Professional Documents

Culture Documents

DS-21-J-0026 - 2 TPCDR Approved PDF

Uploaded by

sumant.c.singh1694Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS-21-J-0026 - 2 TPCDR Approved PDF

Uploaded by

sumant.c.singh1694Copyright:

Available Formats

Technip TECHNIP KT INDIA LTD.

Clough

Project No.

Unit

Doc.

Code

Serial No.

Rev.

Page

00701

Project No.

21

Doc.

SP

Area

1545

Dis.

01

Seq. No

2

Rev.

1 /39

5700

DS

21

0026

The present document or drawing is property of TECHNIP KT INDIA LTD. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for which it is specifically furnished or outside the extent of the agreed upon right of use.

OWNER

: Oil & Natural Gas Corporation Ltd., Mumbai

CONTRACTOR : CLOUGH Engineering Limited, Australia PROJECT : G-1 & GS-15 Fields Development Project (G1-DP)

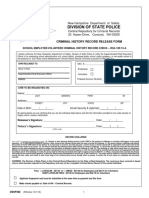

DATA SHEET FOR PRESSURE RELIEF VALVE

(ONSHORE PROCESSING TERMINAL- ODALAREVU)

CLOUGH APPROVAL LEAD ENGINEER

2 1 0 B

REV.

13-MAR-06 03-OCT-05 11-JULY-05 02-APR-05

DATE

REVISED & ISSUED FOR PURCHASE ORDER QTY & PROCESS DATA REVISED ISSUED FOR PURCHASE ISSUED FOR ENQUIRY

STATUS

P. NADKARNI S. VARMA R.SALAM G. GUPTA

WRITTEN BY (Name)

N. PUROHIT N. PUROHIT N. PUROHIT N. PUROHIT

CHECKED BY (Name)

N. PUROHIT R. SINGHAL R. SINGHAL R. SINGHAL

APPROVED BY (Name)

S KATYAL S KATYAL S KATYAL S KATYAL

PM (Name)

DOCUMENT REVISIONS Sections changed in last revision are identified by a line in the right margin

Technip TECHNIP KT INDIA LTD. Clough

Project No.

Unit

Doc.

Code

Serial

Rev.

Page

00701

Project No.

21

Doc.

SP

Area

1545

Dis.

01

Seq. No.

2

Rev.

2/39

5700

DS

21

0026

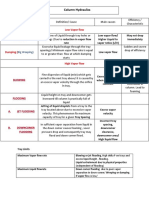

DATASHEET FOR PRESSURE RELIEF VALVE

SR 1

The present document or drawing is property of TECHNIP KT INDIA LTD. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for which it is specifically furnished or outside the extent of the agreed upon right of use.

TAG NO

21-PSV-2000A 21-PSV-2000B 21-PSV-2001A 21-PSV-2001B 21-PSV-2002A 21-PSV-2002B 21-PSV-3020 21-PSV-3021 21-PSV-3012 21-PSV-3017 21-PSV-5000 21-PSV-5001 21-PSV-5002 21-PSV-5003 21-PSV-5004 21-PSV-5005 21-PSV-5006 21-PSV-4001 21-PSV-4000 21-PSV-2011 21-PSV-2012 21-PSV-2003 21-PSV-3006 21-PSV-2006 21-PSV-2402 21-PSV-2403 21-PSV-5011

REV B B B B B B B B B B B B B B B B B B B B B B B 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

SR 28 29 30 31 32 33 34 35 36

TAG NO

21-PSV-5012 21-PVSV-3003 21-PVSV-8030 21-PVSV-3004 21-PVSV-3005 21-PSV-2500 21-PSE-3000 21-PSE-3001 21-PSE-3002

REV 0 0 0 0 0 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

1 1 1 1

2 2

1 1

1 1 2

In general following notes shall be applicable for all the safety valve tag nos.

OWNER CONTRACTOR PROJECT : : : Oil & Natural Gas Corporation Limited, Mumbai CLOUGH Engineering Limited, Australia G-1 & GS-15 Fields Development Project (G1-DP)

Technip TECHNIP KT INDIA LTD. Clough

Project No.

Unit

Doc.

Code

Serial

Rev.

Page

00701

Project No.

21

Doc.

SP

Area

1545

Dis.

01

Seq. No.

2

Rev.

3/39

5700

DS

21

0026

DATASHEET FOR PRESSURE RELIEF VALVE

1. Calculation and sizing shown in enclosed datasheets are for governing cases only. Offered safety valves meet the calculations for all the cases specified in process data sheets.

The present document or drawing is property of TECHNIP KT INDIA LTD. and shall not, under any circumstances, be totally or partially, directly or indirectly, transferred, reproduced, copied, disclosed or used, without its prior written consent, for any purpose and in any way other than that for which it is specifically furnished or outside the extent of the agreed upon right of use.

2. Bidder shall be responsible for correct sizing and selection of safety relief valves. 3. Bolt and Nut material shall be A 193 Gr. B7 / A 194 Gr. 2H Fluorocarbon coated. 4. Painting shall be suitable for salt laden marine environment. 5. For Safety Relief Valves sizing, Refer process data sheet Doc. No. 5700-DS-21-P-0056. 6. For Breather Valve sizing, Refer Process Data Doc. No. 5700-DS-21-P-0082. 7. For Blow Hatch sizing, Refer Process Data Doc. No. 5700-DS-21-P-0086. 8. Process data revised. Vendor to recheck and confirm sizing for applicable tag nos.

OWNER CONTRACTOR PROJECT

: : :

Oil & Natural Gas Corporation Limited, Mumbai CLOUGH Engineering Limited, Australia G-1 & GS-15 Fields Development Project (G1-DP)

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2000A SLUG CATCHER SC-01A 8-PG-2019-A1A-IE Full Safety-Relief Bellows Bellows (Vent) 1005 HYDROCARBON 37882 kg/h 29.33 4.5 kgf/cm-g C 3 kgf/cm-g kgf/cm-g 21 1. 50 1.098

CASE-2 SC-01A

Gas/Vapor

18 487

kgf/cm-g C

Btu IT/lb kg/m cP

59 M API Gas Expansion 4.866 6.38 P in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

4 in Inlet 300# X outlet 150# SA 216 WCB SS316 (Nozzle) SS316 (Disc) Tungsten Alloy SS316L

6 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 4P6H321162/D

Notes: 1. The pressure relief valve has been sized for two cases (Fire and Blocked Outlet) as indicated in process datasheets.

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 4 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2000B SLUG CATCHER SC-01 A 8-PG-2019-A1A-IE Full Safety-Relief Bellows Bellows (Vent) 1005 HYDROCARBON 37882 kg/h 29.33 4.5 kgf/cm-g C 3 kgf/cm-g kgf/cm-g 21 1. 50 1.098

CASE-2 SC-01A

Gas/Vapor

18 487

kgf/cm-g C

Btu IT/lb kg/m cP

59 M API Gas Expansion 4.866 6.38 P in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

4 in Inlet 300 # X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy SS 316L

6 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 4P6H321162/D

Notes: 1. The pressure relief valve has been sized for two cases (Fire and Blocked Outlet) as indicated in process datasheets.

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 5 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2001A CASE-2 SLUG CATCHER SC-01 B VENT TO FLARE SYSTEM 8-PG-2021-A1A-IE SC-01B Full Safety-Relief Bellows Bellows (Vent) 1006 HYDROCARBON Gas/Vapor 37882 kg/h 29.33 4.5 kgf/cm-g 18 kgf/cm-g C 487 C 3 kgf/cm-g kgf/cm-g 21 1. 50 1.098

Btu IT/lb kg/m cP

59 M2 API Gas Expansion 4.866 6.38 P in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

4 in inlet 300# x outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy SS 316L

6 RF

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 4P6H321162/D

Notes: 1. The pressure relief valve has been sized for two cases (Fire and Blocked Outlet) as indicated in process datasheets.

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 6 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fired Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2001B Slug Catcher SC-01 B 8-PG-2021-A1A-IE Full Safety-Relief Bellows Bellows (Vent) 1006 HYDROCARBON 37882 kg/h 29.33 4.5 kgf/cm-g C 3 kgf/cm-g kgf/cm-g 21 1. 50 1.098

CASE-2 SC-01B

Gas/Vapor

18 487

kgf/cm-g C

Btu IT/lb kg/m cP

59 M2 API Gas Expansion 4.866 6.38 P in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

4 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy SS 316L

6 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 4P6H321162/D

Notes: 1. The pressure relief valve has been sized for two cases (Fire and Blocked Outlet) as indicated in process datasheets.

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR ORDER ISSUED FOR ENQUIRY Revision Sheet 7 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2002A SLUG CATCHER SC-01C 8-PG-2023-A1A-IE Full Safety-Relief Bellows Bellows (Vent) 1007 HYDROCARBON 37882 kg/h 29.09 4.5 kgf/cm-g C 3 kgf/cm-g kgf/cm-g 21 1. 50 1.098

CASE-2 SC-01C

Gas/Vapor

18 487

kgf/cm-g C

Btu IT/lb kg/m cP

59 M2 API Gas Expansion 4.866 6.38 P in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

4 in Inlet 300# x Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy SS 316L

6 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 4P6H321162/D

Notes: 1. The pressure relief valve has been sized for two cases (Fire and Blocked Outlet) as indicated in process datasheets.

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 8 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2002B CASE-2 PROCESS GAS FROM SC-01 C TO FLARE SYSTEM 8-PG-2023-A1A-IE SC-01C Full Safety-Relief Bellows Bellows (Vent) 1007 HYDROCARBON Gas/Vapor 37882 kg/h 29.09 4.5 kgf/cm-g 18 kgf/cm-g C 487 C 3 kgf/cm-g kgf/cm-g 21 1. 50 1.098

Btu IT/lb kg/m cP

59 M2 API Gas Expansion 4.866 6.38 P in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

4 in Inlet 300# x Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy SS 316L

6 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 4P6H321162/D

Notes: 1. The pressure relief valve has been sized for two cases (Fire and Blocked Outlet) as indicated in process datasheets.

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR ORDER ISSUED FOR ENQUIRY Revision Sheet 9 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

GENERAL

PROCESS CONDITIONS

BASIS AND SELECTION

CONNECTIONS

MATERIALS

OPTIONS

PURCHASE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -3020 Multiphase Separator MS-01 A 6-GS-3112-A1A Full Safety-Relief Conventional Closed 1010 HYDROCARBON 32054 kg/h 95.36 3 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 0.833 50 1.077

MS-01 A

Gas/Vapor

18 340.9

kgf/cm-g C

Btu IT/lb kg/m cP

48.14 M API Gas Expansion 2.142 2.853 L in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

3 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

4 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 3L4H421162/D 5700-5055

Notes: DELTED.

INSTRUMENT SPECIFICATION 1 SNV 0 RFS B GTG No. By 10/3/2005 11/7/2005 2/4/2005 Date REVISED ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Pressure Relief Valve Sheet 10 Dwg. No.: 00701-21-SP-1545-01 of 39 Rev.: 1

Code: 85

GENERAL

PROCESS CONDITIONS

BASIS AND SELECTION

CONNECTIONS

MATERIALS

OPTIONS

PURCHASE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -3021 Multiphase Separator MS-01 B 6-GS-3114-A1A Full Safety-Relief Conventional Closed 1011 Hydrocarbon 32054 kg/h 95.36 3 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 0.833 50 1.077

MS-01B

Gas/Vapor

18 340.9

kgf/cm-g C

Btu IT/lb kg/m cP

48.14 M API Gas Expansion 2.142 2.853 L in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

3 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

4 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 3L4H421162/D 5700-5055

Notes: DELETED.

INSTRUMENT SPECIFICATION 1 SNV 0 RFS B GTG No. By 10/3/2005 11/7/2005 2/4/2005 Date REVISED ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Pressure Relief Valve Sheet 11 Dwg. No.: 00701-21-SP-1545-01 of 39 Rev.: 1

Code: 85

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -3012 MULTIPHASE SEPARATOR MS-02A 4-GS-3116-A1A MS-02 A Full Safety-Relief Bellows 1012 Hydrocarbon 32054 138.7 8.3 1.7

Gas/Vapor kg/h kgf/cm-g C kgf/cm-g kgf/cm-g 16 397.7 kgf/cm-g C

21 0.706 50 1.105

Btu IT/lb kg/m cP

48.14 M API Gas Expansion 2.066 2.853 L in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

3 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

4 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 5700-5055

Notes: 1. Set pressure and type of valve (row no. 6, 12, 30, 31 & 32 ) has been revised, vendor to supply pressure relief valve in accordance with above data. 2. Model no. to be confirmed by vendor.

PDN 2 PDN 1 RFS 0 GTG B No. By

3/13/2006 3/10/2005 11/7/2005 2/4/2005 Date

INSTRUMENT SPECIFICATION REVISED AND ISSUED FOR PURCHASE Revised for purchase Pressure Relief Valve ISSUED FOR PURCHASE Sheet 12 ISSUED FOR ENQUIRY Revision Code: 85 Dwg. No.: 00701-21-SP-1545-01

of 39 Rev.: 2

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -3017 MULTIPHASE SEPARATOR MS-02 B 4-GS-3118-A1A MS-02 B Full Safety-Relief Bellows Closed 1013 Hydrocarbon Gas/Vapor 32054 kg/h 138.7 0.3 kgf/cm-g 16 C 397.7 1.7 kgf/cm-g kgf/cm-g 21 0.706 50 1.105

kgf/cm-g C

Btu IT/lb kg/m cP

48.14 M API Gas Expansion 2.066 2.853 L in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

3 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

4 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 5700-5055

Notes: 1. Set pressure and type of valve (row no. 6, 12, 30, 31 & 32 ) has been revised, vendor to supply pressure relief valve in accordance with above data. 2. Model no. to be confirmed by vendor.

PDN 2 PDN 1 RFS 0 GTG B No. By

3/13/2006 3/10/2000 11/7/2005 2/4/2005 Date

REVISED ISSUED FOR PURCHASE Revised for Purchase ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision

INSTRUMENT SPECIFICATION Pressure Relief Valve Sheet 13 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -5000 Scrubber SCR-01 2-PG-2208-A1A Full Safety-Relief Conventional Closed 1015 Hydrocarbon 488 kg/h 17.03 4.5 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 1.01 kcal IT/kg 1.141 kg/m cP 15.13 M API Gas Expansion 0.0838 0.11 D in in

SCR-01 A

Gas/Vapor

18 537.7

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 600# X Outlet 150# 1/2% MOLY-C.S. SA 217 WC6 SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H431862/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 14 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -5001 Scrubber SCR-01 B 2-PG-2209-A1A Full Safety-Relief Conventional Closed 1015 Hydrocarbon 488 kg/h 17.03 4.5 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 1.01 kcal IT/kg 1.41 kg/m cP 15.13 M API Gas Expansion 0.0838 0.11 D in in

SCR-01 B

Gas/Vapor

18 537.7

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 600# X Outlet 150# 1/2% MOLY-C.S. SA 217 WC6 SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H431862/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 15 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Exposed Fire Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -5002 Scrubber SCR-01 C 2-PG-2210-A1A Full Safety-Relief Conventional Closed 1015 Hydorcarbon 488 kg/h 17.03 4.5 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 1.01 kcal IT/kg 1.41 kg/m cP 15.13 M API Gas Expansion 0.0838 0.11 D in in

SCR-01 C

Gas/Vapor

18 537.7

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 600# X Outlet 150# 1/2% MOLY C.S. SA 217 WC6 SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H431862/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 16 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -5003 Coalescent Filter CF-01 3-GS-2330-A1A Full Safety-Relief Conventional Closed 1016 Hydrocarbon 1281 kg/h 17.03 4.5 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 1.01 kcal IT/kg 1.41 kg/m cP 39.7 M API Gas Expansion 0.2201 0.307 F in in

CF-01 A

Gas/Vapor

18 537.7

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1.5 in Inlet 600# X Outlet 150# 1/2% MOLY C.S. SA 217 WC6 SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1.5F2H431862/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 17 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -5004 Coalescent Filter CF-01 B 3-GS-2331-A1A Full Safety-Relief Conventional Closed 1016 Hydrocarbon 1281 kg/h 17.03 4.5 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 1.01 kcal IT/kg 1.41 kg/m cP 39.7 M

CF-01 B

Gas/Vapor

18 537.7

kgf/cm-g C

Gas Expansion 0.2201 0.307 F in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1.5 in Inlet 600# X Outlet 150# 1/2% MOLY C.S. SA 217 WC6 SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1.5F2H431862/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 18 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

GENERAL

PROCESS CONDITIONS

BASIS AND SELECTION

CONNECTIONS

MATERIALS

OPTIONS

PURCHASE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -5005 Coalescent Filter CF-02 A 2-GS-2446-A1D Full Safety-Relief Conventional Closed 1052 Hydrocarbon 2519 kg/h 17.03 67 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 0.967 kcal IT/kg 1.326 kg/m cP 12.5 M API Gas Expansion 0.0533 0.11 D in in

CF-02 A

Gas/Vapor

73.7 155

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 600# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) C.S. Aluminium coated

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H4311A2/D 5700-5055

Notes: 1. CAPACITY AND FIRE EXPOSED AREA REVISED. VENDOR TO CHECK AND CONFIRM SIZING & SUITABILITY OF OFFERED MODEL.

INSTRUMENT SPECIFICATION 1 SNV 0 RFS B GTG No. By 10/3/2005 11/7/2005 2/4/2005 Date REVISED ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Pressure Relief Valve Sheet 19 00701-21-SP-1545-01 of 39 Rev.: 1

Code: 85

Dwg. No.:

GENERAL

PROCESS CONDITIONS

BASIS AND SELECTION

CONNECTIONS

MATERIALS

OPTIONS

PURCHASE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -5006 Coalescent Filter CF-02 B 2-GS-2448-A1D Full Safety-Relief Conventional Closed 1052 Hydrocarbon 2519 kg/h 17.03 67 kgf/cm-g C 1.7 kgf/cm-g kgf/cm-g 21 0.967 kcal IT/kg 1.326 kg/m cP 12.5 M API Gas Expansion 0.0533 0.11 D in in

CF-02 B

Gas/Vapor

73.7 155

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 600# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) C.S. Aluminium coated

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H4311A2/D 5700-5055

Notes: CAPACITY AND FIRE EXPOSED AREA REVISED. VENDOR CHECK AND CONFIRM SIZING & SUITABILITY OF OFFERED MODEL.

INSTRUMENT SPECIFICATION 1 SNV 0 RFS B GTG No. By 10/3/2005 11/7/2005 2/4/2005 Date REVISED ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Pressure Relief Valve Sheet 20 Dwg. No.: 00701-21-SP-1545-01 of 39 Rev.: 1

Code: 85

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -4001 INSTRUMENT AIR TANK AT-01 TO ATMOSPHERE 2-IA-7006-A4A AT-01 Full Safety-Relief Conventional Closed 1024 AIR Gas/Vapor 1392 kg/h 28.95 12 kgf/cm-g 15 kgf/cm-g C 202 C kgf/cm-g kgf/cm-g 21 1 kcal IT/kg 1.4 kg/m cP 14.9 M API Gas Expansion 0.1762 0.196 E in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) CS Aluminium coated

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1E2H4211A2/D

Notes: 1. Constant Back pressure is Atmospheric

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 21 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -4000 UTILITY AIR TANK AT-02 TO ATMOSPHRE 2-UA-7005-A4A AT-02 Full Safety-Relief Conventional Closed 1024 AIR Gas/Vapor 4522 kg/h 28.95 12 kgf/cm-g 15 C 202 kgf/cm-g kgf/cm-g 21 1 Btu IT/lb 1.4 kg/m cP 48.4 M API Gas Expansion 0.5723 0.785 H in in

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1.5 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) CS Aluminium coated

3 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1.5H3H4211A2/D

Notes: 1. Constant Back pressure is Atmospheric

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 22 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSV -2011 SCRAPER TRAP ST-01 VENT TO FLARE SYSTEM 2-PL-2032-A2G ST-01 Full Safety-Relief Conventional Closed 1003 HYDROCARBON Gas/Vapor kg/h kgf/cm-g C kgf/cm-g kgf/cm-g 260 38 kgf/cm-g C

1.7

21

kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Gas Expansion

0.11 D

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1.5 in Inlet 2500# X 300# SA 216 WCB SS 316 Stellited (Nozzle) SS 316 Stellited (Disc) Tungsten Alloy

3 in Inlet RTJ x Outlet RF

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1.5D3/482165/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 23 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSV -2012 SCRAPER TRAP ST-02 VENT TO FLARE SYSTEM 2-PL-2039-A2F ST-02 Full Safety-Relief Conventional Closed 1003 HYDROCARBON Gas/Vapor kg/h kgf/cm-g C kgf/cm-g kgf/cm-g 260 38 kgf/cm-g C

1.7

21

kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Gas Expansion

0.11 D

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1.5 in Inlet 2500# X 300# SA 216 WCB SS 316 Stellited (Nozzle) SS 316 Stellited (Disc) Tungsten Alloy

3 in Inlet RTJ x Outlet RF

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1.5D3/482165/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 24 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2003 INLET OIL TANK TK-01 TO FLARE SYSTEM 4-PG-2041-A1A TK-01 Full Safety-Relief Bellows Bellows (Vent) 1008 HYDROCARBON Gas/Vapor 12656 kg/h 96.16 1 kgf/cm-g 18 C 342.2 3 kgf/cm-g kgf/cm-g 21 0.831 50 1.077

kgf/cm-g C

Btu IT/lb kg/m cP

15.49 M API Gas Expansion 0.8877 1.287 J in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

2 in Inlet 300# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) CS Aluminium coated SS 316L

3 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 2J3H321162/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR ORDER ISSUED FOR ENQUIRY Revision Sheet 25 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54 Notes:

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSV -3006 SCRAPER TRAP ST-03 TO OIL STORAGE TANK 2-OL-4104-A2D ST-03 Full Safety-Relief Conventional Closed 1021 HYDROCARBON Gas/Vapor kg/h kgf/cm-g C kgf/cm-g kgf/cm-g 52 kgf/cm-g C

1.7

21

kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Gas Expansion

0.11 D

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 600# X Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) CS Aluminium coated

2 Raised Face

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H4311A2/D

INSTRUMENT SPECIFICATION Pressure Relief Valve RFS 0 GTG B No. By 11/7/2005 2/4/2005 Date ISSUED FOR PURCHASE ISSUED FOR ENQUIRY Revision Sheet 26 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSV -2006 FROM TK-01 TO E-01 2-OW-3028-A2A-IE Thermal Relief

1008 Hydrocarbon 1.1 5.3 6

Liquid Nm/h kgf/cm-g C kgf/cm-g kgf/cm-g 18 80 kgf/cm-g C

kcal IT/kg 740.3 kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Liquid Filled Vessel 0.0167 0.169 in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

0.75 in NPTF X NPTF SA216 WCB SS 3316 (Nozzle) SS 316 (Disc) CS Aluminium coated

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 7D/2DF1A2/BDR

Notes: 1. Thermal Relief valve shall be Balanced pistion type.

INSTRUMENT SPECIFICATION Pressure Relief Valve 0 No. RFS By 11/7/2005 Date ISSUED FOR PURCHASE Revision Sheet 27 00701-21-SP-1545-01 of 39 Rev.: 0

Code: 85

Dwg. No.:

GENERAL

PROCESS CONDITIONS

BASIS AND SELECTION

CONNECTIONS

MATERIALS

OPTIONS

PURCHASE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2402 AT CF-03 A 1-GS-3512-A1A Full Safety-Relief Conventional Closed 1025 HYDROCARBON 35 kg/h 19.47 1.6 kgf/cm-g C 0.3 kgf/cm-g kgf/cm-g 21 1 kcal IT/kg 1.147 kg/m cP 1.91 M2 API Gas Expansion 0.1069 0.11 D in in

CF-03 A

Gas/Vapor

3.5 413.3

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 150# x Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

2 RF

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H411162/D 5700-5055

Notes: 1. CAPACITY REVISED. VENDOR TO CHECK AND CONFIRM SIZING AND SUITABILITY OF OFFERED MODEL.

INSTRUMENT SPECIFICATION Pressure Relief Valve 1 SNV 0 RFS No. By 10/3/2005 11/7/2005 Date REVISED ISSUED FOR PURCHASE Revision Sheet 28 Dwg. No.: 00701-21-SP-1545-01 of 39 Rev.: 1

Code: 85

GENERAL

PROCESS CONDITIONS

BASIS AND SELECTION

CONNECTIONS

MATERIALS

OPTIONS

PURCHASE

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure Fire Exposed Area Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

21-PSV -2403 AT CF-03 B 1-GS-3513-A1A Full Safety-Relief Conventional Closed 1025 HC 35 kg/h 19.47 1.6 kgf/cm-g C 0.3 kgf/cm-g kgf/cm-g 21 1 kcal IT/kg 1.147 kg/m cP 1.91 M2 API Gas Expansion 0.0094 0.11 D in in

Gas/Vapor

3.5 413.3

kgf/cm-g C

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1 in Inlet 150# x Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) Tungsten Alloy

2 RF

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1D2H411162/D 5700-5055

Notes: 1. CAPACITY REVISED. VENDOR TO CHECK & CONFIRM SIZING AND SUITABILITY OF OFFERED MODEL.

INSTRUMENT SPECIFICATION Pressure Relief Valve 1 SNV 0 RFS No. By 10/3/2005 11/7/2005 Date REVISED ISSUED FOR PURCHASE Revision Sheet 29 Dwg. No.: 00701-21-SP-1545-01 of 39 Rev.: 1

Code: 85

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSV -5011 PCV DISCHARGE LINE FLARE STACK 1-EG-5016-A1D Full Safety-Relief Conventional Closed 1032 HYDROCARBON Gas/Vapor 4566 kg/h 17.03 66.8 kgf/cm-g 19.3 C 50 1.7 kgf/cm-g kgf/cm-g 10 0.293 kcal IT/kg 1.47 kg/m cP

kgf/cm-g C

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Blocked Flow 0.2849 0.307 F in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1.5 in Inlet 600# x 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) CS Aluminium coated

2 RF

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1.5F2H4311A2/D 5700-5055

Notes: 1. Flow data is changed to 4566 Kg/hr. Therefore orifice designation and inlet/outlet size has been revised. Vendor to confirm the same as per revised process data. Also changed model no. to be furnished.

INSTRUMENT SPECIFICATION 2 1 0 No. PDN PDN RFS By 3/13/2006 10/3/2005 11/7/2005 Date ISUUED FOR PURCHASE ISSUED FOR PURCHASE ISSUED FOR PURCHASE Revision Pressure Relief Valve Sheet 30 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSV -5012 PCV DISCHARGE LINE FLARE STACK 1-EG-5017-A1D Full Safety-Relief Conventional Closed 1032 Hydrocarbon Gas/Vapor 4636 kg/h 21.69 60 kgf/cm-g 19.3 C 50 1.7 kgf/cm-g kgf/cm-g 10 0.306 kcal IT/kg 1.47 55.32 kg/m cP

kgf/cm-g C

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Blocked Flow 0.2619 0.307 F in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

1.5 in Inlet 600# x Outlet 150# SA 216 WCB SS 316 (Nozzle) SS 316 (Disc) CS Aluminium coated

2 RF

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 1.5F2H4311A2/D 5700-5055

Notes: 1. Flow data is changed to 4566 Kg/hr. Therefore orifice designation and inlet/outlet size has been revised. Vendor to confirm the same as per revised process data. Also changed model no. to be furnished.

INSTRUMENT SPECIFICATION 2 1 0 No. PDN PDN RFS By 3/13/2006 10/3/2005 11/7/2005 Date ISSUED FOR PURCHASE ISSUED FOR PURCHASE ISSUED FOR PURCHASE Revision Pressure Relief Valve Sheet 31 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PVSV -3003 OIL STORAGE TANK TK-03 VENT TO SAFE LOCATION TK-03 Breather Valve

1019 Stabilised Oil

Liquid

-0.0027 61 C

kgf/cm-g C

Over pressure setting 0.034 Kg/cm2g kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

Liquid Filled Vessel

729.8

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows Diaphragm

Outlet Facing

12 in Inlet 150# x Outlet 150# CS - SA216WCB SS316L (Seat) SS316L (Trim - Internals)

12 RF

in

PTFE

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag Flame Arrestor Manufacturer Model Purchase Order Number Price Item Number Serial Number

AMAL make, model LIR/300/LF/600/19/80, CS Housing SS316L element MARVAC LIR/300/LF/600/19/80 5700-5055

Notes: 1. Therm. Out / In breathing flow rate 544.1/ 891.6 Sm3/hr 2. Total Out/In breathing flow rate is 640 / 1161 Sm3/Hr 3. Filling flow rate(max.) 90 m3/Hr, Pump out flow rate (max.) 270 m3/hr 4. Set pressure and process data is revised. Vendor to check and confirm sizing & suitability of offered model.

INSTRUMENT SPECIFICATION PDN 2 SNV 1 RFS 0 No. By 3/13/2006 10/3/2005 11/7/2005 Date ISSUED FOR PURCHASE REVISED ISSUED FOR PURCHASE Revision Pressure Relief Valve Sheet 32 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PVSV -8030 AT TK-13 TK-33 Breather Valve

1036 Methanol

Liquid

-0.0027 C

kgf/cm-g C

Over pressure setting 0.0455 Kg/cm2g kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

Liquid Filled Vessel

45.61

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows Diaphragm

Outlet Facing

3 in Inlet 150# x Outlet 150# CS - SA216 WCB SS316L (Seat) SS316L (Trim - Internals)

3 RF

in

PTFE

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag Flame Arrestor Manufacturer Model Purchase Order Number Price Item Number Serial Number

AMAL make, model LIR/80/LF/150/19/80, CS Housing SS316L element MARVAC LIR/80/LF/150/19/80 5700-5055

Notes: 1. Therm. Out / In breathing flow rate 31.4 Sm3/hr 2. Total Out/In breathing flow rate is 53 / 32 Sm3/Hr. 3. Filling flow rate(max.) 10 m3/Hr, Pump out flow rate 0.7m3/hr, Normal Temperature is Ambient (47.2 Max) 4. Set pressure is revised. Vendor to check and confirm sizing & suitability of offered model.

INSTRUMENT SPECIFICATION PDN 2 SNV 1 RFS 0 No. By 3/13/2006 10/3/2005 11/7/2005 Date ISSUED FOR PURCHASE REVISED ISSUED FOR PURCHASE Revision Pressure Relief Valve Sheet 33 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PVSV -3004 EXISTING OIL STORAGE TANK VENT TO SAFE LOCATION

Breather Valve

1019 Stabilised Oil

Liquid

-0.0027 61 C

kgf/cm-g C

Over Pressure 0.0167 Kg/cm2g kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

Liquid Filled Vessel

324.3

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows Diaphragm

Outlet Facing

8 in Inlet 150# x Outlet 150# CS - SA216WCB SS316L (Seat) SS316L (Trim - Internals)

8 RF

in

PTFE

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag AMAL make, model LIR/200/LF/400/19/80, CS Housing SS316L element MARVAC LIR/200/LF/400/19/80 5700-5055

Manufacturer Model Purchase Order Number Price Item Number Serial Number

Notes: 1. Therm. Out / In breathing flow rate 113.4/ 189 Sm3/hr 2. Total Out/In breathing flow rate is 210 / 279 Sm3/Hr 3. Filling flow rate(max.) 90 m3/Hr, Pump out flow rate (max.) 90 m3/hr 4. Set pressure and process data revised. Vendor to check and confirm sizing & suitability of offered model.

INSTRUMENT SPECIFICATION PDN 2 SNV 1 RFS 0 No. By 3/13/2006 10/3/2005 11/7/2005 Date ISSUED FOR PURCHASE REVISED ISSUED FOR PURCHASE Revision Pressure Relief Valve Sheet 34 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PVSV -3005 EXISTING OIL STORAGE TANK VENT TO SAFE LOCATION

Breather Valve

1019 Stabilised Oil

Liquid

-0.0027 61 C

kgf/cm-g C

Over Pressure 0.0167 Kg/cm2g kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

Liquid Filled Vessel

324.3

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows Diaphragm

Outlet Facing

8 in Inlet 150# x Outlet 150# CS - SA216WCB SS316L (Seat) SS316L (Trim - Internals)

8 RF

in

PTFE

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag AMAL make, model LIR/200/LF/400/19/80, CS Housing SS316L element MARVAC LIR/200/LF/400/19/80 5700-5055

Manufacturer Model Purchase Order Number Price Item Number Serial Number

Notes: 1. Therm. Out / In breathing flow rate 113.4/ 189 Sm3/hr 2. Total Out/In breathing flow rate is 210 / 279 Sm3/Hr 3. Filling flow rate(max.) 90 m3/Hr, Pump out flow rate (max.) 90 m3/hr 4. Set pressure and process data revised. Vendor to check sizing & suitability of offered model.

INSTRUMENT SPECIFICATION PDN 2 SNV 1 RFS 0 No. By 3/13/2006 10/3/2005 11/7/2005 Date ISSUED FOR PURCHASE REVISED ISSUED FOR PURCHASE Revision Pressure Relief Valve Sheet 35 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSV -2500 E-03 OUTLET TO CHILLED WATER TANK 6-WC-5109-A3A-IC Full Relief Conventional Closed 1051 CHILLED WATER Liquid 0.129 Nm/h 5 1.033 kgf/cm-g C kgf/cm-g kgf/cm-g 8 50 kgf/cm-g C

10

kcal IT/kg 987. 0.55 kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Blocked Flow: THERMAL EXPANSION 0.0026 0.11 in in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

0.75 in NPT X NPT SA216 WCB SS316 (NOZZLE) SS316 (DISC) CS ALUMINIUM COATED

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Screwed No

Manufacturer Model Purchase Order Number Price Item Number Serial Number

BAILEY BIRKETT 2C/2DF1A2/D 5700-5055

Notes: 1. NEW ADDITION FOR DEW POINT PACKAGE. 2. VENDOR TO FURNISH AND CONFIRM SIZING CALCULATIONS.

INSTRUMENT SPECIFICATION Pressure Relief Valve PDN 2 SNV 1 No. By 3/13/2006 10/3/2005 Date ISSUED FOR PURCHASE ISSUED FOR PURCHASE Revision Sheet 36 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSE -3000 TK-03 OIL STORAGE TANK TK-03 Blow Hatch

1019 Stabilised Oil 120858 1.033 61

Liquid Nm/h kgf/cm-g C 0.0406 kgf/cm-g C

kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Liquid Filled Vessel

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

24 150# A216 WCB SS316 SS316 SS316

in

24

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Manufacturer Model Purchase Order Number Price Item Number Serial Number

MARVAC 785-Manway 5700-5055

Notes: 1. New Addition. Vendor to select and size the blowhatch. Calculations to be furnished. 2. * indicates vendor to furnish. 3. Boiling point 64.5C at relieving pressure. Flash point 48.05C. Tank capacity 5000 M3.

INSTRUMENT SPECIFICATION Pressure Relief Valve PDN 2 SNV 1 No. By 3/13/2006 10/3/2005 Date ISSUED FOR PURCHASE ISSUED FOR PURCHASE Revision Sheet 37 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSE -3001 EXISTING OIL STORAGE TANK

Blow Hatch

1019 Stabilised Oil 120410 1.033 61

Liquid Nm/h kgf/cm-g C 0.022 kgf/cm-g C

kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Liquid Filled Vessel

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

24 150# A216 WCB SS316 SS316 SS316

in

24

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Manufacturer Model Purchase Order Number Price Item Number Serial Number

MARVAC 785-Manway 5700-5055

Notes: 1. New Addition. Vendor to select and size the blowhatch. Calculations to be furnished. 2. * indicates vendor to furnish. 3. Boiling point 62C at relieving pressure. Flash point 48.05C. Existing Oil Tank capacity 1000 m3.

INSTRUMENT SPECIFICATION Pressure Relief Valve PDN 2 SNV 1 No. By 3/13/2006 10/3/2005 Date ISSUED FOR PURCHASE ISSUED FOR PURCHASE Revision Sheet 38 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

1 2 3 GENERAL 4 5 6 7 8 9 10 11 12 13 14 15 16 17 PROCESS 18 CONDITIONS 19 20 21 22 23 24 25 26 27 28 BASIS 29 AND 30 SELECTION 31 32 33 34 CONNECTIONS 35 36 37 38 39 MATERIALS 40 41 42 43 44 45 46 OPTIONS 47 48 49 50 51 PURCHASE 52 53 54

Tag Number CASE Service Line No. Vessel No. Nozzle (Full, Semi) Design Safety, Relief, Safety-Relief Type Conventional, Bellow, Pilot Operated Bonnet Type PID Reference No. Fluid State Required Capacity Molecular Mass Oper. Pressure Set Pressure Oper. Temperature RelievingTemperature Constant Back Pressure Variable Total % Allowable Overpressure Overpressure Factor Compressibility Factor Latent Heat of Vaporization Ratio of Specific Heats Relief Density Relief Viscosity Barometric Pressure

21-PSE -3002 EXISTING OIL STORAGE TANK

Blow Hatch

1019 Stabilised Oil 120410 1.033 61

Liquid Nm/h kgf/cm-g C 0.022 kgf/cm-g C

kcal IT/kg kg/m cP

Design Code Sizing Basis Calculated Area Selected Area Orifice Designation

API Liquid Filled Vessel

in

Size: Inlet Rating Body and Bonnet Seat and Rings Resilient Seat Seal Guide and Rings Spring Bellows

Outlet Facing

24 150# A216 WCB SS316 SS316 SS316

in

24

in

Cap: Screwed or Bolted Lever: Plain or Packed Test Gag

Manufacturer Model Purchase Order Number Price Item Number Serial Number

MARVAC 785-Manway 5700-5055

Notes: 1. New Addition. Vendor to select and size the blowhatch. Calculations to be furnished. 2. * indicates vendor to furnish. 3. Boiling point 62C at relieving pressure. Flash point 48.05C. Existing Oil Tank capacity 1000 m3.

INSTRUMENT SPECIFICATION Pressure Relief Valve PDN 2 SNV 1 No. By 3/13/2006 10/3/2005 Date ISSUED FOR PURCHASE ISSUED FOR PURCHASE Revision Sheet 39 00701-21-SP-1545-01 of 39 Rev.: 2

Code: 85

Dwg. No.:

You might also like

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- DespresurizaciónDocument3 pagesDespresurizaciónmatrix69No ratings yet

- LP methanol column process specificationDocument7 pagesLP methanol column process specificationidilfitriNo ratings yet

- Optimize Flare System DesignDocument8 pagesOptimize Flare System DesignVinothrajaNo ratings yet

- CompressorDocument27 pagesCompressorsoxal100% (1)

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocument10 pagesEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddNo ratings yet

- A 02Document30 pagesA 02senioor2004No ratings yet

- 2 Phase Horizontal Flow Line Sizing Cal-AUHDocument15 pages2 Phase Horizontal Flow Line Sizing Cal-AUHMike DukasNo ratings yet

- Process Design Basis FOR Unit 06 - Diesel Hydrodesulphurization UnitDocument24 pagesProcess Design Basis FOR Unit 06 - Diesel Hydrodesulphurization Unitdhiaa mohammedNo ratings yet

-  Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)Document16 pages Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)KalpeshJadhavNo ratings yet

- CTBEST PVM 300 Process Design of Separation VesselsDocument22 pagesCTBEST PVM 300 Process Design of Separation Vesselsrzepedac100% (2)

- Ruwais Refinery Expansion Feed Project Feed: PhaseDocument9 pagesRuwais Refinery Expansion Feed Project Feed: PhaseAjit ParanjpeNo ratings yet

- Revision Indication Standard Specification Trays and PackingDocument9 pagesRevision Indication Standard Specification Trays and PackingSenthil KumarNo ratings yet

- Fired Heater Design PDFDocument12 pagesFired Heater Design PDFSterlingNo ratings yet

- Reaction Technologies: ThreeDocument31 pagesReaction Technologies: ThreeProcess EngineerNo ratings yet

- 2 in LACT PipelineDocument4 pages2 in LACT PipelineeugeniuciobanuNo ratings yet

- Process Design QuestionnaireDocument30 pagesProcess Design QuestionnaireNguyen Anh TungNo ratings yet

- Operating case simulation and hydraulic calculationDocument2 pagesOperating case simulation and hydraulic calculationsri9987No ratings yet

- Control Valves Datasheets For Unit 040Document16 pagesControl Valves Datasheets For Unit 040Gopinath GunasekaranNo ratings yet

- Pts 0800 - A (Process Description)Document6 pagesPts 0800 - A (Process Description)ingegnere1234No ratings yet

- Line Sizing For Liquid, (DO IT OWN)Document11 pagesLine Sizing For Liquid, (DO IT OWN)sumitNo ratings yet

- Basic process design requirements and criteriaDocument23 pagesBasic process design requirements and criteriaNguyen Anh Tung100% (1)

- Rigorous Shell & Tube Condenser Simulation in HYSYSDocument6 pagesRigorous Shell & Tube Condenser Simulation in HYSYSWali AhsanNo ratings yet

- Centrifugal Pumps: Process Calculation / Data SheetDocument3 pagesCentrifugal Pumps: Process Calculation / Data SheetMurali MuthuNo ratings yet

- 7810-8110-Ca-1540-651-001 - HP FG KodDocument68 pages7810-8110-Ca-1540-651-001 - HP FG Kodgopal krishnan0% (1)

- TURN DOWN RATIO STUDY REPORTDocument28 pagesTURN DOWN RATIO STUDY REPORTBui Khoi NguyenNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- 1231 de 00 DC PCJ 001 01Document33 pages1231 de 00 DC PCJ 001 01Hamid MansouriNo ratings yet

- 1.review of PFD, Pid, PdsDocument10 pages1.review of PFD, Pid, PdssuhailfarhaanNo ratings yet

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasNo ratings yet

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomNo ratings yet

- 05 FS GduDocument18 pages05 FS GduAnonymous O0lyGOShYGNo ratings yet

- Designing for pressure releases during fires—Part 2Document6 pagesDesigning for pressure releases during fires—Part 2john VilladaNo ratings yet

- TG Temperature GaugeDocument2 pagesTG Temperature GaugeAr RahmanNo ratings yet

- E-I-04-Instrument List PDFDocument4 pagesE-I-04-Instrument List PDFManu BadilloNo ratings yet

- ANZ Technical Guide Heat Exchanger Desig PDFDocument123 pagesANZ Technical Guide Heat Exchanger Desig PDFgiovanni perozziNo ratings yet

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- Line Sizing Philosophy PDFDocument21 pagesLine Sizing Philosophy PDFmohammadhadiNo ratings yet