Professional Documents

Culture Documents

CFT Moment PDF

Uploaded by

ryan rakhmat setiadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CFT Moment PDF

Uploaded by

ryan rakhmat setiadiCopyright:

Available Formats

1759

BEHAVIOR OF MOMENT CONNECTIONS BETWEEN CONCRETE-FILLED STEEL TUBE COLUMNS AND WIDE FLANGE STEEL BEAMS SUBJECTED TO SEISMIC LOADS

Bradley D KOESTER1, Joseph A YURA2 And James O JIRSA3

SUMMARY Split-tee, through-bolted connections between rectangular concrete-filled steel tubes and wideflange steel beams were investigated to determine the ability of the concrete core within the panelzone to transfer join shear forces. By depending on the confined concrete core within the joint for shear transfer, additional labor-intensive details such as exterior diaphragms and internal stiffeners could be avoided. The objective of this research program was to quantify the extent to which the confined concrete core, or compression strut, plays a role in the transfer of joint forces, and to ultimately develop design guidelines and criteria for use in building codes. The testing procedures used are described, and some preliminary results of full-scale moment connection tests are presented. Further analysis of the results will be used to develop design code recommendations in a future paper.

INTRODUCTION Research was conducted at the Phil M. Ferguson Structural Engineering Laboratory at The University of Texas at Austin to study the behavior of the split-tee through-bolted moment connection between concrete-filled steel tubes (CFT) and wide flange beams. The aim of the program was to develop design recommendations for this type of joint, focusing on the role of the concrete core in transferring beam flange forces through the joint. The connection testing program was divided into two phases, which consisted of a total of 21 test specimens. Phase I was an investigation into the shear behavior of 15 half-scale CFT panel-zone specimens, and is referred to as the panel-zone tests. Joint force transfer conditions were simulated without constructing the complete connection. A special loading frame was designed and used to subject the tubes to joint shear forces by applying simulated beam flange forces to the panel-zone region. Phase II consisted of six full-scale, fully assembled moment connections. All specimens in Phase II were cruciform specimens with spit-tee through-bolted connection details. Specimens and Properties For the first 15 experiments (Phase I), test specimens and a reaction frame were designed to idealize the connection zone region on half-scale CFTs without utilizing actual connection details. Test results, which were presented in the SEWC 1998 [Koester, 1998], showed that changing the footprint of the simulated beam flange forces had negligible effect on the capacity of the joint. In addition, joint strength was not limited by the plastic moment capacity of the composite section. A companion FEM analysis [Uchida, 1998] showed satisfactory comparison between the test data and the analytical model. It was also shown by the same FEM analysis that the stress condition of the panel-zone test specimens is similar to that of a beam-column joint with a split-tee through-bolted connection.

1 2 3

Ph.D. Candidate, The University of Texas at Austin, Austin, Texas, USA Professor, The University of Texas at Austin, Austin, Texas, USA Professor, The University of Texas at Austin, Austin, Texas, USA

The remaining six tests (Phase II), the focus of this paper, were conducted on full-scale, through-bolted moment connections (Figure 1). The test setup for the cruciform-shaped beam-to-column moment connections is shown in Figure 2. Phase II specimens were fabricated from 305 mm (12 in.) and 406 mm (16 in.) square concrete filled tubes. All six specimens were based on the same general connection design, but connection component dimensions were varied.

Split-Tee Through-Bolted Connection

CFT Column

Tee Fillet-Welded to Beam Flange

Wide Flange Beam

Through-Bolts: Threaded only at the ends, smooth through interior concrete

Figure 1 Connection Detail

Cyclic Load Direction

Load Cell H= 3.7 m' 12.0 (12 ft) Load Cell Rigid Link

Hydraulic Ram

Out-of-plane bracing omitted for clarity

L ' 15.0

CFT.1 through CFT.4: L = 4.6 m (15 ft) CFT.5 and CFT.6: L = 6.1 m (20 ft)

Figure 2 Test Set-up for Full-Scale Connections The first four specimens in this series, CFT.1 through CFT.4, were 305 mm (12 in.) square CFT specimens, and were designed by scaling the 406 mm (16 in.) CFT specimens by 3/4, and adjusting the beam sizes accordingly. The remaining two full-scale 406 mm (16 in.) CFT moment connections, CFT.5 and CFT.6, were based on the designe and construction of similar specimens tested at Lehigh University. Specimen CFT.5 is based on Lehigh [Ricles, 1997] specimen number 6, and has similar dimensions for the CFT and all of the connection components. Specimen CFT.6 was designed with a smaller tee width bearing against the face of the column. CFT.6 was designed to examine the effect of narrowing the tee width, while preserving the same beam and column properties as those used in CFT.5. The column height for all six specimens was 3.7 m (12 ft.) to permit using the same test set-up for all six tests. The beam spans for CFT.1 through CFT.4 were based on their size relative to specimens CFT.5 and CFT.6. Thus the beam span (L) from inflection point to inflection point was 4.6 m (15 ft.) for CFT.1 through CFT.4, and

1759

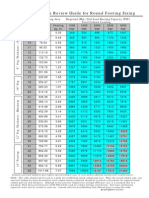

6.1 m (20 ft.) for CFT.5 and CFT.6. The dimensions and material properties of the CFT specimens used in Phase II are shown in Table 1 and Table 2 Table 1 Material Properties of Full-scale CFT Specimens Steel Tube Properties Square CFT Specimen mm (in.) MPa (ksi) MPa (ksi) CFT.1 CFT.2 305 (12) CFT.3 CFT.4 CFT.5 406 (16) CFT.6 49 (7.14) 50 (7.3) 51 (7.4) 49 (7.14) 397 (58) 485 (70) 41 50 (7.2) 50 (7.2) 366 (53) 416 (60) 26 MPa (ksi) Concrete fc fy fu % Elongation

Table 2 Wide-Flange Beam Properties Beam Properties Beam Size Specimen (AISC) MPa (ksi) CFT.1, 2 CFT.3, 4 CFT.5, 6 W 18 x 46 W 18 x 65 W 24 x 62 379 (55) 367 (53) 389 (56) MPa (ksi) 513 (74) 516 (75) 503 (73) 25 21 25 fy fu % Elongation

. Beam Sizes Beam sizes used for all six specimens are shown in Table 2. W18 structural shapes were used for the beams framing into the 305 mm (12 in.) CFT columns. Two different W18 shapes were used to develop different failure modes at the connection. The W18 x 46 beams of specimens CFT.1 and CFT.2 were used to allow the beams to form plastic hinges. W18 x 65 beams were chosen to produce panel-zone failures in specimens CFT.3 and CFT.4. The amount of over-strength in the W18 x 65 beams assured that minimal inelastic deformation would occur in the beams, and that the connection would have to dissipate energy through the connection or panel-zone. Deformation of the panel-zone and connecting elements was the intended mechanism of energy dissipation, although typical U.S. design practice requires a strong-column/weak-beam failure mechanism. For CFT.5 and CFT.6, W24 x 68 beams were used. Both specimens were designed to fail through inelastic beam rotation near the face of the column, a failure mode consistent with current design practice. The main difference

1759

between CFT.5 and CFT.6 was the width of the tee acting on the face of the column. The intent was to determine the influence of the tee width on the transfer of shear forces through the connection even though the panel-zone itself was not designed to fail. Testing Procedure Testing of the CFT specimens was displacement controlled. The displacement was based on values of interstory drift (% ISD), and was used consistently throughout the testing of all six CFT specimens. An identical displacement history was used at Lehigh University during the testing of similar connections. The displacement measurement at the top of the column was used to determine inter-story drift. The load actuator (ram) was controlled by hydraulic pressure, and load was held at each increment momentarily prior to data collection to reduce the influence of dynamic effects. Interstory drift levels ranged between 0.25 and 5.0 percent. To evaluate strength and stiffness degradation, cycles were repeated in the load history. Preliminary Results and Trends Based on the analyses completed to date, a few observations have been made. Results of shear panel distortion versus panel shear are presented in Figures 3 through 8. The values for panel shear are non-dimensionalized by comparing the measured values of panel shear with Equation 1, a hybrid equation for shear strength.

Vn = Vc + Vs C = 0.63 C = 52.5

where

when units are: when units are:

Vc = C f cbe h

kips, ksi, and in2

and

Vs = 0.6 As Fy

(1)

kN, MPa (N/mm2), and mm2

Equation 1 is only used as a reference, and represents the superposition of the shear strength of a well confined concrete core within a reinforced concrete column joint, and the shear strength of the steel outer panels. The term be h represents the cross-sectional area of the concrete core within the shear plane. Specimens 2, 3, and 4 (Figures 3 through 5) were designed to fail in the panel-zone. In each case, peak shear was reached at 3.0% drift at values between 95% and 97% of the theoretical peak shear load calculated using Equation 1. Specimens 5 and 6 (Figures 6 and 7) were designed to develop beam-hinge mechanisms before the panel-zone failed. Panels zones in those two cases, which remained primarily elastic during the tests, reached values of about 60% of the theoretical peak shear capacity. Specimens 1 through 4 were taken to 5% drift before the tests were stopped. Specimens 5 and 6 were halted at 3.5% drift for technical reasons not related to the panel-zone. Figure 8 shows the results typical of the earlier half-scale panel zone experiments nondimsionalized using the simplified model (Equation 1). The concrete term be, the width of the concrete core, used in the comparison for Figures 3 through 8 is assumed to be the full width of the core of the actual specimens, although the load is applied in some cases to only a portion of that width. When the concrete term is scaled according to the actual width of the load application through the tees, all results become conservative, thus predicting values of shear strength well below that obtained in the lab.

1759

1 0.8 0.6 0.4 0.2

V/Vn

0 -0.04 -0.03 -0.02 -0.01 -0.2 0 -0.4 -0.6 -0.8 -1 0.01 0.02 0.03 0.04

CFT.2 Panel Distortion (radians)

Figure 3 Combination Panel/Beam Failure, Tee: 67% Width of Column

1 0.8 0.6 0.4 0.2

V /V n

0 -0.04 -0.03 -0.02 -0.01 -0.2 -0.4 -0.6 -0.8 -1 0 0.01 0.02 0.03 0.04

C F T .3 P an e l D isto rtio n (ra d ian s )

Figure 4 Forced Panel-Zone Failure, Tee: 67% Width of Column

1 0.8 0.6 0.4 0.2

V /V n

0 -0.04 -0.03 -0.02 -0.01 -0.2 -0.4 -0.6 -0.8 -1 0 0.01 0.02 0.03 0.04

C F T .4 P a n e l D is to r tio n (r a d ia n s )

Figure 5 Forced Panel-Zone Failure, Tee: 75% Width of Column

1759

1 0.8 0.6 0.4 0.2

V /V n

0 -0.04 -0.03 -0.02 -0.01 -0.2 -0.4 -0.6 -0.8 -1 0 0.01 0.02 0.03 0.04

C F T .5 P a n e l D is to r tio n (r a d ia n s )

Figure 6 Beam Plastic Hinge Mechanism, Tee: Full Width of Column

1 0.8 0.6 0.4 0.2

V /V n

0 -0.04 -0.03 -0.02 -0.01 -0.2 -0.4 -0.6 -0.8 -1 0 0.01 0.02 0.03 0.04

C F T .6 P a n e l D is to r tio n (r a d ia n s )

Figure 7 Beam Plastic Hinge Mechanism, Tee: 56% Width of Column

1 0.8 0.6 0.4

V/Vn

0.2 0 -0.04 -0.03 -0.02 -0.01 -0.2 0 -0.4 -0.6 -0.8 -1 0.01 0.02 0.03 0.04

8P2 (Earlier Panel Zone Specimen) Distortion (radians)

Figure 8 Forced Panel Failure in Earlier Half-scale Panel Zone Specimen

Design Criteria Work is continuing on the development of models for designing the panel-zone in the split-tee through-bolted connections. The aim of this project is to assist in the development of building code design recommendations for composite joints. Emphasis will be placed on the role of the concrete core in transferring joint shear forces through the connection. If such a joint is to be viable in US practice, it is imperative that the joints not require

1759

additional internal stiffening or complicated exterior details for force transfer between the beamts and the concrete filled tube column. A better understanding of the role of the concrete core will allow for practical and more economical designs with minimal additional detailing. Acknowledgements The authors wish to express their thanks to the National Science Foundation for providing support for the study as part of the US/Japan Cooperative Earthquake Research Program, Phase 5Composite and Hybrid Structures. Special thanks go to Professor Hiroshi Noguchi of Chiba University and Dr. Kazuhiro Uchida with Fujita Corporation for generously sharing their time and resources with us during their stay at the University of Texas as Visiting Researchers. References Koester, B., Uchida, K., Noguchi, H., Yura, J., Jirsa, J., Panel-zone Behavior of Moment Connections Between Steel Beams and Concrete-Filled Steel Tube Columns, Proc. of the Structural Engineering World Congress, San Francisco, CA, July 1998, CD ROM. Ricles, J.M., Lu, L.W., Peng, S.W., Split-Tee Seismic Connections for CFT Column-WF Beam MRFs. Proceedings of Structures Congress XV, 2, ASCE, 1997, 959-963. Uchida, K., Noguchi, H., Koester, B., Jirsa, J., Yura, J., Panel-zone Behavior of Moment Connections Between Steel Beams and Concrete-Filled Steel Tube Columns, Journal of Fujita Technical Research Institute, No. 9, 1998.

1759

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- (1992) Dynamic Response of High-Rise Buildings To Stochastic Wind LoadsDocument9 pages(1992) Dynamic Response of High-Rise Buildings To Stochastic Wind Loadsryan rakhmat setiadiNo ratings yet

- 2016 Evaluation of Simplified and State-of-the-Art Analysis Procedures For Steel Frame Buildings Equipped With Supplemental Damping DevicesDocument17 pages2016 Evaluation of Simplified and State-of-the-Art Analysis Procedures For Steel Frame Buildings Equipped With Supplemental Damping Devicesryan rakhmat setiadiNo ratings yet

- 2007 Analyses of Underground Structures Crossing An Active Fault in CoronadoDocument6 pages2007 Analyses of Underground Structures Crossing An Active Fault in Coronadoryan rakhmat setiadiNo ratings yet

- Section Cut in ETABSDocument20 pagesSection Cut in ETABSryan rakhmat setiadiNo ratings yet

- Termination of Response Spectrum MethodDocument3 pagesTermination of Response Spectrum Methodryan rakhmat setiadi100% (1)

- Remembering The Column AnalogyDocument12 pagesRemembering The Column Analogyryan rakhmat setiadi100% (1)

- (1992) Dynamic Response of High-Rise Buildings To Stochastic Wind LoadsDocument12 pages(1992) Dynamic Response of High-Rise Buildings To Stochastic Wind LoadsAbhijit KulkarniNo ratings yet

- DHDHFD PDFDocument1 pageDHDHFD PDFryan rakhmat setiadiNo ratings yet

- Untitled FsadfscsDocument1 pageUntitled Fsadfscsryan rakhmat setiadiNo ratings yet

- Design Load Parking 2005Document3 pagesDesign Load Parking 2005Andrei MurariuNo ratings yet

- SetgesgsdgseDocument1 pageSetgesgsdgseryan rakhmat setiadiNo ratings yet

- 1924 Krawinkler H. PbeeDocument37 pages1924 Krawinkler H. Pbeeryan rakhmat setiadiNo ratings yet

- Fear of EarthquakesDocument2 pagesFear of EarthquakesPankaj_Taneja_9684No ratings yet

- WtgewtgswDocument1 pageWtgewtgswryan rakhmat setiadiNo ratings yet

- RDHRDTJDTJHDocument1 pageRDHRDTJDTJHryan rakhmat setiadiNo ratings yet

- A Simple Linear Response History Analysis Procedure For Building CodesDocument11 pagesA Simple Linear Response History Analysis Procedure For Building Codesryan rakhmat setiadiNo ratings yet

- Infinity Tower, Dubai, UAEDocument10 pagesInfinity Tower, Dubai, UAEryan rakhmat setiadiNo ratings yet

- AsasdadwdfefegrgrgDocument1 pageAsasdadwdfefegrgrgryan rakhmat setiadiNo ratings yet

- S 2 EdwdafdafDocument1 pageS 2 Edwdafdafryan rakhmat setiadiNo ratings yet

- 222222222222222222222Document1 page222222222222222222222ryan rakhmat setiadiNo ratings yet

- AsvavdasDocument1 pageAsvavdasryan rakhmat setiadiNo ratings yet

- SdvsdgbrddehdDocument1 pageSdvsdgbrddehdryan rakhmat setiadiNo ratings yet

- Untitled GGGGGGGGGFFFFFFFFFFFDDDDDDDDDocument1 pageUntitled GGGGGGGGGFFFFFFFFFFFDDDDDDDDryan rakhmat setiadiNo ratings yet

- QxwceDocument1 pageQxwceryan rakhmat setiadiNo ratings yet

- ASWDRFDocument1 pageASWDRFryan rakhmat setiadiNo ratings yet

- DWDWDWDocument1 pageDWDWDWryan rakhmat setiadiNo ratings yet

- 6 FefsfDocument1 page6 Fefsfryan rakhmat setiadiNo ratings yet

- 3 SDSDWDWDDocument1 page3 SDSDWDWDryan rakhmat setiadiNo ratings yet

- Untitled Alay - AlayDocument1 pageUntitled Alay - Alayryan rakhmat setiadiNo ratings yet

- AsasdDocument1 pageAsasdryan rakhmat setiadiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vignesh New Finance ProjectDocument71 pagesVignesh New Finance Projectrakum81No ratings yet

- JS750 Concrete MixerDocument5 pagesJS750 Concrete MixerErikNo ratings yet

- Draft Indian Standard: Bureau of Indian StandardsDocument9 pagesDraft Indian Standard: Bureau of Indian StandardsPavan KumarNo ratings yet

- Estimate 2Document82 pagesEstimate 2shashirajhans2140No ratings yet

- Smart Technologies For Sustainable DevelopmentDocument420 pagesSmart Technologies For Sustainable DevelopmentMaria Rafaela Bezerra de Macêdo RibeiroNo ratings yet

- 278 CMS PDFDocument266 pages278 CMS PDFRecordTrac - City of OaklandNo ratings yet

- TDS - Mastertile 30 - WPMDocument2 pagesTDS - Mastertile 30 - WPMVenkata RaoNo ratings yet

- GEOWEB Load Support Contruction PackageDocument31 pagesGEOWEB Load Support Contruction PackageJohnEMERYNo ratings yet

- Pedernales Electric Cooperative, Inc. Underground Installation SpecificationsDocument55 pagesPedernales Electric Cooperative, Inc. Underground Installation SpecificationsRemy JuniorNo ratings yet

- 440.11-22 PreviewDocument10 pages440.11-22 Previewjcunha4740No ratings yet

- Roman Arch History PDFDocument31 pagesRoman Arch History PDFkitstonNo ratings yet

- GlassDocument4 pagesGlassShaik Asif AliNo ratings yet

- Class Note Concrete Mix DesignDocument15 pagesClass Note Concrete Mix DesignsudipNo ratings yet

- Department of Labor: BC ms009 Round Footing ChartDocument1 pageDepartment of Labor: BC ms009 Round Footing ChartUSA_DepartmentOfLaborNo ratings yet

- Vacuum Dewatering FlooringDocument4 pagesVacuum Dewatering FlooringArunava Das100% (1)

- UPDADocument1 pageUPDASoumyadip TahNo ratings yet

- Design and Simulation of Engineering ProblemsDocument10 pagesDesign and Simulation of Engineering ProblemspronobNo ratings yet

- Durability of Sustainable Construction MaterialsDocument11 pagesDurability of Sustainable Construction MaterialsAbir DuttaNo ratings yet

- Civil & Structure Design Criteria PDFDocument28 pagesCivil & Structure Design Criteria PDFcharleshutabara951No ratings yet

- Earthing PDFDocument40 pagesEarthing PDFJayadevDamodaranNo ratings yet

- Variation in Cement Properties and Its Effect On Quality of Concrete PDFDocument7 pagesVariation in Cement Properties and Its Effect On Quality of Concrete PDFTran Huynh NamNo ratings yet

- AAC Blocks - Aerated Autoclaved Concrete BlocksDocument12 pagesAAC Blocks - Aerated Autoclaved Concrete BlocksClement OnwordiNo ratings yet

- Engineered Concrete - Mix Design and Test Methods, Second Edition - Engineering BooksDocument4 pagesEngineered Concrete - Mix Design and Test Methods, Second Edition - Engineering BooksHampang HampangNo ratings yet

- Roads & PavementDocument31 pagesRoads & PavementQarirah RasdanNo ratings yet

- Microsoft Word - Design and Detailing of Flat SlabDocument22 pagesMicrosoft Word - Design and Detailing of Flat Slabanjana susan john100% (1)

- ME 118 Material Science Finals BAUTISTA BSME3BDocument2 pagesME 118 Material Science Finals BAUTISTA BSME3Bjethro ganeloNo ratings yet

- Specifying and Selecting Coatings April - 2015 SWr3Document60 pagesSpecifying and Selecting Coatings April - 2015 SWr3arun3kumar00_7691821No ratings yet

- Reinforcement Placement in Slabs PDFDocument6 pagesReinforcement Placement in Slabs PDFLandel SmithNo ratings yet

- Schedule of Rates For ROAD WORKS With New ItemsDocument161 pagesSchedule of Rates For ROAD WORKS With New ItemsShabbir1989No ratings yet

- Reinforced Concrete Slab Design - BS 8110Document8 pagesReinforced Concrete Slab Design - BS 8110Rosaline MainaNo ratings yet