Professional Documents

Culture Documents

Module 40A

Uploaded by

jhacademyhydOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 40A

Uploaded by

jhacademyhydCopyright:

Available Formats

Sub: Structural Engineering

Topic : Steel Structures

MODULE-40A

Connections- simple and eccentric, beamcolumn connections,

Simple Connections: there are three types of connections. 1. Riveted 2. Bolted 3. Pinned

1. Riveted:

2. Bolted:

3. Pinned:

JH ACADEMY

Page 1

Sub: Structural Engineering Patterns of riveted joints:

Topic : Steel Structures

Types of bolted joints: 1. Lap joint: The two members to be connected are overlapped and connected together. Such a joint is called lap joint. 2. Butt joint: The two members to be connected are placed end to end. Additional plate/plates provided on either one or both sides, called cover plates, are placed and are connected to main plates. If the cover plates are provided on one side, it is called single cover butt joint and if the cover plates are provided on both sides of main plates, it is called a double cover butt joint.

JH ACADEMY

Page 2

Sub: Structural Engineering

Topic : Steel Structures

JH ACADEMY

Page 3

Sub: Structural Engineering

Topic : Steel Structures

Failure of bolted joints: 1. Shear failure of bolts:

2. Bearing failure of bolt:

3. Bearing failure of plate

4. Tension failure of bolts: Bolts subjected to tension may fail at the stress area. 5. Tearing failure of plates:

6. Block shear failure:

Specification of bolted joints: Diameter of bolts: The fewer the bolts, the fewer the number of holes to be formed and less installation work. The larger diameter bolts are particularly favorable in

JH ACADEMY

Page 4

Sub: Structural Engineering

Topic : Steel Structures

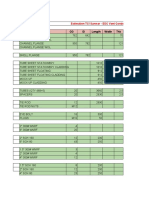

connections where shear governs because the bolt capacity in shear varies as square of bolt diameter. Spacing of bolt holes: Pitch: It is the distance between the centers of two consecutive bolts measured along a row of bolts. A row generally refers to a line of bolts placed parallel to load. Gauge: It is the distance between adjacent bolt lines. Minimum pitch: 2.5 times nominal dia of bolt. Maximum pitch: 16t or 200mm whichever is less for tension members. 12t or 200mm whichever is less for compression members. for compression members butted each other 4.5 time nominal dia of bolt 1.5 times the width of member The distance between the centers of any two consecutive bolts in a line adjacent and parallel to an edge of the outside plate should not exceed 100+4t or 200mm whichever is less. t is thickness of thinner outside plate. The distance between centers of two adjacent bolts should not exceed 32t or 300mm whichever is less. t is the thickness of thinner plate. When the bolts are staggered at equal intervals and gauge does not exceed 75mm, the spacing mentioned above may be increased by 50% subjected to maximum specified as 32t or 300mm whichever is less. Edge distance: Minimum edge distance: 1. For sheared or hard flame cut edges: 1.7 time of whole dia. 2. For rolled or machine flame cut edges: 1.5 time of hole dia Nominal size of bolt (d) 12-14 mm 16-24 mm >24 mm hole dia (D) d+1mm d+2mm d+3mm

JH ACADEMY

Page 5

Sub: Structural Engineering

Topic : Steel Structures

Maximum edge distance: 12t

where

= thickness of thinner outer plate. Shear strength of bolts: Nominal shear capacity of bolt:

= number of shear planes with threads intercepting shear planes. = number of shear planes without threats intercepting shear planes. = shear area at threads = nominal plain shank area. Design strength of the bolt Bearing strength of bolts: Nominal bearing strength of bolt = 1.25

Where e, P= end and pitch distance = diameter of hole = ultimate tensile strength of plate. Nominal dia of bolt = summation of thickness of the connected plates. Design bearing strength of bolts:

Tensile capacity of bolts: Nominal tensile capacity <

JH ACADEMY

Page 6

Sub: Structural Engineering Design tensile capacity =

Topic : Steel Structures

Combined shear and tension: ( ) ( ) = factored shear force on bolt = design shear capacity = factored tensile force on bolt = design tensile capacity Bolt strength is minimum of shear and bearing: Fillet welds: Design strength of fillet weld

Where

= effective length of weld Throat thickness 1.25 For shop welding = 1.5 for site welding = smaller of ultimate strength of weld and parent material.

Size of weld: Maximum size: -1.5mm or Minimum size: 3mm Thickness of thicker plate: 0-10mm 10-20mm 20-32mm 32-50mm 3mm 5mm 6mm 8 first run 10 for min size f weld. where t= thinner plate

JH ACADEMY

Page 7

Sub: Structural Engineering

Topic : Steel Structures

Effective throat thickness: should not be less than 3mm. should not exceed 0.7t or 1.0t under special circumstances. = size of thinner plate. Effective throat thickness= K.S s= size of weld, K=

91-100 K 0.70 0.65

101-106 0.6

107-113 0.55

114-120 0.5

Effective length of weld= L - 2S Eccentric connections: Bolted bracket connection: Type-1

= or K= Torque = = Total torque= = K

JH ACADEMY

Page 8

Sub: Structural Engineering The force F= Type:2 is maximum when distance is maximum.

Topic : Steel Structures

Which is

direct shear load

Tensile force in bolts:

or K= Moment of resistance due to tensile force in bolt = Total moment of resistance due to tensile force =K Total tensile force in the bolted connection =

For equilibrium, total compressive force C should be equal to total tensile force hence

External moment= moment resisted by bolts in tension + moment of the compressive Force. M=

JH ACADEMY

Page 9

Sub: Structural Engineering = [

Topic : Steel Structures ] ) ( ) should be checked.

and (

Welded bracket connection: Type:1

Direct shear stress= (

The shear stress due to twisting moment

where J=

Type:2

Direct shear stress = JH ACADEMY Page 10

Sub: Structural Engineering

( ( ) ) ( )

Topic : Steel Structures

Bending stress

Combined stress

JH ACADEMY

Page 11

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RankersDocument2 pagesRankersjhacademyhydNo ratings yet

- RankersDocument2 pagesRankersjhacademyhydNo ratings yet

- RankersDocument2 pagesRankersjhacademyhydNo ratings yet

- 45CDocument8 pages45Cjhacademyhyd100% (4)

- 50CDocument6 pages50Cjhacademyhyd89% (9)

- JH Academy: Gate-2014 4Th Year StudentsDocument2 pagesJH Academy: Gate-2014 4Th Year StudentsjhacademyhydNo ratings yet

- JH Academy: Gate-2014 4Th Year StudentsDocument2 pagesJH Academy: Gate-2014 4Th Year StudentsjhacademyhydNo ratings yet

- Test 5Document2 pagesTest 5jhacademyhydNo ratings yet

- 51CDocument6 pages51Cjhacademyhyd100% (5)

- TEST-6: Sub: Fluid Mechanics Module: 63-66Document2 pagesTEST-6: Sub: Fluid Mechanics Module: 63-66jhacademyhydNo ratings yet

- 1BDocument5 pages1BjhacademyhydNo ratings yet

- 43CDocument17 pages43Cjhacademyhyd100% (4)

- 44CDocument9 pages44Cjhacademyhyd100% (3)

- 3BDocument2 pages3Bjhacademyhyd100% (1)

- Module-88A: Sub: Transportation Engineering Topic: Highway PlanningDocument4 pagesModule-88A: Sub: Transportation Engineering Topic: Highway PlanningjhacademyhydNo ratings yet

- Module-74A: Sub: Water Resources Engineering Topic: Irrigation EngineeringDocument3 pagesModule-74A: Sub: Water Resources Engineering Topic: Irrigation EngineeringjhacademyhydNo ratings yet

- Module-72A: Design Of: Lined and Unlined Canals, Waterways, Head Works, Gravity Dams and SpillwaysDocument4 pagesModule-72A: Design Of: Lined and Unlined Canals, Waterways, Head Works, Gravity Dams and SpillwaysjhacademyhydNo ratings yet

- Module-55A: Sub: Water Resources Engineering Topic: Fluid Mechanics & HydraulicsDocument2 pagesModule-55A: Sub: Water Resources Engineering Topic: Fluid Mechanics & HydraulicsjhacademyhydNo ratings yet

- Module 63aDocument6 pagesModule 63ajhacademyhydNo ratings yet

- Module-73A: Sub: Water Resources Engineering Topic: Irrigation EngineeringDocument6 pagesModule-73A: Sub: Water Resources Engineering Topic: Irrigation EngineeringjhacademyhydNo ratings yet

- Module 79aDocument1 pageModule 79ajhacademyhydNo ratings yet

- Module-85A: Sub: Environmental Engineering Topic: Municipal SolidwastesDocument4 pagesModule-85A: Sub: Environmental Engineering Topic: Municipal SolidwastesjhacademyhydNo ratings yet

- Module-78A: Sewage and Sewerage Treatment, Quantity and Characteristics of WastewaterDocument4 pagesModule-78A: Sewage and Sewerage Treatment, Quantity and Characteristics of WastewaterjhacademyhydNo ratings yet

- Module-87A: Sub: Transportation Engineering Topic: Highway PlanningDocument9 pagesModule-87A: Sub: Transportation Engineering Topic: Highway PlanningjhacademyhydNo ratings yet

- Module-80A: Sub: Environmental Engineering Topic: Waste Water EngineeringDocument3 pagesModule-80A: Sub: Environmental Engineering Topic: Waste Water EngineeringjhacademyhydNo ratings yet

- Module-82A: Sub: Environmental Engineering Topic: Waste Water EngineeringDocument4 pagesModule-82A: Sub: Environmental Engineering Topic: Waste Water EngineeringjhacademyhydNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Estimation TCI Sanmar - EDC Vent Condenser Tag No E-102Document5 pagesEstimation TCI Sanmar - EDC Vent Condenser Tag No E-102Raviraj Shashikant PatilNo ratings yet

- TANCO 1400EH-2014-EnglishDocument116 pagesTANCO 1400EH-2014-EnglishErwin GerdingNo ratings yet

- Topic 5 PDFDocument16 pagesTopic 5 PDFnrhdyaaNo ratings yet

- AGCO Power Gensets Land V2Document2 pagesAGCO Power Gensets Land V2Tawfiq ZidanNo ratings yet

- Suction Pile SpecDocument33 pagesSuction Pile Specriaz16shaik100% (1)

- Gasitaly f1 Eng ManualDocument13 pagesGasitaly f1 Eng ManualSekson Junsukpluk50% (2)

- Electrification in MotorsportDocument8 pagesElectrification in Motorsportddi11No ratings yet

- Deformacao AxialDocument31 pagesDeformacao AxialANTONIONo ratings yet

- Manual Msi3 A4 en ScreenDocument8 pagesManual Msi3 A4 en ScreenVladNo ratings yet

- IES Conventional Mechanical Engineering 1987Document7 pagesIES Conventional Mechanical Engineering 1987eklavya koshtaNo ratings yet

- Mindman MVSC-300 Solenoid ValveDocument3 pagesMindman MVSC-300 Solenoid ValvecoronaqcNo ratings yet

- Heat Exchangers Designing For Super-Critical Fluid ServiceDocument6 pagesHeat Exchangers Designing For Super-Critical Fluid ServiceHsein WangNo ratings yet

- Slapdriver Interference Screwdriver SystemDocument8 pagesSlapdriver Interference Screwdriver SystemFreddy Churata SuriNo ratings yet

- Tech Spec For Centrifugal PumpDocument5 pagesTech Spec For Centrifugal PumpRoby Mirza100% (1)

- Power Plant QuestionsDocument20 pagesPower Plant QuestionsSubhransu Mohapatra50% (2)

- Turbine RepairDocument67 pagesTurbine RepairFrancisco Novoa Rodriguez50% (2)

- Bixby MaxFire HighlightsDocument6 pagesBixby MaxFire HighlightsAl Malley100% (2)

- Intergraph Caesar Course ContentDocument2 pagesIntergraph Caesar Course ContentValesh MonisNo ratings yet

- Lab Report No 6 Bs PhysicsDocument6 pagesLab Report No 6 Bs PhysicsITZ SUFYANNo ratings yet

- KR 150Document2 pagesKR 150Mindaugas RimkusNo ratings yet

- SY16 Maintenance ManualDocument148 pagesSY16 Maintenance ManualAndres SorinNo ratings yet

- ASME Boiler and Pressure Vessel Code, Section III NF, EditioDocument101 pagesASME Boiler and Pressure Vessel Code, Section III NF, EditiorazvannuNo ratings yet

- Minishover Komatsu SK820-5E0Document260 pagesMinishover Komatsu SK820-5E0Jose A. Basanta H.100% (1)

- Forging PresentationDocument17 pagesForging PresentationRakesh PuriNo ratings yet

- 6.missile DescriptionDocument31 pages6.missile DescriptionJorge Antonio Chávez MirandaNo ratings yet

- V Clic Workshop ManualDocument44 pagesV Clic Workshop ManualWG-Friend IvybridgeNo ratings yet

- Flat Wakaf Mek Zainab P1Document1 pageFlat Wakaf Mek Zainab P1Nur NaziraNo ratings yet

- Transducer: TypesDocument39 pagesTransducer: Typestujuh belasNo ratings yet

- F5ae9484 9454 AgricolaDocument150 pagesF5ae9484 9454 Agricolajvega_534120No ratings yet

- IcatDocument122 pagesIcatViraj ParmarNo ratings yet