Professional Documents

Culture Documents

ICPC 2013 Country Report Mongolia-130927 PDF

Uploaded by

Гэндээхүү ДаваацэрэнOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICPC 2013 Country Report Mongolia-130927 PDF

Uploaded by

Гэндээхүү ДаваацэрэнCopyright:

Available Formats

PAST, PRESENT SITUATION AND FUTURE DEVELOPMENT OF COAL PROCESSING INDUSTRY IN MONGOLIA

Gendeekhuu Davaatseren(1), Helga Wittmers(2) and Magsar Bazarragchaa(3).

Mongolyn Alt (MAK) Corporation, Vice president for Technology and Research, Ulan bator, Mongolia gedavaa@mak.mn, (2) MBE Coal & Minerals Technology GmbH, Sales Director East Asia, Cologne, Germany, helga.wittmers@mbecmt.com, (3) Mongolyn Alt (MAK) Corporation, Process Engineer, Ulan bator, Mongolia, bazarragchaa@mak.mn.

(1)

ABSTRACT

Coal is the main source of energy vitally important asset that drives the economic development of the country. Mongolias geological probable reserves of coal are estimated at 173.3 billion tons which about 70% is lignite. There are over 300 deposits and occurrences in 15 different basins at which over 21.5 billion tons of coal reserves are estimated through detailed exploration work. These reserves place Mongolia among top 10 countries in terms of coal resources. In 2012, Mongolia produced 31.1 million tons of coal are exported, 20.5 million tons bringing MNT 828.5 billion to the central budget of the Government. Today, we have around 60 companies, including wholly state-owned Erdenes TT, partly state-owned Baganuur, Shivee Ovoo, locally owned Tavantolgoi, Bayanteeg, Mogoingol joint-stock companies, as well as domestic and foreign invested private sector companies such as Energy Resources LLC, Tavantolgoi JSC, MAK LLC, Qinhua-MAK-Narynsukhait LLC, Southgobi Sands LLC, COAL LLC, Mo En Co LLC, Chingisiin Har-Alt LLC, etc., that are engaged actively in the production and marketing of coal. Presently about 20 coal companies export unprocessed and processed coals. Key Words: Mongolian coking coal, wet process, dry process, Batac jig, plant.

1. BRIEF HISTORY:

1922, The Nalaikh underground mine, the first Mongolian coal deposit has been taken to the state ownership. 1965, commissioning Sharyngol opencast coal mine. 1966, commissioning Tavantolgoi opencast coal mine. 1978, commissioning Baganuur opencast coal mine. 1992, commissioning Shivee Ovoo opencast coal mine. 2002, commissioning Mongolyn Alt (MAK) NarynSukhait opencast mine. 2008, commissioning Energy Resources Ukhaa-Khudag opencast mine. 2011, Erdenes Tavantolgoi opencast mine, East Tsankhi.

Table 1. Forecast for coal consumption of Mongolia, 2010-2025 /thousand tons/ Balance Power stations Industry, construction Transport, communications Agriculture Household, utility services Processing industry Central region for heating use Rural demand Export demand TOTAL 2011 5349.5 299.2 144.0 16.0 520.0 500.0 6828.7 806.0 25000.0 32634.7 2012 5910.5 324.0 147.0 20.0 525.0 600.0 7526.5 814.0 30000.0 38340.0 2013 7061.5 348.4 150.0 24.0 530.0 700.0 8813.9 822.0 33000.0 42635.0 2014 10636.0 373.0 153.0 28.0 535.0 800.0 12525.0 830.0 40000.0 53355.0 2015 11717.0 397.6 156.0 32.0 540.0 900.0 13742.6 838.0 50000.0 64580.0 2020 13000.0 521.0 171.0 52.0 565.0 1400.0 15709.0 878.0 65000.0 81587.0 2025 15000.0 630.0 210.0 60.0 610.5 1600.0 18110.5 900.0 75000.0 94010.5

Figure 1. Distribution of large-scale coal-bearing basins

2. CURRENT STATE OF COAL PREPARATION

Dry coal beneficiation (FGX) plant of Eldev coal, MAK Corp. Coal handling and preparation plant of Ukhaa-Khudag coal, Energy Resource Co.Ltd. Dry coal beneficiation plant of coal, South Gobi Sands Co.Ltd Erdenes Tavantolgoi Coal washing project 20 million tons/a. MAK Naryn-sukhait coal washing project 7 million tons/a.

3. COAL MARKET

Mongolia has a geographical proximity to China, the largest consumer and importer of coal and is the closest potential supply source for coking coal to major consumers in Asia-Pacific region for countries like Japan, China and South Korea. Due to favorable geological and mining conditions the country has big potential for large scale low cost open-pit mining operations - low precipitation and dry weather conditions are additional advantages. The coal quality is comparable to leading coking coal brands from Bowen Basin and Shanxi, China. Mongolia is a land-locked country with limited access to global markets, in particular for bulk commodities. The coal mines are located in very remote areas with undeveloped infrastructure in respect to transportation, road and railway network, water and power supply. Another problem is the lack of skilled labor. The regulatory in respect to legal conditions like ownership of mines or concessions etc. are evolving and get stricter and the same applies for the environmental regulations for the mining industry. Mongolias capital and funding sources are very limited to meet the significant investment requirements for the coal projects. China became the worlds largest importer of coal and the second largest importer of coking coal within the last years. In 2012 China has imported 53.6 Mt compared to 44.7 Mt in 2011. Mongolias coal exports gradually increased to a level above 20Mt in 2011 by that the country surpassed Australia and became the largest supplier of coking coal to China.

Figure 2. Mongolian coal export to China and Chinese coal import Despite the challenges faced in 2012, Mongolia preserved its position as the largest supplier of coking coal to China with around 36% share by volume in total of the Chinese coking coal import in 2012. The Ukhaa-Khudag coal handling and processing plant has 15 Mtpa total projected ROM coal processing capacity which will be achieved by three modules each with 5 Mtpa capacity. Module-I and Module-II were commissioned in 2011 and 2012, respectively, currently are in full operations. Module-III is under construction and expected to be in operation from second half of 2013. Production schedule of the coal mine is directed for production of clean coal quality for export. It is predicted that export coal will remain in a range of 40~50 million tons of clean coal after washing with stagnation of the economy by 2025 even if the Chinese coal import shows an increasing tendency. Therefore, operation start of new coal mines and production of clean coal for export will result in an over production and unsalable coal has to be stored temporarily however, it is necessary to push forward coal mine development for export in consideration of the demand of China. The use of coal for primary energy in Mongolia was high, which is featuring the energy balance of our country. In recent year, the development project of a large-scale coal mine has been underway in Mongolia, and development of coking coal mines, especially in a South Gobi district, has attracted global attention.

Table 2. Forecast of production of coal mines for export Forecast of production in 2025 (1000t) Mine name Remarks ROM Clean coal Erdenes Tavan Tolgoi 20.000 14.000 Under planning CHPP (East Tsankhi) Tavan Tolgoi 20.000 14.000 Presumed plane of CHPP (West Tsankhi) UHG (Ukhaa-Khudag) 15.000 11.000 15MTP CHPP Under planning of 7 Mtpa MAK Naryn Sukhait 14.000 5.000 CHPP Ovoot Tolgoi 8.000 5.000 Dry and wet CHPP Baruun Naran 7.000 Tsant Uul 2.000 Soumber 5.000 Khushuut 5.000 Maanit 2.000 Huren Gol 3.000 Total 101.000 49.000 Table 3. Expectation of constructing coal preparation plants 2011 2013 2015 2017 2019 5.000 3.500 15.000 10.500 20.000 14.000 37.000 25.000 52.000 36.400

Year Total capacity, Mtpa Clean coal. Mtpa

2021 62.000 43.400

2025 62.000 43.400

4. PREPARATION TECHNOLOGY 4.1. Dry coal preparation technology

equivalent to coking coal exports. Mongolia already has optimal conditions for implementing this technology. If use of this technology can be made practical and with achieving higher product qualities, the technology could also be exported to regions with low water resources in other countries.

In Mongolia, it is difficult to secure the water resources required for coal preparation. As a coal processing technology in regions with limited water resources dry coal preparation technology is vital it provides superior options in terms of environmental measures in those arid areas. At existing facilities, the precision of coal preparation is very low and it will be difficult to achieve levels of coal quality

Table 4. Action plan Action plan Dry coal preparation validation facilities Construction of commercial plant Short term (2015) Intermediate (2020) Long term (2025)

4.2.

Wet coal preparation technology

Anyhow, the vulnerable environment has to be protected and environmental regulations for Mongolia get strict. The climatic conditions in Mongolia with very low temperatures in winter time require processing plants installed in well heated and insulated buildings to ensure continuous operation all over the year. Due to the very windy whether all over the year covering of belt conveyors has to be considered in order to protect the environment of dust emission. Dust depression facilities should be installed at raw coal receiving stations as well as at open stockpiles, dedusting units should also be arranged especially at belt conveyor discharges and where ever required in the processing plant. Two technologies are used for coal beneficiation heavy-media-system (HMS) requiring magnetite as separation media which can achieve high yield but has high investment and very high operation cost. And on the other hand the jigging technology that has slightly lower yield but much less investment and operation cost. The jigging process, using the advanced BATAC-jig technology, is characterized by a simple design, very gentle way of processing and by that avoiding unnecessary selfcomminution. Less equipment is required and full automation as well as small plant footprints are additional features which lead to low capital investment. The plant design follows the one-line-philosophy, which means that also for high throughput rates only one BATAC-jig system has to be installed, and an availability of > 98% is guaranteed. Water only is required for the sorting process and low energy consumption and easy maintenance beside other advantages of the jigging technology are resulting in low operation cost. Long terms power cuts are unproblematic a re-start is possible after less than 5 minutes

The much more efficient way of processing is wet coal preparation technology. In order to fit to the features of the specific raw material the plants have to be tailor-made. Two processing technologies are applicable - the heavy-mediasystem (HMS) and on the other hand the jigging technology. These processing technologies are quiet different, but each of them has its own advantages and disadvantages. The decision for which processing method to be applied, has to consider the special conditions in Mongolia like extreme climatic conditions, water shortage, inexperienced operators etc.. Additionally it has to base on calculations in order to find out the cost efficiency, which is shown in the comparison of targeted yield, investment and operation cost. Most deposits in Mongolia have young coals, which are quite brittle and the raw coal has high fine coal content. Processing should be done in the gentlest way; in order to avoid further self-comminuting of the material as a result the slurry circuit can be kept as small as possible leading to lower investment cost. However, due to the climatic conditions in Mongolia (in winter time up to -45C, in summer time up to +45C) the products of the coal processing plant have to be dewatered in order to recover and to recycle most of the process water as well as being enabled to transport the products to the customers respectively to deposit the tailings. According to experience, the dewatering equipment of a processing plant forms the highest portion of the investment. Coal processing plants for Mongolia have to be designed with closed water circuits, using thickeners for the water clarification and they have to be equipped with integrated high-efficient dewatering and filter systems for greatest possible water recovery. Water is a very precious good in our country; it has to be used very carefully and as less as possible. .

Table 5. Flow sheet jigging process It has to be calculated very carefully whether the HMSoption is really the most suitable beneficiation method. Its application is mainly for processing of coking coal and if the raw coal has a near-gravity-material content of >20%. Since dense media pulp of specific density is required to float the lighter material the process needs very fine and high quality magnetite (100% < 0.1 mm, Fe-content >68%) to be mixed into water. That high-price consumable has to be imported which a significant influence on the operation has cost. Therefore as much as possible magnetite has to be recovered in order to minimize the losses. New HMS-plants start operating with a magnetite consumption of <1 kg/t raw coal very proper maintenance is required in order to keep that figure, but as per experience the magnetite consumption increases after some years of operation sometimes to double or triplicate. Another side effect is high wear due to the use of magnetite resulting in high maintenance necessity and increased spare parts consumption. The specific density of the pulp has to be controlled continuously to guarantee smooth operation and to achieve the targeted products and yields. Three different pulp and water circuits are necessary: Operating pulp circuit for . separation process, diluted pulp for recovery of magnetite, and wash water circuit for washing magnetite out of the products which results in high amount of required equipment and instrumentation. The process mainly uses HMS-Cyclones for beneficiation, which produces high fine particle content due to the centrifugal force in the HMS-cyclones. Additional self-comminution occurs due to pumping the pulp to the next processing steps. More fines means that more slurry needs to be treated in the dewatering phase, which will raise the capital investment significantly since the dewatering equipment will be not only increasing in numbers but also in dimension. Long terms power cut have severe influences on the HMS process, since the magnetite will sediment instantly. By that it would take some time to re-start the process since the blockages have to be removed. Depending on the raw material features and the quality rating both sorting technologies could also be combined and supplemented by flotation systems for fine coal recovery, i.e. the PNEUFLOT pneumatic flotation, in order to achieve the best and most economical products

Table 6. Flow sheet HM-process

4.3.

Use of middling product after washing

thermal power plants that utilize this product as a part of their coal for urban city planning. There is potential to use middlings product as energy coal export but there are still problems related to infrastructure and coal prices.

Based on coal preparation construction plans, the volume of middling product will be 2.8 million tons in 2015, 8 million tons in 2020, and 8.7 million tons in 2025. It is vital that they evaluate heat supply facilities and coal

5. DEVELOPMENT COAL PREPARATION ENGINEERS

Coal preparation plants are facilities that tie directly to the coal sale profits so the country needs to develop specialist able to evaluate coal preparation technology from a third-party standpoint. It would be ideal to cultivate Mongolians who learn the technology and can serve as a plant director in order to ensure quality management and operational management. The cultivation of coal preparation engineers should involve the development of educational curriculum that uses local coal preparation plants. Recently the Mongolian National Technical University is under modification in order to improve the education of young mining and processing engineers, which happens under cooperation of the German universities Freiberg and Aachen. Furthermore the education of Mongolian engineers could also be assisted by conducting training in the R&D centers of experienced international mining and processing companies.

6. ENVIRONMENTAL REGULATIONS

The Mongolian Mining Law, which was introduced in 2006, is under revision and will probably bring significant reforms on the existing legal frame work, but also of the environmental regulations. The overall aim of the law is to promote economically viable mining along with the national interests in respect to social and environmental policies.The environmental regulations in respect to water and soil pollution get stricter same applies for the regulations in respect to the environmental impact to the landscape by coal dust emission.

REFERENCES:

1. Mongolian National Mining Association, http://www.miningmongolia.mn/ 2. Master Plan Study on the Development and Utilization of coal, Draft Final Report, February 2013.

3. The Implementing Agency of Mongolian Government, Mineral Resource Authority. http://www.mram.gov.mn/index.php?lang=mn 4. Mongolian Mining Journal. http://www.mongolianminingjournal.com/home.shtml 5. http://www.mbe-cmt.com/

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Report GDK 11Document11 pagesReport GDK 11Kamlesh Kumar Sahoo100% (1)

- Fatality Prevention Program - Development and ImplementationDocument54 pagesFatality Prevention Program - Development and ImplementationRoni Enjelani100% (1)

- D25KS Sanvick PDFDocument4 pagesD25KS Sanvick PDFJiménez Manuel100% (1)

- Makalah - Tonggotua Sormin-Restu Glorya Simangunsong - SMAN 2 Lintongnihuta - G - Nas2022Document8 pagesMakalah - Tonggotua Sormin-Restu Glorya Simangunsong - SMAN 2 Lintongnihuta - G - Nas2022ivn strssdNo ratings yet

- PCBC Block Cave Schedule Geovia DatasheetDocument2 pagesPCBC Block Cave Schedule Geovia DatasheetDiego Ignacio VelizNo ratings yet

- Impact of Mining Ban On The Goan Economy - A Case StudyDocument12 pagesImpact of Mining Ban On The Goan Economy - A Case StudyirjmssNo ratings yet

- Nass Assignment 1Document6 pagesNass Assignment 1Ashi Chifamba100% (2)

- Instructions On How To Properly Fill in The WAIRDocument17 pagesInstructions On How To Properly Fill in The WAIRRudy BancoroNo ratings yet

- Natural Resources Classification and ImportanceDocument27 pagesNatural Resources Classification and ImportanceJoydeep BhattacharjeeNo ratings yet

- Determining The Bond Efficiency of Industrial Grinding CircuitsDocument23 pagesDetermining The Bond Efficiency of Industrial Grinding CircuitsLuis Wes MolesNo ratings yet

- 2010 College of Science & Engineering Career FairDocument31 pages2010 College of Science & Engineering Career FairSilvia CanelonNo ratings yet

- Yinlu vs. Trans-AsiaDocument2 pagesYinlu vs. Trans-AsiaRaf RufNo ratings yet

- M. Tomović-Kraku Lu Jordan and Gold Mining and Metallurgy in AntiquityDocument31 pagesM. Tomović-Kraku Lu Jordan and Gold Mining and Metallurgy in AntiquityDragan GogicNo ratings yet

- Reliability Engineer - J DDocument2 pagesReliability Engineer - J Dch subhashis sukumar praharajNo ratings yet

- Mining Valuation Lesson: Cut-Off Grade Theory and Practice: 04 Dec 2011 Comment: 0Document8 pagesMining Valuation Lesson: Cut-Off Grade Theory and Practice: 04 Dec 2011 Comment: 0davidchaileNo ratings yet

- Andrews-Speed, P., - Hove, A. (2023)Document26 pagesAndrews-Speed, P., - Hove, A. (2023)Miguel Montalván AraozNo ratings yet

- The Effect of Illegal Mining On School Attendance and Academic Performance of Junior High School Students in Upper Denkyira West District of GhanaDocument23 pagesThe Effect of Illegal Mining On School Attendance and Academic Performance of Junior High School Students in Upper Denkyira West District of GhanaVethavarnaa SundaramoorthyNo ratings yet

- Report of The Parliamentary Committee On Natural Resources On Sand Mining in UgandaDocument96 pagesReport of The Parliamentary Committee On Natural Resources On Sand Mining in UgandaAfrican Centre for Media Excellence100% (4)

- HCIG 2019 Open Pres - GrupoMX - Follow Up Visit (Compressed)Document38 pagesHCIG 2019 Open Pres - GrupoMX - Follow Up Visit (Compressed)Ernesto ZavalaNo ratings yet

- ENERGY REQUIREMENT FOR SIZE REDUCTION - BOND WORK INDEXDocument32 pagesENERGY REQUIREMENT FOR SIZE REDUCTION - BOND WORK INDEXMuhammad RifkiNo ratings yet

- Kiocl ReportDocument7 pagesKiocl Reportsubhram nandaNo ratings yet

- Microstructure Carbon Doped CSDocument15 pagesMicrostructure Carbon Doped CSBu AliNo ratings yet

- CMPDI VisionReportDocument32 pagesCMPDI VisionReportShubham RajNo ratings yet

- Studio OpDocument15 pagesStudio OpMilan LLanque Conde100% (2)

- CoalAsia 66 LowresDocument122 pagesCoalAsia 66 LowresDery Oktory NofendraNo ratings yet

- Energy Performance of Dump Trucks in Opencast Mine PDFDocument8 pagesEnergy Performance of Dump Trucks in Opencast Mine PDFIsaac VisualNo ratings yet

- The Terrible Truth of Gold Mining Cost ReportingDocument6 pagesThe Terrible Truth of Gold Mining Cost ReportinggaryNo ratings yet

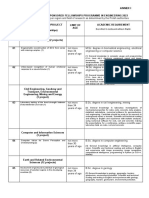

- Annex I 2023 EnglishDocument7 pagesAnnex I 2023 EnglishDr. KAVITHA. R SASTRANo ratings yet

- 40 Sink and FloatDocument38 pages40 Sink and Floatleandro hualverdeNo ratings yet

- GeoResources Journal 4 2017Document52 pagesGeoResources Journal 4 2017ansariNo ratings yet