadetal Colorants PDFJose LopezNo ratings yet

- Thermodynamics Properties of Pure SubstancesDocument30 pagesThermodynamics Properties of Pure Substancesleelamech36No ratings yet

- ASTM D2563 Defectos VisualesDocument24 pagesASTM D2563 Defectos VisualesCristian VegaNo ratings yet

- Sedimentation Process and Design of Settling Systems PDFDocument338 pagesSedimentation Process and Design of Settling Systems PDFVu Thanh ThuongNo ratings yet

- C 1087 00 Sellantes Compatibilidad EstructurasDocument4 pagesC 1087 00 Sellantes Compatibilidad Estructurasadrianhhhh1984No ratings yet

- 07 Reactions With CopperDocument6 pages07 Reactions With CopperEloizaDaSilvaNunesNo ratings yet

- 2 Design Radial Inflow Turbine Using RitalDocument18 pages2 Design Radial Inflow Turbine Using Ritaljared_tan_5100% (1)

- A Bibliometric Analysis of Research On Upflow Anaerobic Sludge Blanket (UASB) From 1983 To 2012Document14 pagesA Bibliometric Analysis of Research On Upflow Anaerobic Sludge Blanket (UASB) From 1983 To 2012Helton SantanaNo ratings yet

- SS!L EDocument19 pagesSS!L EJeffry FontaineNo ratings yet

- Module 8 QDEDocument7 pagesModule 8 QDERanier Factor AguilarNo ratings yet

- Fundamental EquationDocument7 pagesFundamental Equationlmcristina5No ratings yet

- Asme B16.34Document15 pagesAsme B16.34Achraf Ismail100% (1)

- Low Mach Number ApproximationDocument42 pagesLow Mach Number ApproximationDiana MitroiNo ratings yet

- VCPBR 05043 en PRV OverviewDocument24 pagesVCPBR 05043 en PRV OverviewmagveyNo ratings yet

- Gavião Arqueiro # 03Document9 pagesGavião Arqueiro # 03SuaniSBSNo ratings yet

- Soot & ScaleDocument12 pagesSoot & ScaleLow Shen WeiNo ratings yet

- Light Weight ConcreteDocument16 pagesLight Weight ConcretePandi AnNo ratings yet

- Project On Refractive Index of Different LiquidsDocument5 pagesProject On Refractive Index of Different LiquidsPRABHU JENANo ratings yet

- Argar Block ExperimentDocument3 pagesArgar Block ExperimentSaira SakulsachaNo ratings yet