Professional Documents

Culture Documents

Crude Oil Storage Tanks

Uploaded by

Kmt_AeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crude Oil Storage Tanks

Uploaded by

Kmt_AeCopyright:

Available Formats

e nggcyclo pe dia.

co m

http://www.enggcyclo pedia.co m/2011/01/crude-o il-sto rage-tanks/

Crude oil storage tanks

Crude oil untreated and unref ined are stored in tanks f or shipment to other locations or processing into f inished products. T here are f our basic types of tanks used to store petroleum products: (1) Floating Roof Tank used f or crude oil, gasoline, and naphtha. (2) Fixed Roof Tank used f or diesel, kerosene, catalytic cracker f eedstock, and residual f uel oil (3) Bullet Tank used f or normal butane, propane, and propylene (4) Spherical Tank used f or isobutane and normal butane. It is to be noted that fixed roof tanks could be used for storing low amounts of crude oil as compared to the million barrels stored in floating roof tanks. Floating roof tanks (as compared to fixed roofs) Pros and Cons Floating roof tanks are advantageous, compared to f ixed roof tanks, as it prevents vapour emissions (that are highly combustible) that help eliminate the chances of f ire or an internal tank explosion. T hey are usually used f or stable liquids (with no dynamic loads acting, as discussed later). However, adverse environmental conditions could af f ect f loating roof s as accumulation of snow and rain water could result in roof submersing in the stored liquid. Nonetheless this static load can be incorporated in making assumptions on the response of the roof , which can be f urther used in the design of the tank with a signif icant f actor of saf ety. An area of concern, although, is the dynamic loads that act upon the roof due to constant splashing of water or leaks that result in f looding of roof compartments. T his could be partly corrected by having suf f icient stif f ness in the circumf erential direction at the roof , but due to the irregular nature of such loads, it may not be possible to accurately predict its magnitude. Also, while the liquid exits the tank, the f loating roof steadily approaches the bottom leaving behind a wet shell (liquid droplets that are lef t behind as the level drops). T his results in the evaporation of liquid droplets to the atmosphere and is termed as the withdrawal loss, a f orm of emissions similar to hydrocarbon leaving the f ixed roof tanks. A f lawless rim seal (closure between the roof and the shell) could impede the loss of liquid but most seals have a loss f actor associated to them that is calculated based on tank diameter and wind blowing over the tank. Another alternative to external f loating roof s is an internal roof that combines the concept of conical f ixed roof tanks that lie on top of pontoons. T hey too are af f ected by the withdrawal and storage losses that are mitigated using similar means. Most recently, engineers have been designing f loating roof tanks with secondary seals to mitigate such emissions and prevent any seal f riction caused by using tighter seals (a simpler solution to prevent any vapours to exist) Fixed roof tanks storage During the process of storing crude oil, light hydrocarbons such as natural gas liquids, volatile organic compounds, hazardous air pollutants and some inert gases, vaporize and collect between the liquid level and the f ixed roof tanks. As the liquid level in the tank varies, these gases slowly release out to the atmosphere. A solution to prevent this f rom occurring is by installing vapour recovery units. T hese units capture the BT U-rich units f or sale or use it onsite as f uel.

Another solution could be the use of f oam chambers. T hese are designed to cover f lammable hydrocarbon or water miscible liquids with low expansion f oam or f ire extinguishment or vapour suppression. T he f oam occupies the vacant space that was initially f illed with air, one of the main sources of combustion, to prevent any potential hazards. T hey have the advantage over ground based monitors of directing all their f oam directly onto the f lammable liquid surf ace regardless of weather conditions. T he f oam generator made f oam by introducing air into a f oam solution stream that was delivered to the top pourer system (T PS) in a variety of ways. T he inlet of the T PS is f itted with a venturi jet designed to draw air into the stream through a series of holes located around the f oam generator. T he f oam solution is obtained f rom mobile f oam proportioning equipment located f ar away f rom the tank and routed back to it through pipelines.

You might also like

- Pipe Stess Static and Dynamic AnalysisDocument5 pagesPipe Stess Static and Dynamic AnalysisKmt_AeNo ratings yet

- World Class ShutdownDocument6 pagesWorld Class ShutdownKmt_AeNo ratings yet

- Heat Exchanger Fouling Mitigation TechnologyDocument5 pagesHeat Exchanger Fouling Mitigation TechnologyKmt_AeNo ratings yet

- ASME VIII Pressure Vessel MasterclassDocument6 pagesASME VIII Pressure Vessel MasterclassKmt_AeNo ratings yet

- Aerosol Adhesives LitDocument18 pagesAerosol Adhesives LitKmt_AeNo ratings yet

- API 580 and 581risk Based InspectionDocument5 pagesAPI 580 and 581risk Based InspectionKmt_Ae100% (1)

- Pressure ReliefDocument207 pagesPressure ReliefAH100% (1)

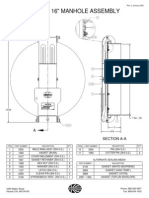

- Ld3310 16" Manhole Assembly: Rev. 0, January 2003Document1 pageLd3310 16" Manhole Assembly: Rev. 0, January 2003Kmt_AeNo ratings yet

- Catalog 2001Document10 pagesCatalog 2001Kmt_AeNo ratings yet

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocument5 pagesAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeNo ratings yet

- Corrosion Control in E&PDocument7 pagesCorrosion Control in E&PKmt_AeNo ratings yet

- Corrosion Control in Refining IndustryDocument8 pagesCorrosion Control in Refining IndustryKmt_Ae0% (1)

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocument5 pagesAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeNo ratings yet

- API 579 Fitness For ServiceDocument5 pagesAPI 579 Fitness For ServiceKmt_Ae100% (1)

- API 570 Piping InspectorDocument6 pagesAPI 570 Piping InspectorBuddharaju KiranNo ratings yet

- API 571 Damage Mechanism Affecting Fixed Refining EquipmentsDocument4 pagesAPI 571 Damage Mechanism Affecting Fixed Refining EquipmentsKmt_AeNo ratings yet

- API 510 Inspector CourseDocument6 pagesAPI 510 Inspector CourseKmt_AeNo ratings yet

- API 579 Fitness For ServiceDocument5 pagesAPI 579 Fitness For ServiceKmt_Ae100% (1)

- Acoustic and Flow Induced VibrationDocument5 pagesAcoustic and Flow Induced VibrationKmt_AeNo ratings yet

- Tema & HtriDocument5 pagesTema & HtriKmt_AeNo ratings yet

- FC Catalogue PDFDocument36 pagesFC Catalogue PDFIndra FandyNo ratings yet

- Heat Exchanger Fouling Mitigation TechnologyDocument5 pagesHeat Exchanger Fouling Mitigation TechnologyKmt_AeNo ratings yet

- z4 Coupe Roadster CatalogueDocument19 pagesz4 Coupe Roadster CatalogueKmt_AeNo ratings yet

- Aboveground Storage Tank Design Masterclass (M'Sia) - LynnDocument5 pagesAboveground Storage Tank Design Masterclass (M'Sia) - LynnKmt_AeNo ratings yet

- z4 Coupe Roadster CatalogueDocument19 pagesz4 Coupe Roadster CatalogueKmt_AeNo ratings yet

- x3 DatasheetDocument7 pagesx3 DatasheetKmt_AeNo ratings yet

- Advanced Pressure Vessels and Other Pressure EquipmentsDocument6 pagesAdvanced Pressure Vessels and Other Pressure EquipmentsKmt_AeNo ratings yet

- z4 Coupe Roadster DatasheetDocument8 pagesz4 Coupe Roadster DatasheetStephenNo ratings yet

- x5 DatasheetDocument7 pagesx5 DatasheetKmt_AeNo ratings yet

- x5 CatalogueDocument18 pagesx5 CatalogueKmt_AeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fermi DistrbutionDocument17 pagesFermi DistrbutionnazarNo ratings yet

- Nano EmulsionDocument52 pagesNano EmulsionAbdul NadeemNo ratings yet

- The Four Types of Refrigeration Systems You Need To KnowDocument2 pagesThe Four Types of Refrigeration Systems You Need To KnowtakayNo ratings yet

- B 193 - 02Document5 pagesB 193 - 02alanetn100% (1)

- Fiitjee Rit 2Document11 pagesFiitjee Rit 2Baljeet SinghNo ratings yet

- CMB Chapter 15Document32 pagesCMB Chapter 15cyorogNo ratings yet

- Powder Metallurgy Process and ApplicationsDocument32 pagesPowder Metallurgy Process and ApplicationsChandan KumarNo ratings yet

- Question Paper Applied Physics, Sem-1, BS-105Document5 pagesQuestion Paper Applied Physics, Sem-1, BS-105Kartik AgrawalNo ratings yet

- VAPOR AND COMBINED POWER CYCLESDocument9 pagesVAPOR AND COMBINED POWER CYCLESzabidullahNo ratings yet

- On Water Cycle With Unlocking of DifficultiesDocument38 pagesOn Water Cycle With Unlocking of DifficultiesShirly Basilio100% (1)

- B705 Acpt1003Document3 pagesB705 Acpt1003taya1401No ratings yet

- Stereoisomers Part 1Document14 pagesStereoisomers Part 1Mabelle DucusinNo ratings yet

- CompressorDocument27 pagesCompressorsoxal100% (1)

- 1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionDocument3 pages1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionroxanaNo ratings yet

- Modern Chemical Process SimulationDocument21 pagesModern Chemical Process SimulationWahab MaqboolNo ratings yet

- The Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFDocument452 pagesThe Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFJim Leonard100% (2)

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Document45 pagesBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraNo ratings yet

- ACRYREX® CM-211: Chi Mei CorporationDocument3 pagesACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongNo ratings yet

- Maximizing profits from heavy crude oils and reducing fuel oil productionDocument5 pagesMaximizing profits from heavy crude oils and reducing fuel oil productionsantiagoNo ratings yet

- Turton - Appb 30 37Document8 pagesTurton - Appb 30 37asadNo ratings yet

- PSA Oxygen Generator: Typical ApplicationsDocument2 pagesPSA Oxygen Generator: Typical ApplicationsRaghu Vir ArjampudiNo ratings yet

- (Re) Coating of Pylons With ZINGAENDocument5 pages(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateNo ratings yet

- Spectro RamanDocument6 pagesSpectro RamanSampada, Astrologer and Vastu Spl. SSBNo ratings yet

- Wetland Assessment in KampalaDocument9 pagesWetland Assessment in KampalaBonny OgwalNo ratings yet

- 1 Crab Meat Analog PreparationDocument4 pages1 Crab Meat Analog PreparationKizzy RennieNo ratings yet

- Week No.2 - CLO-1 Size ReductionDocument18 pagesWeek No.2 - CLO-1 Size ReductionkhalifaNo ratings yet

- Course Outline For 125:355, Physiological Systems For Biomedical EngineersDocument2 pagesCourse Outline For 125:355, Physiological Systems For Biomedical EngineersbillNo ratings yet

- Ultrasonic Gas Flowmeters For Permanent Installation in Hazardous AreasDocument31 pagesUltrasonic Gas Flowmeters For Permanent Installation in Hazardous AreasrudrakrNo ratings yet

- IEEE Xplore - SearchResultDocument4 pagesIEEE Xplore - SearchResultSalman KhanNo ratings yet

- UTP ABRADISC 6000 Offers Cost-Efficient Wear ProtectionDocument4 pagesUTP ABRADISC 6000 Offers Cost-Efficient Wear ProtectionpakhansNo ratings yet