Professional Documents

Culture Documents

Design, Manufacturing of Windmill Blades

Uploaded by

Sudhanwa KulkarniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design, Manufacturing of Windmill Blades

Uploaded by

Sudhanwa KulkarniCopyright:

Available Formats

INTERNATIONAL JOURNAL of RENEWABLE ENERGY RESEARCH M. M. Wagh et al., Vol.2, No.

4, 2012

Design, Development, Manufacturing and Testing of Aerofoil Blades for Small Wind Mill

M. M. Wagh*, N. N. Shinde**

* Department of Energy Technology, Shivaji University

energyunishivaji@gmail.com, waghmahesh2006@gmail.com

Corresponding Author; M. M. Wagh, Department of Energy Technology, Shivaji University, Kolhapur, Maharashtra, India, energyunishivaji@gmail.com Received: 22.08.2012 Accepted: 23.09.2012

Abstract- In India the average per capita electricity consumption for domestic utilities is from 1-1.5kWhrs, which means a small wind mill of 1 kWp is reasonably sufficient to cope up with every day need of a family. This paper has dealt with design, manufacturing and performance testing of aerodynamic rotor blade for 1kWp small wind machine. It is observed that the small wind mills available in this range are not indigenous and are designed for higher rated wind speeds. A new design methodology was established for indigenous development of small wind machine technology, which considers aerodynamic rotor blade design for rotor blade performance and finite element design practices for strength of rotor blades. This has facilitated to consider the cut in speed from 2m/s onwards, rated speed 11-14m/s and cut out speed of 25m/s. The FRP/ERP rotor blades having light weight and highest strength to weight ratio was selected and has fulfilled the conditions of low initial torque for lower cut in speeds. The power curves obtained by testing wind machines by IEC 61400-121 methods shows improved performance over market similar capacity wind machines. Keywords- Small wind mill design, Aerofoil section for wind mill, testing of small wind mill, performance of small wind mill, rotor blade design of small wind mill.

1. Introduction 2. Windmills have been used for at least 3000years, mainly for grinding grain or pumping water, while in sailing ships the wind has been an essential source of power for even longer. Locally, wind velocities are significantly reduced by obstacles such as trees or buildings. The survey carried out for representative samples at Kolhapur, states that the energy consumption per capita per day ranges from 5 to 6 units (kWhrs) for domestic applications. This leads to energy source/supply @ 1 to 1.5 kW per day available for 5 to 6 hrs. A renewable energy source will be ideally suited to comply these energy needs. The sources available easily are wind, solar, biogas, etc. out of which wind energy is studied in length in this paper. Design of rotor blades for small wind machine

2.1. Design methodology The research has established that the new design methodology need to be worked out for small wind machines < 10 kW. The various books and literature survey shows the different aspects and component design including aerodynamic rotor blade design. The finite element method can be used, instead complex computer aided rotor blade designs as in case of large wind mills of MW scale where complexities are important. However for small wind a mill following methodology is set herewith. a) b) c) The localized wind speed pattern establishment. Power in the wind calculations. Selection of wind mill type namely HWAT or VWAT etc.

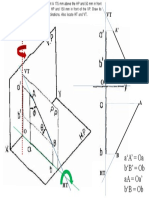

INTERNATIONAL JOURNAL of RENEWABLE ENERGY RESEARCH M. M. Wagh et al., Vol.2, No.4, 2012 d) e) f) Find the swept area, diameter and speed of the rotor vis-a- vis wind speed. Find rotor blade lift, drag and chord length. Blade strength considerations for the designed wind speed using finite element method with respect to aerodynamic profile. Fixing blade aerodynamic and twist. 3.1. Design of blade using sectional method The blade is designed for mechanical strength. The blade is the main element that converts wind energy into useful work and in doing so is loaded to deliver the desired power. Blade load is then transferred to the shaft and then to the generator. Hence it is very essential to establish the forces acting on the blade. The blade being considerably long is loaded with varying forces from the inner root to the outer tip. The best way to consider such loading is to write down expressions for an immeasurably small section of the blade at radius r and find out the distribution. This is the blade element theory.

g)

2.2. The Power in the Wind No device, however well-designed, can extract all of the winds energy because the wind would have to be brought to a halt and this would prevent the passage of more air thorough the rotor. The most that is possible is for the rotor to decelerate the whole horizontal column of intercepted air to about one-third of its free velocity. A 100% efficient aerogenerator would therefore only be able to convert up to a maximum of 59% (Betz limit) of the available energy in wind into mechanical energy. Assumptions considered for design: 1) Efficiency of the generator 2) The design wind speed for the wind mill is 3) The mechanical efficiency of the wind mill 4) The transmission efficiency of the wind mill 5) The aerodynamic efficiency 6) The 20% for nacelle are accommodated. 7) Density of the air = 1.125 kg/m3 3. Results 1) Propeller diameter 2) Rotational speed 3) Effective blade length 4) Power output = 1.75 m = 455 r.p.m. = 0.875 m = 1 kW

Evaluation of Fx and Fy for an elemental segment has to be done and rotational velocity N has already established, the functional requirements that lead to define . For good aerofoil design, the ratio of Cd/Cl can be assumed initially and then reverified. For an aerofoil this value is to be very low such as less than 0.1 for the wind turbine under consideration, the blade element is considered to be 0.175 meter along its radius and calculations are done. The table is prepared for the various parameters of each element of the blade the List the values of Fx and Fy for r = 0.175 and r = 0.262, 0.437, 0.612, 0.787, 0.962. Table 1. List the bending moments of Fx and Fy about the points R = 0.175, 0. 350, 0.525, 0.700, 0.875. Radius Angle of Bending Bending R attack moment in X moment in Y direction direction Bmx N-m Bmy N-m 0 0 231.32 38.62 0.175 27 174.46 26.79 0.350 53.41 120.08 16.40 0.525 66.01 72.20 8.81 0.700 72.38 34.07 3.73 0.875 76.12 8.93 0.898 641

The blades are designed on two principles, as drag design and lift design. Drag designed turbines are characterized by slower rotational speeds and high torque capabilities while lift designed turbines are characterized by much higher rotational speed with corresponding lower torque. Drag and lift are the forces exerted by wind flowing over the aerofoil section of the blades. Blade strength is based on either drag or lift forces. The forces acting on the blade element are also shown in the figure. The resultant of lift and drag forces is Fr, which has axial and tangential components (Fx and Fy)

INTERNATIONAL JOURNAL of RENEWABLE ENERGY RESEARCH M. M. Wagh et al., Vol.2, No.4, 2012 The maximum bending moment acting on the blades in Y direction is considered it gives the torque acting on machine. So check the power developed: Counter check the power by iterative procedure. If we assume that the ineffective central area is about 10 %, the design presented gives an acceptable answer of 1000 watts and average blade efficiency assumed as 75 % is correct. 3.2. Design of blade for strength: The blades are subjected to bending moment Bmx along the axial direction and Bmy along the tangential direction. The blade can be treated as a cantilever with aerofoil cross section. This cross section changes direction with respect to Bmx and Bmy along the length of the blade. Hence bending moments are to be resolved along with lift line as the design is based on lift, as the vane angle at every cross section is different. Initially it has been assumed to some portion of the aerofoil in terms of any one dimension and estimate modulus of section Zxx in terms of single variable. Though we have estimated bending moments for the normal operating conditions, it is generally recommended to base the design for the worst operation of the wind, i. e. gust, which is five times the operational wind speed. Although the wind speeds of 250 km/h occur very rarely, the hurricane velocities are about 150 km/h. hence strength components calculations will be based on wind speed of 150 km/h and further safeguarding will be provided by furling action. So all values of forces and bending moments are to be estimated for wind velocities of 150 km/h. however, it is seen that the wind force is a function of Vu2 and therefore for 3 times velocity, the forces and bending moments are to be simply multiplied by factor of 9. based on the lift design principle, bending moment due to these forces along lift line will decide the section size of the aerofoil. Bending moment along lift line = (BMx sin + BMy cos ) / no. of blades The bending moments along lift line are calculated from the above formula for the values of as = 27, 53.41, 66.01, 72.38, 76.12 and listed in the table below Calculation for the L and t for the aerofoil section: For the calculation of the section unknown values such as L and t the following formula is used. BMlift x 9 = FS) x no. of blades Zxx x (ultimate Strength of material /

For the blades the composite material of ultimate tensile strength 150 Mpa is selected. And for each BMlift the values for the L and t are calculated and tabulated as below in table Calculation for the twist of blade: The twist of the blade is defined in terms of the chord line. Blade twist angle is a synonym for the pitch angle; however the twist defines the pitch settings at each position along the blade according to local flow conditions. Radius R 0 0.175 0.350 0.525 0.700 0.875 0 27 53.4 66.0 72.3 76.1 BMlift N-m 0 34.35 35.39 23.18 11.20 2.96 L meters --0.0439 0.0443 0.0385 0.0302 0.0193 t meters ---0.00732 0.00739 0.00642 0.00503 0.00323

The pitch angle b is large near the root, where the rotational speed is (Vt = r) low and small at the tip where the rotational speed is high. This situation suggests a match between the twist and rotational speed, since the relative wind velocity W is Here is a decision to be made: 1) Fixing and searching for the optimum twist , or 2) Fixing and searching for the optimum . The first choice is better because it is easier for designing the gear and the generator. was chosen to be 130 rpm for 4 m/s. As a first estimate of the twist, we use the equation for twist of the zero lift line: = [ ( Rt/ r) - t] - k (1-r/R)

Over and above the design margins, a factor of safety of 2 is generally recommended. The proportions adopted for an aerofoil cross section are shown in the above figure. Its modulus of section about X-X axis and cross sectional area is estimated as, Zxx = 0.2 x t3 Area A = 3.5 t2

Therefore U = 2 x x N/60 = 13.6 m/s Rotational speed = Vt = r = 113m/s

For calculation of twist u is taken 13.6 m/s Therefore, t = tan-1(u/Vt)= 6.860

Bending moment due to Fx and Fy will have their components along the lift and drag lines. This design being

642

INTERNATIONAL JOURNAL of RENEWABLE ENERGY RESEARCH M. M. Wagh et al., Vol.2, No.4, 2012 Since is the angle of twist, for the first radius it is considered 00 20 taking = 20 gives t = ( - ) = 6.86 - 2 = 4.860 The equation for the twist of the blade for zero lift line is = [ ( Rt/ r) - t] - k (1-r/R) In the above equation the value of k should be greater than zero. For the value of r= 0.175, 0.350, 0.525, 0.700, 0.875 the values of the twist angles are calculated and tabulated in the table below. Radius R 0 0.175 0.350 0.525 0.700 0.875 0 27 53.4 66.0 72.3 76.1 BMlift N-m 0 34.35 35.39 23.18 11.20 2.96 L meters --0.0439 0.0443 0.0385 0.0302 0.0193 t meters ---0.00732 0.00739 0.00642 0.00503 0.00323

Analysis: The analysis is as per the guidelines available in IEC 61400-12-1, design requirements of small wind mill turbines. The duration testing provides the information about structural integrity, quality of environmental protection (safety, noise etc.) and dynamic behavior of small wind machines. Though IEC standards indicate 250 hrs of testing periods, in the present case the IEC procedure was followed for performance characterization of small wind machine. Wind speed Vs RPM- at load 800 700 600 500 400 300 200 100 0 0 5 10

Model of blade drawn in IDEA -11software

RPM

at tip Linear (at tip)

Testing and Performance of small wind mill a) The 1 kW small wind machine is a three bladed, up -wind, horizontal axis, variable speed wind turbine, that uses tilting of the rotor for power regulation and speed control. The turbine uses a direct-drive PMG generator, to produce three-phase, variable-frequency, variable voltage, AC power. This power is directed thorough rectifier located in the nacelle to the turbines controller. b) The wind turbine was connected to a 48 V battery bank with a storage capacity of C10=260 Ah, c) Test is performed in accordance to the IEC 61400121 Ed. 1: Power Performance Measurements of grid Connected Wind Turbines, and in particular following the specific guidelines of the annex H: Power Performance Testing of Small Wind Turbines

Wind Speed RPM Full Load

Wind speed Vs current

Current I

20,00 15,00 10,00 5,00 0,00 0 5 10 15 Current I

643

INTERNATIONAL JOURNAL of RENEWABLE ENERGY RESEARCH M. M. Wagh et al., Vol.2, No.4, 2012 a) Wind speed Vs Power

Power Curve

1000,00 900,00 Power watts 800,00 700,00 600,00 500,00 400,00 300,00 200,00 100,00 0,00 0 5 10 15 Wind speed m/s

Se

References [1] Paul Gipe Califonia, USA www.wind-works.org [2] S.P.Patil-Mechanical publications.(2009) System DesignJaico

[3] V. B. Bhandari- Design of Machine Elements- Tata Mcgraw Hill publications. (2009) [4] S.M.Habali, I.A.Saleh - Local design, testing and manufacturing of small mixed airfoil wind turbine blades of glass fiber reinforced plastics Part-I-International Journal Energy Conservation and Managementwww.elsevier.com (2005) [5] D.M.Somers- The S822 and S823 Airfoils- Report by National Renewable Energy Laboratory Colorado (2005) [6] Tony Burton, David Sharpe, Nick Jenkins, Ervin Bossanyi- Willey publications-Wind Energy Handbook, ( 2004) [7] Dr.S.P.Sukhatme- Solar energy- Tata Mcgraw Hill publications (2009) [8] Dr.R.K.Bansal - Fluid Mechanics and Machines - Laxmi publications ( 2009) [9] Hydraulic

4.

Conclusion

A new design methodology was established for indigenous development of small wind machine technology, which considers aerodynamic rotor blade design for rotor blade performance and finite element design practices for strength of rotor blades. This has facilitated to consider the cut in speed from 2m/s onwards, rated speed 11-14m/s and cut out speed of 25m/s. The FRP/ERP rotor blades having light weight and highest strength to weight ratio was selected and has fulfilled the conditions of low initial torque for lower cut in speeds. The mounting plates, power transmission, coupling, shaft bearings are designed based on regular practices of ASME, ASTM and BIS standards. While tested as per guideline procedures of IEC 61400-12-1 standards for performance characterization, it is found that the small wind machine manufactured and developed has resulted with one of the best average performance among available small wind turbines. Though it was designed for 10-14m/s rated speed the actual maximum efficiency is observed at 8-10m/s wind velocities. The machine has started at the cut in speed of 2.8m/s and has run at 1.8m/s. Due to limitations of wind velocities at site, it is not possible to calculate the performance at higher wind speeds above 12m/s. The lower cut in wind speed and maximum efficiency at lower wind speed than designed rated speed could be because of selection of aerofoil section NREL S-822, light weight rotor blades, bearing and tail vane selection and also low rpm high permanent magnet strength generator used during the testing. The performance testing at higher wind speed is required, since maximum rotor blade tip rpm observed is @ 1000 rpm. The further wind speed testing requires safety measures.

Ron Stimmel A Guide for State and Local Governments In the Public Interest How and Why to permit for Small Wind Systems-American Wind Energy Association September 2008,

[10] Wind Energy Integration in the Urban Environment by Weinuer 2007 [11] Mr. Josua Kirsch-Design of a small wind turbine for electric power generation November 2009 [12] Paul Gipe A Guide to Small and Micro Wind Systems - Wind Energy Basics [13] Erich Hau - Wind Turbines- Tata Mcgraw Hill publications [14] Luis Arribas de Paz, Flix Avia, Luis Cano, Ignacio Cruz, and Enrique Soria - Power Performance Testing of Small Wind Turbines: Experiences and findings obtained testing the Bornay1500 Inclin Neo Wind Turbine. Department of Renewable Energies CIEMAT [15] D.E.Warne- Wind Power Equipment - E. & F.N. Spon Ltd. New York.(1983) [16] Small Wind Turbine Testing Results from the National Renewable Energy Lab A. Bowen, A. Huskey, H. Link, K. Sinclair, T. Forsyth, and D. Jager National Renewable Energy Laboratory J. van Dam and J. Smith Windward Engineering. [17] Power Performance Testing IEC 61400-12-1 1stedition NWTC Joe Smith 20 October 2009.

644

You might also like

- Jurnal Airfoil PDFDocument9 pagesJurnal Airfoil PDFExsan SanjayaNo ratings yet

- Wake Effect of A WT Wind TurbulenceDocument3 pagesWake Effect of A WT Wind TurbulencejslrNo ratings yet

- Design and Analysis of A Wind TurbineDocument9 pagesDesign and Analysis of A Wind TurbinetechfiNo ratings yet

- Ijriet: Analysis of Blade Design Horizontal Axis Wind TurbineDocument6 pagesIjriet: Analysis of Blade Design Horizontal Axis Wind TurbineHarshad Pawar PatilNo ratings yet

- Overview of Wind Energy TechDocument7 pagesOverview of Wind Energy TechDeborah CrominskiNo ratings yet

- Clean Alternative Energy - Searl Effect Generators: Business PlanDocument18 pagesClean Alternative Energy - Searl Effect Generators: Business PlanFernando CastilloNo ratings yet

- Applied Superconductivity: Volume IIFrom EverandApplied Superconductivity: Volume IIVernon L. NewhouseNo ratings yet

- WHY WEG - Quality Aspects of Hydro-GeneratorsDocument57 pagesWHY WEG - Quality Aspects of Hydro-GeneratorsSridhar TholasingamNo ratings yet

- Aerodynamic Optimization and Open Field Testing of A 1 KW Vertical-Axis Wind TurbineDocument10 pagesAerodynamic Optimization and Open Field Testing of A 1 KW Vertical-Axis Wind Turbinemtl0612No ratings yet

- Experimental study of wind turbine rotor blades with wingletsDocument44 pagesExperimental study of wind turbine rotor blades with wingletsyooki147No ratings yet

- Hawt Vawt PDFDocument4 pagesHawt Vawt PDFDilipraja KolliNo ratings yet

- An Assessment of The Impact of Wind Generation On Frequency ControlDocument9 pagesAn Assessment of The Impact of Wind Generation On Frequency ControlNadil AminNo ratings yet

- 2 08 OsullivanDocument11 pages2 08 Osullivanmoro1381No ratings yet

- Hawt Power Enhancement Using Its Characteristics: Navin Kumar Kohli, Eshan AhujaDocument7 pagesHawt Power Enhancement Using Its Characteristics: Navin Kumar Kohli, Eshan AhujaGamers PocketNo ratings yet

- Benefits of Wind EnergyDocument3 pagesBenefits of Wind Energyhuma tehreemNo ratings yet

- Vision For Offshore Wind Power Industry - 1stDocument30 pagesVision For Offshore Wind Power Industry - 1stNam Hoai LeNo ratings yet

- Improved BEMDocument10 pagesImproved BEMMurali Kuna ShekaranNo ratings yet

- (2016) BEM in Wind TurbineDocument7 pages(2016) BEM in Wind Turbinearda rizkiNo ratings yet

- Lugares Machine A Centrfugal SpacecraftDocument37 pagesLugares Machine A Centrfugal SpacecraftJanai VargasNo ratings yet

- Harnessing the Power of Wind and WavesDocument14 pagesHarnessing the Power of Wind and WavesAsha D'saNo ratings yet

- Tubular Steel Sections Offer Cost Savings Over Angular SectionsDocument3 pagesTubular Steel Sections Offer Cost Savings Over Angular SectionsKripasindhu BordoloiNo ratings yet

- 249 EOW2009presentationDocument10 pages249 EOW2009presentationJACKNo ratings yet

- @hydrogen As A Renewable Energy Carrier For Commercial AircraftDocument42 pages@hydrogen As A Renewable Energy Carrier For Commercial AircraftMila BaltazarNo ratings yet

- Nuclear Energy EssayDocument7 pagesNuclear Energy EssayAlaina WeinheimerNo ratings yet

- Fuelless Generator: Comparison of Two Prototype DesignDocument6 pagesFuelless Generator: Comparison of Two Prototype DesignsardinetaNo ratings yet

- Advanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enDocument14 pagesAdvanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enclaralisieNo ratings yet

- Dynamic Shape Optimization of A Vertical-Axis Wind Turbine Via Blade Morphing Technique PDFDocument35 pagesDynamic Shape Optimization of A Vertical-Axis Wind Turbine Via Blade Morphing Technique PDFJorge Arturo Pulido PerezNo ratings yet

- Offshore Wind Turbine Dynamics in Nonlinear SoilDocument7 pagesOffshore Wind Turbine Dynamics in Nonlinear SoilMa RcoNo ratings yet

- Comparative Aerodynamic Analysis of A Missile With 8 Fin TailDocument8 pagesComparative Aerodynamic Analysis of A Missile With 8 Fin Tailtolomeo05No ratings yet

- Development of Dual-Lifting Technique For Installation of Topside Mega-ModulesDocument8 pagesDevelopment of Dual-Lifting Technique For Installation of Topside Mega-ModulesbehnamNo ratings yet

- Advanced Fusion Energy SystemDocument11 pagesAdvanced Fusion Energy SystemPhilip KadickNo ratings yet

- Hummer Dynamo Co - LTD Anhui China Hummer Wind TurbineDocument6 pagesHummer Dynamo Co - LTD Anhui China Hummer Wind TurbinefazarNo ratings yet

- Externally Fired Microturbine FlyerDocument1 pageExternally Fired Microturbine FlyerPaulFerry100% (1)

- Offshore Wind Turbine Support Structure AnalysisDocument12 pagesOffshore Wind Turbine Support Structure Analysissunil reddyNo ratings yet

- Energy and Exergy Efficiency ComparisonDocument12 pagesEnergy and Exergy Efficiency ComparisonEfrain ValleNo ratings yet

- Wind and Solar Hybrid Street Lights Rev-01-Feb-11Document28 pagesWind and Solar Hybrid Street Lights Rev-01-Feb-11TERASAT SANo ratings yet

- Eee Project ON WIND FARM FIRST YEAR B.TECHDocument10 pagesEee Project ON WIND FARM FIRST YEAR B.TECHsamarpit_anandNo ratings yet

- Dissertation FINAL PDFDocument50 pagesDissertation FINAL PDFTina MoodyNo ratings yet

- AerodynamicsDocument99 pagesAerodynamicsKarthi KeyanNo ratings yet

- Sun To Gas UAEDocument11 pagesSun To Gas UAEAnonymous YOeo7EIVurNo ratings yet

- Offshore Wind in China 2014Document38 pagesOffshore Wind in China 2014wangwen zhao100% (1)

- 2011 Design and Construction of Axial Flux Permanent Magnet Generator For Wind Turbine Generated DC Voltage at Rated Power 1500 W (Office)Document4 pages2011 Design and Construction of Axial Flux Permanent Magnet Generator For Wind Turbine Generated DC Voltage at Rated Power 1500 W (Office)Fazal Karim Mahsud100% (1)

- 1st HFGW Trip Report 2003may RevADocument7 pages1st HFGW Trip Report 2003may RevAGary V StephensonNo ratings yet

- 1 5kW Raum Energy System Specs 2009Document2 pages1 5kW Raum Energy System Specs 2009LucasZheNo ratings yet

- Homopolar MotorDocument3 pagesHomopolar MotorYashwanth SrinivasaNo ratings yet

- Tower Dynamics Damping ProjectDocument5 pagesTower Dynamics Damping ProjectreaperhellmanNo ratings yet

- Windmill: Power Generation Using Wind EnergyDocument23 pagesWindmill: Power Generation Using Wind EnergyAlok Ranjan PandeyNo ratings yet

- T. Ohji and M. Fukushima Macroporous Ceramics Processing and Properties PDFDocument17 pagesT. Ohji and M. Fukushima Macroporous Ceramics Processing and Properties PDFcris_ufrgsNo ratings yet

- Design and Analysis of Vertical Axis Wind Turbine Rotors: MD. Saddam Hussen, Dr. K. Rambabu, M. Ramji, E. SrinivasDocument9 pagesDesign and Analysis of Vertical Axis Wind Turbine Rotors: MD. Saddam Hussen, Dr. K. Rambabu, M. Ramji, E. SrinivasHaseeb UddinNo ratings yet

- On The Performance Analysis of Savonius Rotor With Twisted BladesDocument13 pagesOn The Performance Analysis of Savonius Rotor With Twisted BladesSatya PrakashNo ratings yet

- 130 Electrical Energy InnovationsDocument144 pages130 Electrical Energy InnovationsAnonymous SeVjtYNo ratings yet

- Analysis of Hybrid Systems Software ToolsDocument5 pagesAnalysis of Hybrid Systems Software ToolssoualmiaNo ratings yet

- High Voltage GenerationDocument6 pagesHigh Voltage Generationdp500100% (1)

- Offshore wind farms feasibility in PugliaDocument11 pagesOffshore wind farms feasibility in PugliaPanji NugrohoNo ratings yet

- Fracture Analysis of Wind Turbine Main Shaft PDFDocument11 pagesFracture Analysis of Wind Turbine Main Shaft PDFKaio Dos Santos SilvaNo ratings yet

- FSI Analysis and Fatigue Analysis of BOP Gantry CraneDocument6 pagesFSI Analysis and Fatigue Analysis of BOP Gantry CranePetros IosifidisNo ratings yet

- 500W vertical axis wind turbine with long service lifeDocument3 pages500W vertical axis wind turbine with long service lifeinvic7usNo ratings yet

- 1 s2.0 S026772611731182X Main PDFDocument19 pages1 s2.0 S026772611731182X Main PDFdafo407No ratings yet

- Nuclear Battery Seminar Report Prg2Document27 pagesNuclear Battery Seminar Report Prg2Shanil Pazhayapurayil50% (6)

- FlilippovDocument8 pagesFlilippovSudhanwa KulkarniNo ratings yet

- 1 s2.0 S0950705121008170 MainDocument21 pages1 s2.0 S0950705121008170 MainSudhanwa KulkarniNo ratings yet

- Mache 2014Document9 pagesMache 2014Sudhanwa KulkarniNo ratings yet

- Lathe Alignment Tests (MetrologyDocument63 pagesLathe Alignment Tests (MetrologySudhanwa KulkarniNo ratings yet

- Improving The Predictive Accuracy of Artificial Neural Network (ANN) Approach in A Mild Steel Turning OperationDocument10 pagesImproving The Predictive Accuracy of Artificial Neural Network (ANN) Approach in A Mild Steel Turning OperationSudhanwa KulkarniNo ratings yet

- Find roots using bisection, false position & Newton Raphson methodsDocument2 pagesFind roots using bisection, false position & Newton Raphson methodsSudhanwa KulkarniNo ratings yet

- Special Cases-Matrix FormulationDocument68 pagesSpecial Cases-Matrix FormulationSudhanwa KulkarniNo ratings yet

- A Jaya Algorithm Trained Neural Network For Stock Market PredictionDocument6 pagesA Jaya Algorithm Trained Neural Network For Stock Market PredictionSudhanwa KulkarniNo ratings yet

- Training MLPs Using JAYADocument6 pagesTraining MLPs Using JAYASudhanwa KulkarniNo ratings yet

- BIGM - Two PhaseDocument58 pagesBIGM - Two PhaseSudhanwa KulkarniNo ratings yet

- Machine Alignment TestDocument4 pagesMachine Alignment TestSudhanwa KulkarniNo ratings yet

- 3 Simplex ProcedureDocument38 pages3 Simplex ProcedureSudhanwa KulkarniNo ratings yet

- A Simple Formula For Large Angle PendulumDocument3 pagesA Simple Formula For Large Angle PendulumSudhanwa KulkarniNo ratings yet

- Introduction To Aluminum Alloys and TempersDocument237 pagesIntroduction To Aluminum Alloys and Temperselvis hidalgo100% (4)

- Class NotesDocument1 pageClass NotesSudhanwa KulkarniNo ratings yet

- MIT College of Engineering Numerical Methods and Optimization Question BankDocument1 pageMIT College of Engineering Numerical Methods and Optimization Question BankSudhanwa KulkarniNo ratings yet

- LinesDocument1 pageLinesSudhanwa KulkarniNo ratings yet

- MIT College of Engineering, Pune Numerical Methods and Optimization Question Bank 1 (For Week 26Document1 pageMIT College of Engineering, Pune Numerical Methods and Optimization Question Bank 1 (For Week 26Sudhanwa KulkarniNo ratings yet

- Projections of LineDocument1 pageProjections of LineSudhanwa KulkarniNo ratings yet

- Exam TimetableDocument1 pageExam TimetableSudhanwa KulkarniNo ratings yet

- Metrology and Quality ControlDocument11 pagesMetrology and Quality ControlSudhanwa KulkarniNo ratings yet

- Online Exam Time Table for Engineering StudentsDocument3 pagesOnline Exam Time Table for Engineering StudentsNavanath DarwanteNo ratings yet

- IIT Kanpur Micro Manufacturing BrochureDocument2 pagesIIT Kanpur Micro Manufacturing BrochureSudhanwa Kulkarni100% (1)

- Time Table For SE (2012) Sem II Phase II Mar 2017 Online Exam - 11!1!17Document3 pagesTime Table For SE (2012) Sem II Phase II Mar 2017 Online Exam - 11!1!17Sudhanwa KulkarniNo ratings yet

- MEASUREMENTS & CONTROLSDocument23 pagesMEASUREMENTS & CONTROLSSudhanwa KulkarniNo ratings yet

- Quantum Mechanics Chapter 2Document12 pagesQuantum Mechanics Chapter 2Archit DubeNo ratings yet

- Broucher AMET 2015 28012015-1Document2 pagesBroucher AMET 2015 28012015-1Sudhanwa KulkarniNo ratings yet

- IIT KharagpurDocument2 pagesIIT KharagpurSudhanwa KulkarniNo ratings yet

- Report WritingDocument17 pagesReport WritingSudhanwa KulkarniNo ratings yet

- Flow ChartDocument14 pagesFlow ChartSudhanwa KulkarniNo ratings yet

- User Interface DesignDocument6 pagesUser Interface DesignpoojaqNo ratings yet

- BPC BW HierarchyDocument8 pagesBPC BW HierarchyJulio RafaelNo ratings yet

- TUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILDocument4 pagesTUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILFaturrachman Nanu Rengga WisnuNo ratings yet

- Billing No. 4 Accomplishement ReportDocument1 pageBilling No. 4 Accomplishement ReportGOB ConstructionNo ratings yet

- 04 Metal and Glass-Wood PolicyDocument1 page04 Metal and Glass-Wood Policykitek100% (1)

- Coal Drying Technology and Plant DesignDocument12 pagesCoal Drying Technology and Plant DesignJigar M. UpadhyayNo ratings yet

- LAP Register To WLCDocument12 pagesLAP Register To WLCAditya NugrahaNo ratings yet

- Magic Quadrant For Identity Governance and AdministrationDocument18 pagesMagic Quadrant For Identity Governance and AdministrationmilosvblNo ratings yet

- 2.3 One Way Slab Design-SS, Cant, ContinuousDocument54 pages2.3 One Way Slab Design-SS, Cant, ContinuousAhmed SiddiqueNo ratings yet

- Direct Stiffness Method for Truss AnalysisDocument28 pagesDirect Stiffness Method for Truss Analysisgilberthufana446877No ratings yet

- PC Pump ManualDocument540 pagesPC Pump ManualtelephonicaNo ratings yet

- 9040 - User ManualDocument236 pages9040 - User ManualWallie Billingsley77% (13)

- BaaN IV VDADocument126 pagesBaaN IV VDARostane Horvath ErzsebetNo ratings yet

- Partition WallDocument24 pagesPartition WallSHRADDHA GHUGENo ratings yet

- Premiertrak 1100x650 Parts ENGDocument276 pagesPremiertrak 1100x650 Parts ENGarttv44100% (1)

- Computer Science & Engineering Department ElectivesDocument13 pagesComputer Science & Engineering Department Electivesnitro gtnaNo ratings yet

- Psan en Tcd210185ab 20220523 Inst WDocument2 pagesPsan en Tcd210185ab 20220523 Inst Wsinar automationNo ratings yet

- Updated Infra-IIVendor ListDocument22 pagesUpdated Infra-IIVendor ListabhibaikarNo ratings yet

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 pagesIbm Lenovo Whistler Rev s1.3 SCH1cvbnmNo ratings yet

- PDF Main - PsDocument34 pagesPDF Main - PsIsaiah GarciaNo ratings yet

- 2016 Popsicle Stick Bridge RulesDocument6 pages2016 Popsicle Stick Bridge RulesMahendra DewasiNo ratings yet

- Main Engine Cylinder Liner Crack: Return To TOCDocument2 pagesMain Engine Cylinder Liner Crack: Return To TOCRani NoumanNo ratings yet

- Data Acquisition Systems (DAS) in GeneralDocument3 pagesData Acquisition Systems (DAS) in GeneralArjun SinghNo ratings yet

- Remeha Gas 310 ECO: Technical InformationDocument59 pagesRemeha Gas 310 ECO: Technical InformationAdrian Blazquez MolinaNo ratings yet

- Manual WkhtmltopdfDocument5 pagesManual WkhtmltopdfGeorge DiazNo ratings yet

- DB2 WebSphere BestPracticeDocument53 pagesDB2 WebSphere BestPracticeSpeedyKazamaNo ratings yet

- R12 Period-End Procedures For Oracle Financials E-Business Suite Document 961285Document3 pagesR12 Period-End Procedures For Oracle Financials E-Business Suite Document 961285Ravi BirhmanNo ratings yet

- Elsa CableDocument2 pagesElsa CableJay WangNo ratings yet

- Inspection Checklist For Lifting Tools & TacklesDocument2 pagesInspection Checklist For Lifting Tools & Tacklesnil thaeu100% (1)

- Capitulos 10 y 11Document34 pagesCapitulos 10 y 11mlpz188669No ratings yet